How to Use dia contactor: Examples, Pinouts, and Specs

Design with dia contactor in Cirkit Designer

Design with dia contactor in Cirkit DesignerIntroduction

The DIA Contactor (Manufacturer: Rover, Part ID: 1234) is an electromechanical switch designed to control the flow of electricity in a circuit. It is primarily used in high-power applications where reliable switching is required. The contactor operates by utilizing an electromagnetic coil to open or close its contacts, enabling or interrupting the current flow as needed.

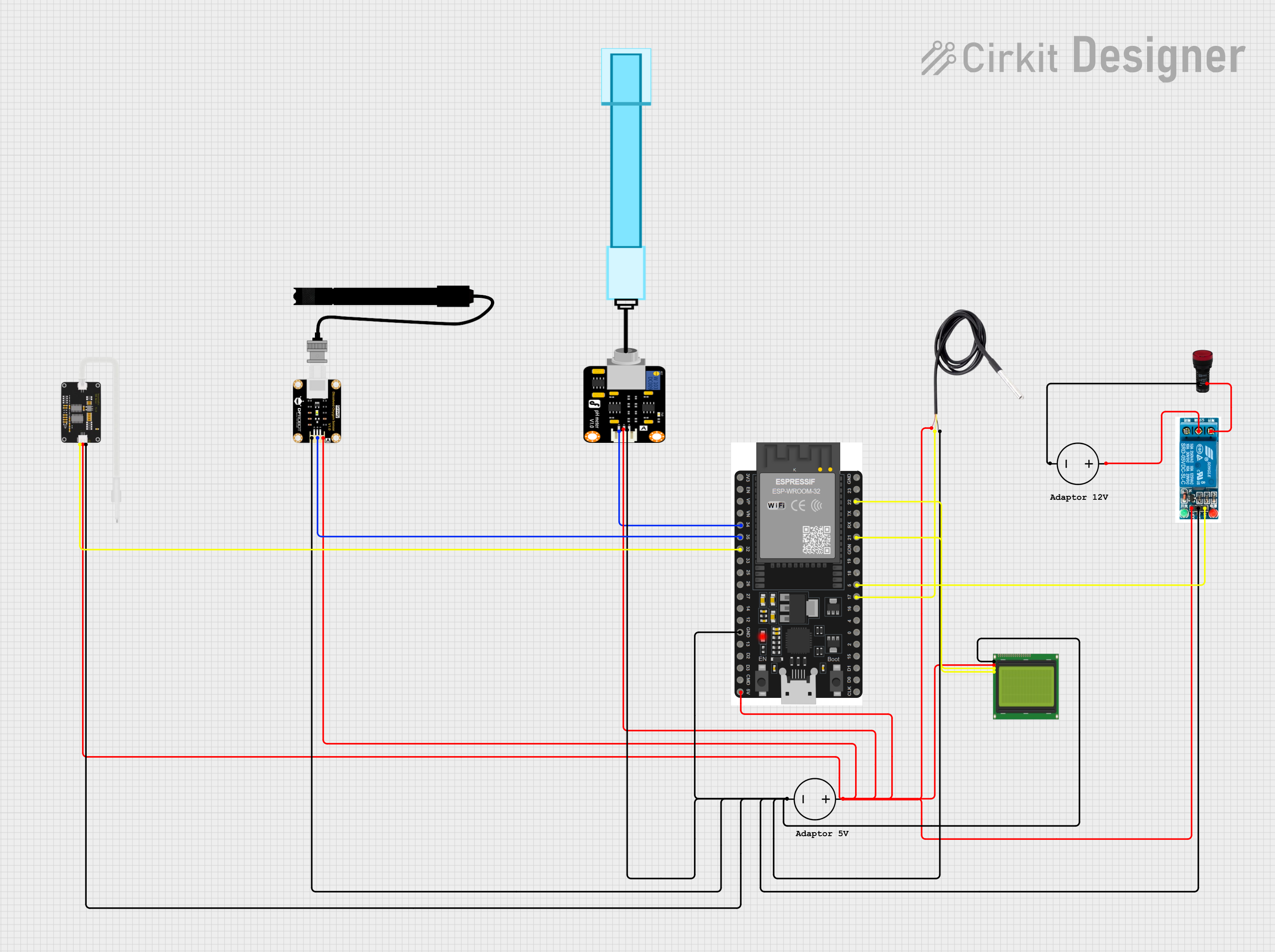

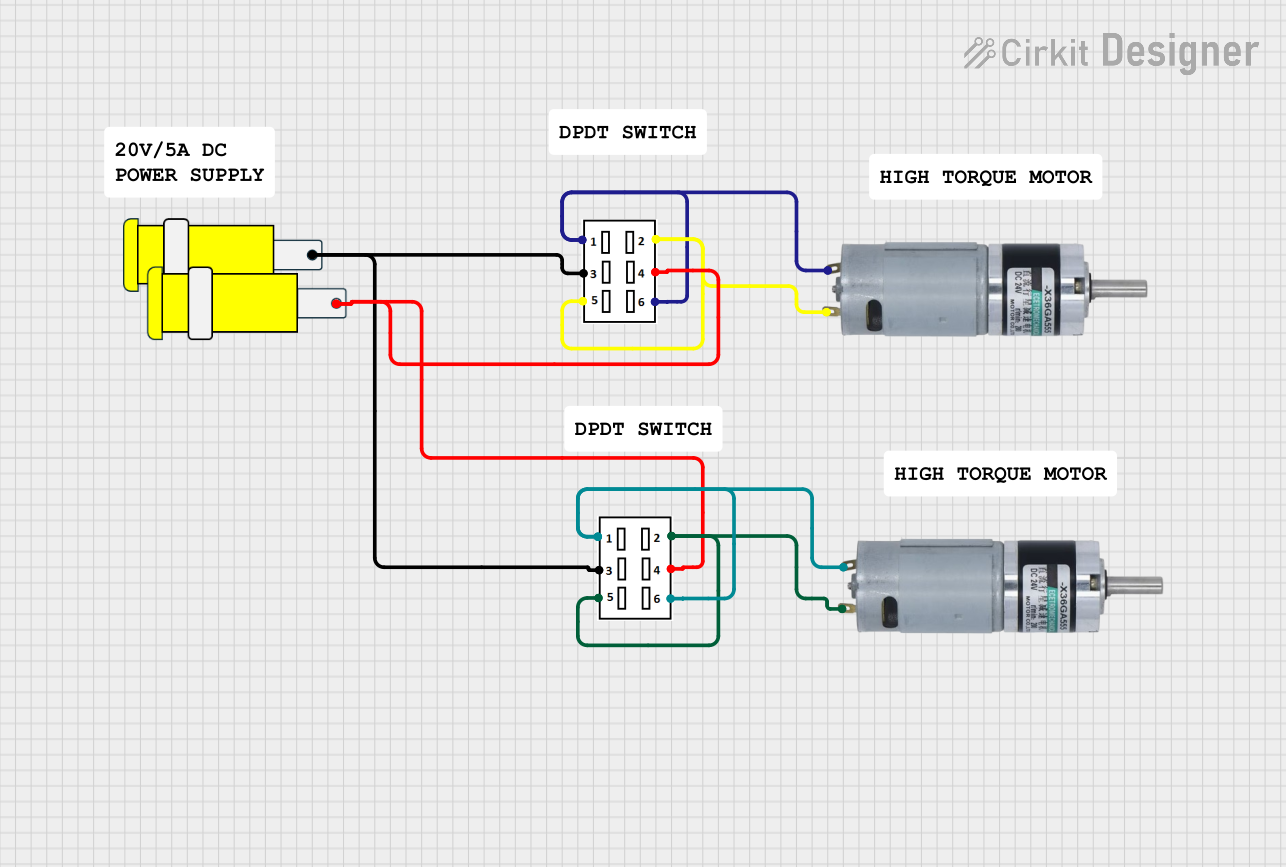

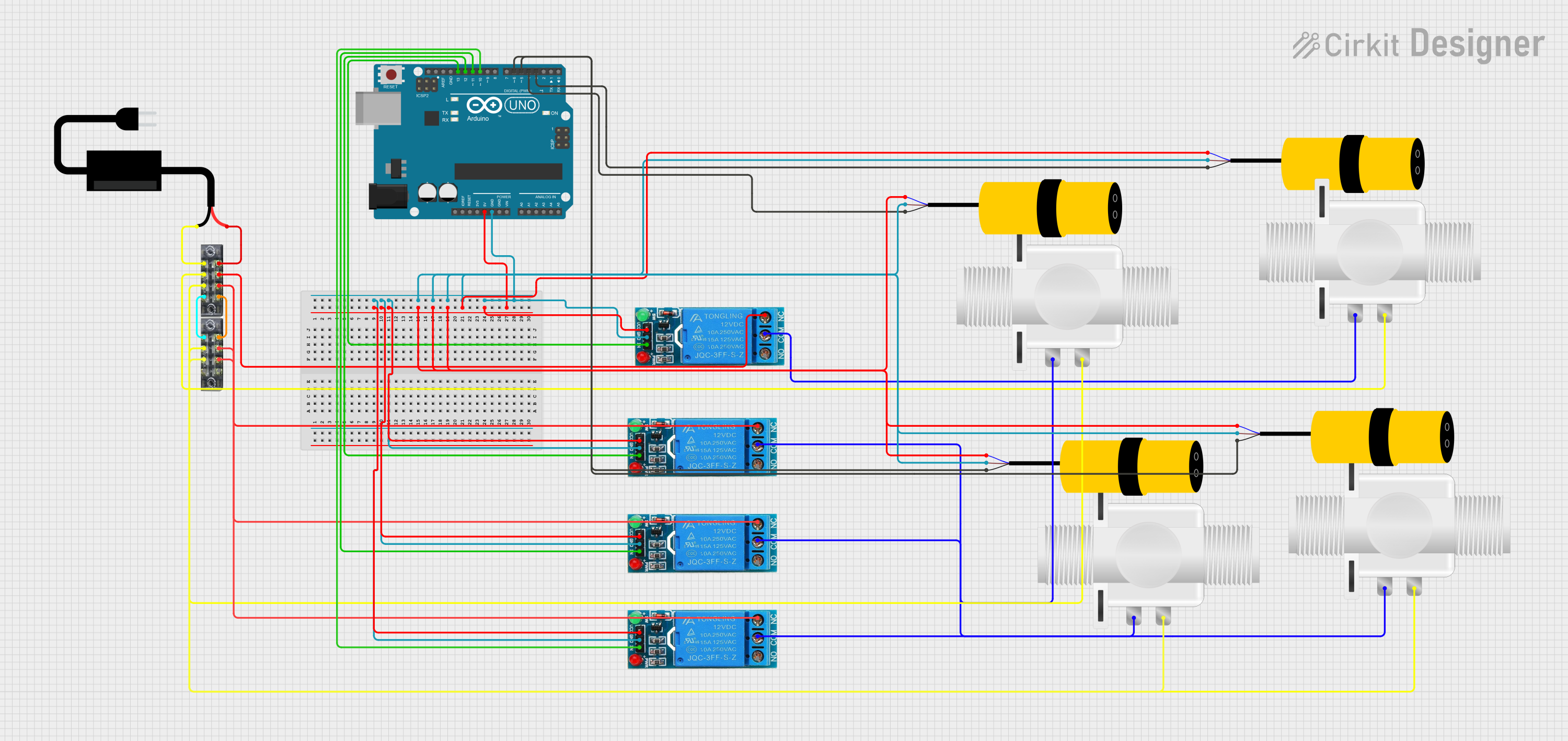

Explore Projects Built with dia contactor

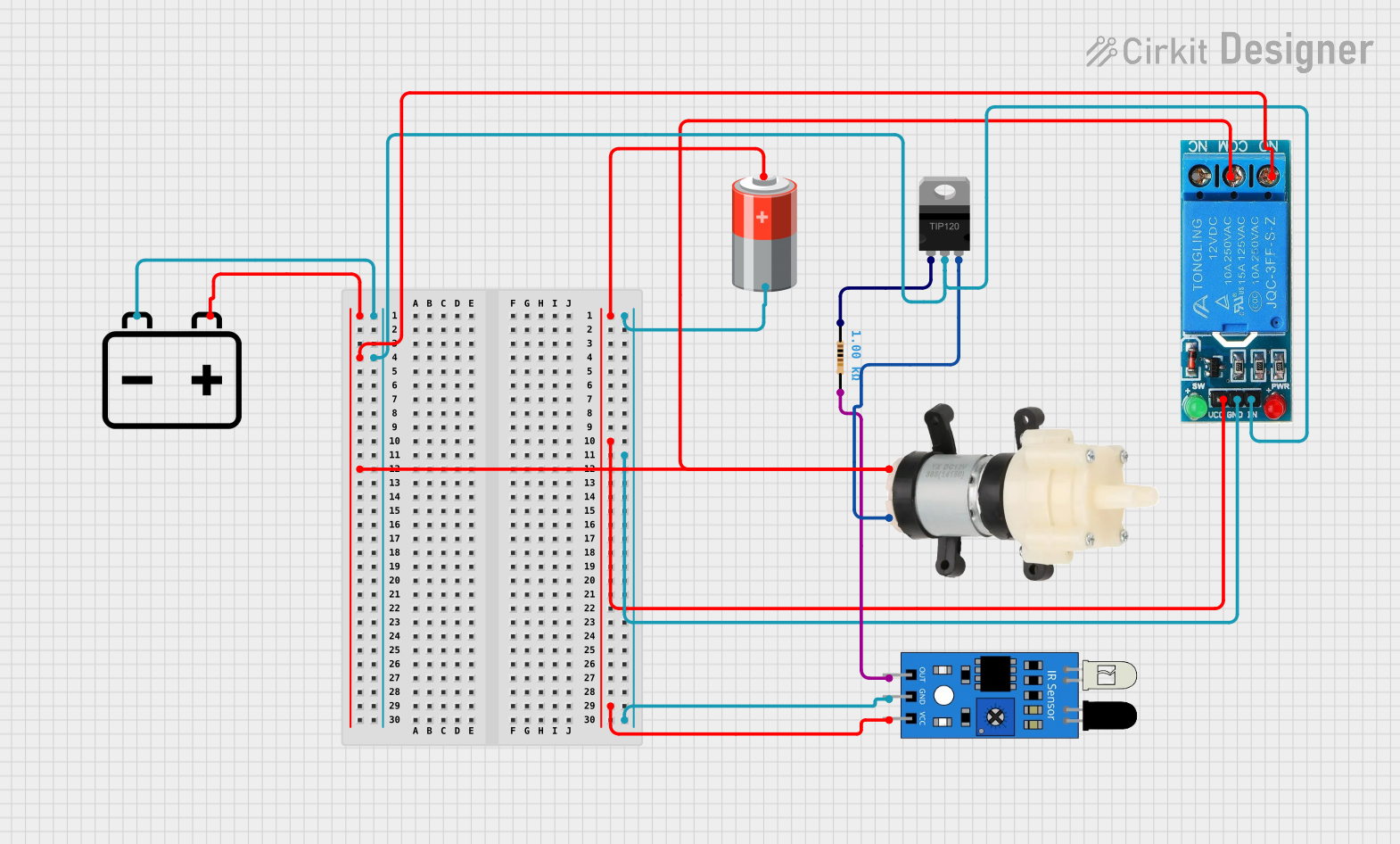

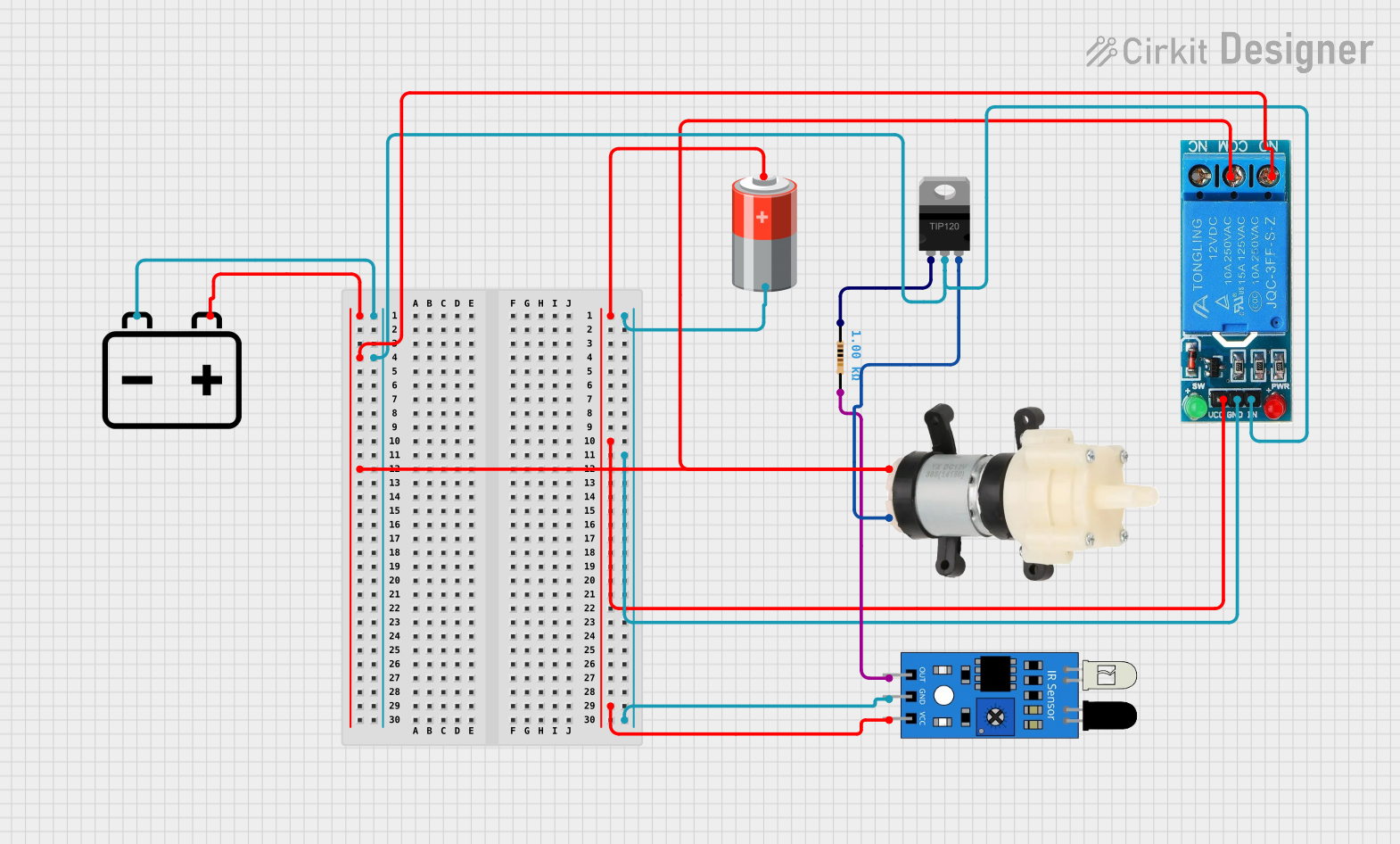

Open Project in Cirkit Designer

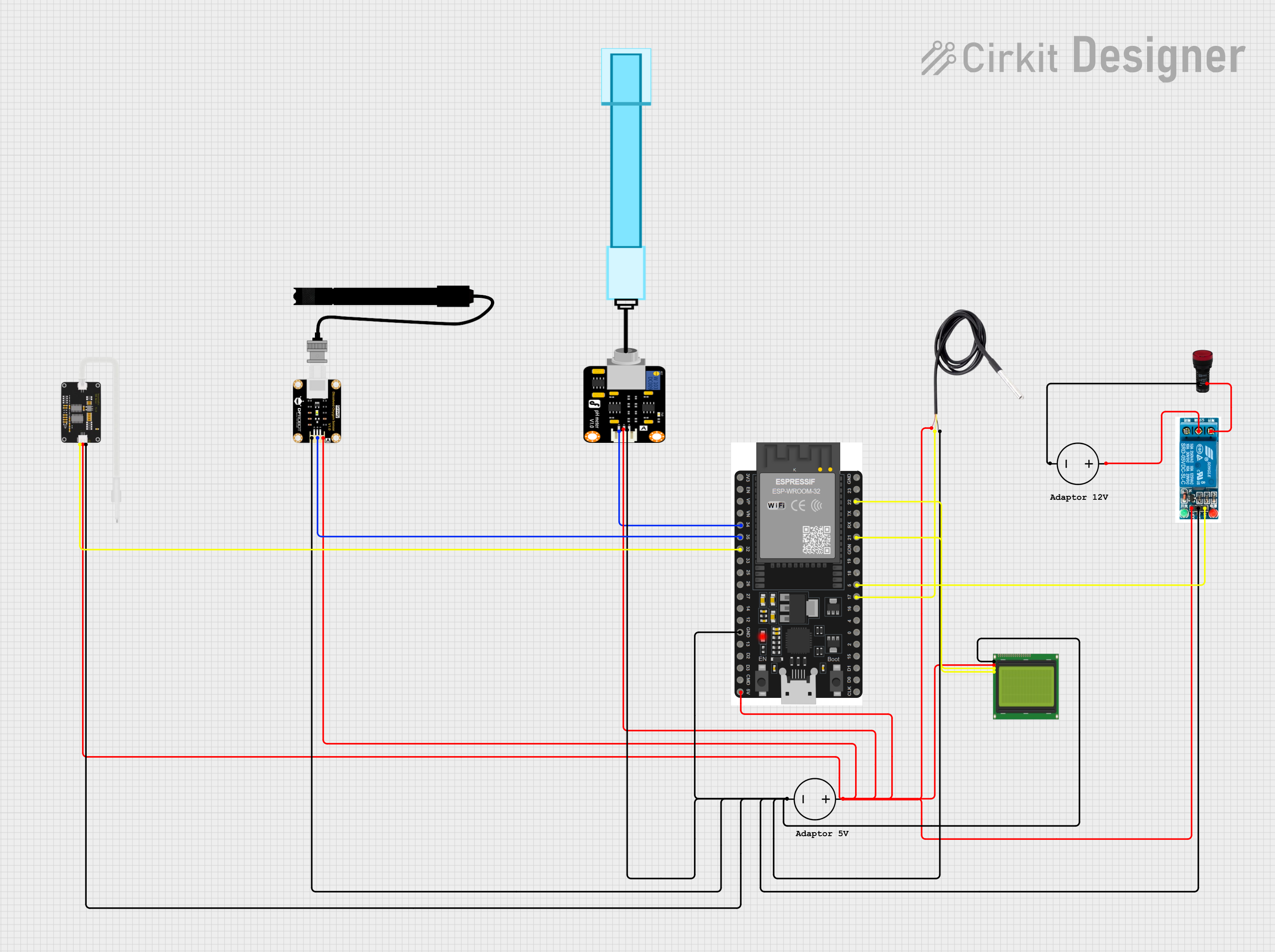

Open Project in Cirkit Designer

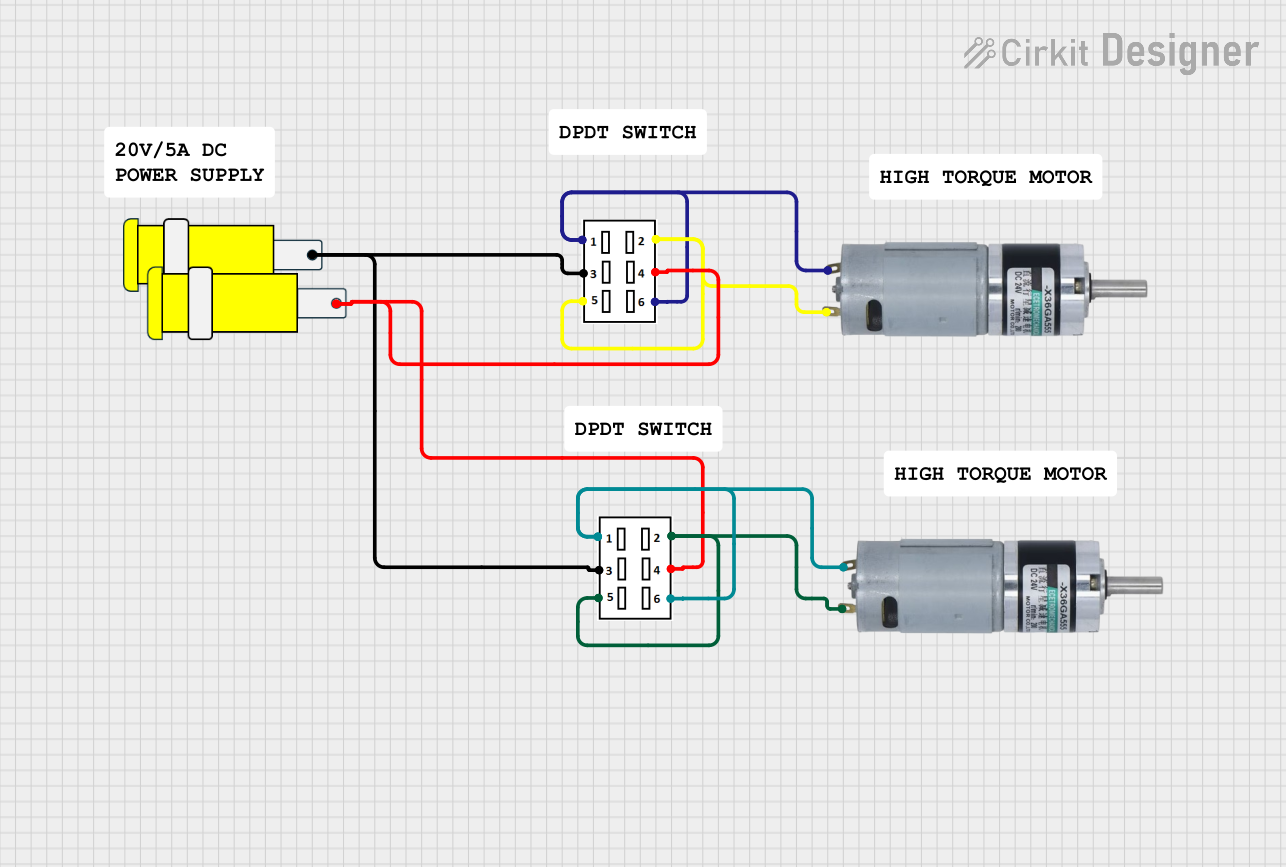

Open Project in Cirkit Designer

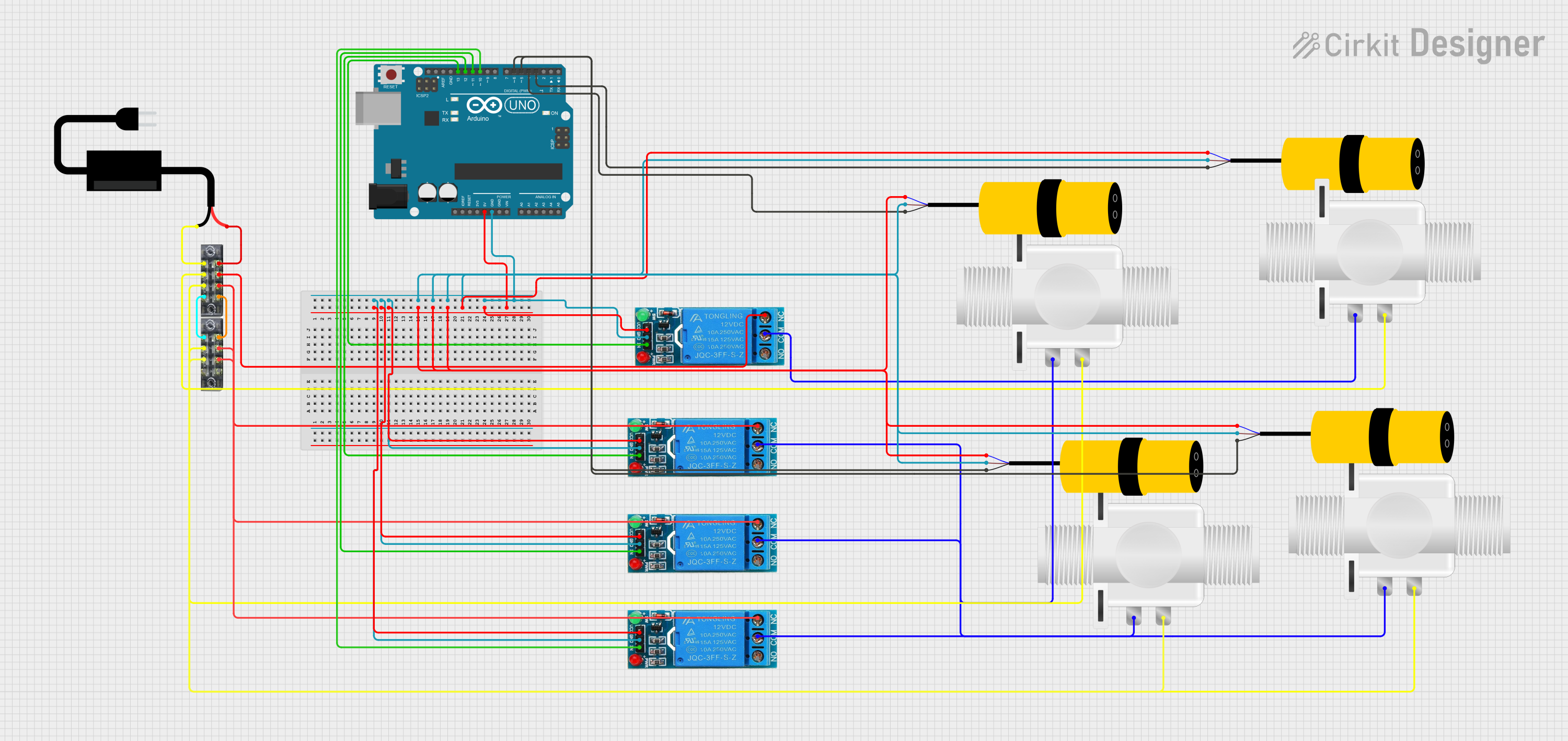

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit DesignerExplore Projects Built with dia contactor

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit DesignerCommon Applications and Use Cases

- Industrial motor control systems

- HVAC (Heating, Ventilation, and Air Conditioning) systems

- Lighting control in commercial and industrial environments

- Power distribution and automation systems

- Renewable energy systems, such as solar inverters

Technical Specifications

Key Technical Details

| Parameter | Value |

|---|---|

| Manufacturer | Rover |

| Part ID | 1234 |

| Rated Voltage (Coil) | 24V DC / 230V AC (varies by model) |

| Rated Current (Contacts) | 25A, 40A, 63A (depending on variant) |

| Contact Configuration | 3P (Three Pole) or 4P (Four Pole) |

| Operating Temperature | -25°C to +55°C |

| Insulation Voltage | 690V AC |

| Mechanical Life | 10 million operations |

| Electrical Life | 1 million operations |

| Mounting Type | DIN Rail or Panel Mount |

Pin Configuration and Descriptions

The DIA Contactor typically has the following pin configuration:

Main Power Terminals

| Pin Label | Description |

|---|---|

| L1, L2, L3 | Input terminals for three-phase power |

| T1, T2, T3 | Output terminals for three-phase load |

Control Circuit Terminals

| Pin Label | Description |

|---|---|

| A1 | Positive terminal for the coil |

| A2 | Negative terminal for the coil |

Auxiliary Contacts (Optional)

| Pin Label | Description |

|---|---|

| 13, 14 | Normally Open (NO) auxiliary contact |

| 21, 22 | Normally Closed (NC) auxiliary contact |

Usage Instructions

How to Use the DIA Contactor in a Circuit

Power Supply Connection:

- Connect the three-phase power supply to the input terminals (L1, L2, L3).

- Ensure the voltage and current ratings of the contactor match the circuit requirements.

Load Connection:

- Connect the load (e.g., motor, lighting system) to the output terminals (T1, T2, T3).

Control Circuit:

- Connect the control voltage to the coil terminals (A1 and A2). For DC coils, ensure correct polarity.

- Use a push-button or relay to control the coil voltage, enabling or disabling the contactor.

Auxiliary Contacts:

- If auxiliary contacts are available, use them for signaling or interlocking purposes in the control circuit.

Important Considerations and Best Practices

- Overload Protection: Always use an appropriate overload relay or circuit breaker in series with the contactor to protect the load.

- Voltage Compatibility: Verify that the coil voltage matches the control circuit voltage.

- Mounting: Ensure proper mounting on a DIN rail or panel to avoid vibrations and mechanical stress.

- Wiring: Use appropriately rated wires and tighten all connections securely to prevent overheating.

- Testing: Test the contactor operation before connecting it to the load to ensure proper functionality.

Example: Connecting the DIA Contactor to an Arduino UNO

The DIA Contactor can be controlled using an Arduino UNO by driving a relay module that supplies the required coil voltage.

Arduino Code Example

// This code demonstrates how to control a DIA Contactor using an Arduino UNO

// and a relay module. The relay module is used to switch the contactor's coil.

const int relayPin = 7; // Pin connected to the relay module

void setup() {

pinMode(relayPin, OUTPUT); // Set the relay pin as an output

digitalWrite(relayPin, LOW); // Ensure the relay is off initially

}

void loop() {

// Turn the contactor ON

digitalWrite(relayPin, HIGH); // Activate the relay

delay(5000); // Keep the contactor ON for 5 seconds

// Turn the contactor OFF

digitalWrite(relayPin, LOW); // Deactivate the relay

delay(5000); // Keep the contactor OFF for 5 seconds

}

Note: Ensure the relay module is rated to handle the contactor's coil voltage and current. Use an external power supply for the relay module if required.

Troubleshooting and FAQs

Common Issues and Solutions

Contactor Does Not Activate:

- Cause: No voltage at the coil terminals (A1, A2).

- Solution: Check the control circuit wiring and ensure the correct voltage is applied to the coil.

Excessive Heating:

- Cause: Loose connections or overcurrent.

- Solution: Tighten all connections and verify the load current does not exceed the contactor's rating.

Chattering Noise:

- Cause: Insufficient coil voltage or unstable power supply.

- Solution: Check the power supply and ensure the coil voltage is stable and within the specified range.

Auxiliary Contacts Not Working:

- Cause: Incorrect wiring or damaged contacts.

- Solution: Verify the wiring and test the auxiliary contacts for continuity.

FAQs

Q: Can the DIA Contactor be used for single-phase applications?

A: Yes, connect the single-phase power to one of the poles (e.g., L1 and T1) and leave the other poles unused.Q: How do I select the correct contactor for my application?

A: Choose a contactor with a current rating higher than the load current and ensure the coil voltage matches your control circuit.Q: Can I mount the contactor in any orientation?

A: It is recommended to mount the contactor vertically for optimal performance and longevity.Q: What is the purpose of auxiliary contacts?

A: Auxiliary contacts are used for signaling, interlocking, or controlling other devices in the circuit.

By following this documentation, you can effectively integrate the Rover DIA Contactor (Part ID: 1234) into your electrical systems for reliable and efficient operation.