How to Use Emergency STOP: Examples, Pinouts, and Specs

Design with Emergency STOP in Cirkit Designer

Design with Emergency STOP in Cirkit DesignerIntroduction

An Emergency Stop (E-STOP) button is a critical safety device designed to halt the operation of machinery and processes in the event of an emergency. It is a fail-safe control mechanism that can be activated with a simple push, providing an immediate response to potential hazards. E-STOP buttons are commonly found in industrial settings, on control panels, and within electronic systems where human safety or equipment protection is paramount.

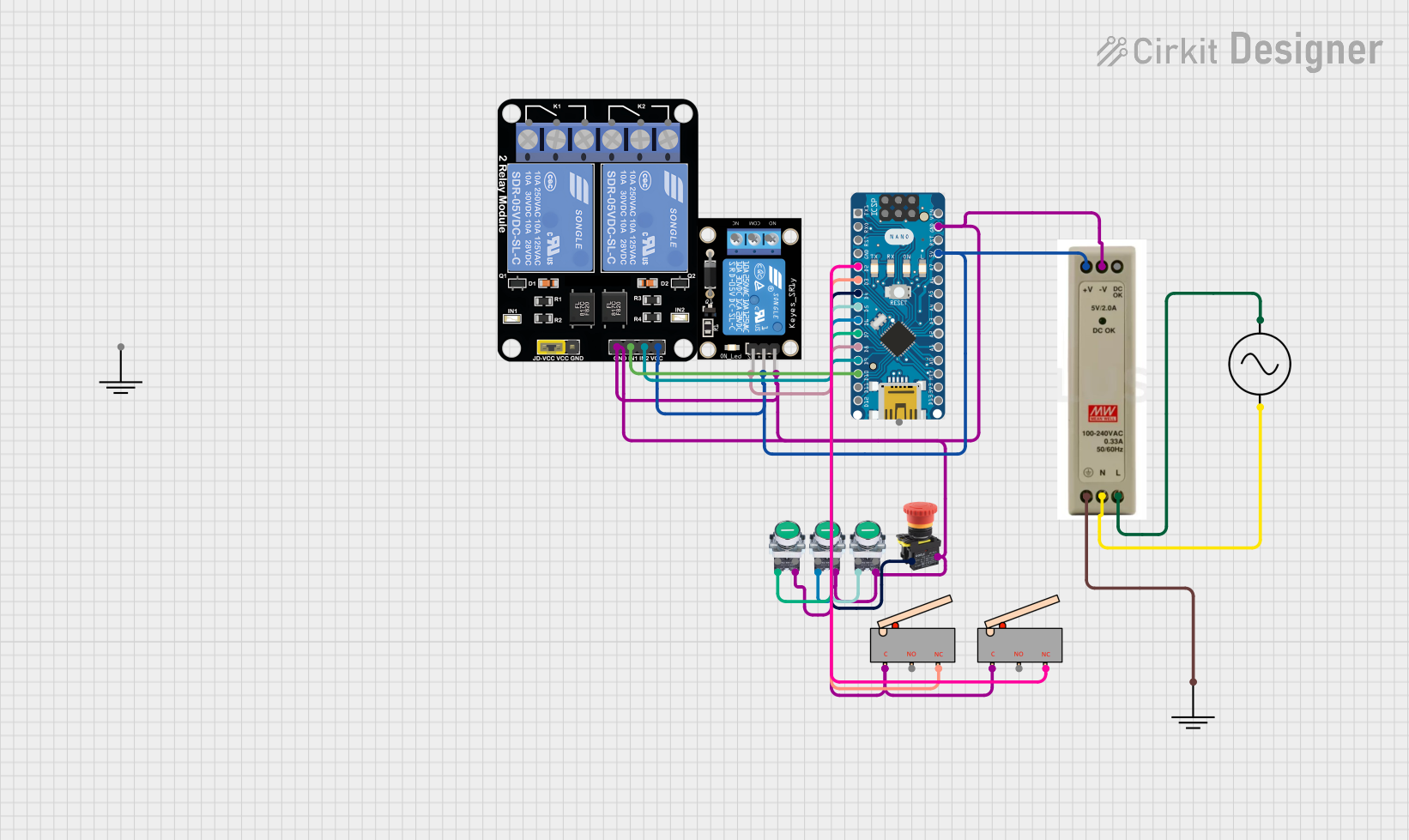

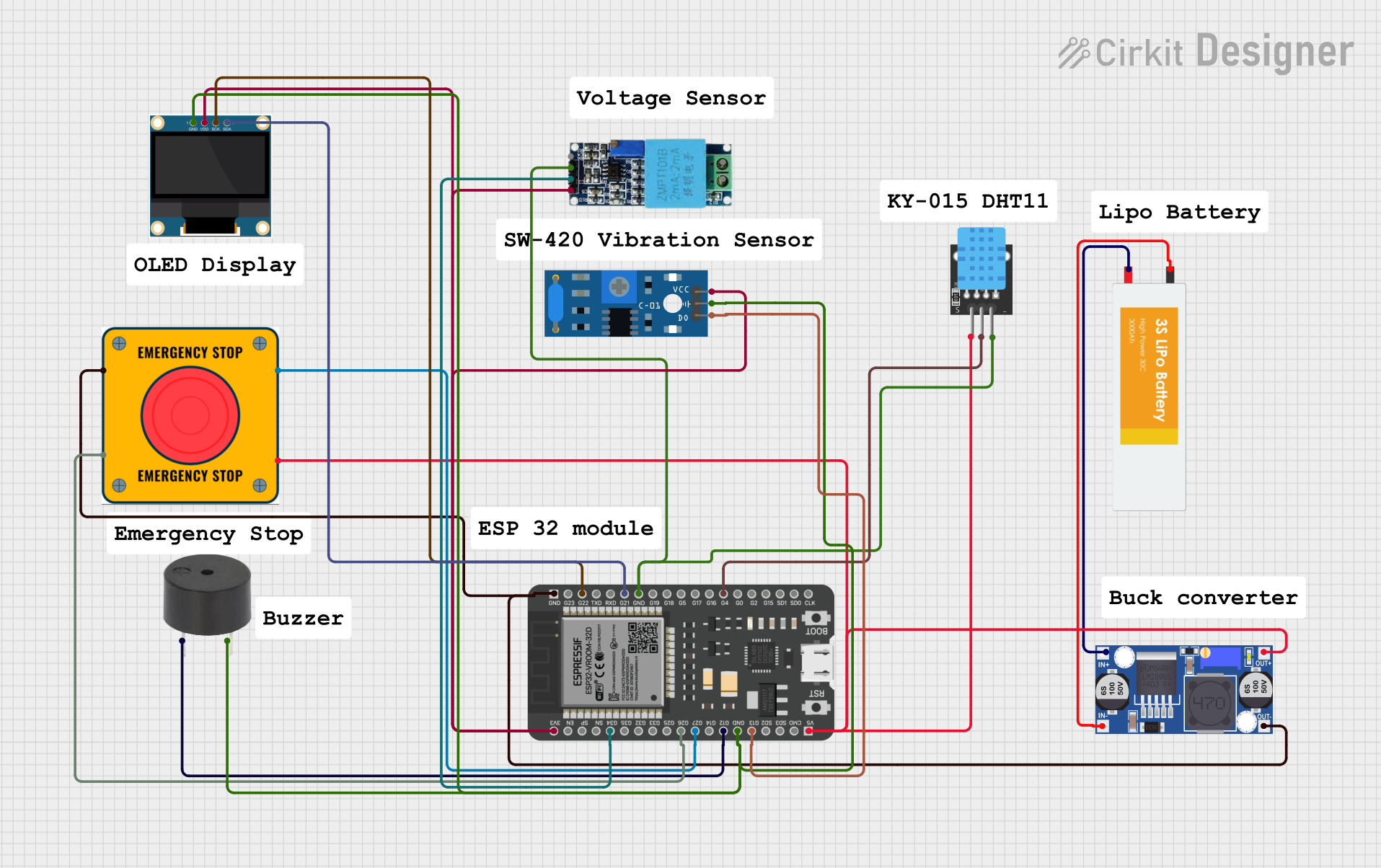

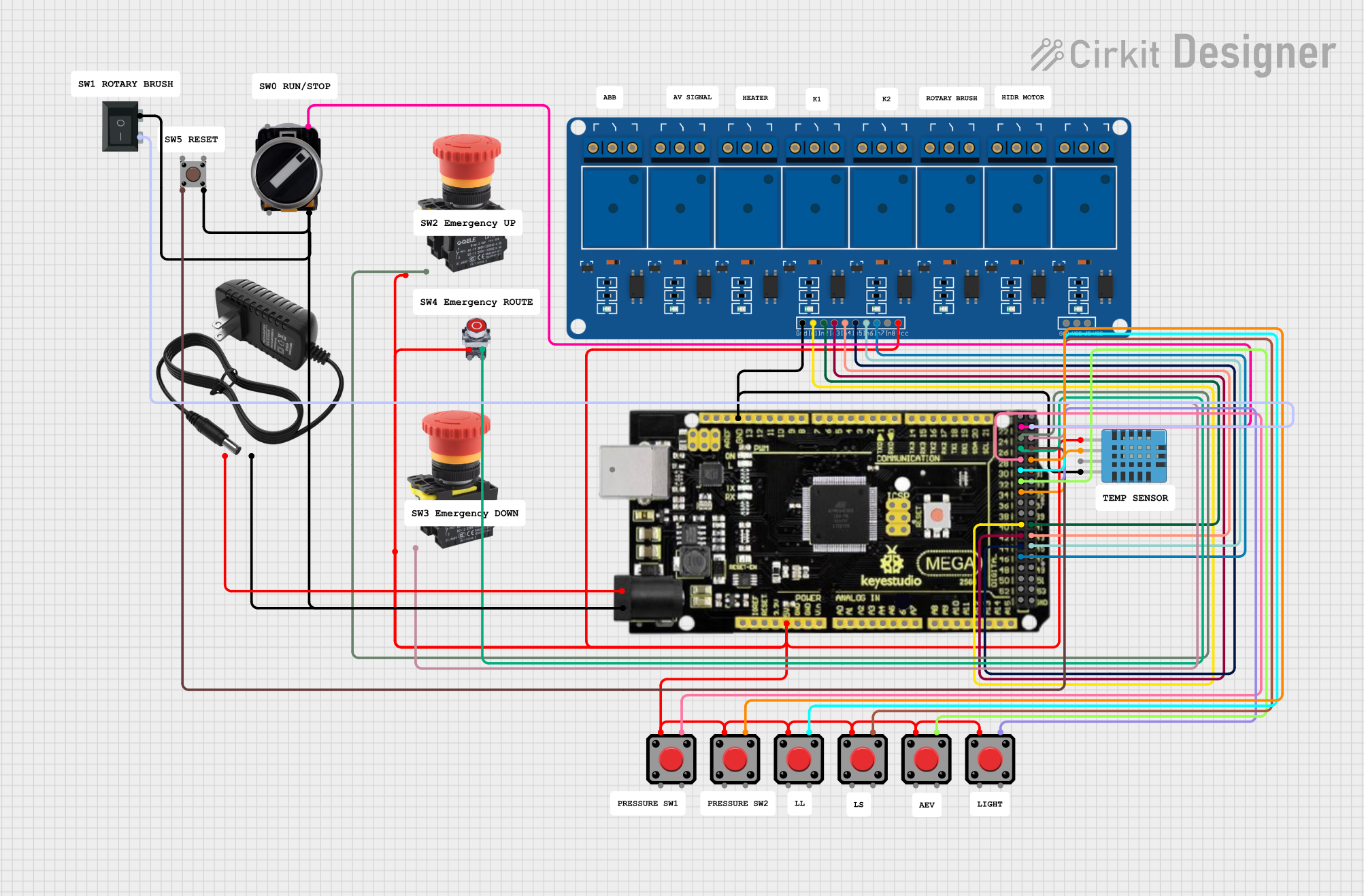

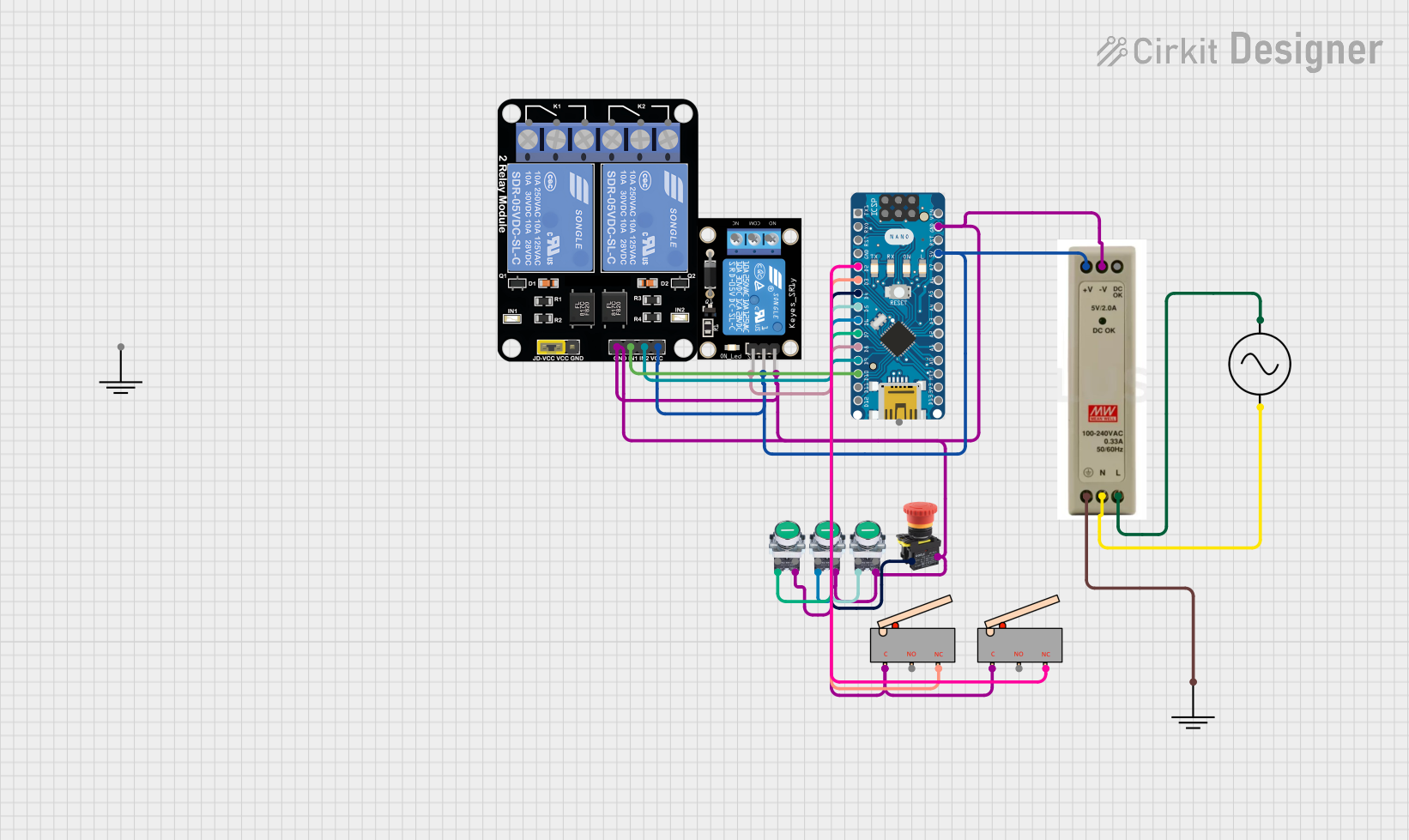

Explore Projects Built with Emergency STOP

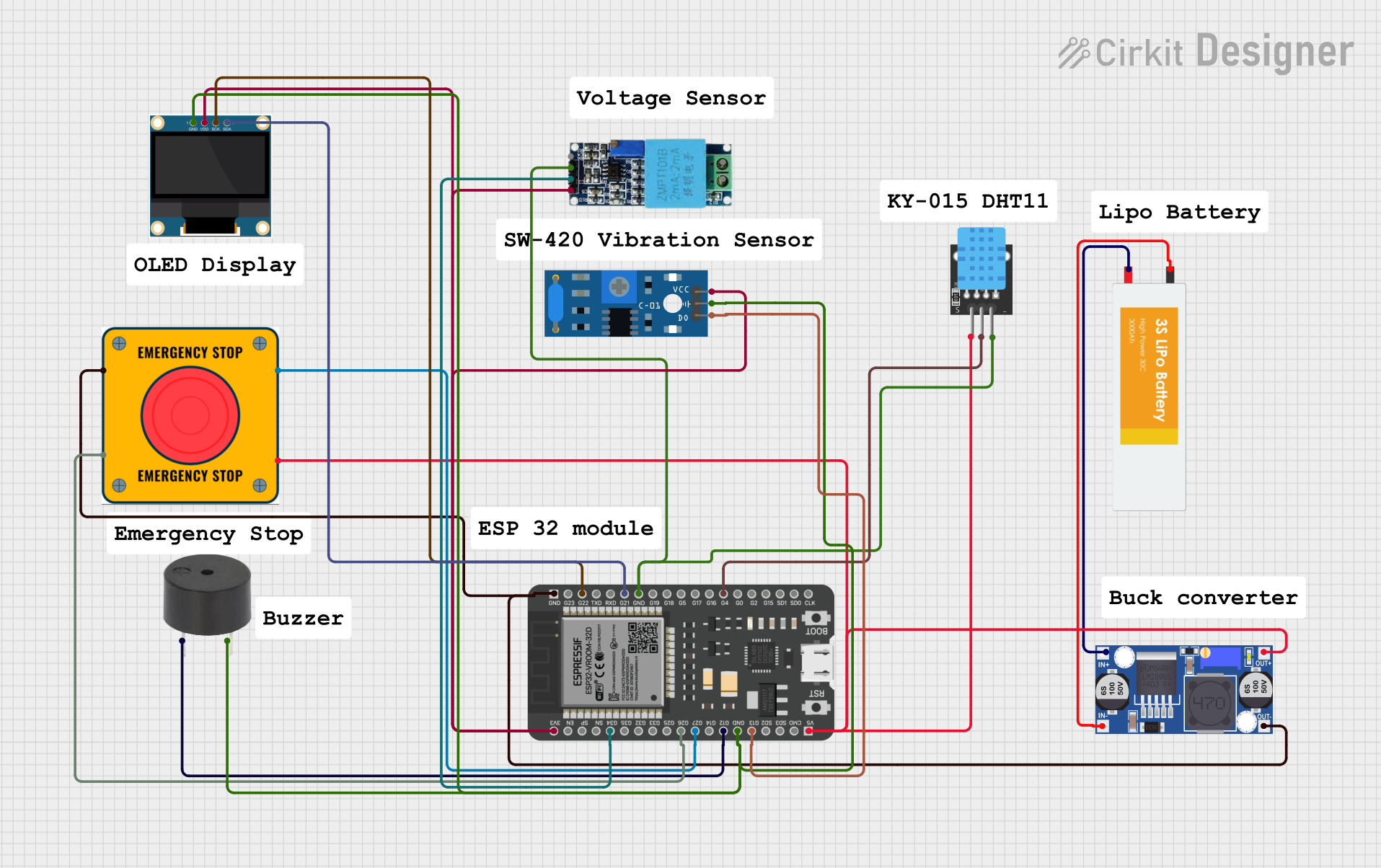

Open Project in Cirkit Designer

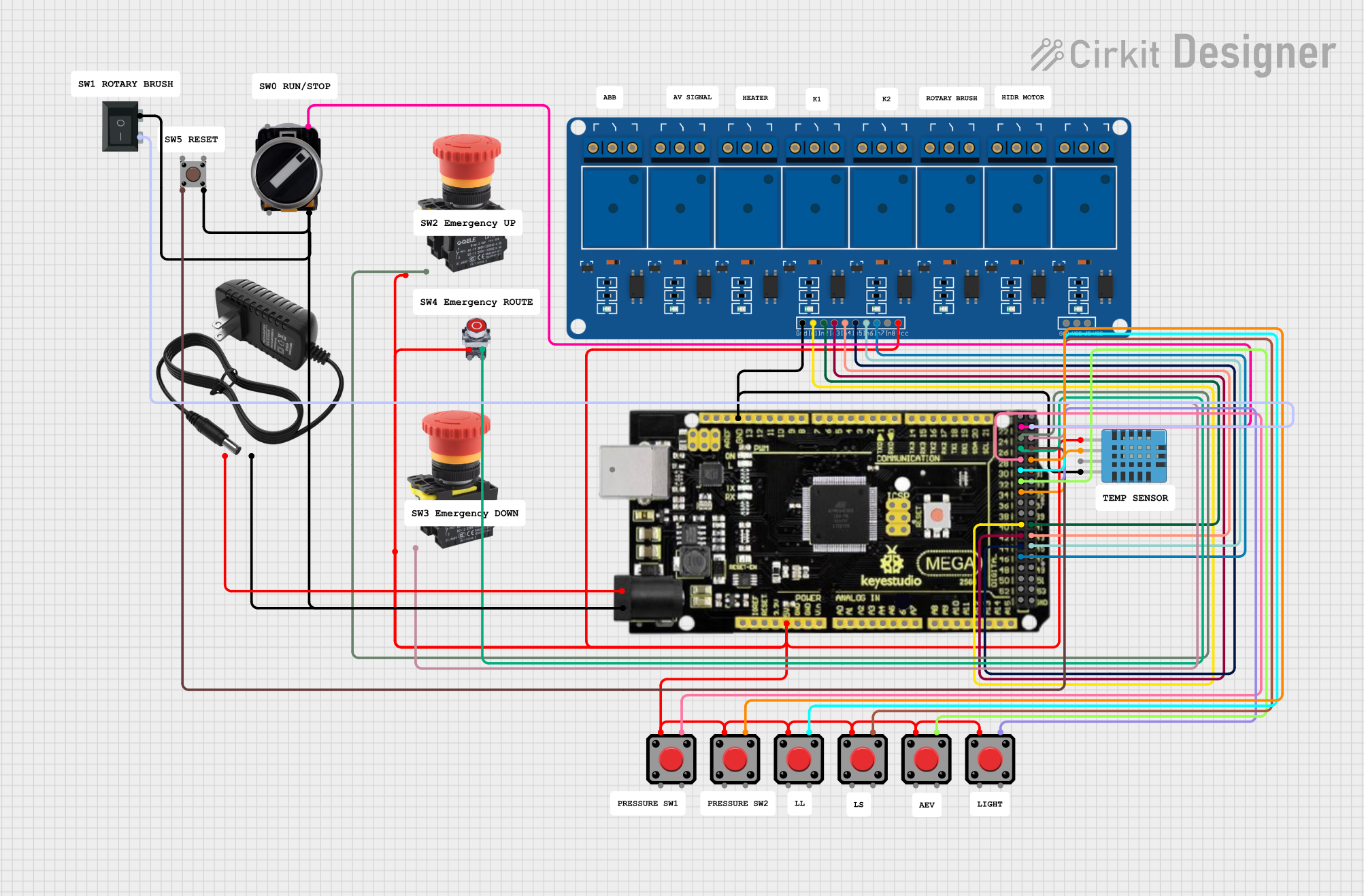

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit DesignerExplore Projects Built with Emergency STOP

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit DesignerCommon Applications and Use Cases

- Industrial machinery

- Robotic systems

- Conveyor belts

- Automated production lines

- CNC machines

- Laboratory equipment

Technical Specifications

Key Technical Details

- Voltage Rating: Typically 24V to 240V AC/DC

- Current Rating: Up to 10A (varies by model)

- Contact Configuration: Normally closed (NC), opens upon activation

- Durability: Rated for a high number of cycles (mechanical and electrical)

Pin Configuration and Descriptions

| Pin Number | Description | Notes |

|---|---|---|

| 1 | Common (COM) | Connect to power supply |

| 2 | Normally Closed (NC) | Connect to the control circuit |

| 3 | Normally Open (NO) | Unused in most E-STOP circuits |

Usage Instructions

How to Use the Component in a Circuit

Wiring the E-STOP Button:

- Connect the COM pin to the positive terminal of the power supply.

- Connect the NC pin to the control circuit that needs to be interrupted during an emergency.

Mounting the E-STOP Button:

- Place the E-STOP button in an accessible location.

- Ensure it is clearly marked and unobstructed.

Testing the E-STOP Button:

- Perform regular tests to ensure functionality.

- Check for mechanical freedom and reliable contact break.

Important Considerations and Best Practices

- Visibility: The E-STOP button should be highly visible and marked with a red color.

- Accessibility: It must be easily accessible and within reach of the operator at all times.

- Wiring: Use appropriate gauge wire to handle the expected current.

- Compliance: Ensure the E-STOP button meets relevant safety standards and regulations.

Troubleshooting and FAQs

Common Issues Users Might Face

E-STOP Button Does Not Respond:

- Check the wiring connections for any loose or broken wires.

- Verify the power supply is functioning and delivering the correct voltage.

- Inspect the button for any physical damage or obstructions.

False Triggering:

- Ensure there is no vibration or mechanical stress causing accidental activation.

- Check for any electrical interference that may cause unintended operation.

Solutions and Tips for Troubleshooting

- Regularly inspect and maintain the E-STOP button for reliable performance.

- If the button is unresponsive, consider replacing it as it is a critical safety component.

- For false triggering, isolate the button from sources of interference or mechanical stress.

FAQs

Q: Can I use the NO pin for an E-STOP function? A: No, the E-STOP function should always use the NC contact to ensure the circuit is broken in an emergency.

Q: How often should I test the E-STOP button? A: It is recommended to test the E-STOP button before each use of the machinery or at least once a month.

Q: What should I do if the E-STOP button is accidentally activated? A: Reset the system according to the manufacturer's instructions, ensuring that it is safe to resume operation.

Example Code for Arduino UNO

// Define the E-STOP button pin

const int estopPin = 2;

void setup() {

// Set the E-STOP pin as an input with an internal pull-up resistor

pinMode(estopPin, INPUT_PULLUP);

// Initialize serial communication for debugging

Serial.begin(9600);

}

void loop() {

// Check the E-STOP button state

int estopState = digitalRead(estopPin);

// If the button is pressed (circuit is open), halt the system

if (estopState == HIGH) {

// Implement emergency stop procedures

Serial.println("EMERGENCY STOP ACTIVATED");

// Add code here to safely shut down any connected systems

// ...

}

// Otherwise, continue normal operation

else {

// Normal operation code

// ...

}

}

Note: In this example, the Arduino's internal pull-up resistor is used, which means the E-STOP button is connected between the pin and ground. The circuit is normally closed, and when the E-STOP is pressed, the circuit opens, reading HIGH on the input pin.