How to Use Peltier Module: Examples, Pinouts, and Specs

Design with Peltier Module in Cirkit Designer

Design with Peltier Module in Cirkit DesignerIntroduction

A Peltier module, also known as a thermoelectric cooler (TEC), is a solid-state device that transfers heat from one side to the other when an electric current is applied. This creates a temperature difference, with one side becoming cold and the other side becoming hot. Peltier modules are widely used in applications requiring precise temperature control, compact cooling solutions, or silent operation.

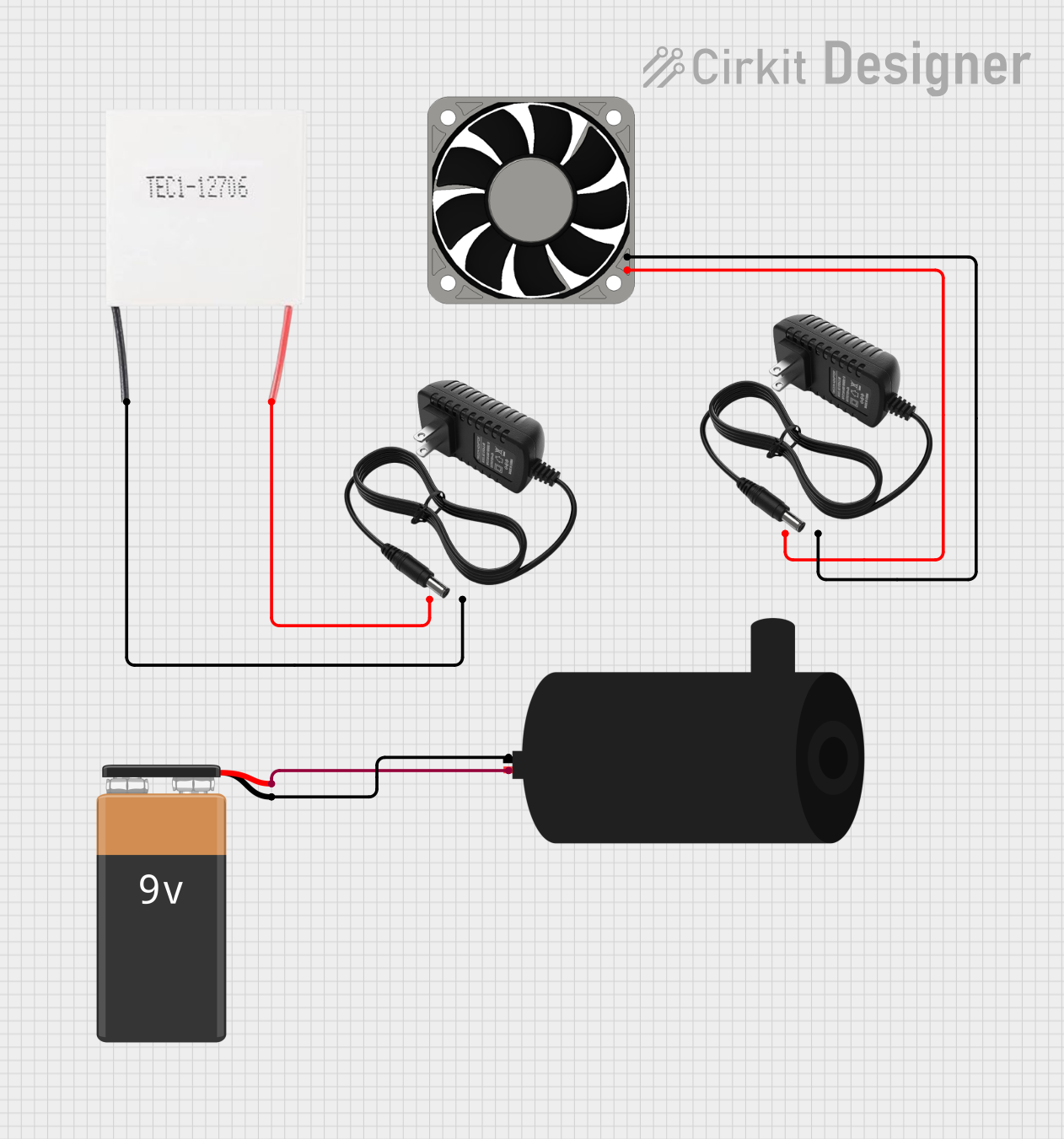

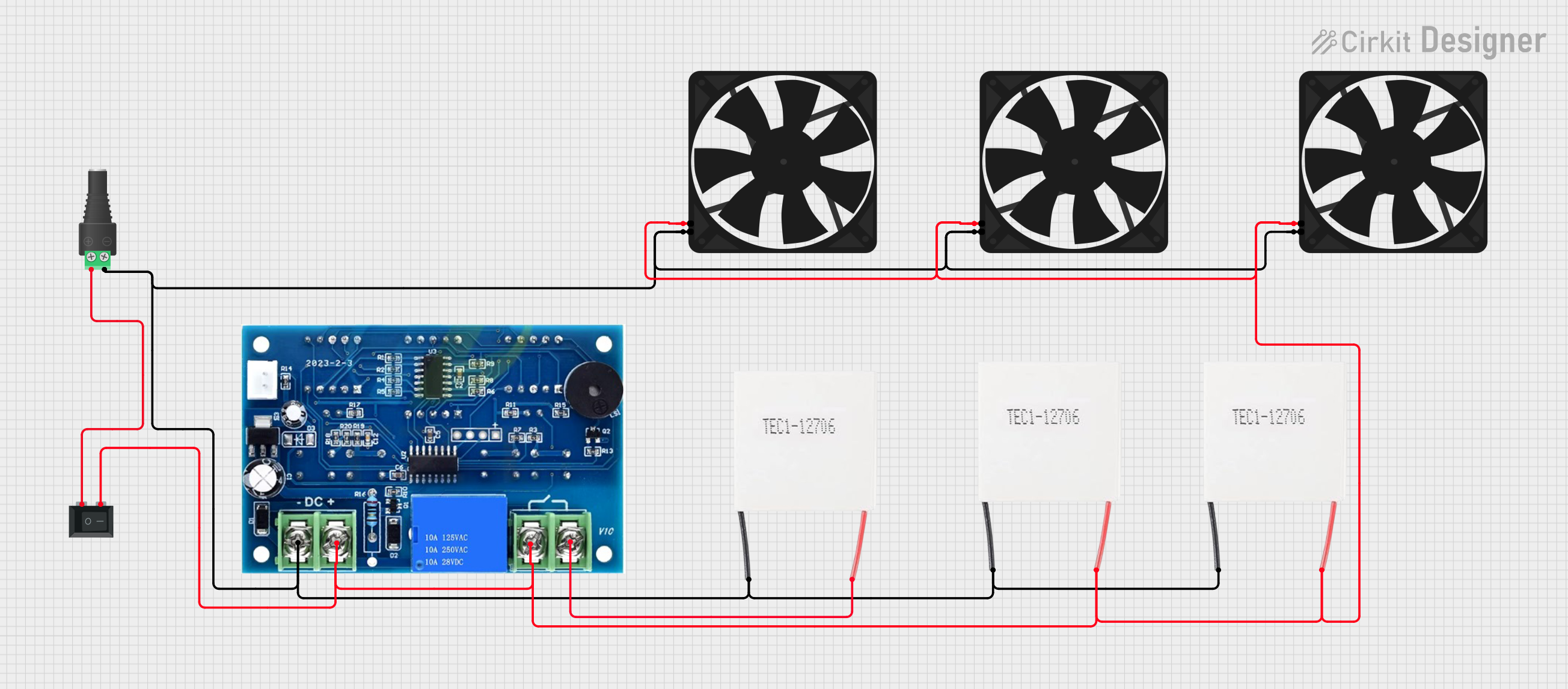

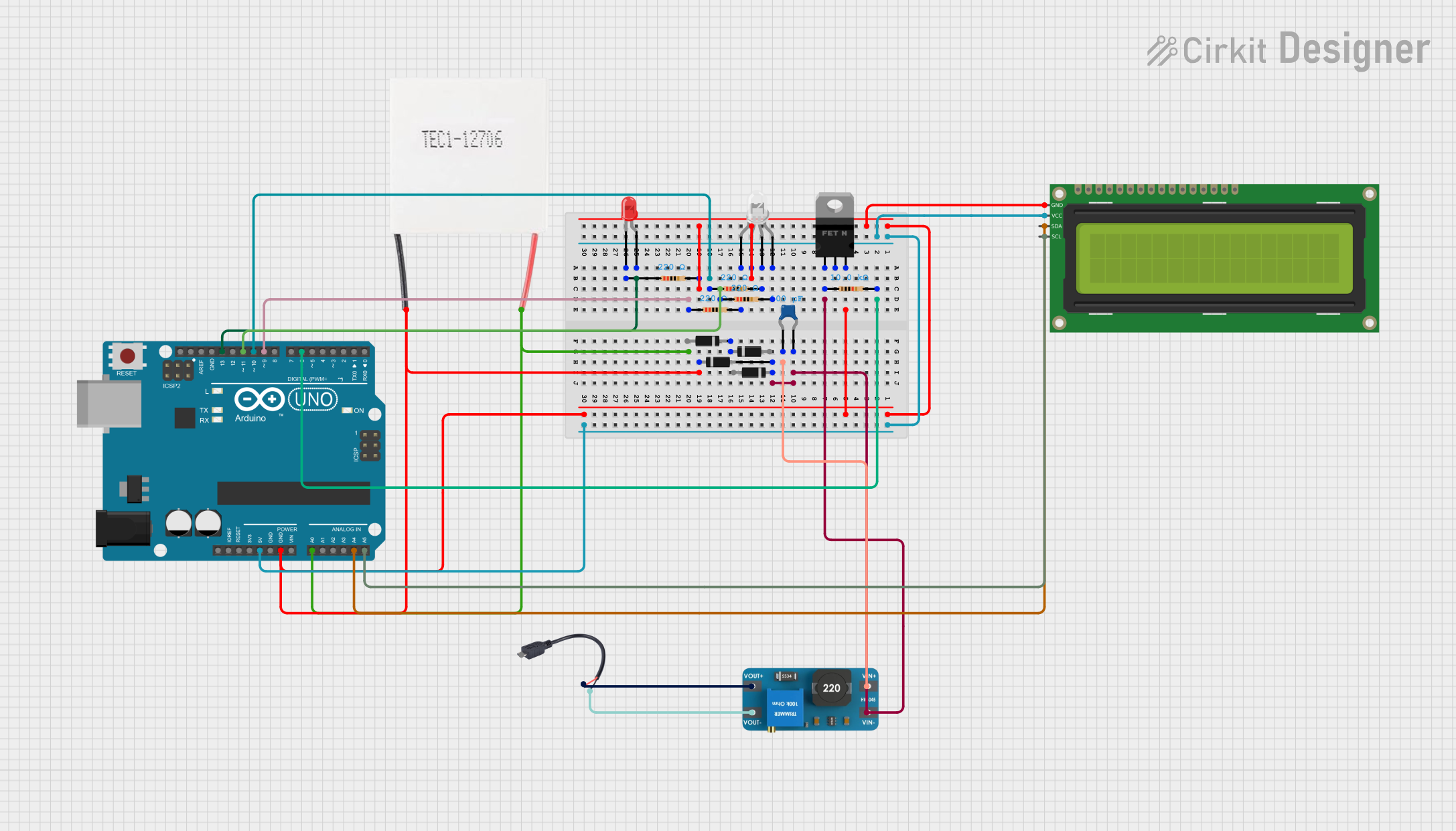

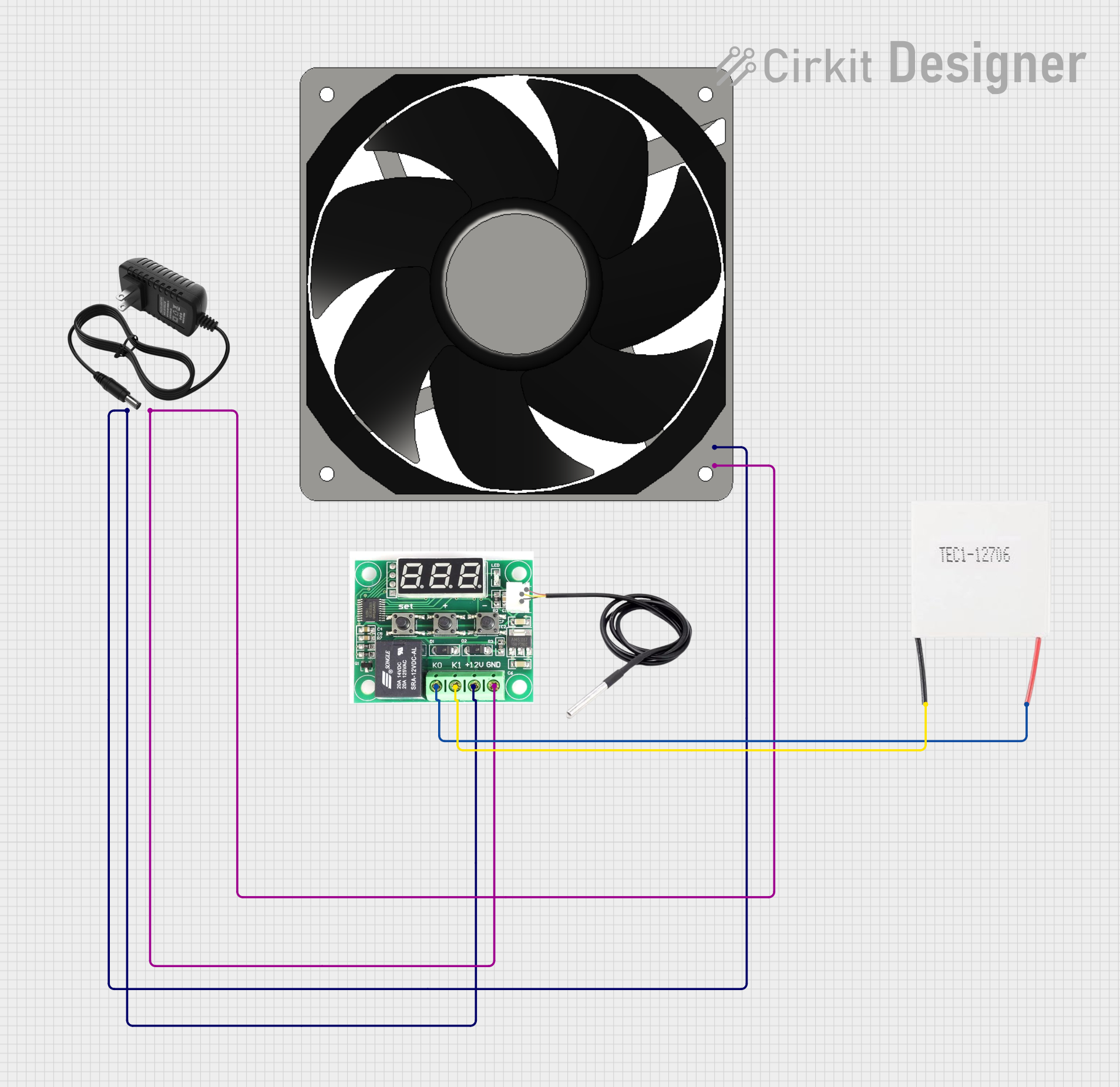

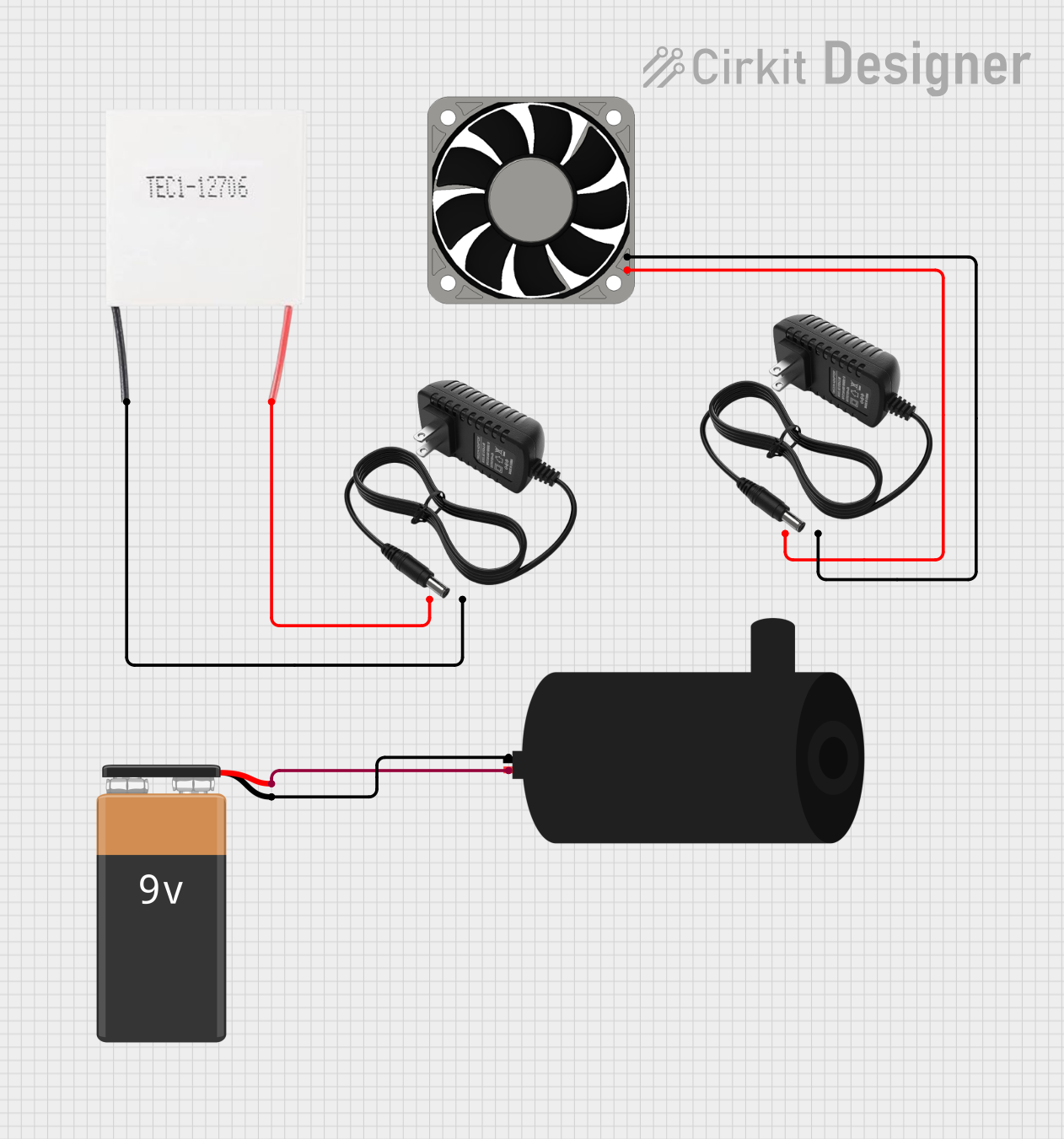

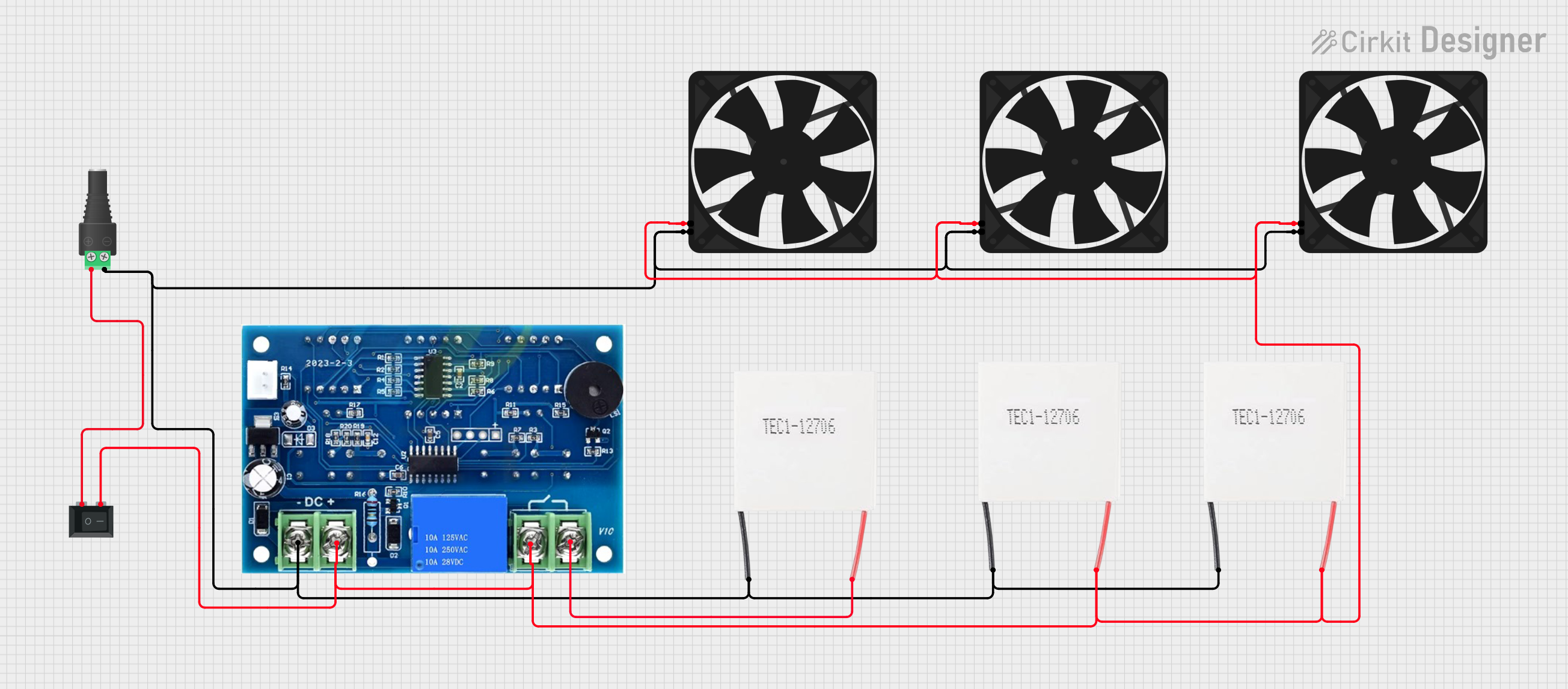

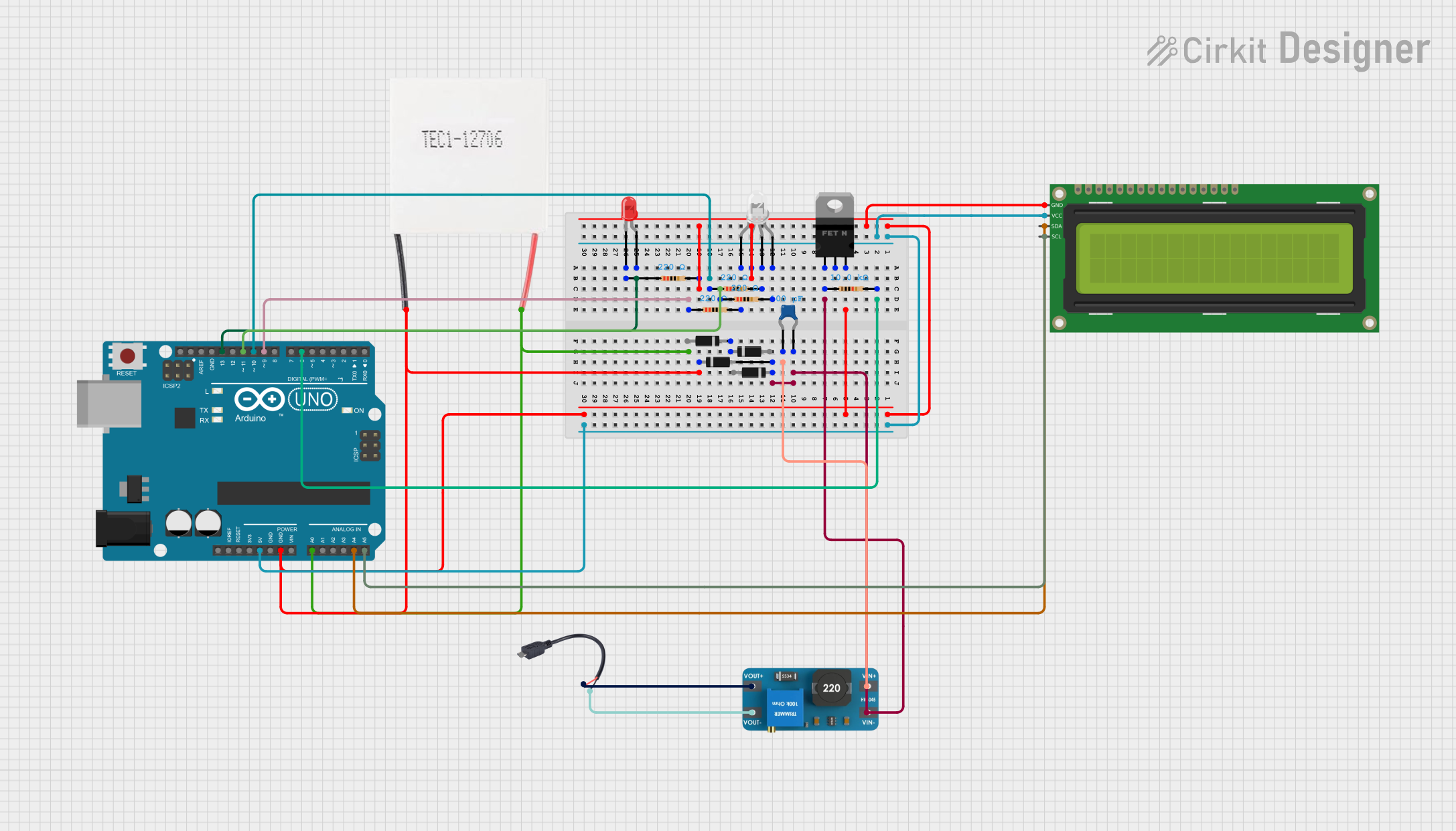

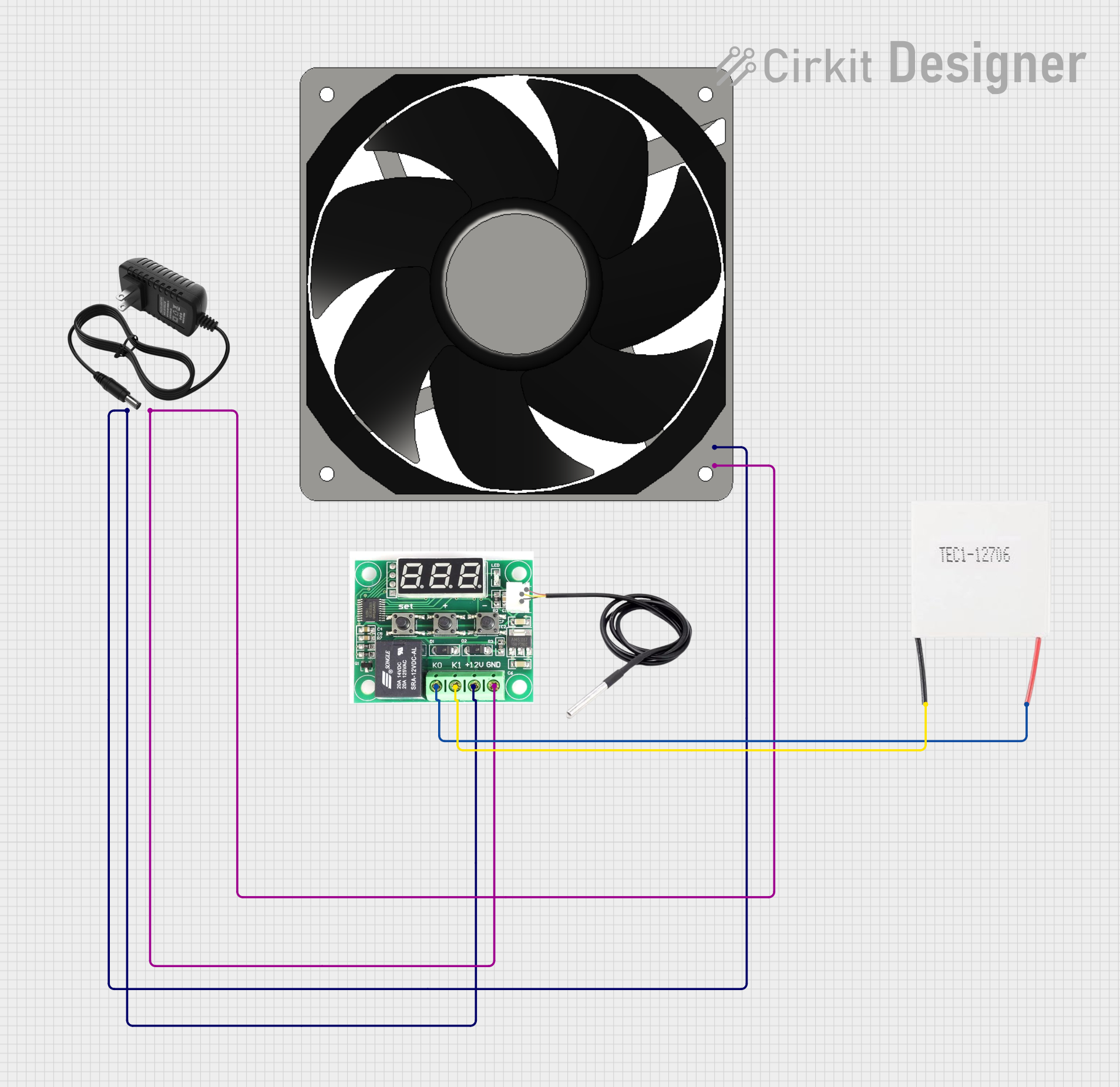

Explore Projects Built with Peltier Module

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit DesignerExplore Projects Built with Peltier Module

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit DesignerCommon Applications and Use Cases

- CPU and electronics cooling

- Portable refrigerators and beverage coolers

- Laser diode temperature stabilization

- Medical devices requiring localized heating or cooling

- Scientific instruments for temperature-sensitive experiments

Technical Specifications

Below are the general technical specifications for a standard Peltier module. Note that specific models may vary, so always refer to the datasheet of your module.

| Parameter | Typical Value | Description |

|---|---|---|

| Operating Voltage (V) | 12V | Nominal voltage required for operation. |

| Operating Current (A) | 5A | Current drawn at nominal voltage. |

| Maximum Temperature ΔT | 70°C | Maximum temperature difference between sides. |

| Maximum Power (W) | 60W | Maximum heat pumping capacity. |

| Dimensions (mm) | 40 x 40 x 3.6 | Physical size of the module. |

| Hot Side Temperature | Up to 85°C | Maximum allowable temperature on the hot side. |

Pin Configuration and Descriptions

Peltier modules typically have two wires for electrical connections:

| Wire Color | Function |

|---|---|

| Red | Positive terminal (connect to +V) |

| Black | Negative terminal (connect to GND) |

Usage Instructions

How to Use the Peltier Module in a Circuit

- Power Supply: Use a DC power supply that matches the voltage and current requirements of the Peltier module. For example, a 12V, 5A power supply is suitable for a typical module.

- Heat Dissipation: Attach a heatsink or fan to the hot side of the module to dissipate heat effectively. Failure to do so can cause the module to overheat and fail.

- Polarity: Connect the red wire to the positive terminal of the power supply and the black wire to the negative terminal. Reversing the polarity will reverse the hot and cold sides.

- Temperature Control: Use a temperature controller or a PWM (Pulse Width Modulation) circuit to regulate the power supplied to the module for precise temperature control.

Important Considerations and Best Practices

- Thermal Interface Material: Apply thermal paste or a thermal pad between the module and the heatsink to improve heat transfer.

- Avoid Overheating: Always ensure proper cooling on the hot side to prevent damage to the module.

- Do Not Exceed Ratings: Operate the module within its specified voltage and current limits to avoid permanent damage.

- Insulation: Insulate the cold side to minimize heat gain from the environment and improve efficiency.

Example: Using a Peltier Module with Arduino UNO

You can use an Arduino UNO to control the Peltier module via a MOSFET and PWM. Below is an example circuit and code:

Circuit Setup

- Connect the Peltier module to the drain of an N-channel MOSFET.

- Connect the source of the MOSFET to GND.

- Connect the MOSFET gate to a PWM-capable pin on the Arduino (e.g., pin 9).

- Use a 12V power supply to power the Peltier module, with the positive terminal connected to the module and the negative terminal to GND.

Arduino Code

// Peltier Module Control with Arduino

// This code uses PWM to control the power supplied to the Peltier module.

const int peltierPin = 9; // PWM pin connected to the MOSFET gate

void setup() {

pinMode(peltierPin, OUTPUT); // Set the pin as an output

}

void loop() {

// Example: Gradually increase and decrease power to the Peltier module

for (int dutyCycle = 0; dutyCycle <= 255; dutyCycle++) {

analogWrite(peltierPin, dutyCycle); // Set PWM duty cycle

delay(10); // Wait 10ms before increasing duty cycle

}

for (int dutyCycle = 255; dutyCycle >= 0; dutyCycle--) {

analogWrite(peltierPin, dutyCycle); // Decrease PWM duty cycle

delay(10); // Wait 10ms before decreasing duty cycle

}

}

Troubleshooting and FAQs

Common Issues and Solutions

Module Not Cooling or Heating:

- Cause: Incorrect polarity or insufficient power supply.

- Solution: Verify the wiring and ensure the power supply meets the module's voltage and current requirements.

Overheating:

- Cause: Inadequate heat dissipation on the hot side.

- Solution: Attach a larger heatsink or use a fan to improve cooling.

Low Efficiency:

- Cause: Poor thermal contact or environmental heat gain.

- Solution: Apply thermal paste and insulate the cold side to reduce heat loss.

Module Damage:

- Cause: Exceeding voltage/current ratings or prolonged overheating.

- Solution: Operate the module within its specified limits and ensure proper cooling.

FAQs

Q: Can I reverse the hot and cold sides?

A: Yes, reversing the polarity of the power supply will reverse the hot and cold sides.Q: Can I use a Peltier module without a heatsink?

A: No, a heatsink is essential to prevent overheating and ensure proper operation.Q: How do I know which side is hot or cold?

A: When powered, the side with the heatsink attached will become hot, and the opposite side will become cold.Q: Can I stack multiple Peltier modules?

A: Yes, but ensure proper thermal management and electrical connections for stacked modules.

By following this documentation, you can effectively use a Peltier module in your projects while avoiding common pitfalls.