How to Use XL6009 Auto Step Up Down COnverter: Examples, Pinouts, and Specs

Design with XL6009 Auto Step Up Down COnverter in Cirkit Designer

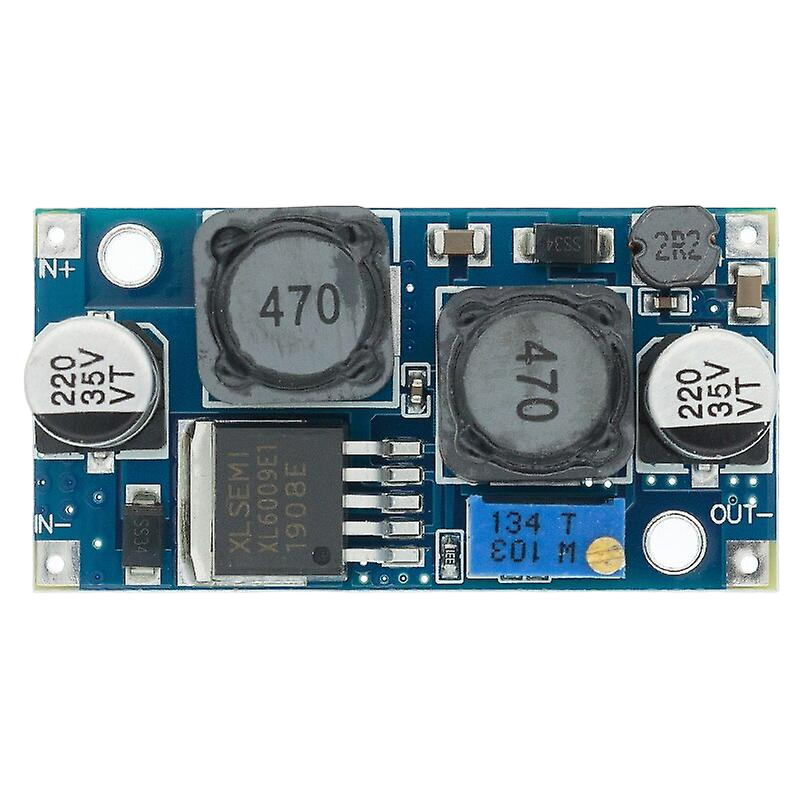

Design with XL6009 Auto Step Up Down COnverter in Cirkit DesignerXL6009 Auto Step Up Down Converter Documentation

1. Introduction

The XL6009 Auto Step Up Down Converter, manufactured by Voltage, is a versatile DC-DC converter designed to either step up or step down the input voltage to a stable output voltage. This component is widely used in power supply circuits where a consistent voltage is required despite variations in the input voltage. Its ability to handle a broad range of input voltages makes it ideal for applications such as battery-powered devices, solar power systems, and automotive electronics.

2. Technical Specifications

Key Technical Details

| Parameter | Value |

|---|---|

| Input Voltage | 3V to 32V |

| Output Voltage | 1.25V to 35V |

| Output Current | 2A (max) |

| Efficiency | Up to 94% |

| Switching Frequency | 400kHz |

| Operating Temperature | -40°C to +85°C |

| Dimensions | 43mm x 21mm x 14mm |

Pin Configuration and Descriptions

| Pin Number | Pin Name | Description |

|---|---|---|

| 1 | VIN | Input Voltage (3V to 32V) |

| 2 | GND | Ground |

| 3 | VOUT | Output Voltage (1.25V to 35V) |

| 4 | EN | Enable Pin (Active High) |

| 5 | FB | Feedback Pin (for setting output voltage) |

3. Usage Instructions

How to Use the XL6009 in a Circuit

Connect the Input Voltage:

- Connect the positive terminal of your input power source to the VIN pin.

- Connect the negative terminal of your input power source to the GND pin.

Set the Output Voltage:

- Use a potentiometer connected to the FB pin to adjust the output voltage.

- Measure the output voltage at the VOUT pin and adjust the potentiometer until the desired voltage is achieved.

Enable the Converter:

- Connect the EN pin to a high logic level (typically the same voltage as VIN) to enable the converter.

- To disable the converter, connect the EN pin to a low logic level (GND).

Important Considerations and Best Practices

- Heat Dissipation: Ensure adequate heat dissipation, especially when operating at high currents. Use a heat sink if necessary.

- Input Voltage Range: Always ensure the input voltage is within the specified range (3V to 32V) to avoid damaging the converter.

- Output Voltage Adjustment: Use a precise multimeter to measure the output voltage when adjusting the potentiometer.

- Capacitors: Use appropriate input and output capacitors to stabilize the voltage and reduce noise.

Example Circuit with Arduino UNO

Here is an example of how to connect the XL6009 to an Arduino UNO to power it with a stable 5V output:

/*

* Example code to demonstrate the use of XL6009 with Arduino UNO.

* This code does not interact with the XL6009 directly but shows

* how to power the Arduino using the converter.

*/

void setup() {

// Initialize serial communication for debugging

Serial.begin(9600);

Serial.println("Arduino powered by XL6009 Converter");

}

void loop() {

// Your main code here

}

4. Troubleshooting and FAQs

Common Issues and Solutions

No Output Voltage:

- Solution: Check the input voltage to ensure it is within the specified range. Verify all connections, especially the VIN and GND pins.

Output Voltage Fluctuations:

- Solution: Ensure that the input voltage is stable. Add input and output capacitors to filter out noise and stabilize the voltage.

Overheating:

- Solution: Ensure proper ventilation and consider adding a heat sink to the converter. Check if the current draw is within the specified limit (2A max).

FAQs

Q1: Can the XL6009 be used to power a Raspberry Pi?

- A1: Yes, the XL6009 can be used to power a Raspberry Pi. Ensure the output voltage is set to 5V and the current rating is sufficient for the Raspberry Pi model you are using.

Q2: How do I adjust the output voltage?

- A2: Use a potentiometer connected to the FB pin to adjust the output voltage. Measure the output voltage with a multimeter and adjust the potentiometer until the desired voltage is achieved.

Q3: What is the efficiency of the XL6009?

- A3: The efficiency of the XL6009 can be up to 94%, depending on the input and output voltage conditions.

By following this documentation, users can effectively utilize the XL6009 Auto Step Up Down Converter in their projects, ensuring stable and reliable power supply solutions.

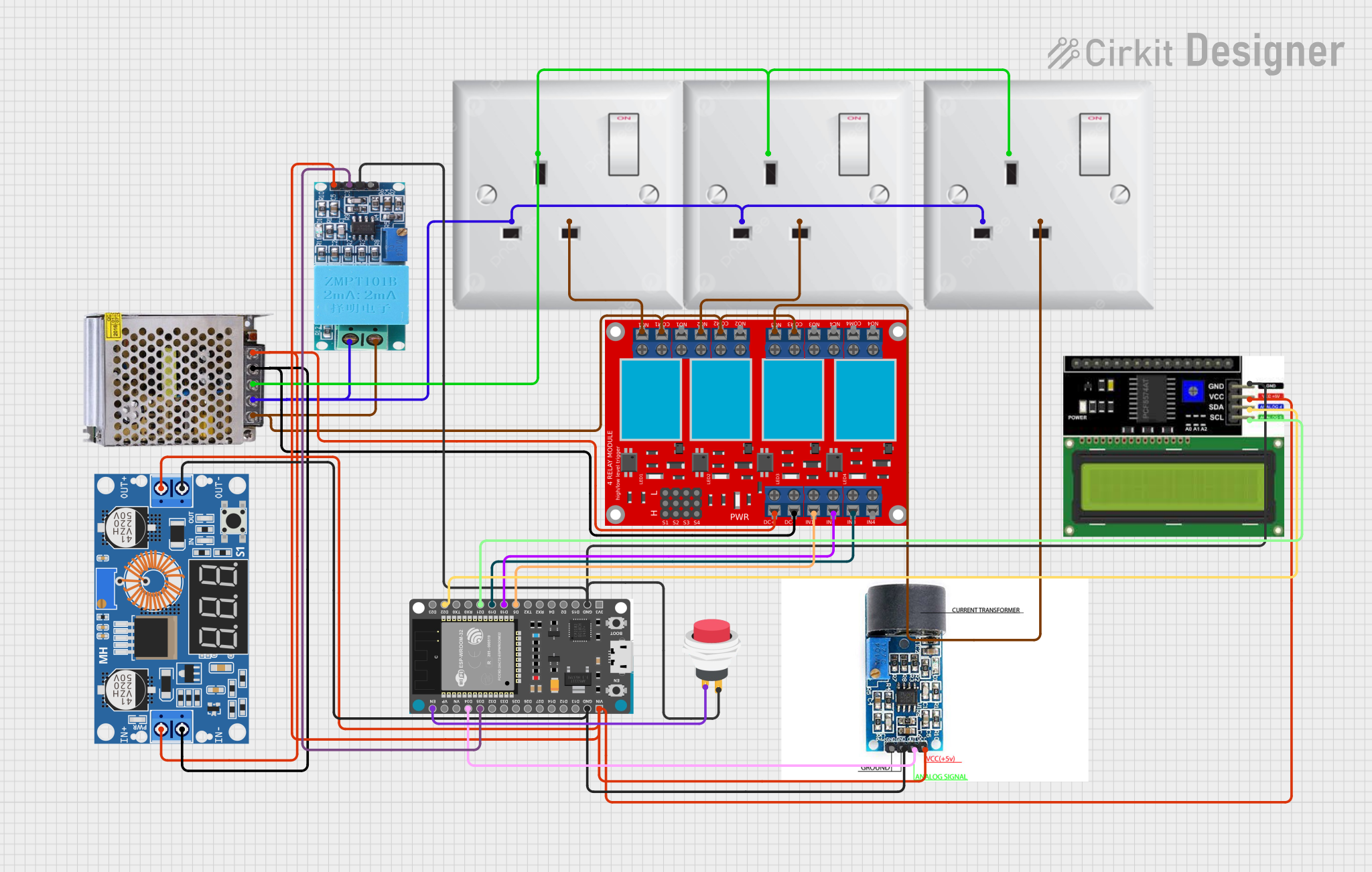

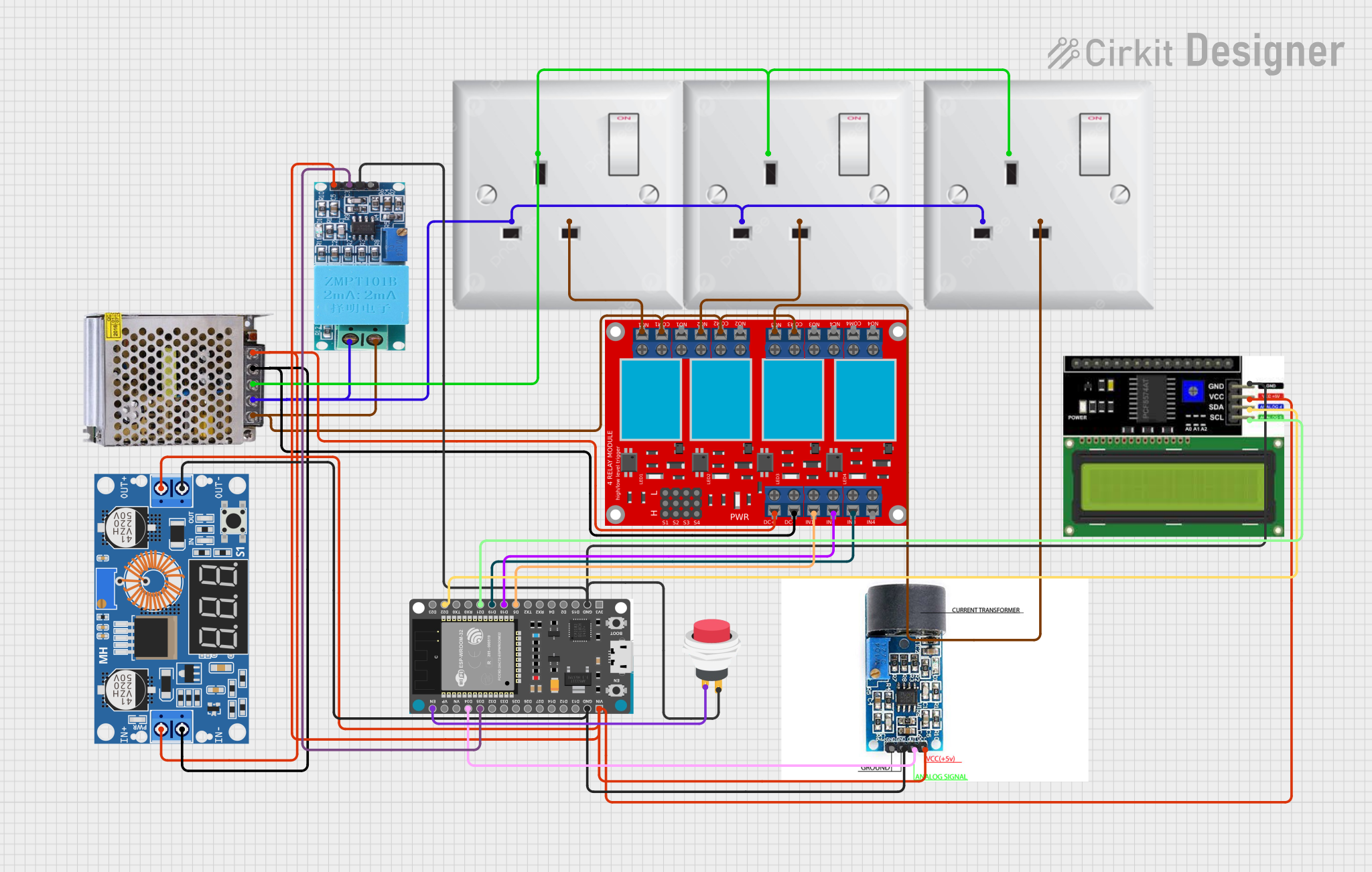

Explore Projects Built with XL6009 Auto Step Up Down COnverter

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit DesignerExplore Projects Built with XL6009 Auto Step Up Down COnverter

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer