How to Use Trimmer Potentiometer: Examples, Pinouts, and Specs

Design with Trimmer Potentiometer in Cirkit Designer

Design with Trimmer Potentiometer in Cirkit DesignerIntroduction

A trimmer potentiometer, commonly referred to as a "trimpot," is a small, adjustable resistor used to fine-tune or calibrate voltage levels in electronic circuits. It is typically adjusted using a screwdriver and is designed for infrequent adjustments. Trimmer potentiometers are widely used in applications such as setting reference voltages, adjusting gain in amplifiers, and calibrating sensors.

Explore Projects Built with Trimmer Potentiometer

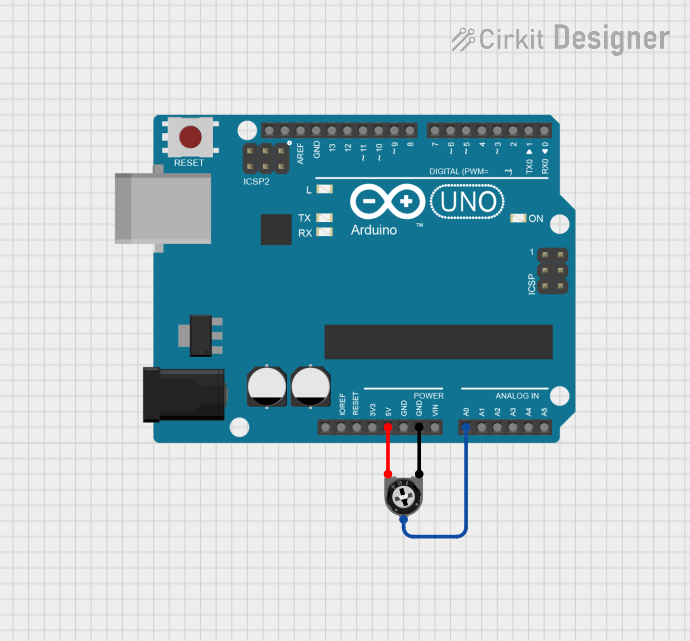

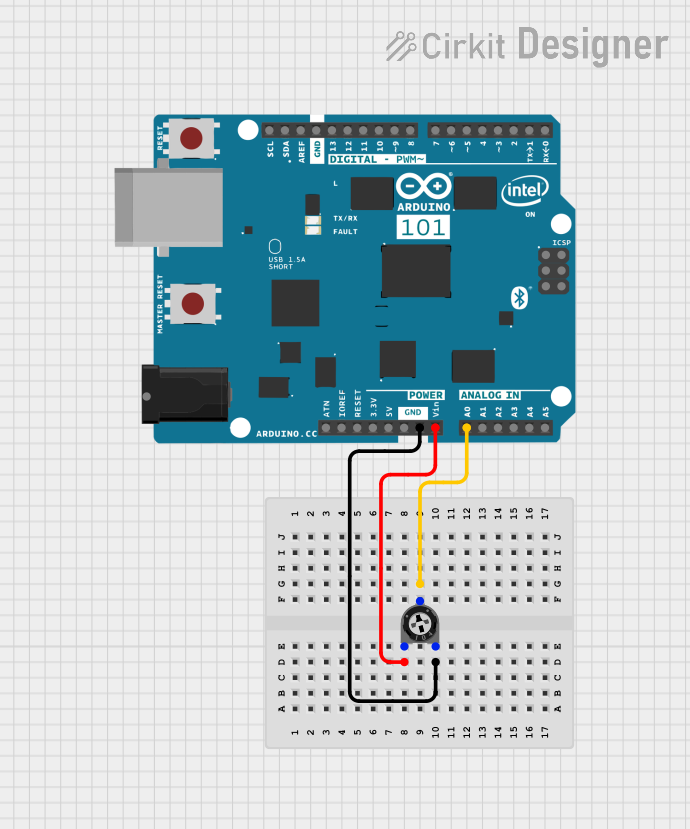

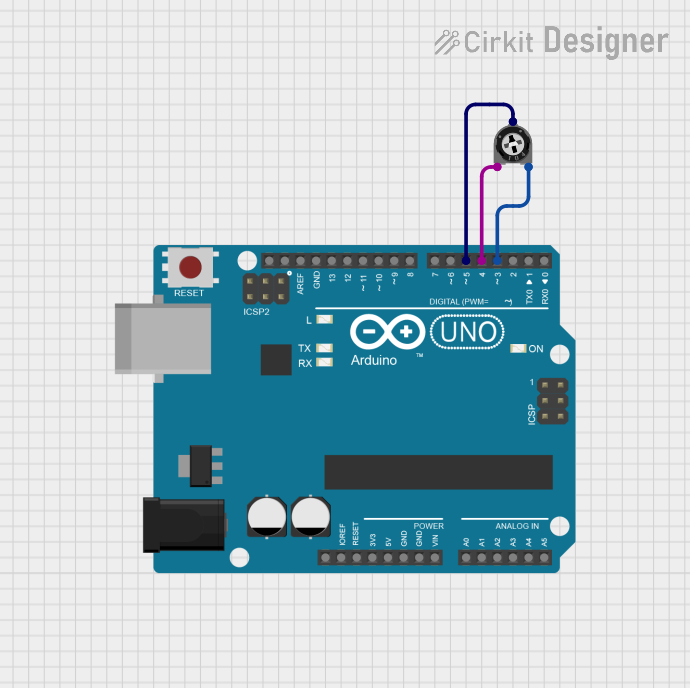

Open Project in Cirkit Designer

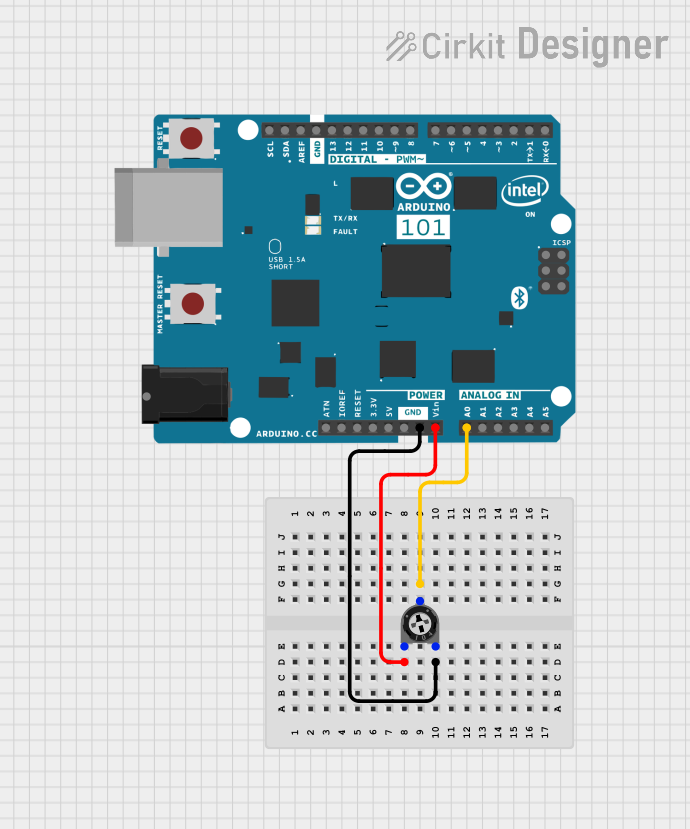

Open Project in Cirkit Designer

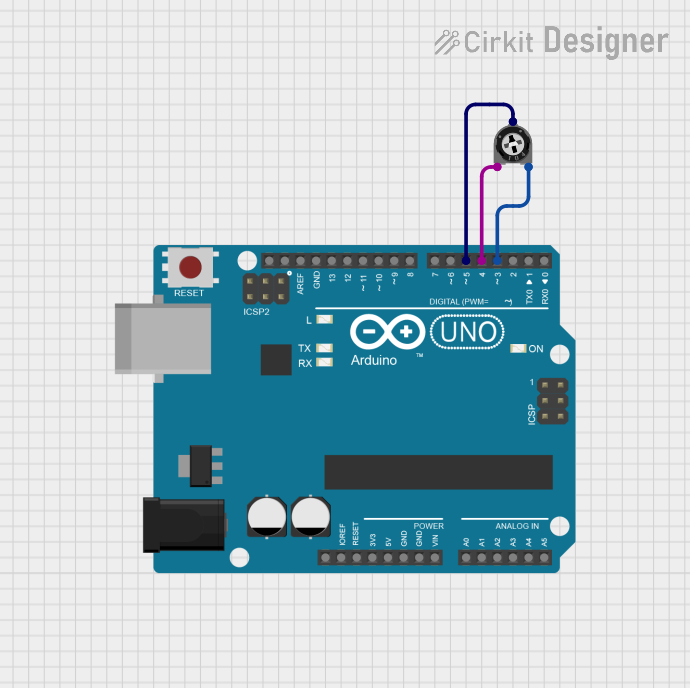

Open Project in Cirkit Designer

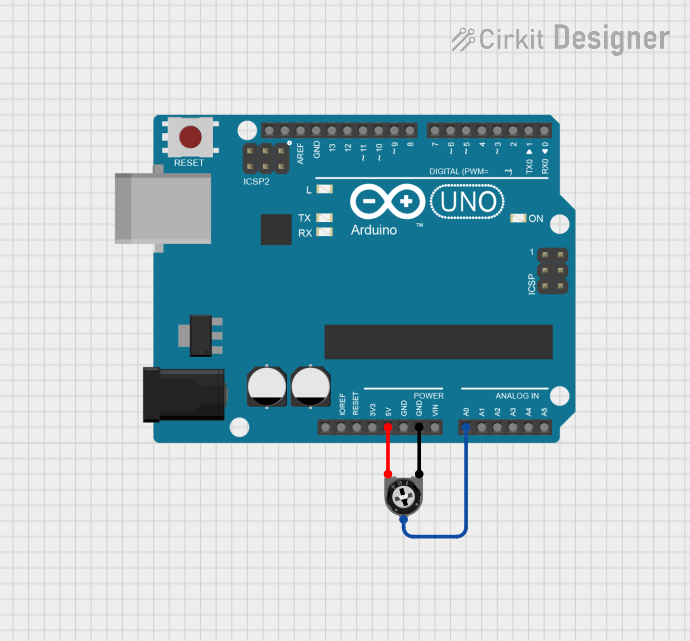

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit DesignerExplore Projects Built with Trimmer Potentiometer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit DesignerCommon Applications:

- Calibration of analog circuits

- Adjusting reference voltages in power supplies

- Fine-tuning sensor outputs

- Setting gain in operational amplifier circuits

- Balancing bridge circuits

Technical Specifications

Below are the general technical specifications for a typical trimmer potentiometer. Note that specific values may vary depending on the model and manufacturer.

| Parameter | Specification |

|---|---|

| Resistance Range | 100 Ω to 1 MΩ (varies by model) |

| Tolerance | ±10% to ±20% |

| Power Rating | 0.1 W to 0.5 W |

| Adjustment Type | Single-turn or multi-turn |

| Operating Voltage | Up to 50 V (varies by model) |

| Operating Temperature | -55°C to +125°C |

| Mounting Type | Through-hole or surface-mount |

Pin Configuration and Descriptions

Trimmer potentiometers typically have three pins:

| Pin | Description |

|---|---|

| Pin 1 | One end of the resistive track |

| Pin 2 | Wiper (adjustable output, connected to the slider) |

| Pin 3 | The other end of the resistive track |

The resistance between Pin 1 and Pin 3 is fixed, while the resistance between Pin 1 and Pin 2 (or Pin 2 and Pin 3) changes as the wiper is adjusted.

Usage Instructions

How to Use a Trimmer Potentiometer in a Circuit

- Identify the Pins: Use a multimeter to determine the fixed resistance between Pin 1 and Pin 3. Pin 2 is the wiper.

- Connect the Component:

- Connect Pin 1 and Pin 3 across the voltage source or circuit where the resistance is needed.

- Use Pin 2 as the adjustable output to fine-tune the voltage or current.

- Adjust the Resistance:

- Use a small screwdriver to turn the adjustment screw on the trimmer.

- Turning clockwise typically decreases the resistance between Pin 1 and Pin 2, while increasing the resistance between Pin 2 and Pin 3 (and vice versa).

Important Considerations and Best Practices

- Power Rating: Ensure the trimmer potentiometer's power rating is not exceeded to avoid damage.

- Adjustment Frequency: Trimmer potentiometers are not designed for frequent adjustments. Use a standard potentiometer for applications requiring regular tuning.

- Mounting: Secure the trimmer properly on the PCB to prevent mechanical stress during adjustment.

- Debris: Avoid over-tightening the adjustment screw, as this can damage the resistive track or introduce debris.

Example: Using a Trimmer Potentiometer with Arduino UNO

Below is an example of how to use a trimmer potentiometer to adjust an analog input on an Arduino UNO.

Circuit Setup:

- Connect Pin 1 to 5V on the Arduino.

- Connect Pin 3 to GND on the Arduino.

- Connect Pin 2 (wiper) to an analog input pin (e.g., A0).

Code Example:

// Arduino code to read the value of a trimmer potentiometer

// connected to analog pin A0 and display it in the Serial Monitor.

void setup() {

Serial.begin(9600); // Initialize serial communication at 9600 baud

}

void loop() {

int potValue = analogRead(A0); // Read the analog value from the potentiometer

float voltage = potValue * (5.0 / 1023.0); // Convert to voltage (0-5V range)

// Print the raw value and voltage to the Serial Monitor

Serial.print("Raw Value: ");

Serial.print(potValue);

Serial.print(" | Voltage: ");

Serial.print(voltage);

Serial.println(" V");

delay(500); // Wait for 500ms before the next reading

}

Troubleshooting and FAQs

Common Issues and Solutions

No Output or Incorrect Adjustment:

- Cause: Incorrect pin connections.

- Solution: Verify the pin configuration using a multimeter and ensure proper connections.

Trimmer Potentiometer Not Responding to Adjustments:

- Cause: Damaged resistive track or adjustment screw.

- Solution: Replace the trimmer potentiometer if it is physically damaged.

Fluctuating Output:

- Cause: Loose connections or poor soldering.

- Solution: Check and secure all connections. Re-solder if necessary.

Overheating:

- Cause: Exceeding the power rating.

- Solution: Ensure the power dissipation is within the specified limits.

FAQs

Q: Can I use a trimmer potentiometer for frequent adjustments?

A: No, trimmer potentiometers are designed for infrequent adjustments. Use a standard potentiometer for applications requiring regular tuning.

Q: How do I choose the correct resistance value for my application?

A: Determine the required resistance range for your circuit and select a trimmer potentiometer with a value that covers this range.

Q: Can I use a trimmer potentiometer in high-power circuits?

A: Trimmer potentiometers are typically low-power components. For high-power applications, use a suitable resistor or potentiometer with a higher power rating.

Q: What is the difference between single-turn and multi-turn trimmer potentiometers?

A: Single-turn trimmers adjust resistance with one full rotation, while multi-turn trimmers allow finer adjustments over multiple rotations. Choose based on the precision required.