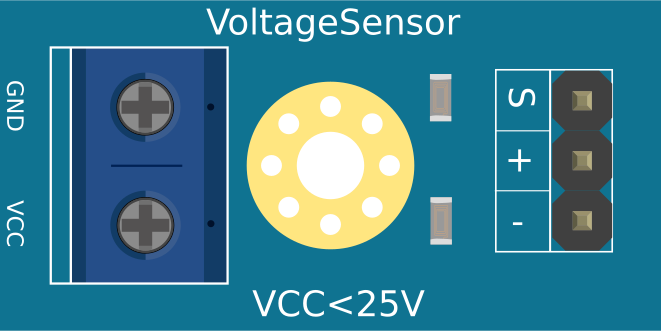

How to Use Voltage sensor: Examples, Pinouts, and Specs

Design with Voltage sensor in Cirkit Designer

Design with Voltage sensor in Cirkit DesignerIntroduction

A voltage sensor is a device that measures the electrical potential difference between two points in a circuit. It provides real-time voltage readings, which are essential for monitoring and controlling electrical systems. Voltage sensors are widely used in applications such as battery monitoring, power supply regulation, renewable energy systems, and industrial automation. They are particularly useful in scenarios where precise voltage measurement is critical for system performance and safety.

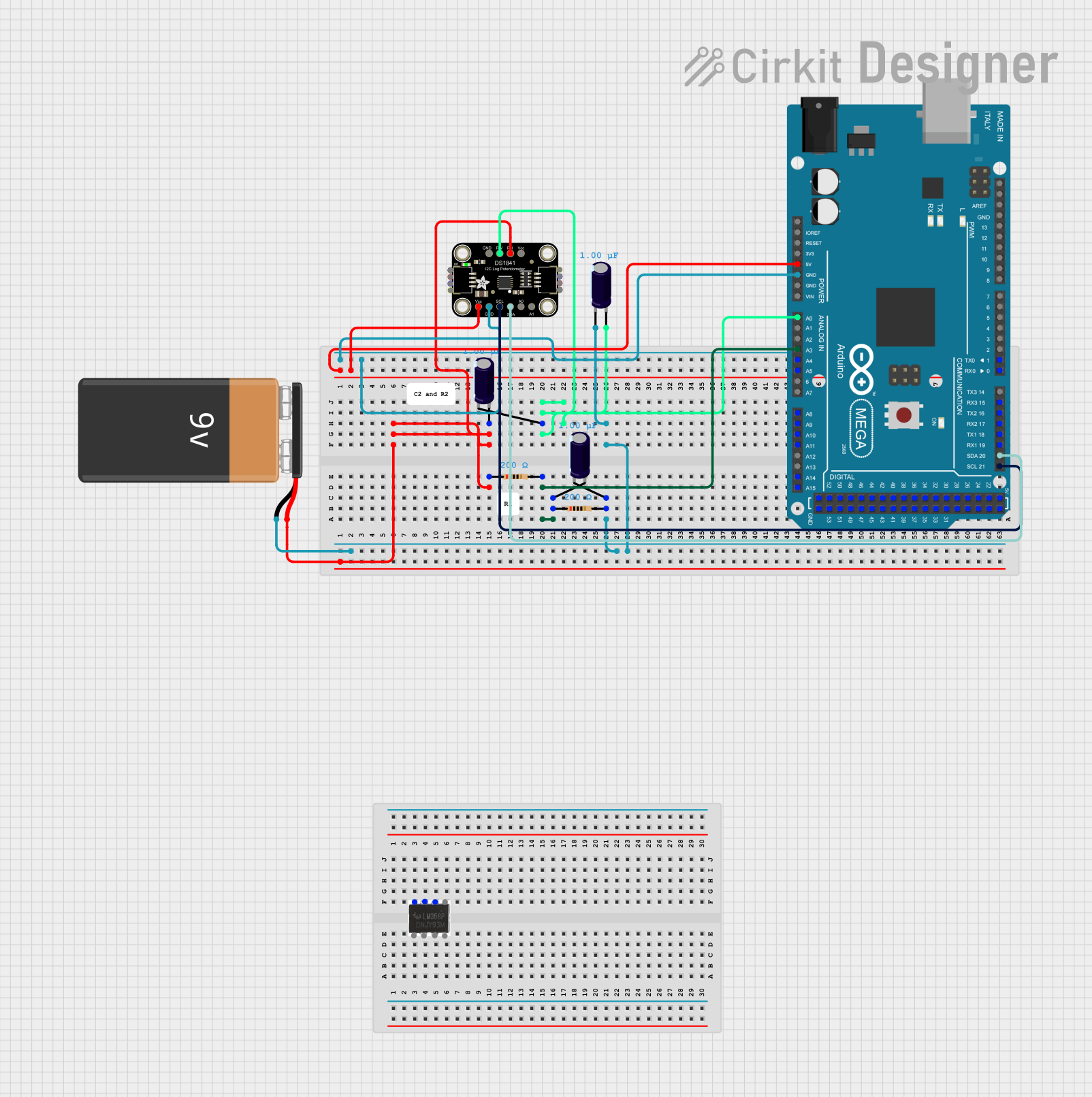

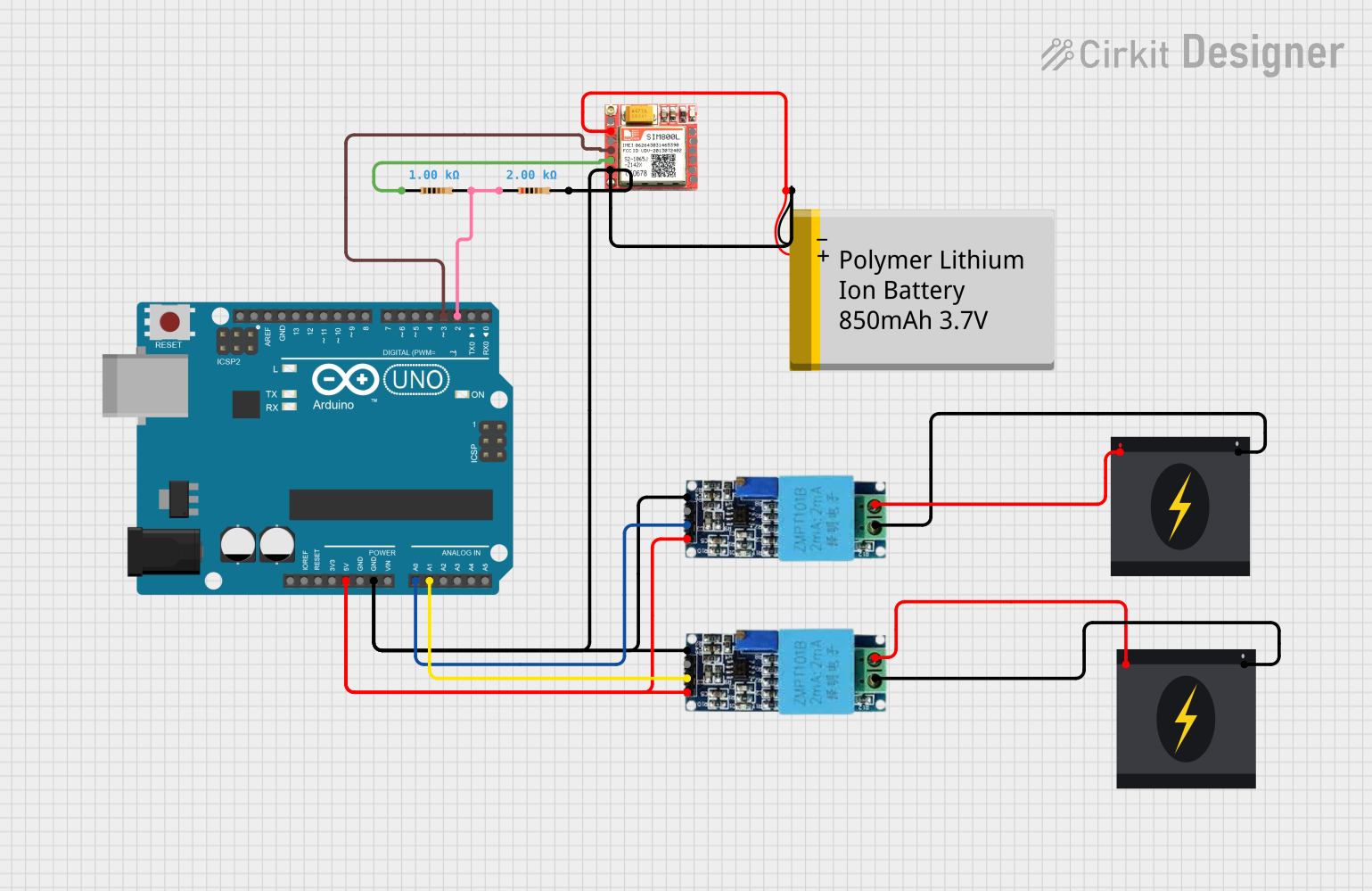

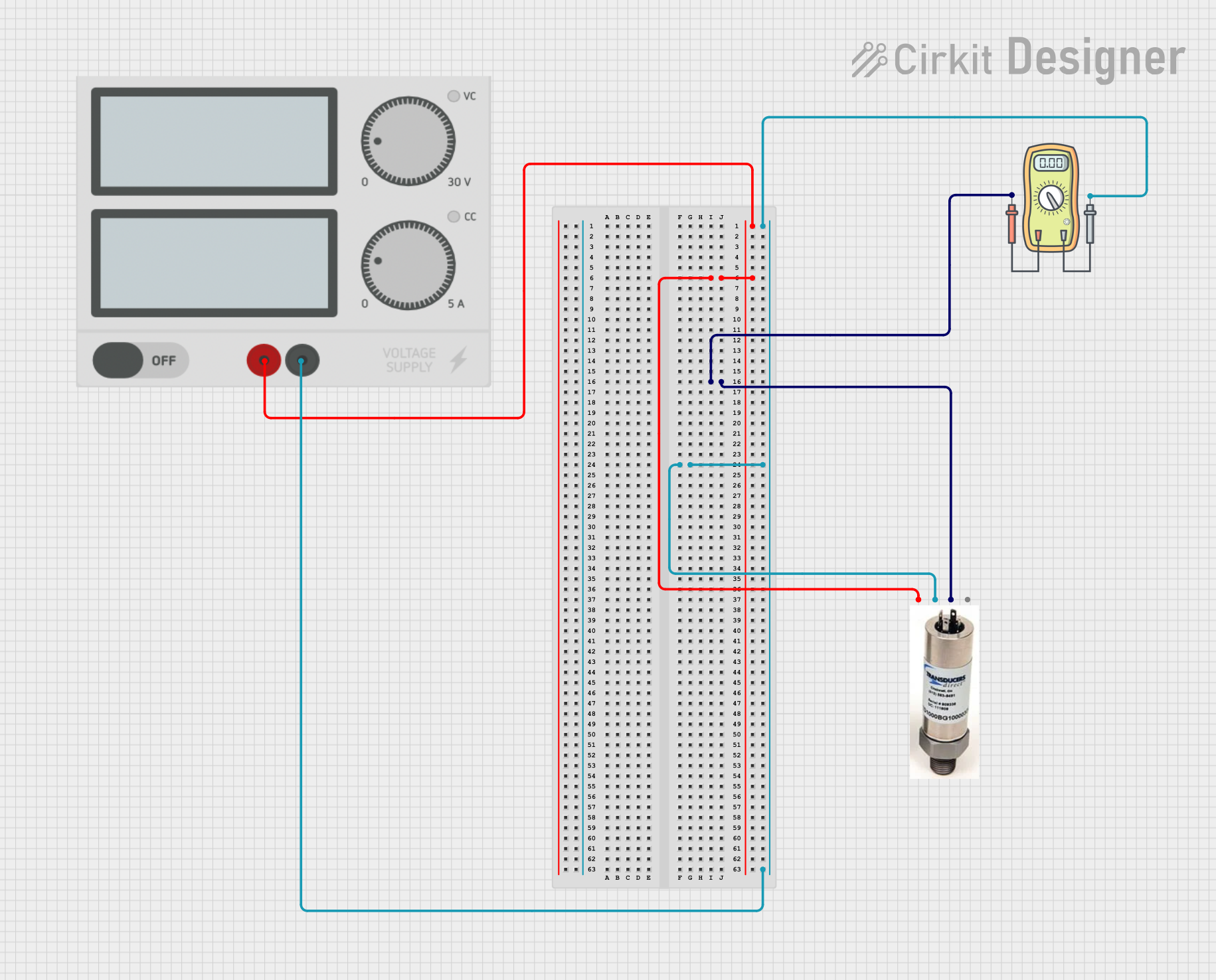

Explore Projects Built with Voltage sensor

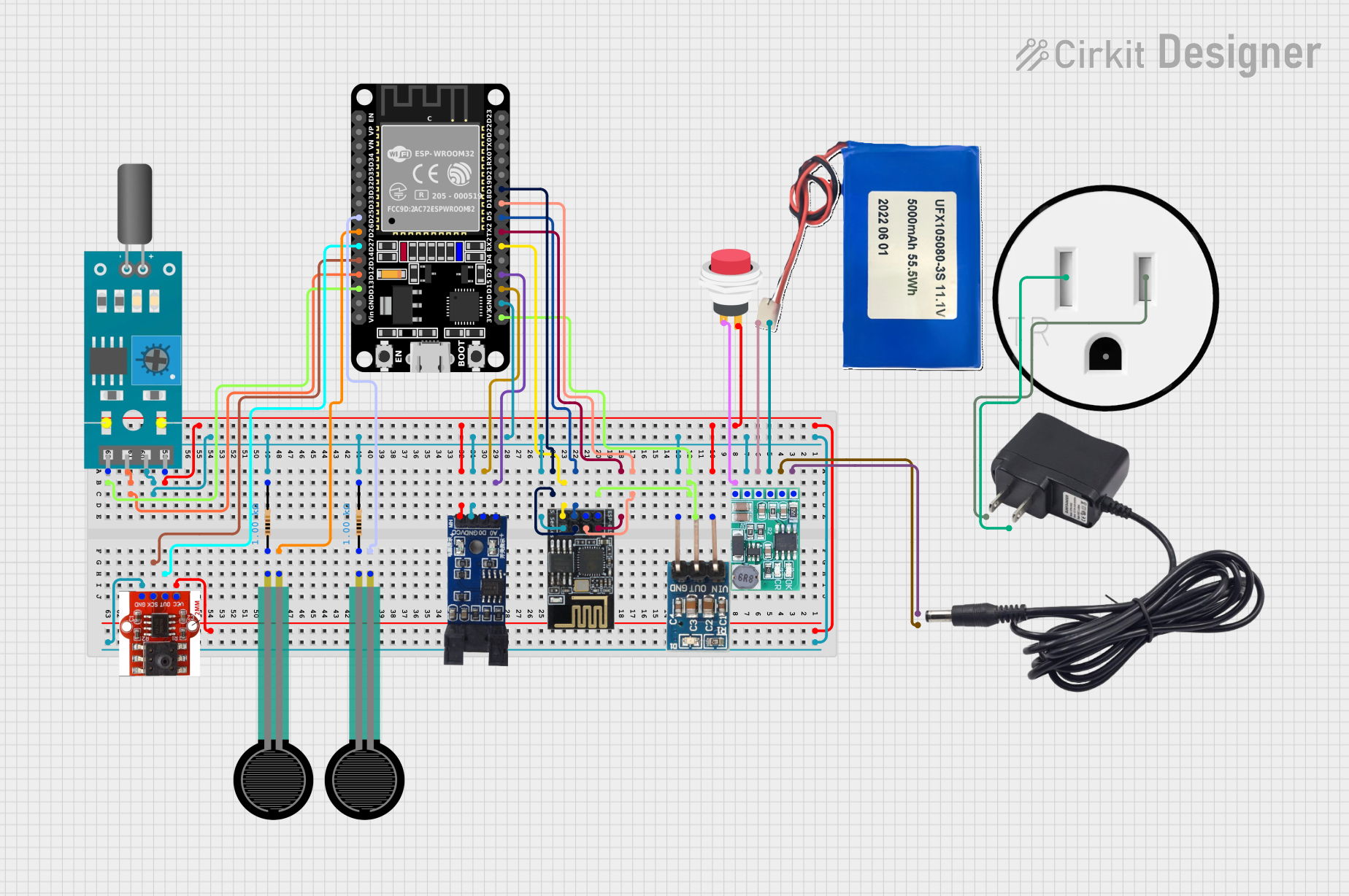

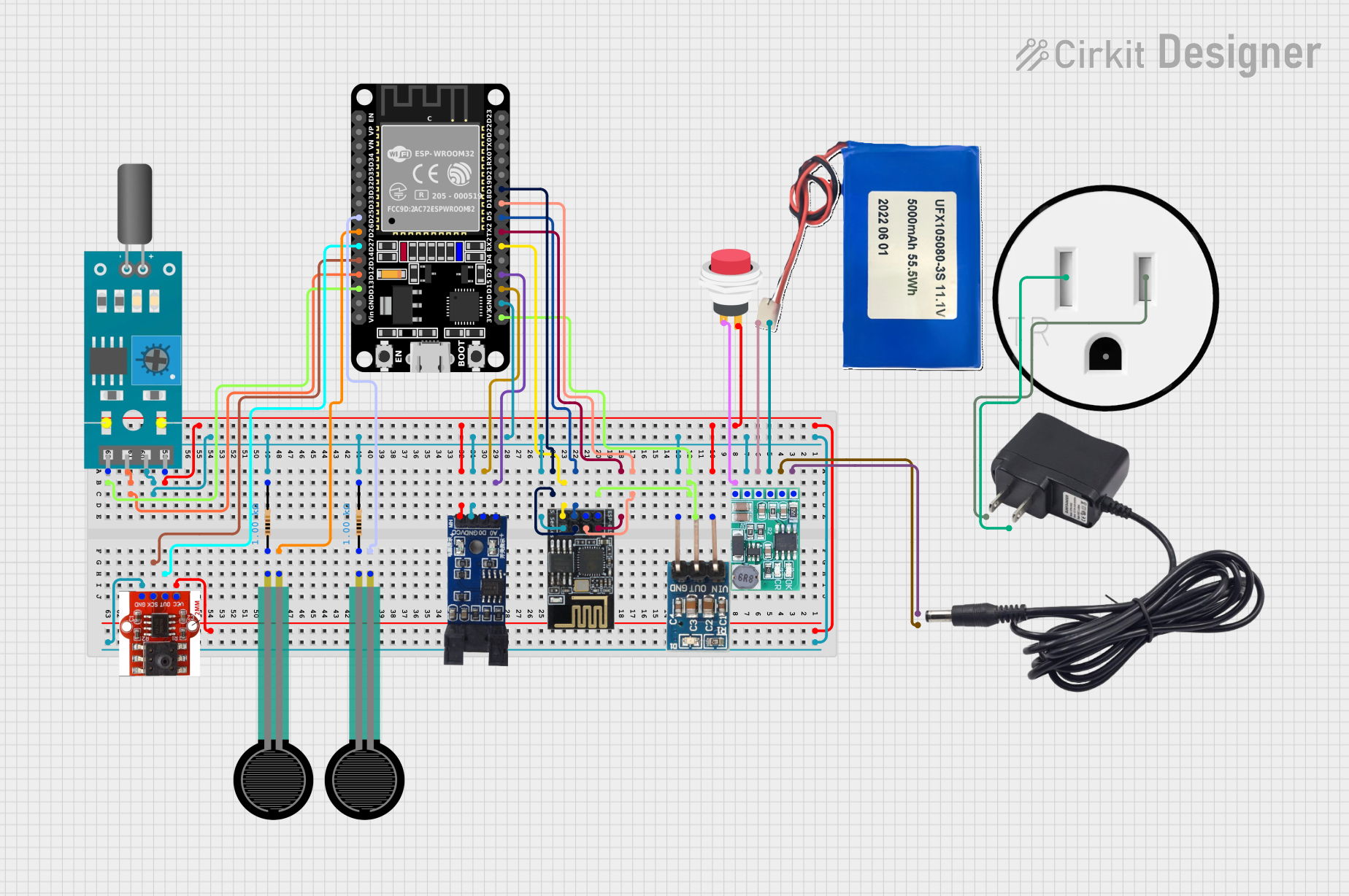

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

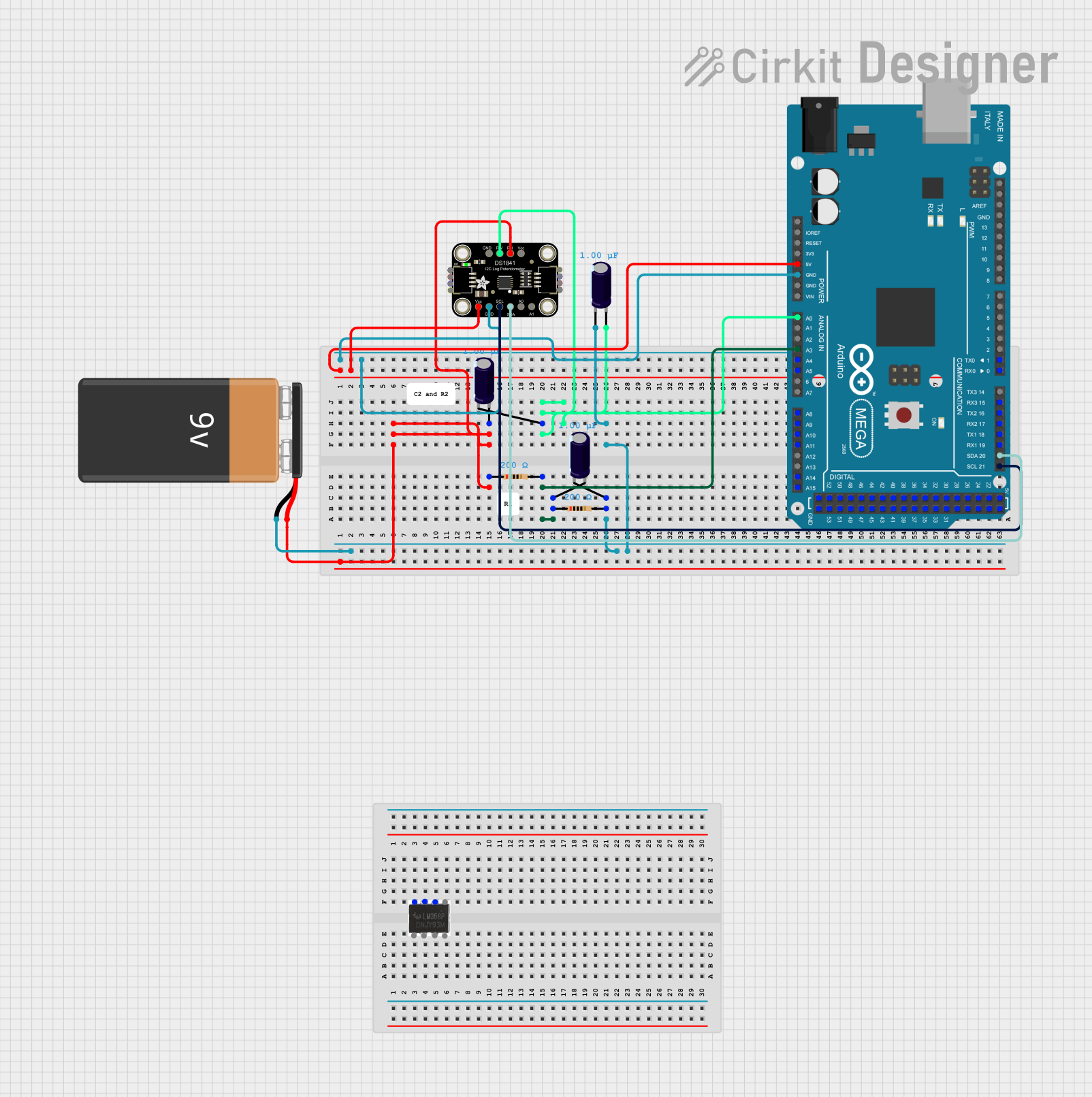

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit DesignerExplore Projects Built with Voltage sensor

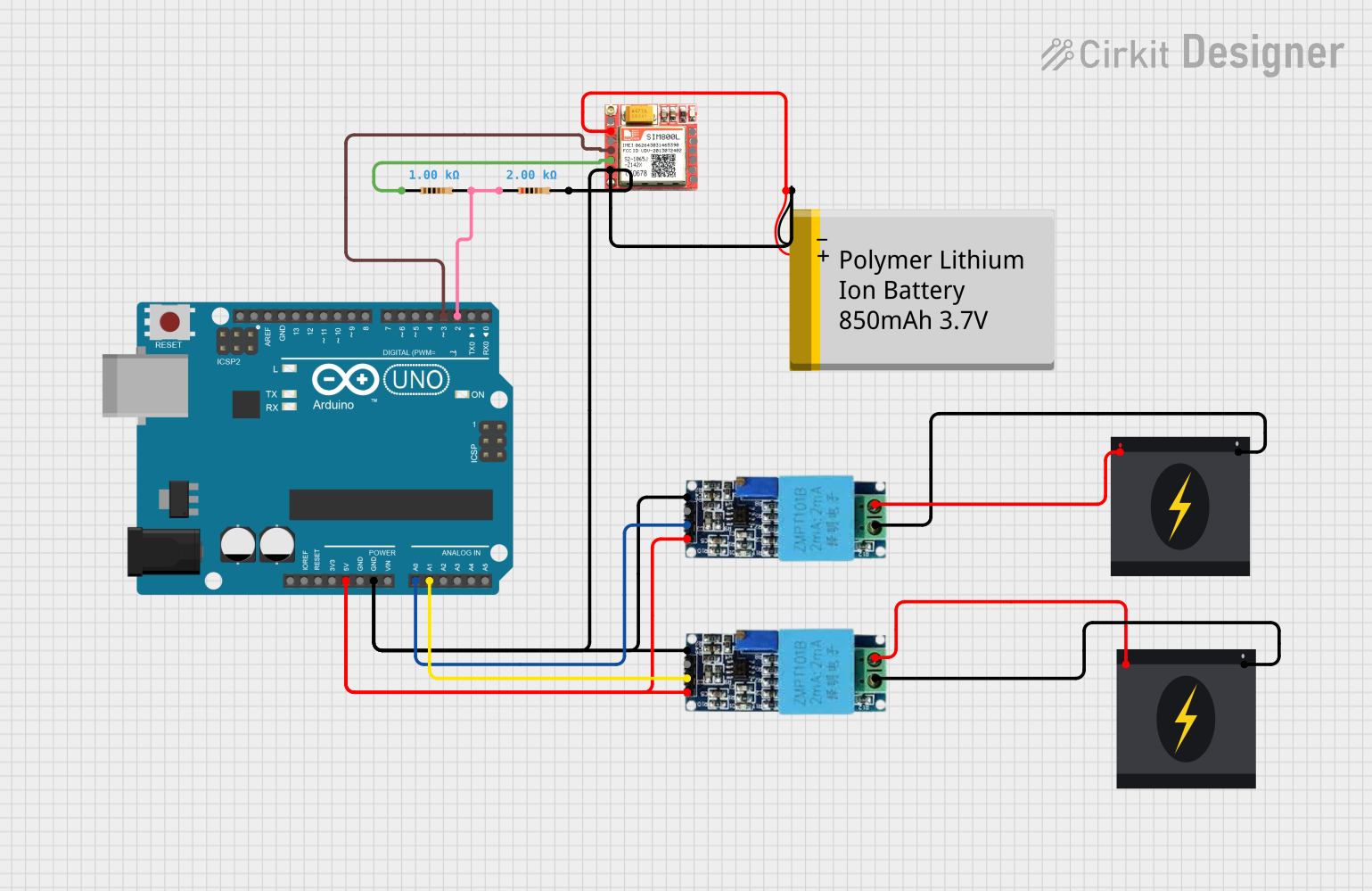

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

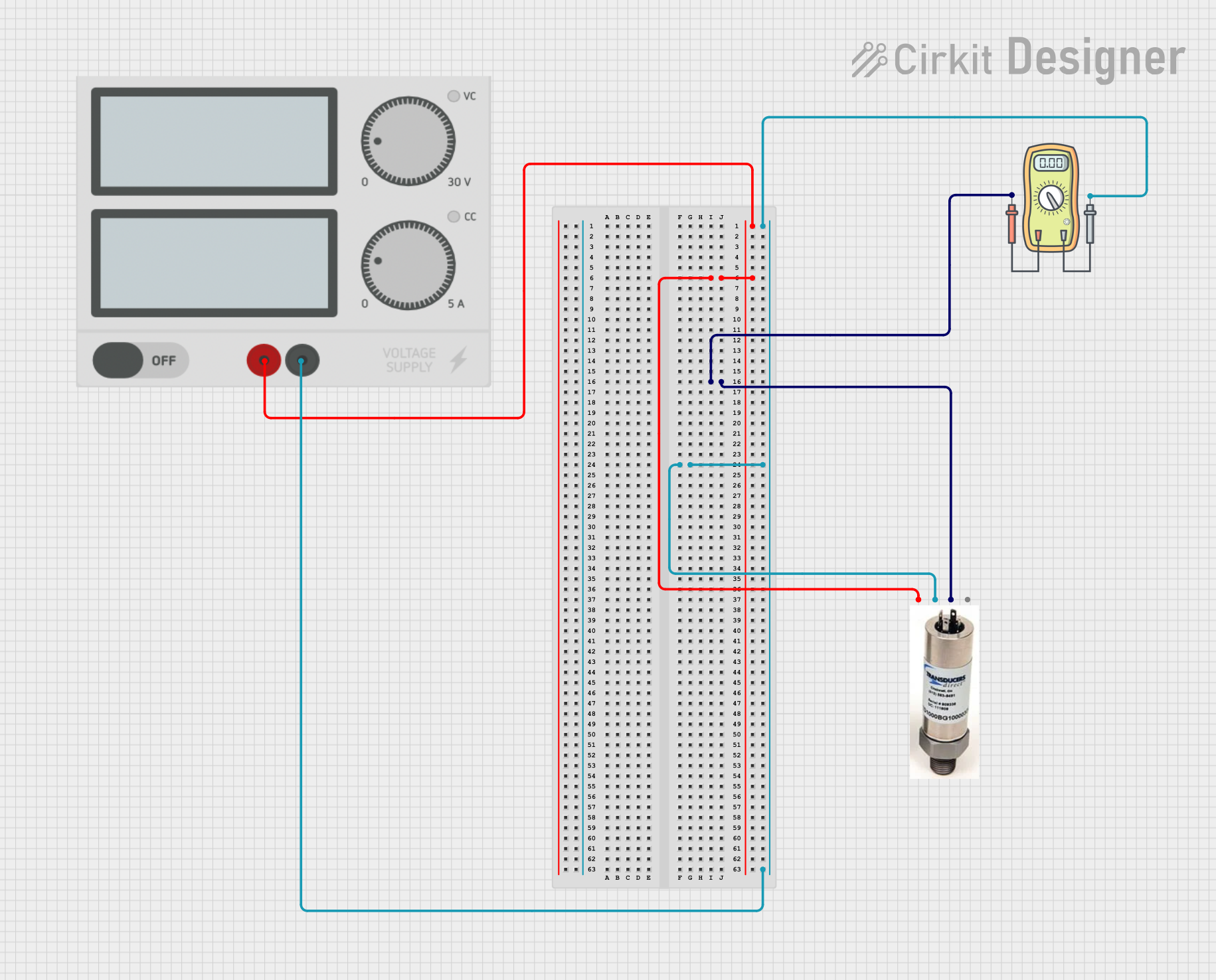

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit DesignerTechnical Specifications

Below are the general technical specifications for a typical voltage sensor module (e.g., a voltage divider-based sensor like the commonly used 0-25V sensor module):

- Input Voltage Range: 0V to 25V DC

- Output Voltage Range: 0V to 5V DC (scaled for microcontroller ADC input)

- Accuracy: ±1% (varies by model)

- Operating Voltage: 3.3V or 5V DC (compatible with most microcontrollers)

- Input Impedance: High (to minimize circuit loading)

- Dimensions: Typically small, e.g., 30mm x 15mm

- Interface: Analog output

Pin Configuration and Descriptions

The following table describes the pinout of a standard voltage sensor module:

| Pin Name | Description |

|---|---|

VCC |

Power supply input (3.3V or 5V DC, depending on the microcontroller used). |

GND |

Ground connection. |

OUT |

Analog voltage output, proportional to the input voltage (scaled down). |

VIN+ |

Positive terminal for the voltage to be measured. |

VIN- |

Negative terminal for the voltage to be measured (usually connected to ground). |

Usage Instructions

How to Use the Voltage Sensor in a Circuit

- Power the Sensor: Connect the

VCCpin to the 5V or 3.3V output of your microcontroller and theGNDpin to the ground. - Connect the Voltage Source: Attach the voltage source to be measured across the

VIN+andVIN-pins. Ensure the input voltage does not exceed the sensor's maximum rating (e.g., 25V). - Read the Output: Connect the

OUTpin to an analog input pin on your microcontroller. The output voltage will be proportional to the input voltage, scaled down by the sensor's internal voltage divider.

Important Considerations and Best Practices

- Scaling Factor: Most voltage sensors use a voltage divider to scale the input voltage. For example, a 0-25V sensor typically has a scaling factor of 5:1. This means the output voltage is 1/5th of the input voltage. Ensure you account for this factor in your calculations.

- Input Voltage Limits: Do not exceed the sensor's maximum input voltage, as this may damage the sensor or connected devices.

- Calibration: For precise measurements, calibrate the sensor by comparing its readings with a known reference voltage.

- Noise Reduction: Use decoupling capacitors or software filtering to reduce noise in the output signal.

Example: Using a Voltage Sensor with Arduino UNO

Below is an example of how to use a voltage sensor with an Arduino UNO to measure a voltage and display the result on the Serial Monitor.

// Define the analog pin connected to the sensor's OUT pin

const int sensorPin = A0;

// Define the scaling factor (e.g., 5:1 for a 0-25V sensor)

const float scalingFactor = 5.0;

// Define the reference voltage of the Arduino (typically 5V)

const float referenceVoltage = 5.0;

void setup() {

// Initialize the Serial Monitor for debugging

Serial.begin(9600);

}

void loop() {

// Read the analog value from the sensor

int sensorValue = analogRead(sensorPin);

// Convert the analog value to a voltage

float voltage = (sensorValue * referenceVoltage / 1023.0) * scalingFactor;

// Print the measured voltage to the Serial Monitor

Serial.print("Measured Voltage: ");

Serial.print(voltage);

Serial.println(" V");

// Wait for a short period before the next reading

delay(1000);

}

Troubleshooting and FAQs

Common Issues and Solutions

No Output or Incorrect Readings:

- Cause: Incorrect wiring or loose connections.

- Solution: Double-check all connections, ensuring the

VCC,GND, andOUTpins are properly connected.

Output Voltage Exceeds Expected Range:

- Cause: Input voltage exceeds the sensor's maximum rating.

- Solution: Verify the input voltage and ensure it is within the sensor's specified range.

Fluctuating or Noisy Readings:

- Cause: Electrical noise or unstable power supply.

- Solution: Add decoupling capacitors near the sensor or use software filtering techniques.

Arduino Displays Incorrect Voltage:

- Cause: Incorrect scaling factor or reference voltage in the code.

- Solution: Verify the scaling factor and reference voltage used in the calculations.

FAQs

Q: Can I use this sensor to measure AC voltage?

A: No, this sensor is designed for DC voltage only. Measuring AC voltage requires additional circuitry, such as a rectifier and filter.

Q: What happens if I reverse the VIN+ and VIN- connections?

A: Reversing the connections may result in incorrect readings or damage to the sensor. Always connect the terminals as specified.

Q: Can I use this sensor with a 3.3V microcontroller?

A: Yes, most voltage sensors are compatible with 3.3V systems. However, ensure the output voltage does not exceed the microcontroller's ADC input range.

Q: How do I improve the accuracy of the sensor?

A: Calibrate the sensor using a known reference voltage and account for any offset or scaling errors in your calculations.