How to Use L298_BRIDGE_DRIVER: Examples, Pinouts, and Specs

Design with L298_BRIDGE_DRIVER in Cirkit Designer

Design with L298_BRIDGE_DRIVER in Cirkit DesignerIntroduction

The L298 Bridge Driver is an integrated circuit (IC) designed for controlling and driving DC motors or stepper motors in a bi-directional mode. It achieves this through two H-bridge configurations, which allow for individual control of two motors simultaneously. The L298 is widely used in robotics, CNC machines, and other applications where precise motor control is required.

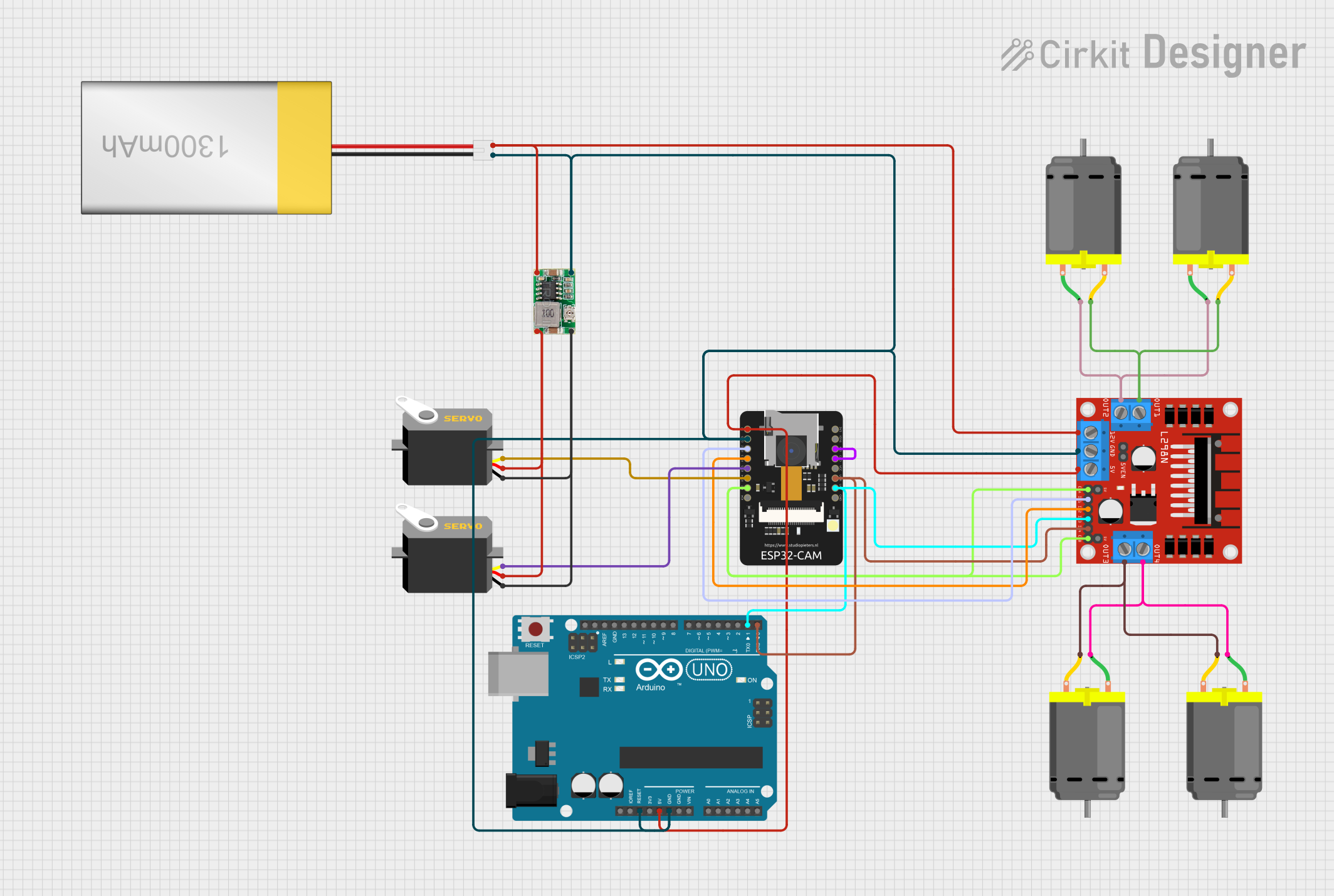

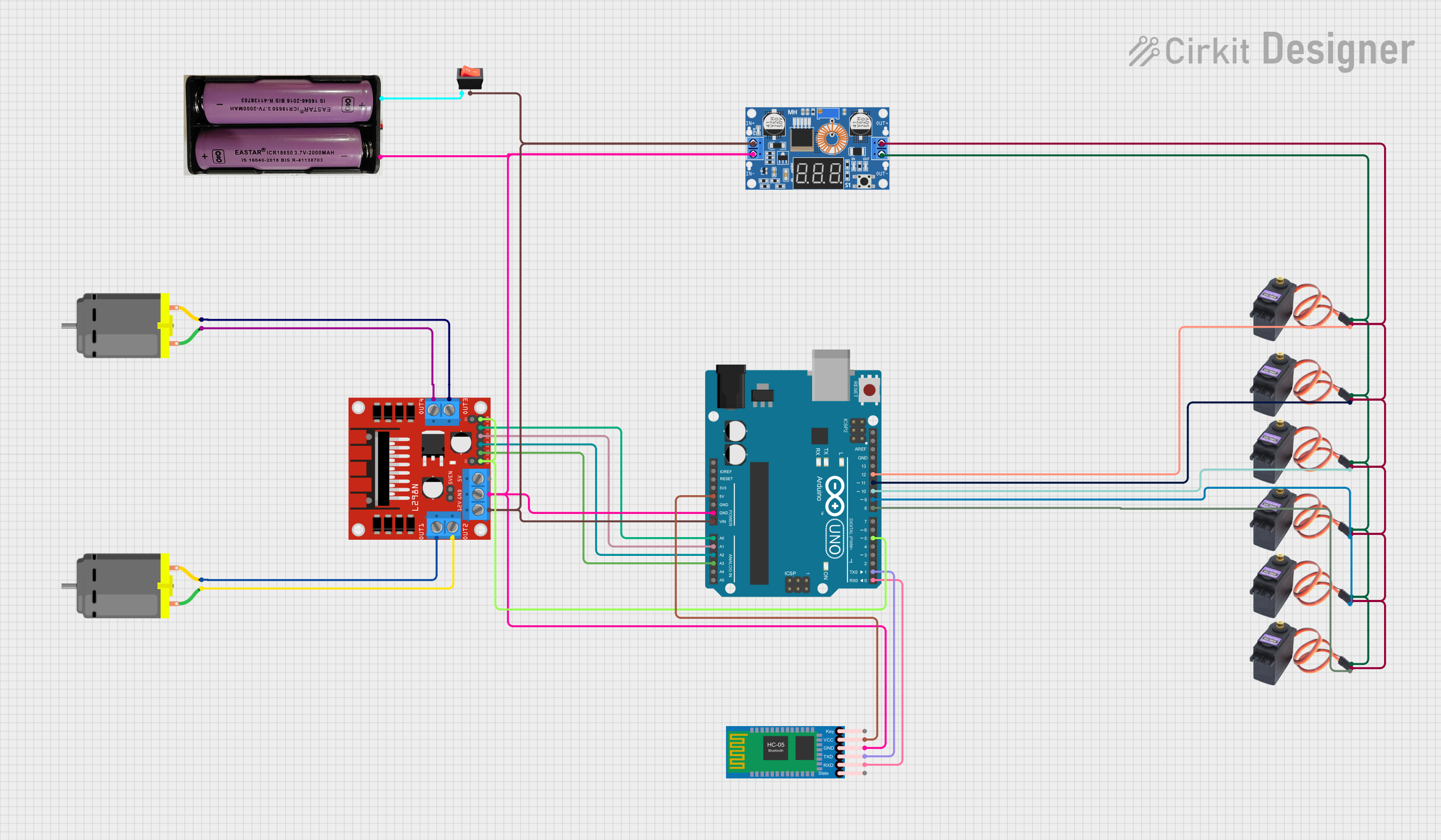

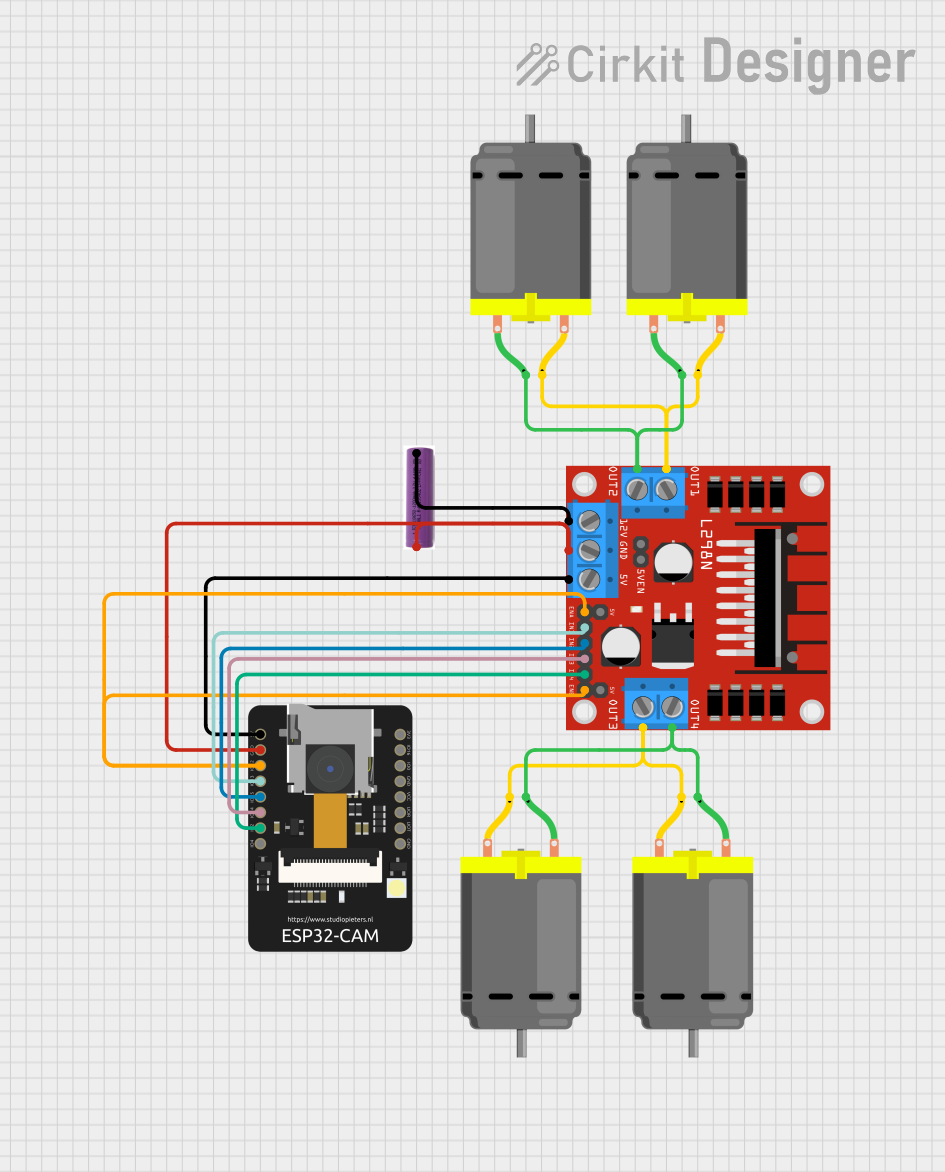

Explore Projects Built with L298_BRIDGE_DRIVER

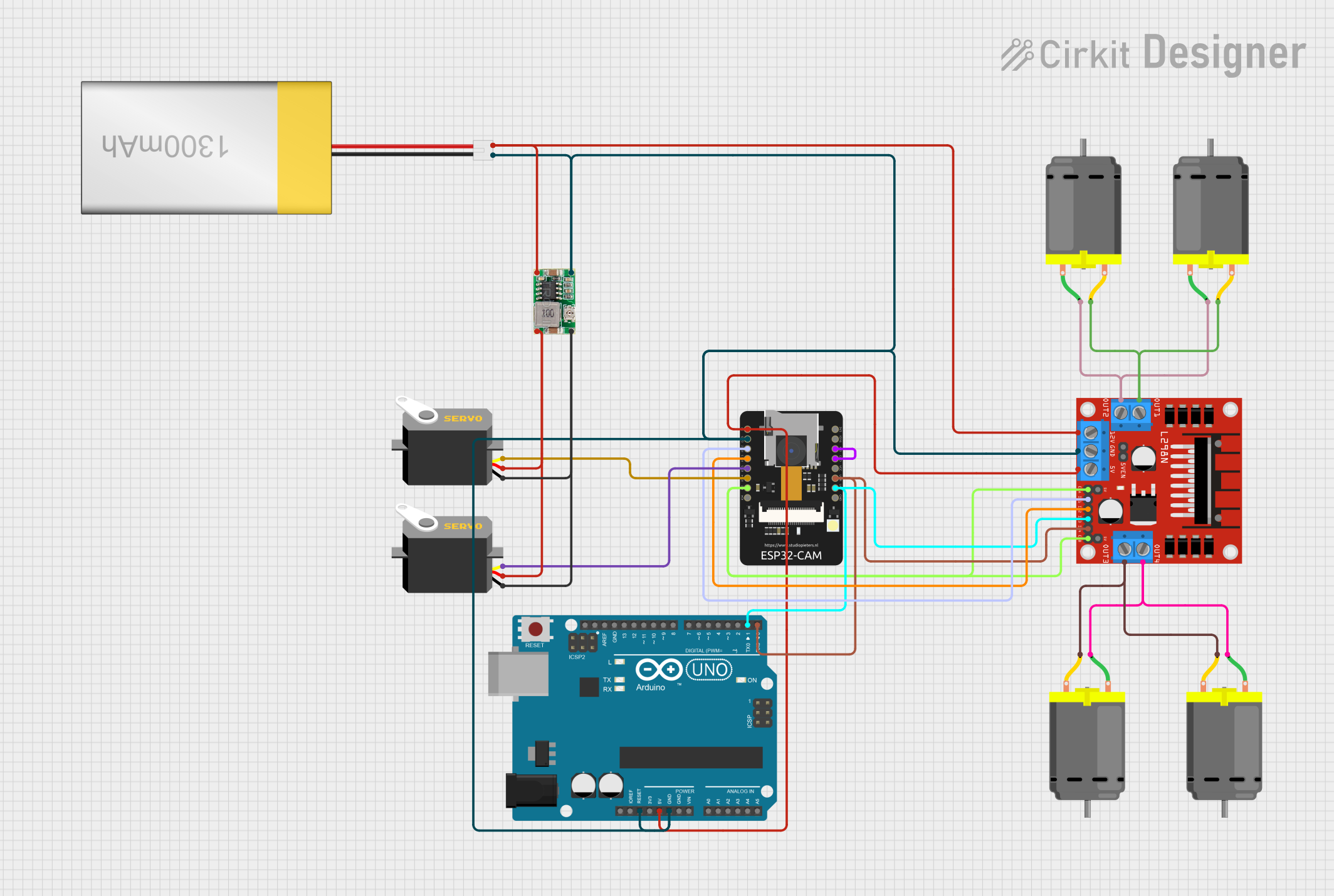

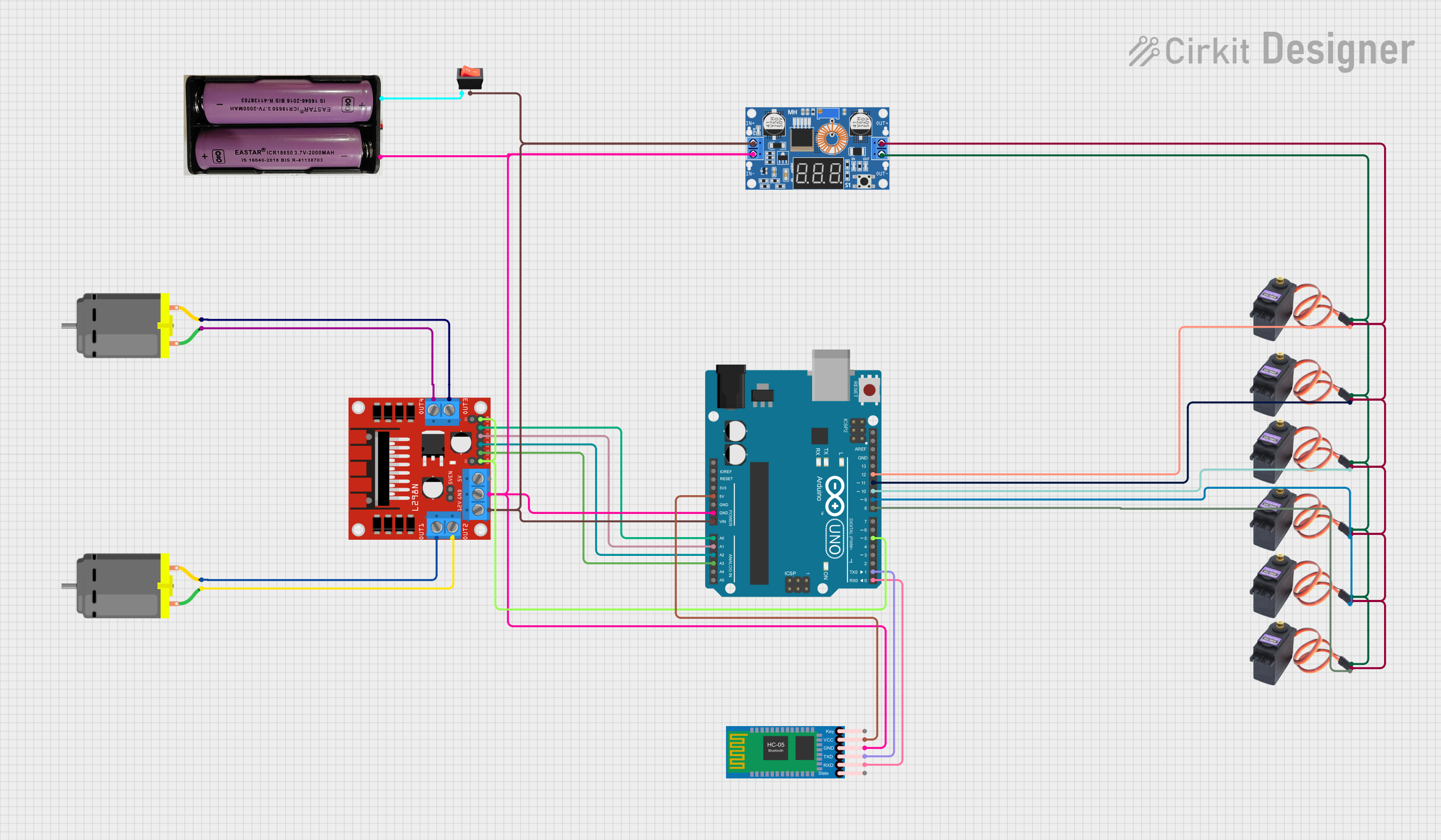

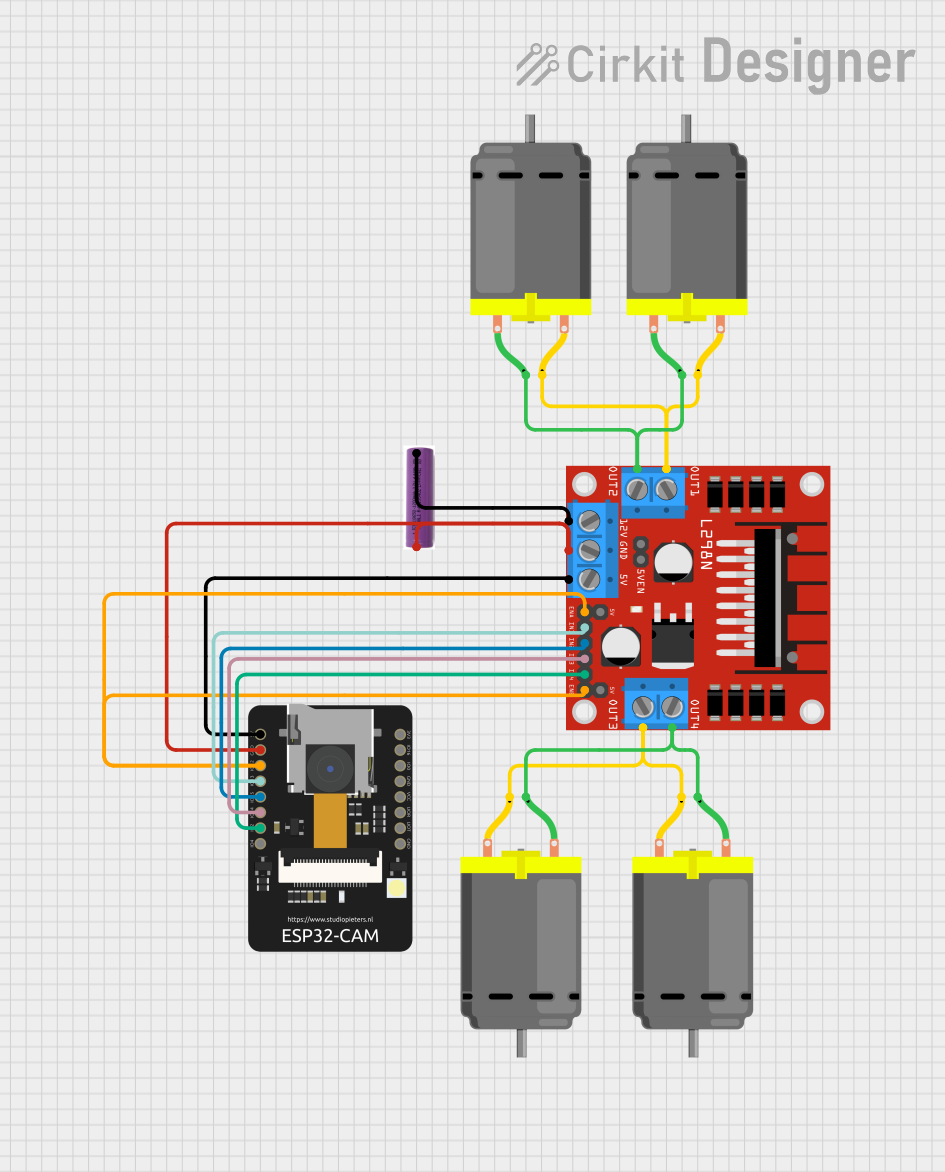

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit DesignerExplore Projects Built with L298_BRIDGE_DRIVER

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit DesignerCommon Applications and Use Cases

- Robotics: Driving wheels or actuator motors.

- CNC Machines: Controlling stepper motors for precise movements.

- Electric Vehicles: Managing small DC motors for propulsion or steering.

- Hobby Projects: Used in DIY projects that require motor control.

Technical Specifications

Key Technical Details

- Operating Voltage (Vss): Up to 46V

- Total DC Current (up to 25°C): 4A per channel or 2A per channel for L298N

- Peak Output Current (non-repetitive t = 100ms): 3A

- Logical Input Voltage (Vss): 4.5V to 7V

- Power SO20 (Derating Factor): 13W at 25°C

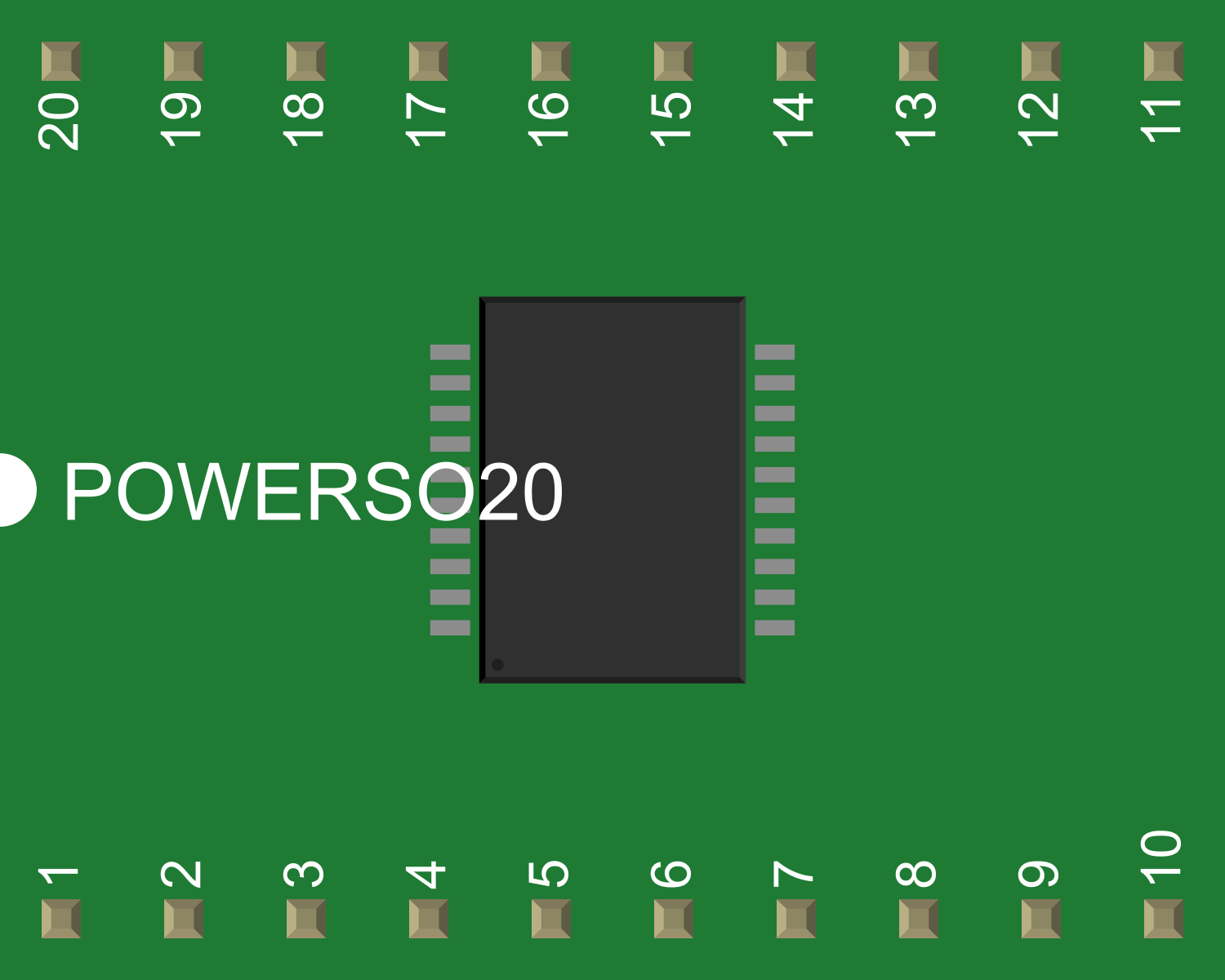

Pin Configuration and Descriptions

| Pin Number | Pin Name | Description |

|---|---|---|

| 1 | Vs | Power supply for the H-bridges (motor voltage) |

| 2 | GND | Ground |

| 3 | Vss | Logic supply voltage |

| 4 & 5 | Out 1 & 2 | Outputs for Motor 1 |

| 6 & 7 | In 1 & 2 | Inputs for controlling Out 1 & 2 |

| 8 | EnA | Enable input for Out 1 & 2 |

| 9 | In 3 & 4 | Inputs for controlling Out 3 & 4 |

| 10 & 11 | Out 3 & 4 | Outputs for Motor 2 |

| 12 | EnB | Enable input for Out 3 & 4 |

| 13 | GND | Ground (Heat Sink) |

| 14 | Vs | Power supply for the H-bridges (motor voltage) |

Usage Instructions

How to Use the Component in a Circuit

- Connect the motor supply voltage to Vs (Pin 1 and 14) and ground to GND (Pin 2 and 13).

- Apply the logic supply voltage to Vss (Pin 3).

- Connect the motors to Out 1 & 2 (Pin 4 & 5) and Out 3 & 4 (Pin 10 & 11).

- Use In 1 & 2 (Pin 6 & 7) and In 3 & 4 (Pin 9) to control the direction of the motors.

- Use EnA (Pin 8) and EnB (Pin 12) to enable or disable the motor outputs.

Important Considerations and Best Practices

- Ensure that the power supply voltage does not exceed the maximum rating.

- Use appropriate heat sinking for the IC to manage heat dissipation.

- Implement flyback diodes to protect against voltage spikes when driving inductive loads.

- Avoid running the IC at its maximum current rating continuously to prevent overheating.

Example Code for Arduino UNO

// Define the L298N control pins

#define ENA 9

#define IN1 8

#define IN2 7

#define IN3 6

#define IN4 5

#define ENB 3

void setup() {

// Set all the motor control pins to outputs

pinMode(ENA, OUTPUT);

pinMode(IN1, OUTPUT);

pinMode(IN2, OUTPUT);

pinMode(IN3, OUTPUT);

pinMode(IN4, OUTPUT);

pinMode(ENB, OUTPUT);

}

void loop() {

// Drive motor 1 forward

digitalWrite(IN1, HIGH);

digitalWrite(IN2, LOW);

analogWrite(ENA, 200); // Set speed (0-255)

// Drive motor 2 forward

digitalWrite(IN3, HIGH);

digitalWrite(IN4, LOW);

analogWrite(ENB, 200); // Set speed (0-255)

delay(2000); // Run for 2 seconds

// Stop both motors

digitalWrite(IN1, LOW);

digitalWrite(IN2, LOW);

digitalWrite(IN3, LOW);

digitalWrite(IN4, LOW);

delay(1000); // Stop for 1 second

}

Troubleshooting and FAQs

Common Issues Users Might Face

- Motor not running: Check power supply connections, ensure that the logic and motor supply voltages are correctly applied.

- Overheating: Ensure proper heat sinking and avoid running the IC at maximum current for extended periods.

- Inconsistent motor operation: Verify that the input signals are correct and that there are no loose connections.

Solutions and Tips for Troubleshooting

- Double-check wiring against the pin configuration.

- Use a multimeter to verify the presence of supply voltages at the appropriate pins.

- Implement code debugging by using serial outputs to monitor the state of control pins.

FAQs

Q: Can the L298 drive two motors independently? A: Yes, the L298 can control two motors independently using separate input and enable pins for each H-bridge.

Q: What is the maximum voltage and current the L298 can handle? A: The maximum motor supply voltage is 46V, and it can handle up to 4A per channel or 2A per channel for the L298N variant.

Q: Do I need to use flyback diodes with the L298? A: The L298 has internal clamp diodes, but external flyback diodes are recommended for better protection, especially with higher inductive loads.