How to Use Coreless Motor Clock: Examples, Pinouts, and Specs

Design with Coreless Motor Clock in Cirkit Designer

Design with Coreless Motor Clock in Cirkit DesignerIntroduction

A coreless motor clock is a precision timekeeping device that utilizes a coreless DC motor to drive the clock mechanism. Unlike traditional motors with iron cores, coreless motors have a rotor that is not surrounded by an iron core, which reduces inertia and enables more precise control. This makes coreless motor clocks highly accurate and reliable for applications where precise timekeeping is essential, such as in wall clocks, wristwatches, and timing devices in various electronics.

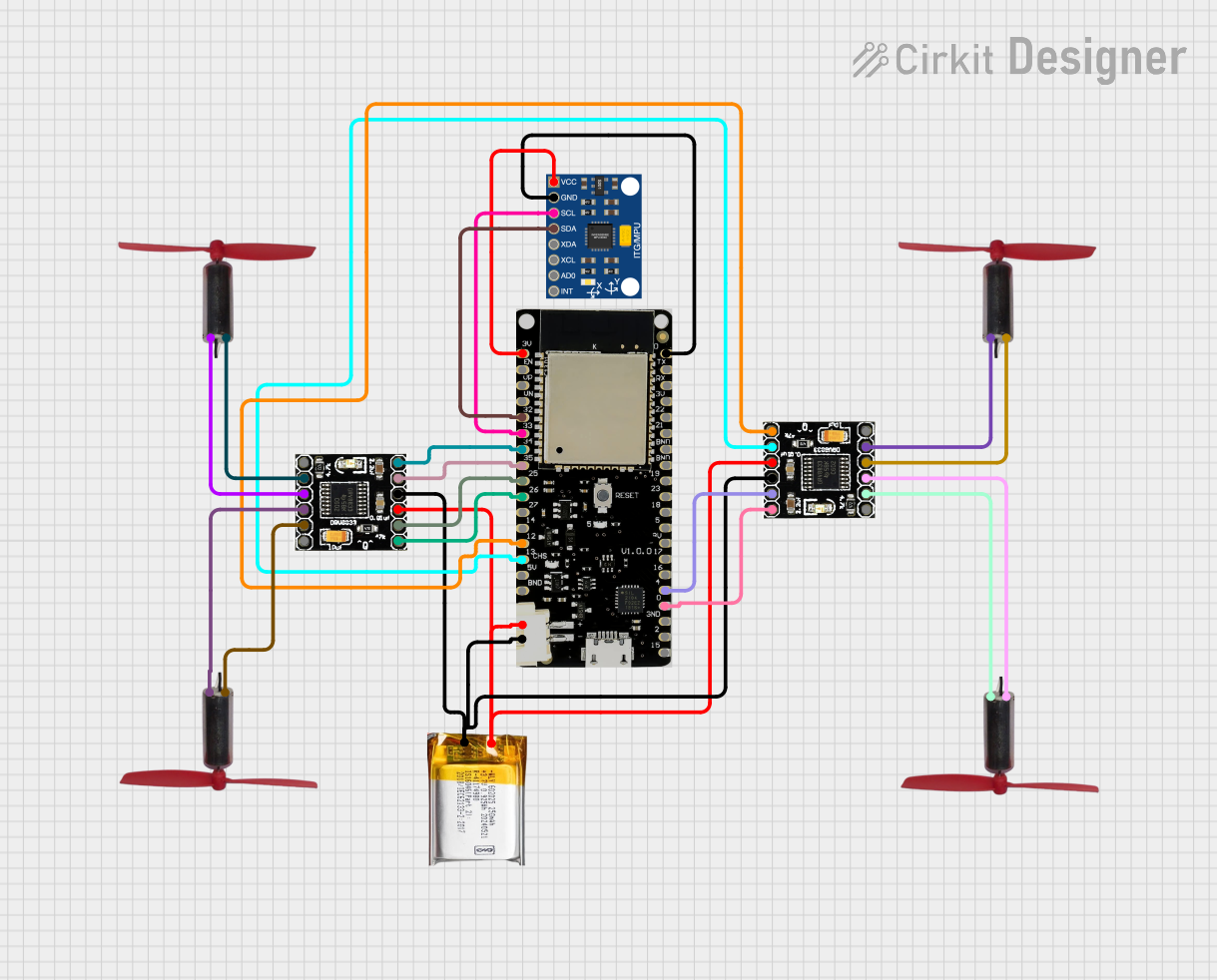

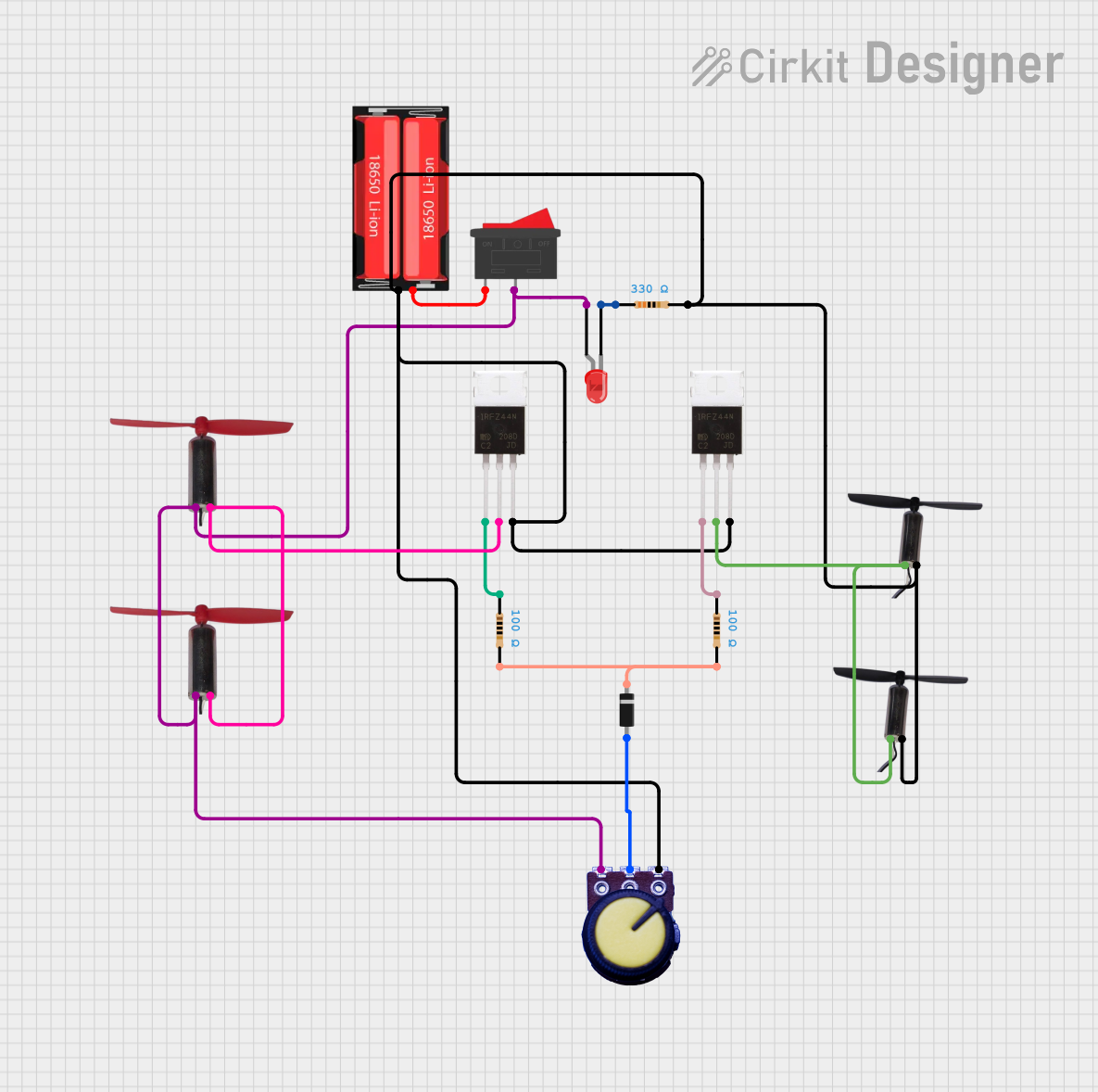

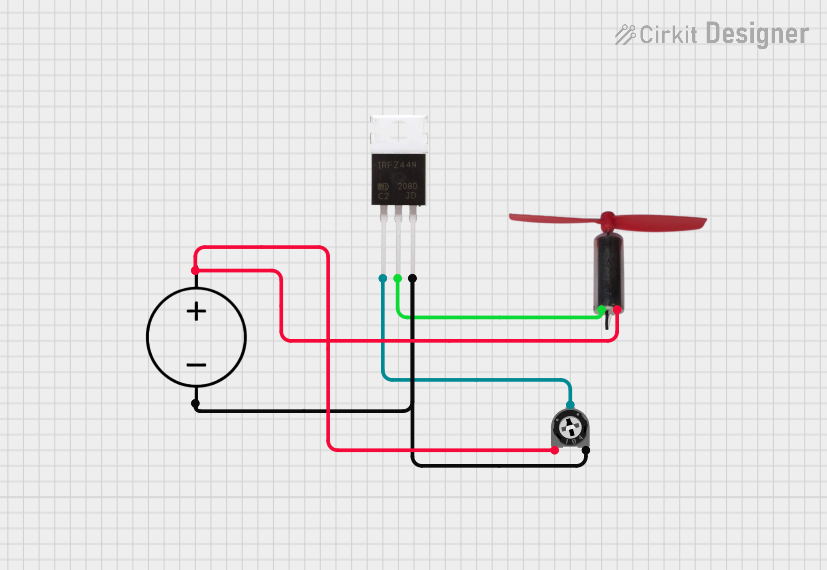

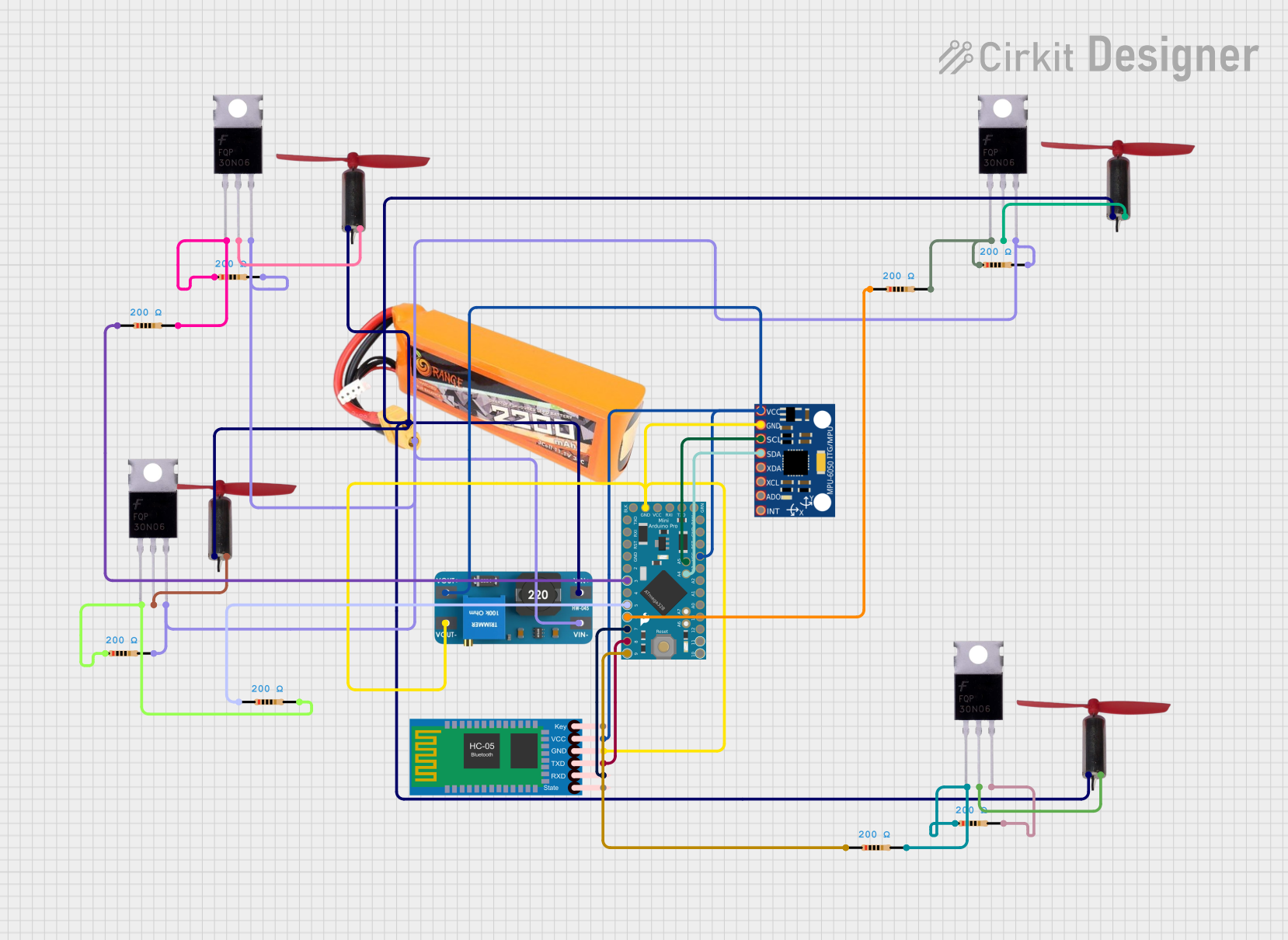

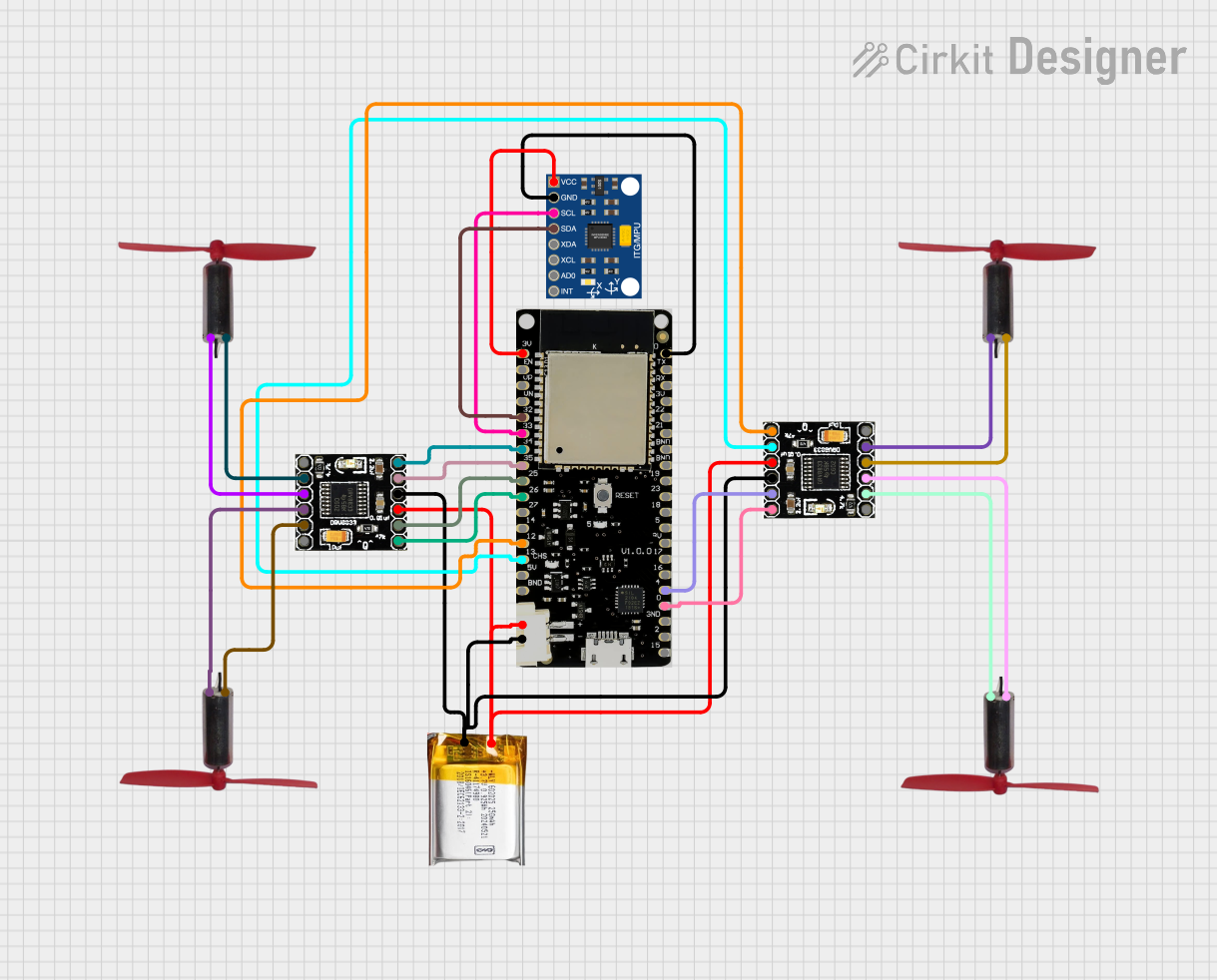

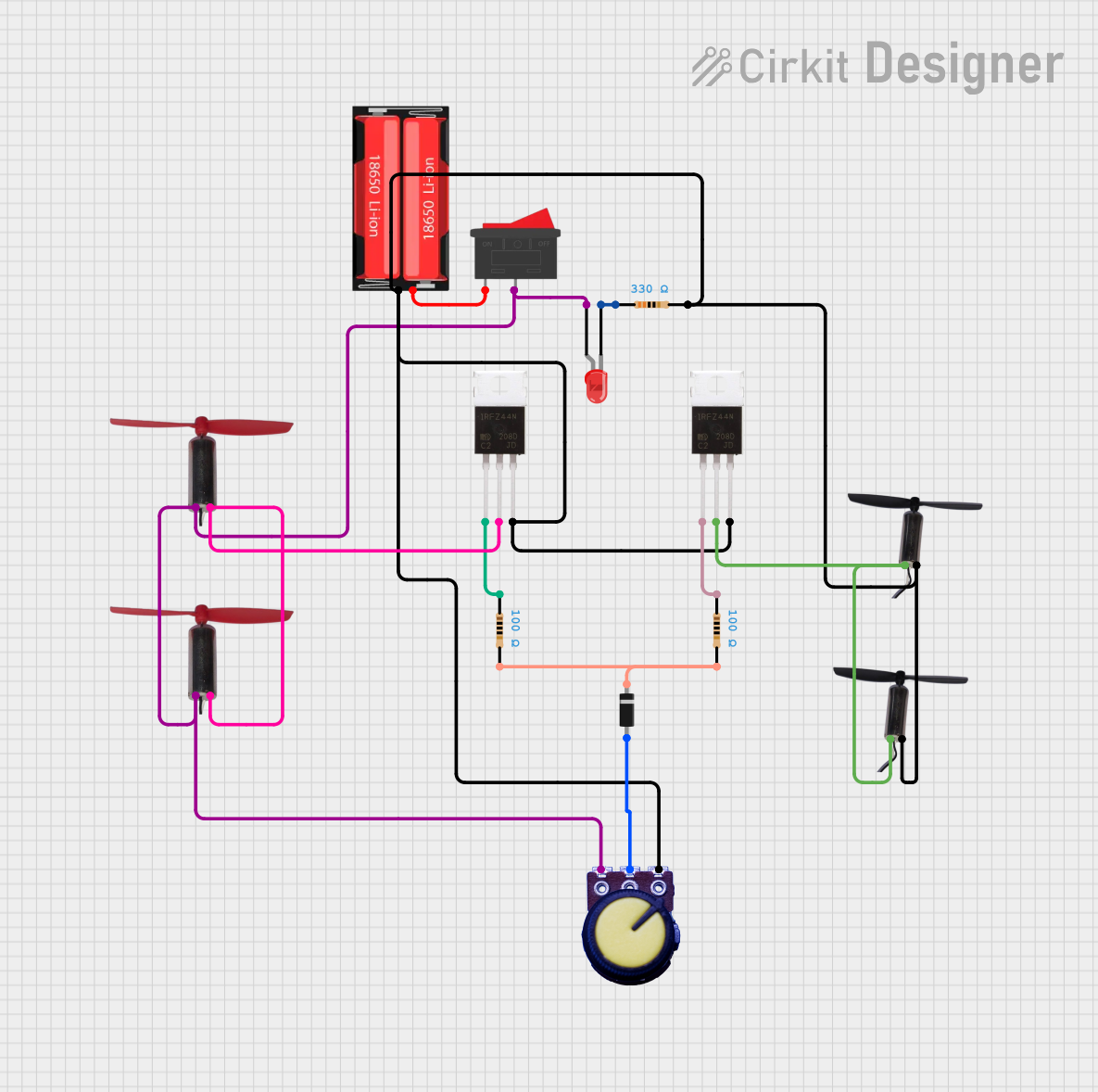

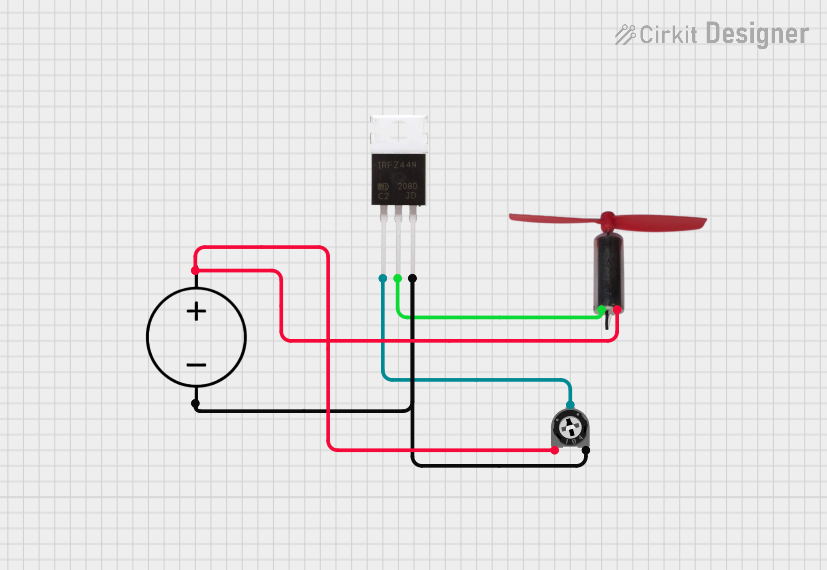

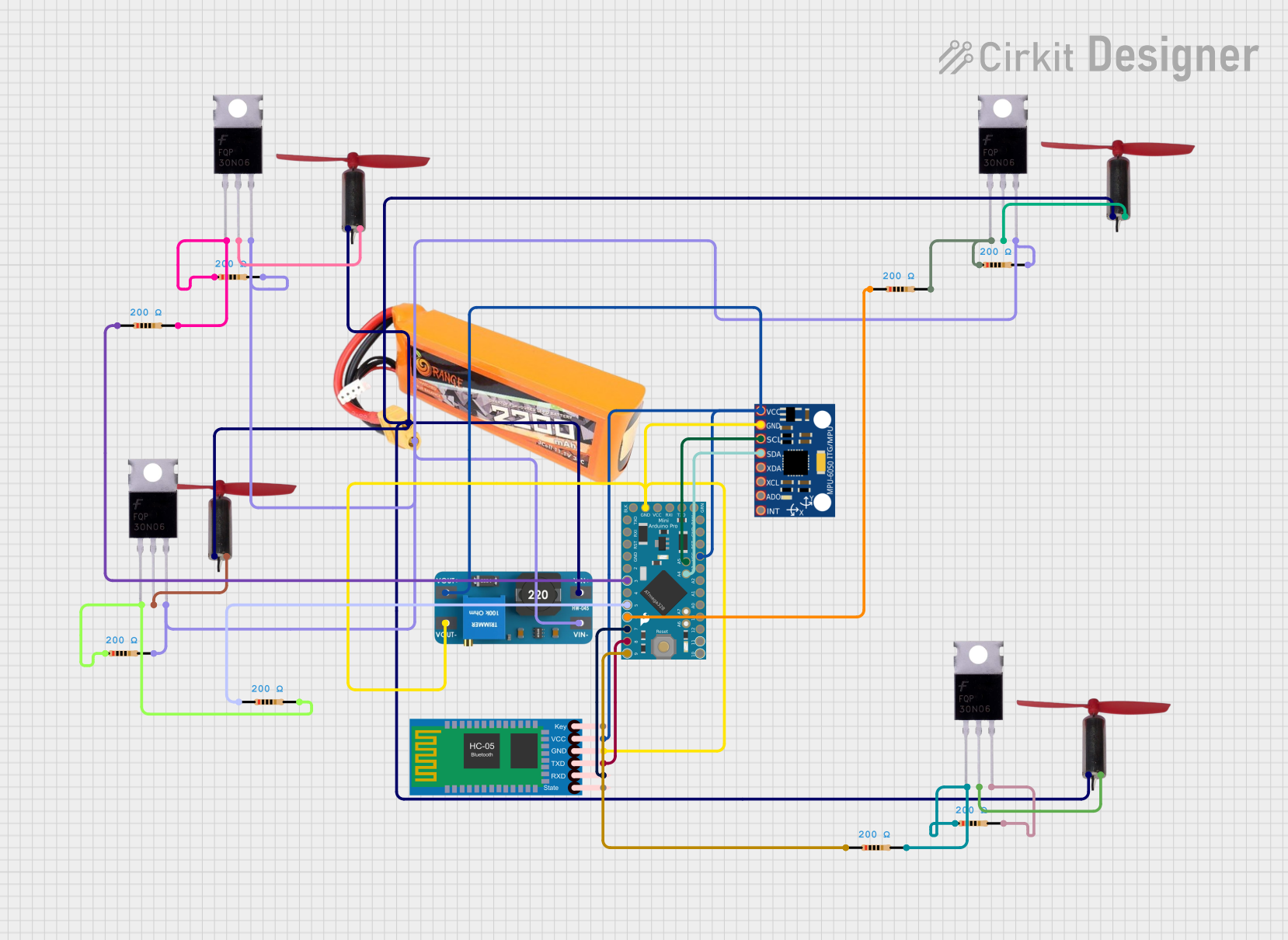

Explore Projects Built with Coreless Motor Clock

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit DesignerExplore Projects Built with Coreless Motor Clock

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit DesignerCommon Applications and Use Cases

- Wall clocks

- Wristwatches

- Timing mechanisms in electronic devices

- Precision instrumentation

Technical Specifications

Key Technical Details

| Specification | Value | Description |

|---|---|---|

| Operating Voltage | X - Y V | The range of voltages the motor can operate at safely. |

| Current Rating | Z mA | The maximum current the motor can draw under load. |

| Power Rating | W mW | The power consumption of the motor. |

| Timekeeping Accuracy | ±A ppm | The precision of timekeeping, typically in parts per million. |

| Operating Temperature | B - C °C | The range of ambient temperatures within which the motor operates reliably. |

Pin Configuration and Descriptions

| Pin Number | Name | Description |

|---|---|---|

| 1 | VCC | Connect to the positive voltage supply. |

| 2 | GND | Connect to the ground. |

| 3 | TIME_ADJ | Input for time adjustment. |

| 4 | PULSE_OUT | Output pulse for clock mechanism. |

Usage Instructions

How to Use the Component in a Circuit

Power Supply Connection: Connect the VCC pin to a power supply within the specified operating voltage range and the GND pin to the ground.

Time Adjustment: The TIME_ADJ pin can be used to fine-tune the timekeeping of the clock. This can be done through a variable resistor or a digital signal that adjusts the motor speed.

Clock Mechanism Drive: Connect the PULSE_OUT pin to the clock mechanism. This pin outputs a pulse that advances the clock by one increment, typically one second.

Important Considerations and Best Practices

- Ensure that the power supply does not exceed the recommended voltage range to prevent damage to the motor.

- Avoid placing the clock in environments that exceed the operating temperature range.

- For precise time adjustment, use a high-quality variable resistor or a stable digital signal.

- Keep magnetic materials away from the coreless motor to prevent interference with its operation.

Troubleshooting and FAQs

Common Issues Users Might Face

- Clock is not keeping accurate time: Check the TIME_ADJ setting and adjust as necessary. Ensure the power supply is stable and within the specified range.

- Motor does not start: Verify that the power connections are correct and that the voltage is within the specified range. Check for any obstructions in the clock mechanism.

Solutions and Tips for Troubleshooting

- If the clock is running fast or slow, fine-tune the TIME_ADJ pin.

- Ensure that all connections are secure and free from corrosion or damage.

- Replace the power supply if it is not providing a consistent voltage.

FAQs

Q: Can the coreless motor clock run on battery power? A: Yes, as long as the battery voltage is within the operating voltage range.

Q: How long will the coreless motor last? A: Coreless motors have a long lifespan due to their low friction and wear, but the exact duration depends on usage conditions.

Q: Is it possible to replace the coreless motor if it fails? A: Yes, the motor can be replaced, but it requires some technical skill to ensure proper alignment and connection with the clock mechanism.

Example Arduino Code for Coreless Motor Clock

// Define the pins

const int pulseOutPin = 3; // PULSE_OUT connected to digital pin 3

void setup() {

// Set the pulseOutPin as an output:

pinMode(pulseOutPin, OUTPUT);

}

void loop() {

// Send a pulse every second to advance the clock

digitalWrite(pulseOutPin, HIGH); // Turn on the pulse

delay(10); // Wait for 10 milliseconds

digitalWrite(pulseOutPin, LOW); // Turn off the pulse

delay(990); // Wait for the remainder of the second

}

Note: The above code assumes that a single pulse advances the clock by one second. Adjust the delay times if your clock mechanism requires a different pulse duration or frequency.