How to Use DRV8834: Examples, Pinouts, and Specs

Design with DRV8834 in Cirkit Designer

Design with DRV8834 in Cirkit DesignerIntroduction

The DRV8834 Low-Voltage Stepper Motor Driver Carrier by Pololu is a compact and versatile motor driver designed to control bipolar stepper motors. It features dual H-bridge outputs, adjustable current control, and microstepping capabilities, allowing for precise and efficient motor control. The DRV8834 is particularly well-suited for low-voltage applications, operating with motor supply voltages as low as 2.5V. Additionally, it includes built-in protection features such as overcurrent protection, thermal shutdown, and undervoltage lockout, ensuring reliable operation in demanding environments.

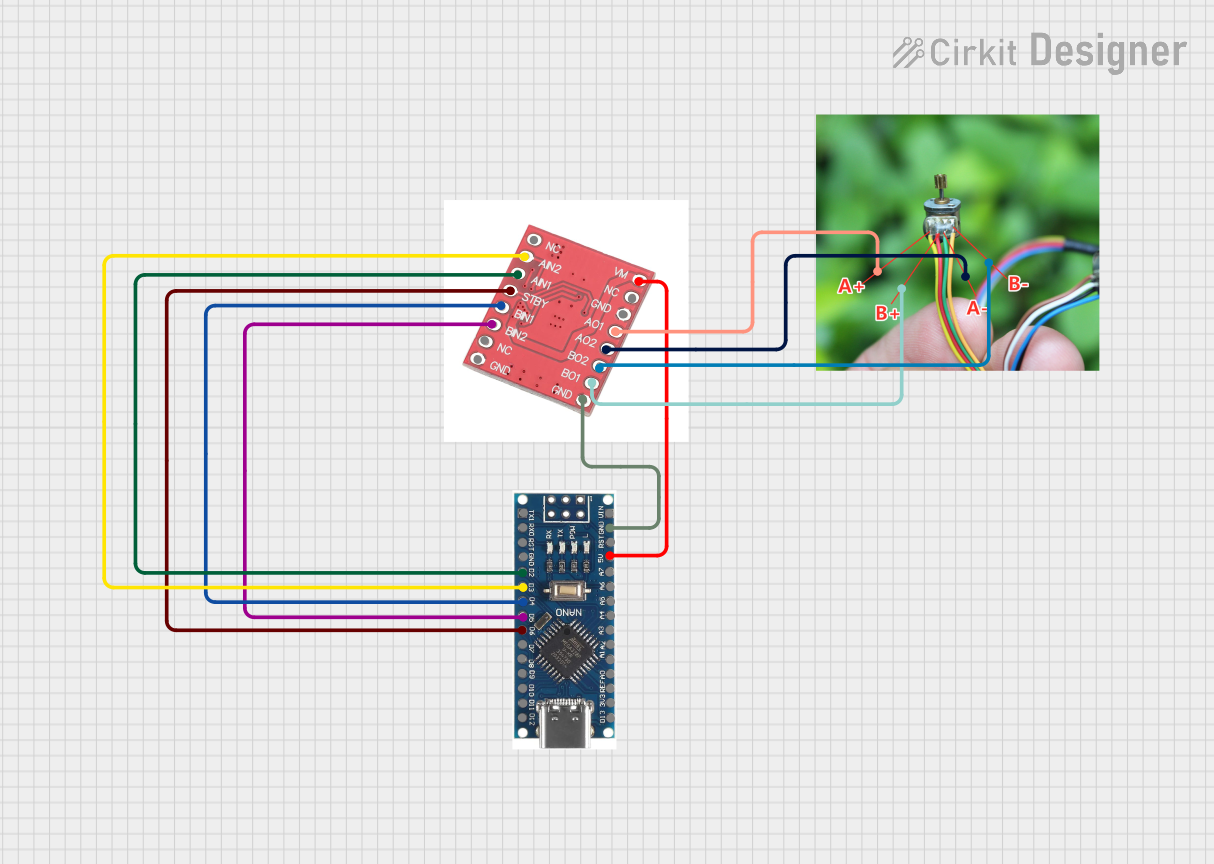

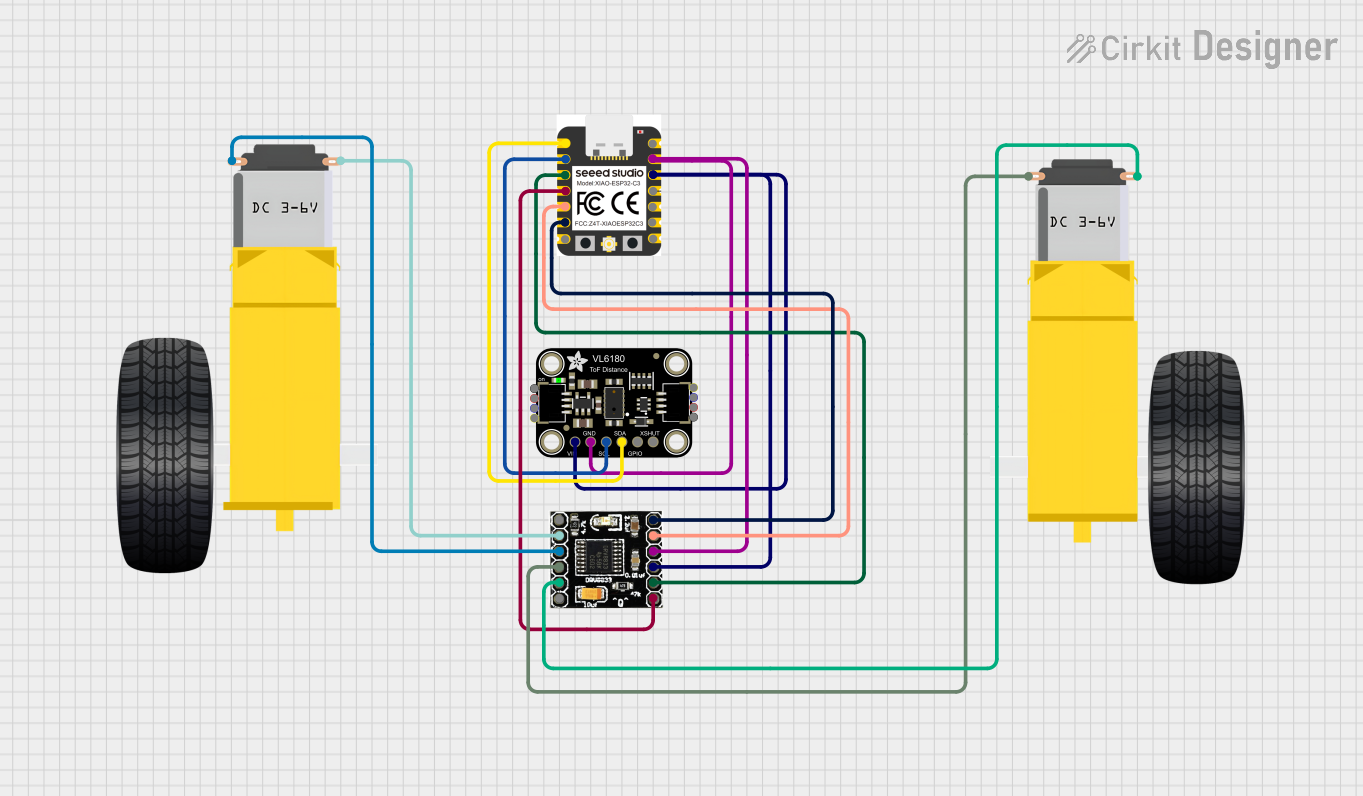

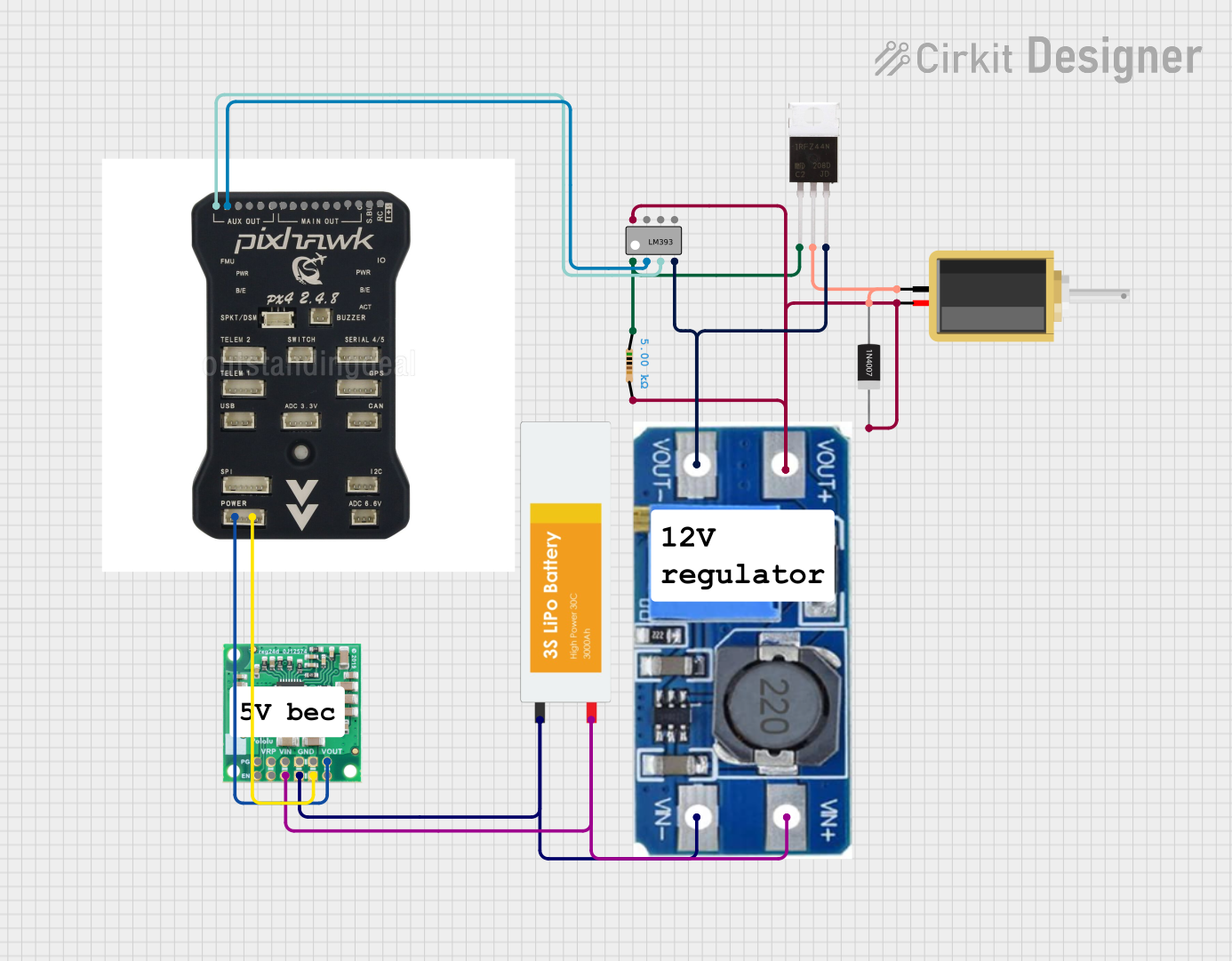

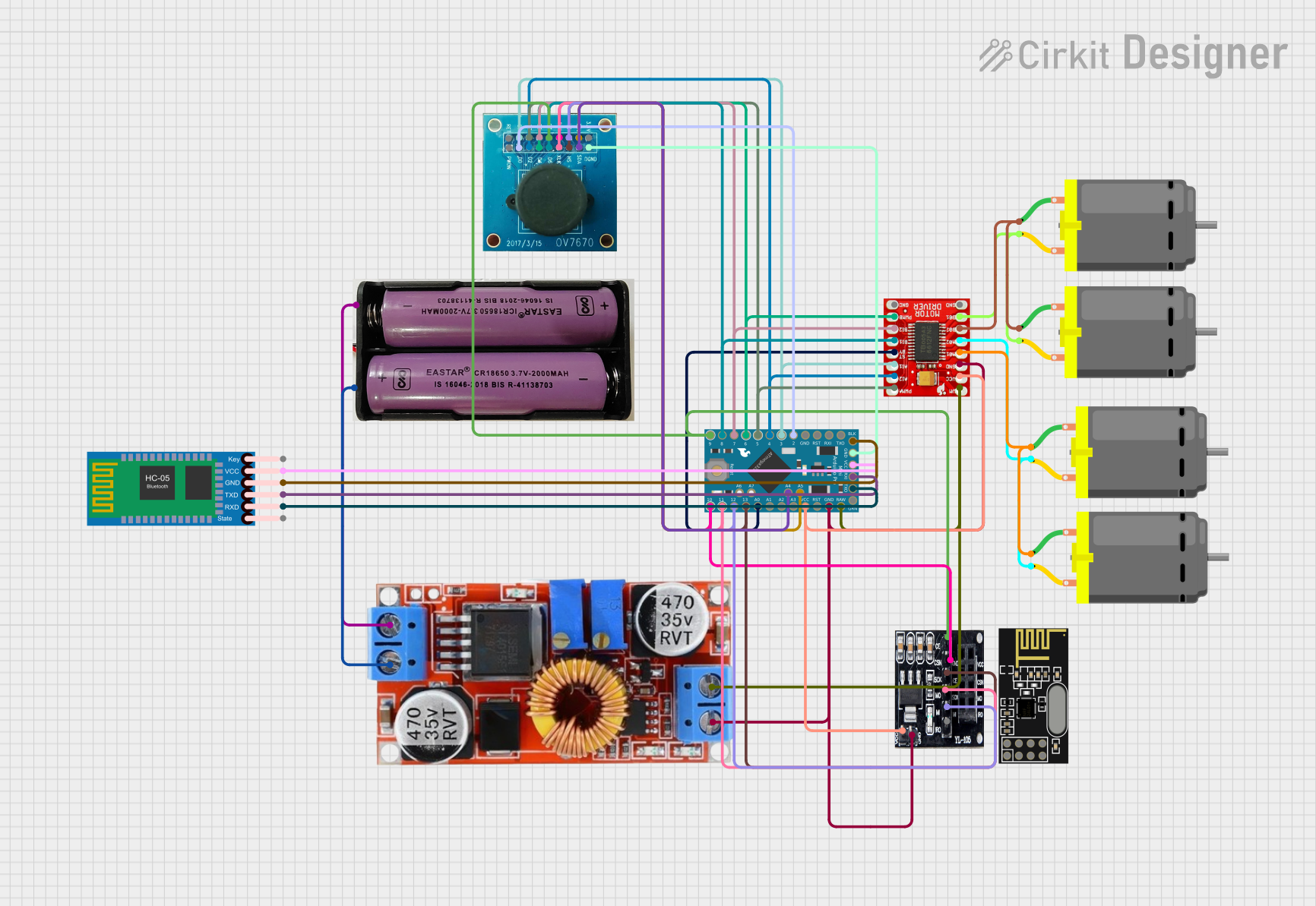

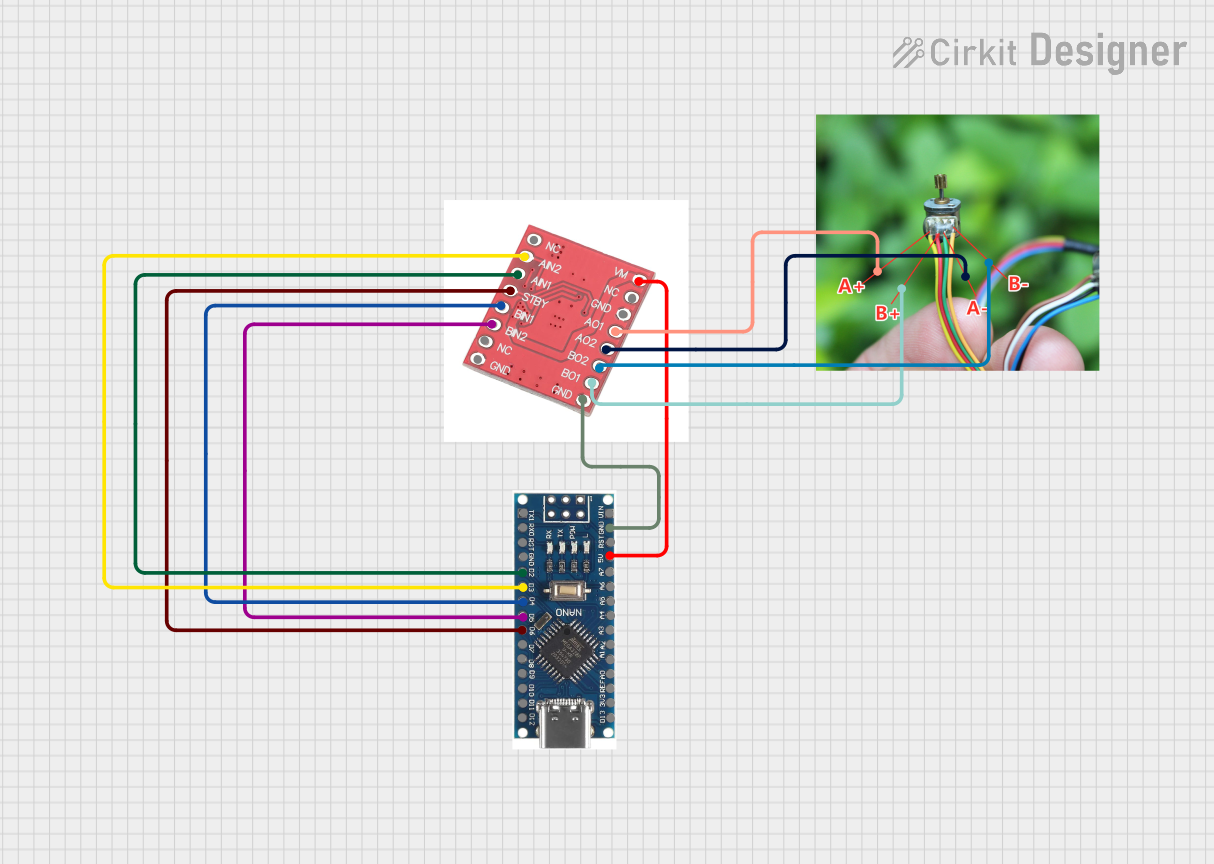

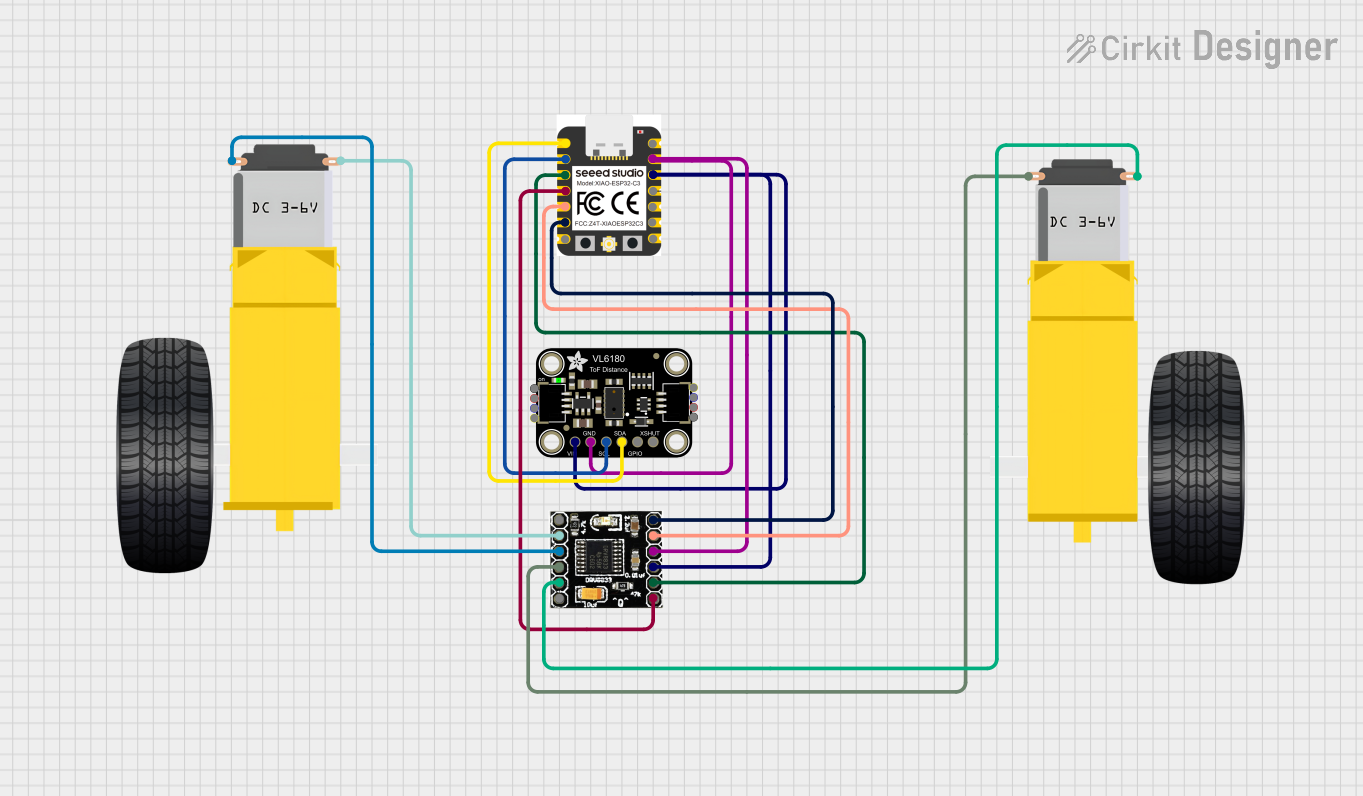

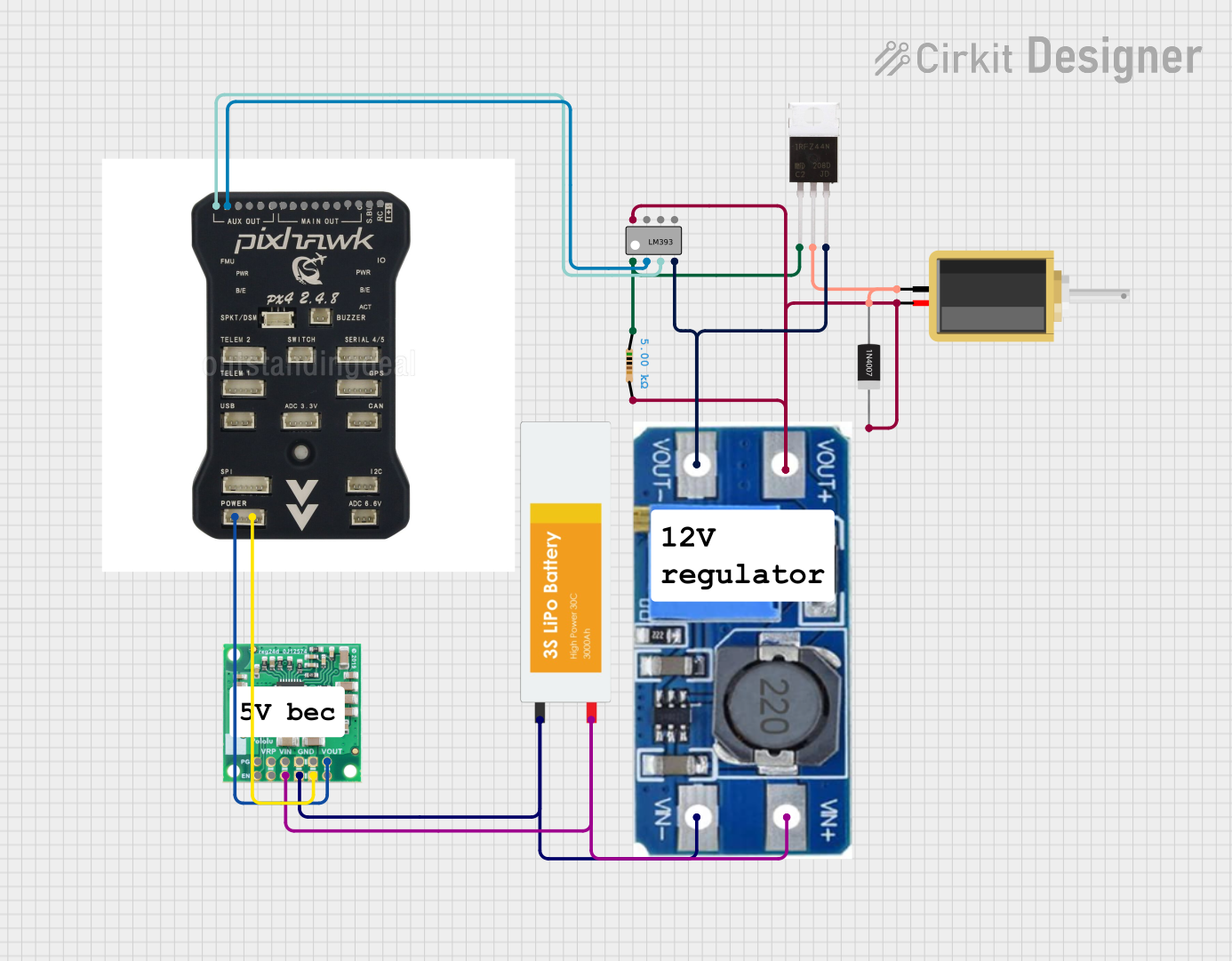

Explore Projects Built with DRV8834

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit DesignerExplore Projects Built with DRV8834

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit DesignerCommon Applications

- Robotics and automation systems

- 3D printers and CNC machines

- Camera gimbals and pan-tilt mechanisms

- Precision positioning systems

- Educational and DIY electronics projects

Technical Specifications

The following table outlines the key technical details of the DRV8834:

| Parameter | Value |

|---|---|

| Motor Supply Voltage (VMOT) | 2.5V to 10.8V |

| Logic Voltage (VCC) | 1.8V to 7V |

| Maximum Output Current | 1.5A per phase (continuous), 2A (peak) |

| Microstepping Modes | Full-step, half-step, 1/4-step, 1/8-step, 1/16-step, 1/32-step |

| Current Control | Adjustable via external potentiometer |

| Protection Features | Overcurrent, thermal shutdown, undervoltage lockout |

| Dimensions | 0.6" × 0.8" × 0.1" (15.2 mm × 20.3 mm × 2.7 mm) |

| Operating Temperature | -40°C to +85°C |

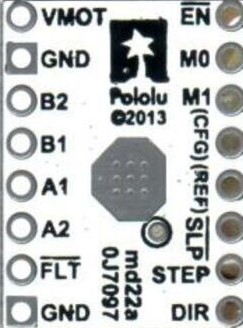

Pin Configuration and Descriptions

The DRV8834 has 16 pins, which are described in the table below:

| Pin | Name | Description |

|---|---|---|

| 1 | VMOT | Motor power supply (2.5V to 10.8V). Connect a decoupling capacitor close to this pin. |

| 2 | GND | Ground connection for motor power supply. |

| 3 | B2 | Output for motor coil B (phase 2). |

| 4 | B1 | Output for motor coil B (phase 1). |

| 5 | A1 | Output for motor coil A (phase 1). |

| 6 | A2 | Output for motor coil A (phase 2). |

| 7 | VCC | Logic power supply (1.8V to 7V). |

| 8 | GND | Ground connection for logic power supply. |

| 9 | STEP | Step input. A rising edge on this pin advances the motor by one step. |

| 10 | DIR | Direction input. High or low determines the rotation direction of the motor. |

| 11 | M0 | Microstepping mode selection input 0. |

| 12 | M1 | Microstepping mode selection input 1. |

| 13 | DECAY | Decay mode selection input. |

| 14 | FAULT | Fault output. Active low when a fault condition occurs. |

| 15 | SLEEP | Sleep mode input. Pull low to put the driver into low-power sleep mode. |

| 16 | ENABLE | Enable input. Pull low to disable the motor outputs. |

Usage Instructions

How to Use the DRV8834 in a Circuit

Power Connections:

- Connect the motor power supply (VMOT) to the VMOT pin and ground to the GND pin. Use a decoupling capacitor (e.g., 100 µF) close to the VMOT pin to reduce noise.

- Connect the logic power supply (VCC) to the VCC pin and ground to the GND pin.

Motor Connections:

- Connect the two coils of the stepper motor to the A1, A2, B1, and B2 pins. Ensure the correct pairing of the motor wires.

Control Inputs:

- Use the STEP pin to send step pulses to the driver. Each rising edge advances the motor by one step.

- Use the DIR pin to control the rotation direction of the motor.

- Configure the microstepping mode by setting the M0 and M1 pins according to the desired mode (refer to the datasheet for the mode selection table).

Current Limiting:

- Adjust the current limit using the onboard potentiometer. This prevents the motor from drawing excessive current and overheating.

Optional Features:

- Use the SLEEP pin to put the driver into low-power mode when not in use.

- Monitor the FAULT pin for error conditions such as overcurrent or thermal shutdown.

Example: Connecting the DRV8834 to an Arduino UNO

Below is an example of how to control a stepper motor using the DRV8834 and an Arduino UNO:

// Define pin connections

#define STEP_PIN 3 // Connect to the STEP pin of DRV8834

#define DIR_PIN 4 // Connect to the DIR pin of DRV8834

void setup() {

pinMode(STEP_PIN, OUTPUT); // Set STEP pin as output

pinMode(DIR_PIN, OUTPUT); // Set DIR pin as output

digitalWrite(DIR_PIN, LOW); // Set initial direction (LOW = clockwise)

}

void loop() {

// Generate step pulses to move the motor

digitalWrite(STEP_PIN, HIGH); // Set STEP pin HIGH

delayMicroseconds(500); // Wait 500 microseconds

digitalWrite(STEP_PIN, LOW); // Set STEP pin LOW

delayMicroseconds(500); // Wait 500 microseconds

}

Important Considerations

- Ensure the motor supply voltage (VMOT) and logic voltage (VCC) are within the specified ranges.

- Avoid connecting or disconnecting the motor while the driver is powered to prevent damage.

- Use appropriate heat dissipation methods if operating near the maximum current rating.

Troubleshooting and FAQs

Common Issues and Solutions

Motor Not Moving:

- Verify the STEP and DIR signals are being sent correctly.

- Check the motor connections to ensure proper wiring.

- Ensure the current limit is set appropriately for the motor.

Overheating:

- Reduce the current limit using the potentiometer.

- Improve heat dissipation by adding a heatsink or increasing airflow.

FAULT Pin Active (Low):

- Check for overcurrent or thermal shutdown conditions.

- Ensure the motor supply voltage is within the specified range.

Erratic Motor Movement:

- Verify the microstepping mode settings (M0 and M1 pins).

- Ensure the STEP signal timing meets the minimum pulse width requirements.

FAQs

Q: Can the DRV8834 drive unipolar stepper motors?

A: No, the DRV8834 is designed for bipolar stepper motors only.

Q: What is the maximum step rate supported by the DRV8834?

A: The maximum step rate depends on the STEP signal timing. Refer to the datasheet for the minimum pulse width requirements.

Q: Can I use the DRV8834 with a 12V motor?

A: No, the maximum motor supply voltage for the DRV8834 is 10.8V. Using a higher voltage may damage the driver.

Q: How do I reset the driver after a fault condition?

A: Toggle the SLEEP pin or cycle the power to reset the driver. Ensure the fault condition is resolved before restarting.