How to Use MPU-9250/6500/9255: Examples, Pinouts, and Specs

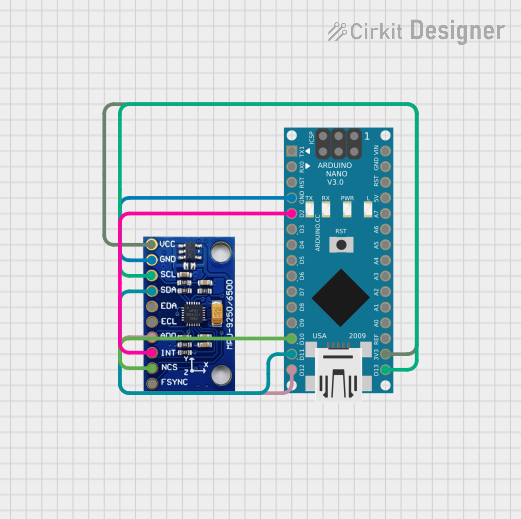

Design with MPU-9250/6500/9255 in Cirkit Designer

Design with MPU-9250/6500/9255 in Cirkit DesignerIntroduction

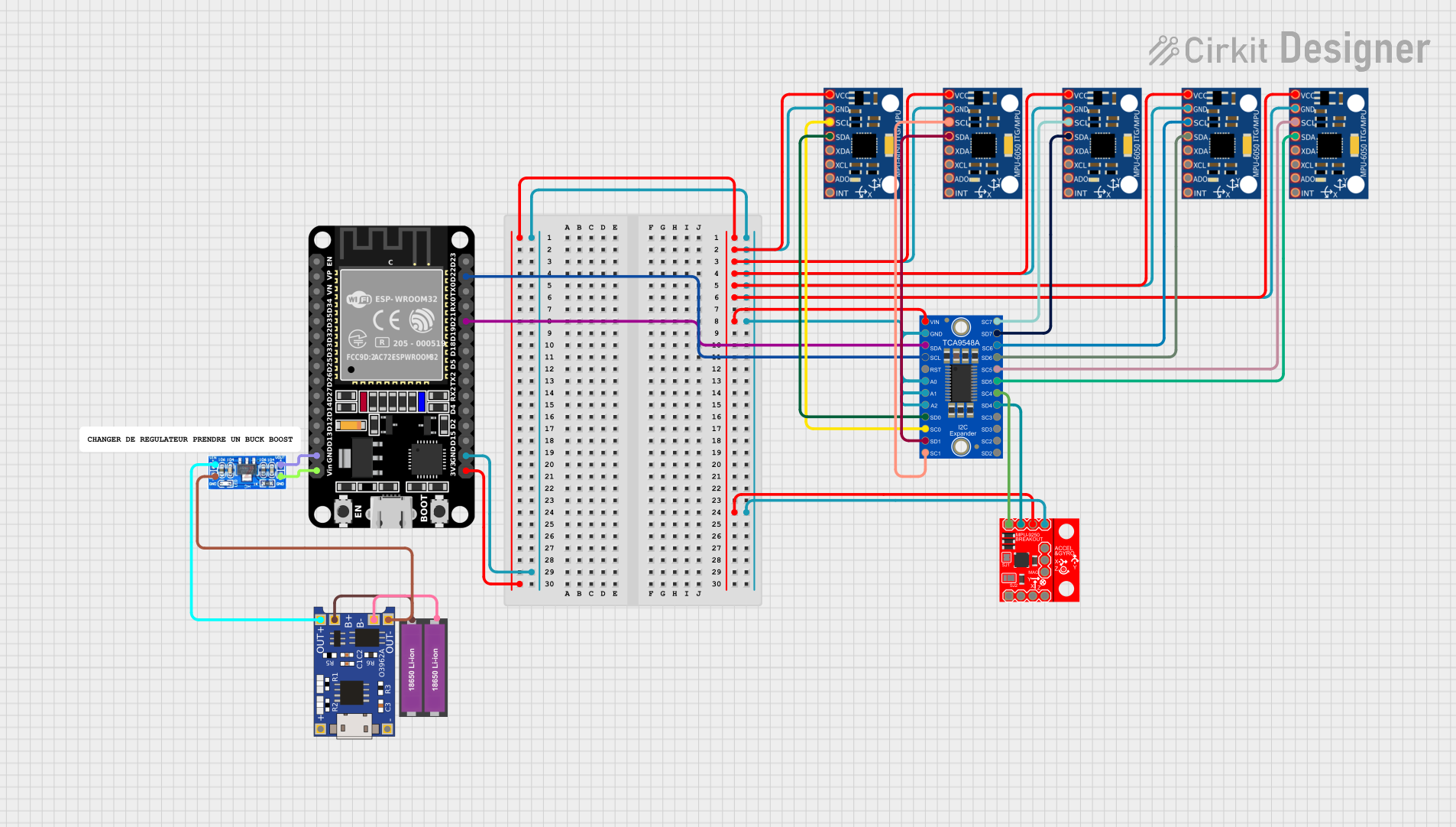

The MPU-9250/6500/9255 is a highly integrated 9-axis motion tracking device that combines a 3-axis gyroscope, a 3-axis accelerometer, and a 3-axis magnetometer in a single compact package. This component is widely used for applications requiring precise orientation, motion detection, and inertial measurements. Its small size, low power consumption, and high performance make it ideal for use in robotics, drones, mobile devices, gaming controllers, and wearable technology.

Explore Projects Built with MPU-9250/6500/9255

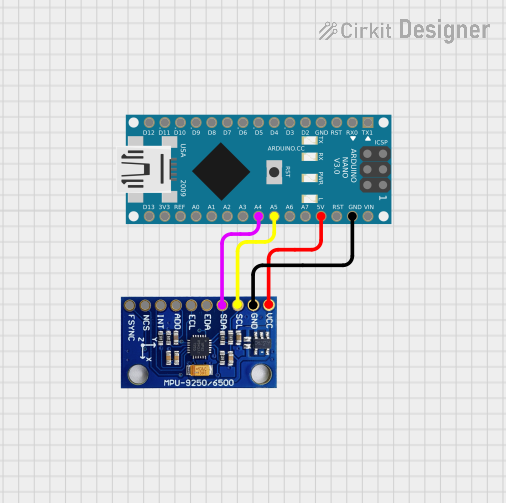

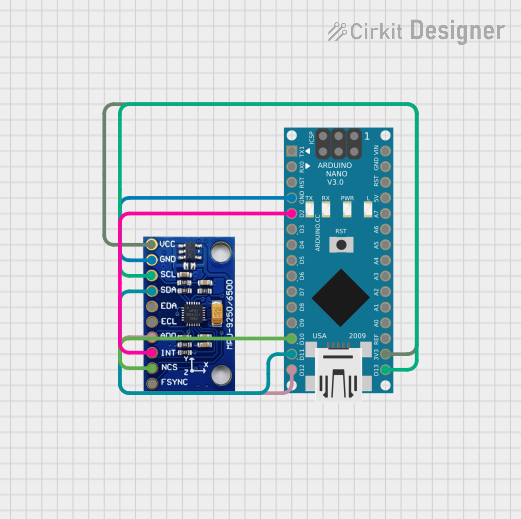

Open Project in Cirkit Designer

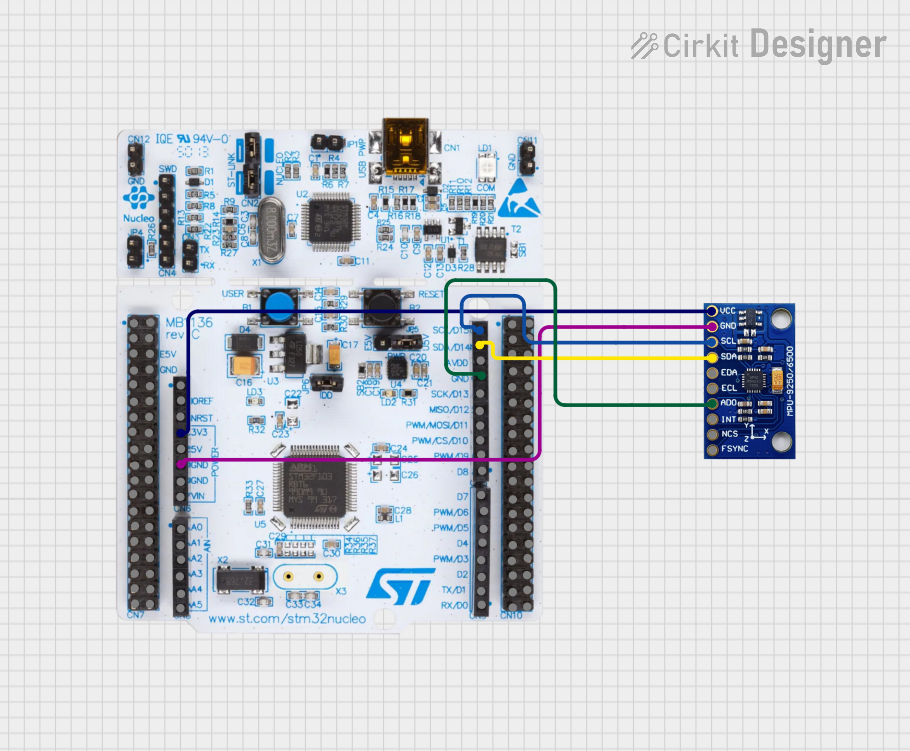

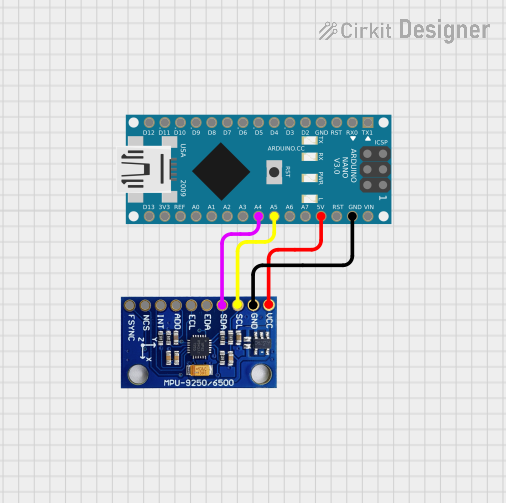

Open Project in Cirkit Designer

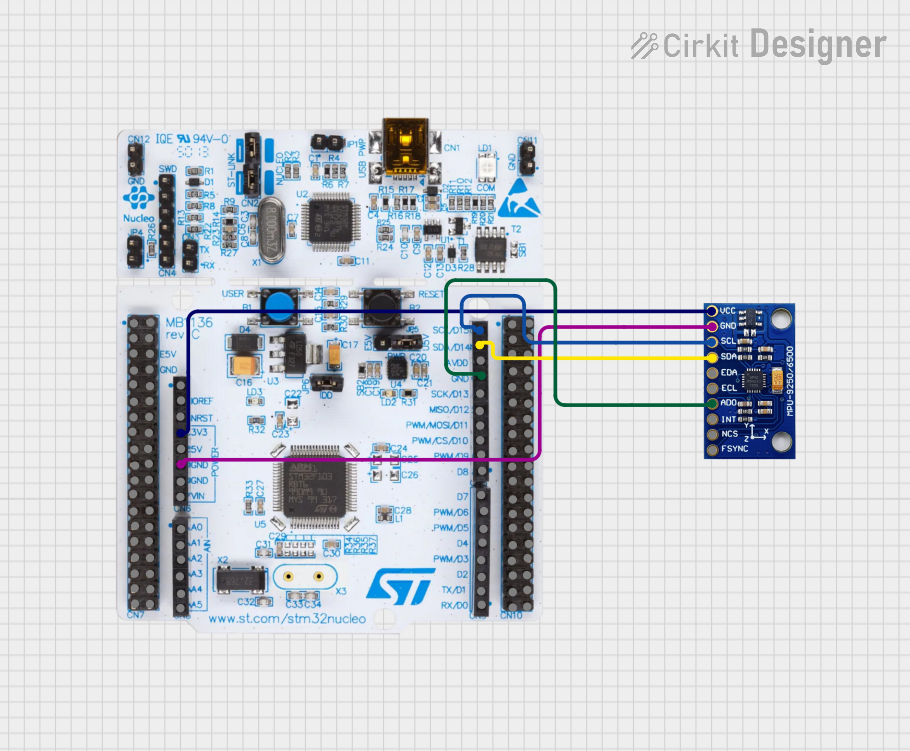

Open Project in Cirkit Designer

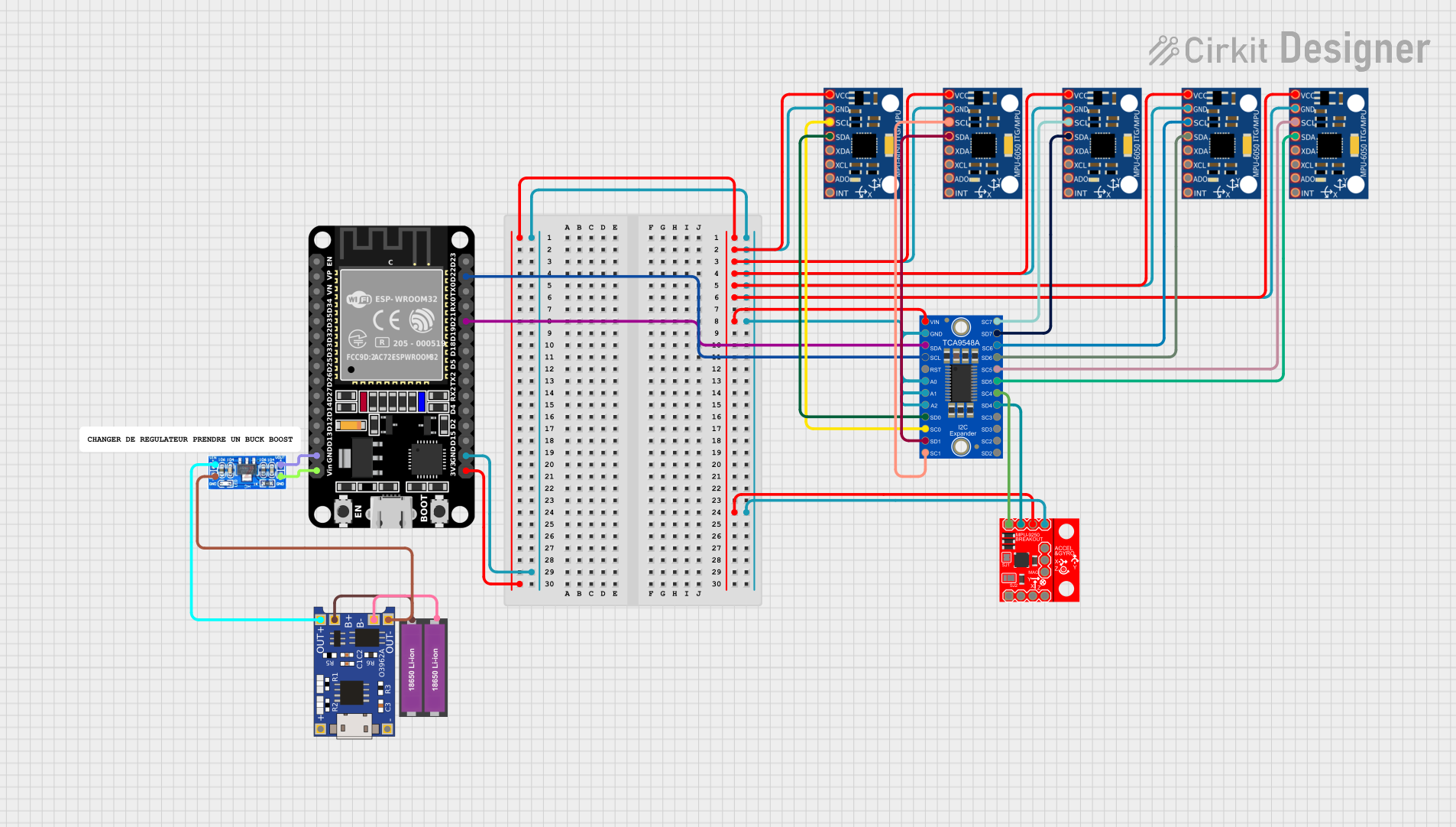

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit DesignerExplore Projects Built with MPU-9250/6500/9255

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit DesignerCommon Applications:

- Robotics for motion tracking and navigation

- Drones for stabilization and orientation control

- Mobile devices for gesture recognition and augmented reality

- Wearable devices for fitness tracking and activity monitoring

- Gaming controllers for motion-based input

Technical Specifications

Key Technical Details:

- Gyroscope Range: ±250, ±500, ±1000, ±2000 degrees/second

- Accelerometer Range: ±2g, ±4g, ±8g, ±16g

- Magnetometer Range: ±4800 µT

- Communication Interface: I²C (up to 400 kHz) and SPI (up to 1 MHz)

- Operating Voltage: 2.4V to 3.6V

- Power Consumption:

- Gyroscope: 3.2 mA

- Accelerometer: 450 µA

- Magnetometer: 280 µA

- Operating Temperature Range: -40°C to +85°C

- Package Dimensions: 3x3x1 mm (QFN package)

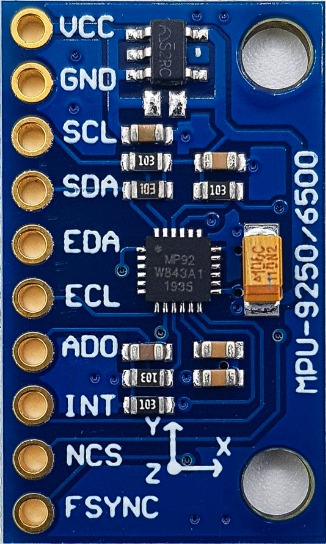

Pin Configuration and Descriptions:

The MPU-9250/6500/9255 has 24 pins. Below is a summary of the key pins:

| Pin Number | Pin Name | Description |

|---|---|---|

| 1 | VDD | Power supply input (2.4V to 3.6V) |

| 2 | VDDIO | I/O voltage reference |

| 3 | GND | Ground |

| 4 | SCL | I²C clock line |

| 5 | SDA | I²C data line |

| 6 | CS | Chip select for SPI |

| 7 | INT | Interrupt output |

| 8 | FSYNC | Frame synchronization input |

| 9-24 | NC | Not connected or reserved for internal use |

Usage Instructions

How to Use the MPU-9250/6500/9255 in a Circuit:

Power Supply:

- Connect the VDD pin to a 3.3V power source.

- Connect the GND pin to the ground of your circuit.

- If using a 5V microcontroller, use a level shifter for the I²C or SPI lines.

Communication Interface:

- For I²C communication, connect the SCL and SDA pins to the corresponding I²C pins on your microcontroller. Use pull-up resistors (typically 4.7kΩ) on both lines.

- For SPI communication, connect the CS, SCL, and SDA pins to the SPI pins on your microcontroller.

Interrupts:

- The INT pin can be used to signal events such as data availability or motion detection.

Magnetometer:

- The magnetometer is accessed via a secondary I²C bus within the MPU-9250/9255. Ensure proper initialization in your code.

Important Considerations and Best Practices:

- Use decoupling capacitors (e.g., 0.1 µF) near the VDD pin to reduce noise.

- Place the MPU-9250/6500/9255 on a stable, vibration-free surface for accurate measurements.

- Calibrate the gyroscope, accelerometer, and magnetometer before use to ensure precise readings.

- Avoid placing the device near strong magnetic fields or high-frequency noise sources.

Example Code for Arduino UNO:

Below is an example of how to interface the MPU-9250 with an Arduino UNO using the I²C protocol:

#include <Wire.h>

// MPU-9250 I2C address

#define MPU9250_ADDR 0x68

// Register addresses

#define PWR_MGMT_1 0x6B

#define ACCEL_XOUT_H 0x3B

void setup() {

Wire.begin(); // Initialize I2C communication

Serial.begin(9600); // Start serial communication

// Wake up the MPU-9250

Wire.beginTransmission(MPU9250_ADDR);

Wire.write(PWR_MGMT_1); // Access power management register

Wire.write(0x00); // Set to zero to wake up the sensor

Wire.endTransmission();

}

void loop() {

int16_t accelX, accelY, accelZ;

// Request accelerometer data

Wire.beginTransmission(MPU9250_ADDR);

Wire.write(ACCEL_XOUT_H); // Start reading at ACCEL_XOUT_H

Wire.endTransmission(false);

Wire.requestFrom(MPU9250_ADDR, 6); // Request 6 bytes (X, Y, Z)

// Read accelerometer data

accelX = (Wire.read() << 8) | Wire.read();

accelY = (Wire.read() << 8) | Wire.read();

accelZ = (Wire.read() << 8) | Wire.read();

// Print accelerometer data

Serial.print("Accel X: "); Serial.print(accelX);

Serial.print(" | Accel Y: "); Serial.print(accelY);

Serial.print(" | Accel Z: "); Serial.println(accelZ);

delay(500); // Wait 500ms before next reading

}

Troubleshooting and FAQs

Common Issues and Solutions:

No Communication with the Sensor:

- Ensure the correct I²C address (0x68 or 0x69) is used in your code.

- Check the wiring and ensure pull-up resistors are present on the I²C lines.

- Verify that the sensor is powered and the VDD voltage is within the specified range.

Incorrect or No Data Output:

- Calibrate the sensor before use to eliminate offsets.

- Ensure the sensor is not exposed to strong vibrations or magnetic fields.

- Verify that the correct registers are being accessed in your code.

Device Overheating:

- Check for proper power supply voltage and current limits.

- Ensure the sensor is not placed near heat-generating components.

FAQs:

Q: Can the MPU-9250/6500/9255 be used with a 5V microcontroller?

A: Yes, but you must use a level shifter for the I²C or SPI lines to avoid damaging the sensor.Q: How do I calibrate the sensor?

A: Calibration involves collecting raw data from the gyroscope, accelerometer, and magnetometer, then calculating offsets and scaling factors. Many libraries (e.g., MPU9250 library) include built-in calibration functions.Q: What is the difference between the MPU-9250, MPU-6500, and MPU-9255?

A: The MPU-9250 and MPU-9255 include a magnetometer, while the MPU-6500 does not. The MPU-9255 has improved magnetometer performance compared to the MPU-9250.