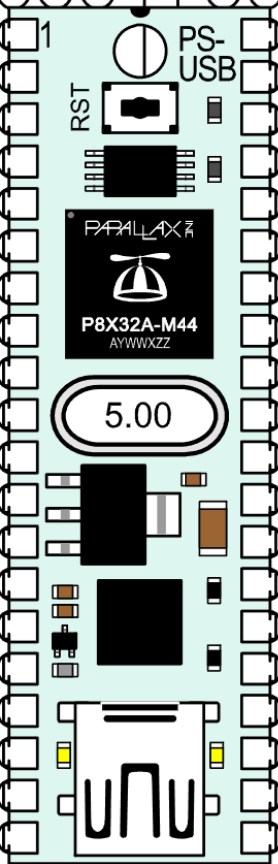

How to Use Propeller Microcontroller: Examples, Pinouts, and Specs

Design with Propeller Microcontroller in Cirkit Designer

Design with Propeller Microcontroller in Cirkit DesignerIntroduction

The Propeller Microcontroller (PBX32A), manufactured by Propeller, is a versatile and powerful microcontroller designed for multitasking applications. It features multiple cores, allowing it to run independent threads simultaneously. This makes it an excellent choice for complex control systems, robotics, real-time signal processing, and other applications requiring parallel processing.

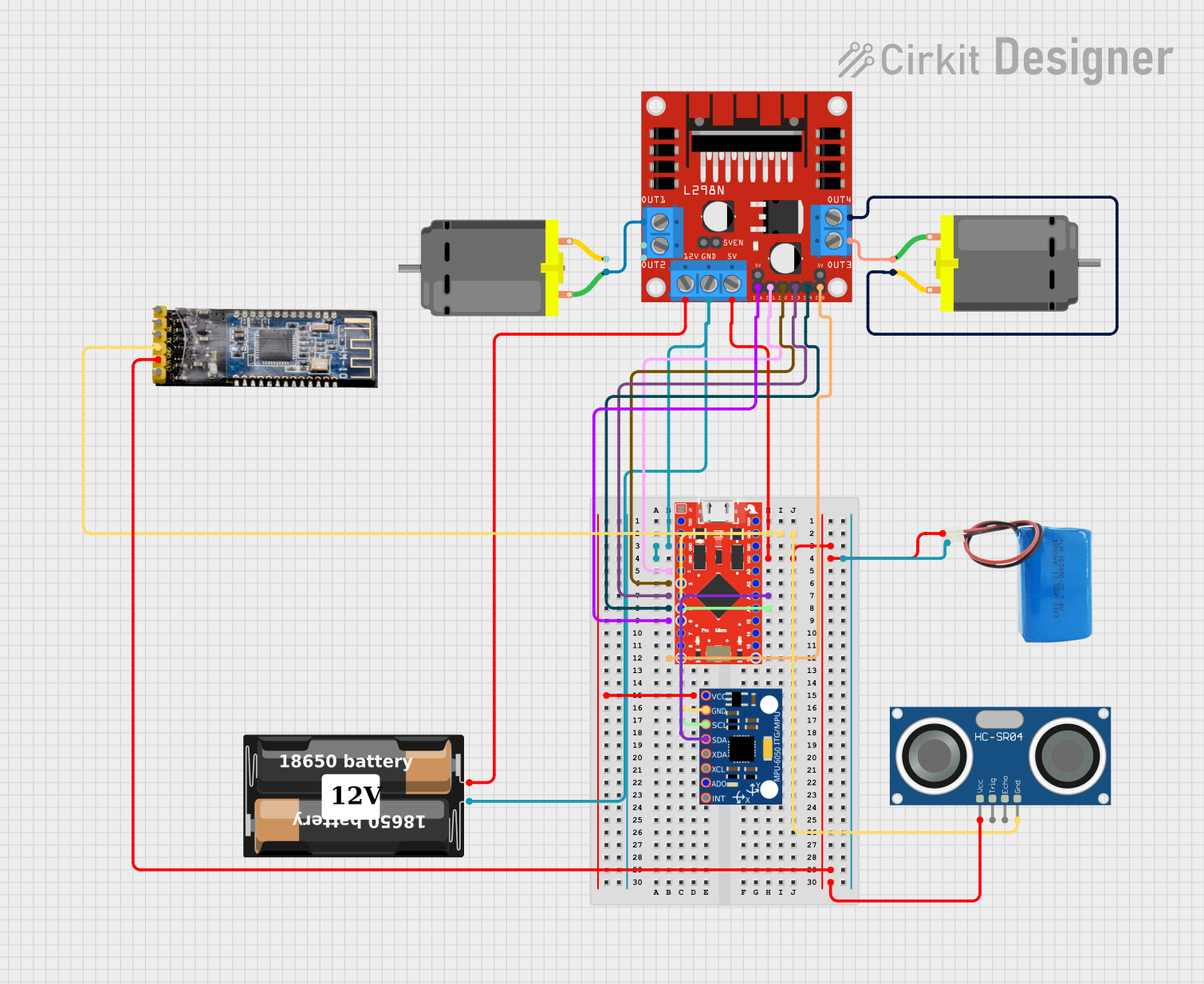

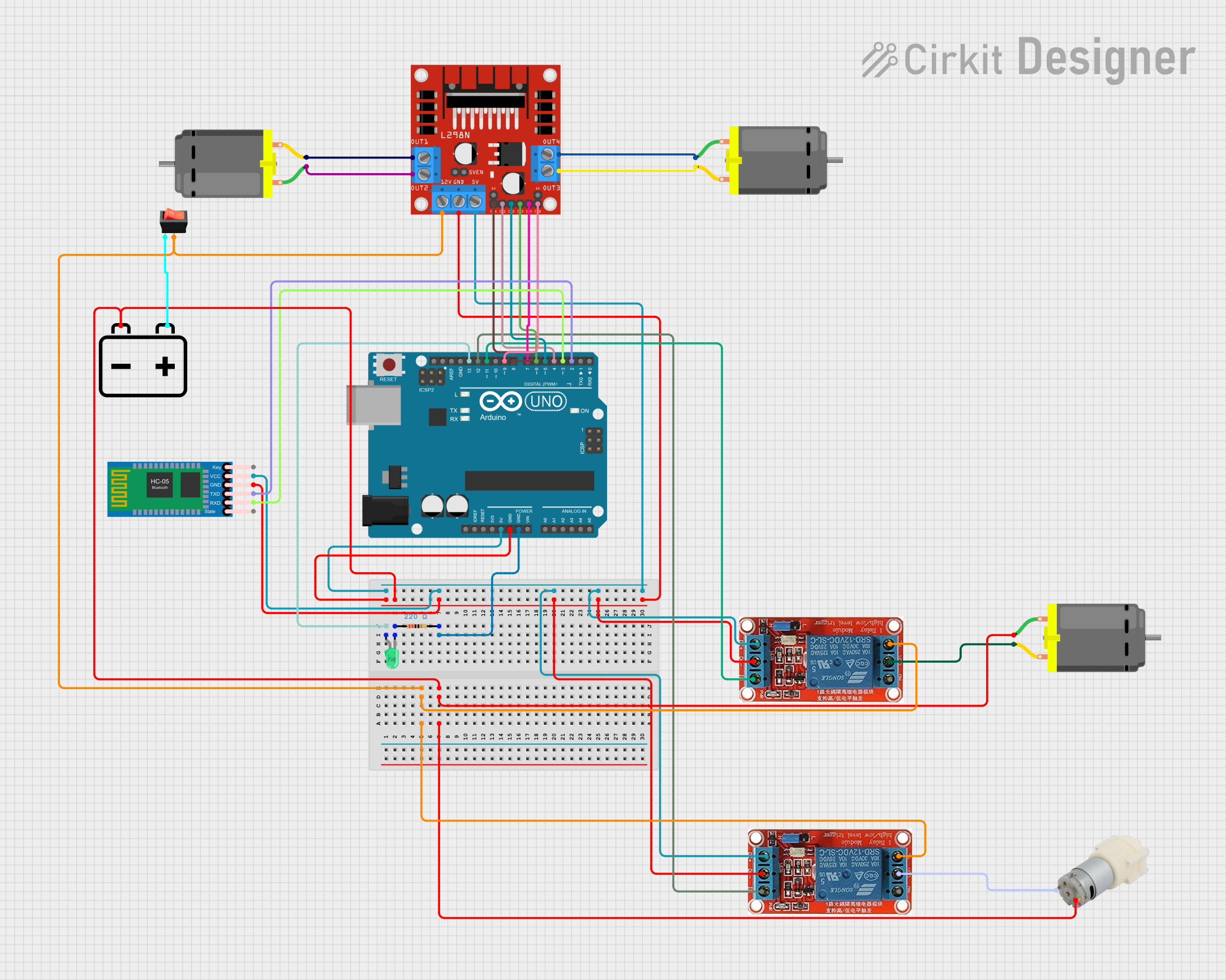

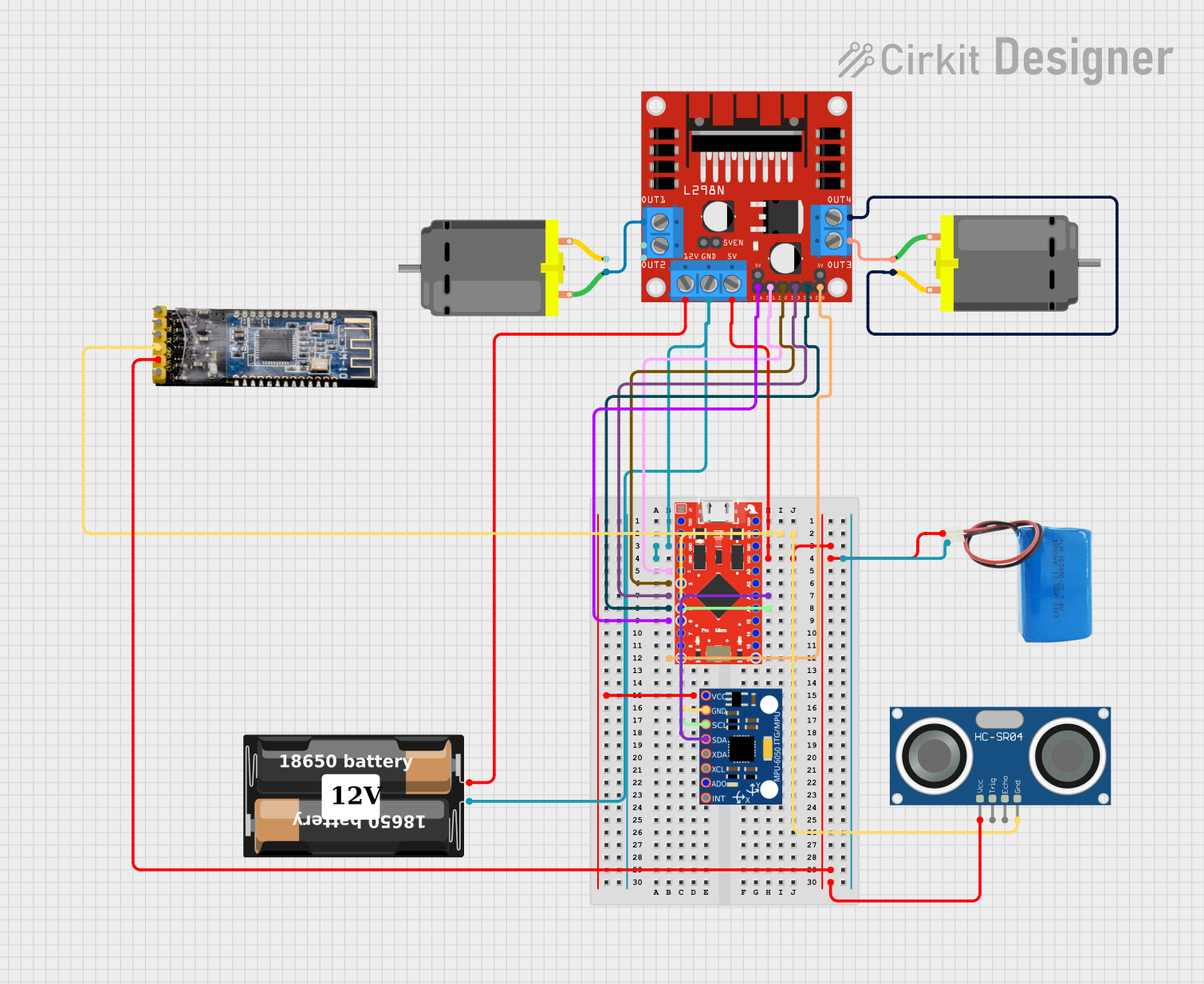

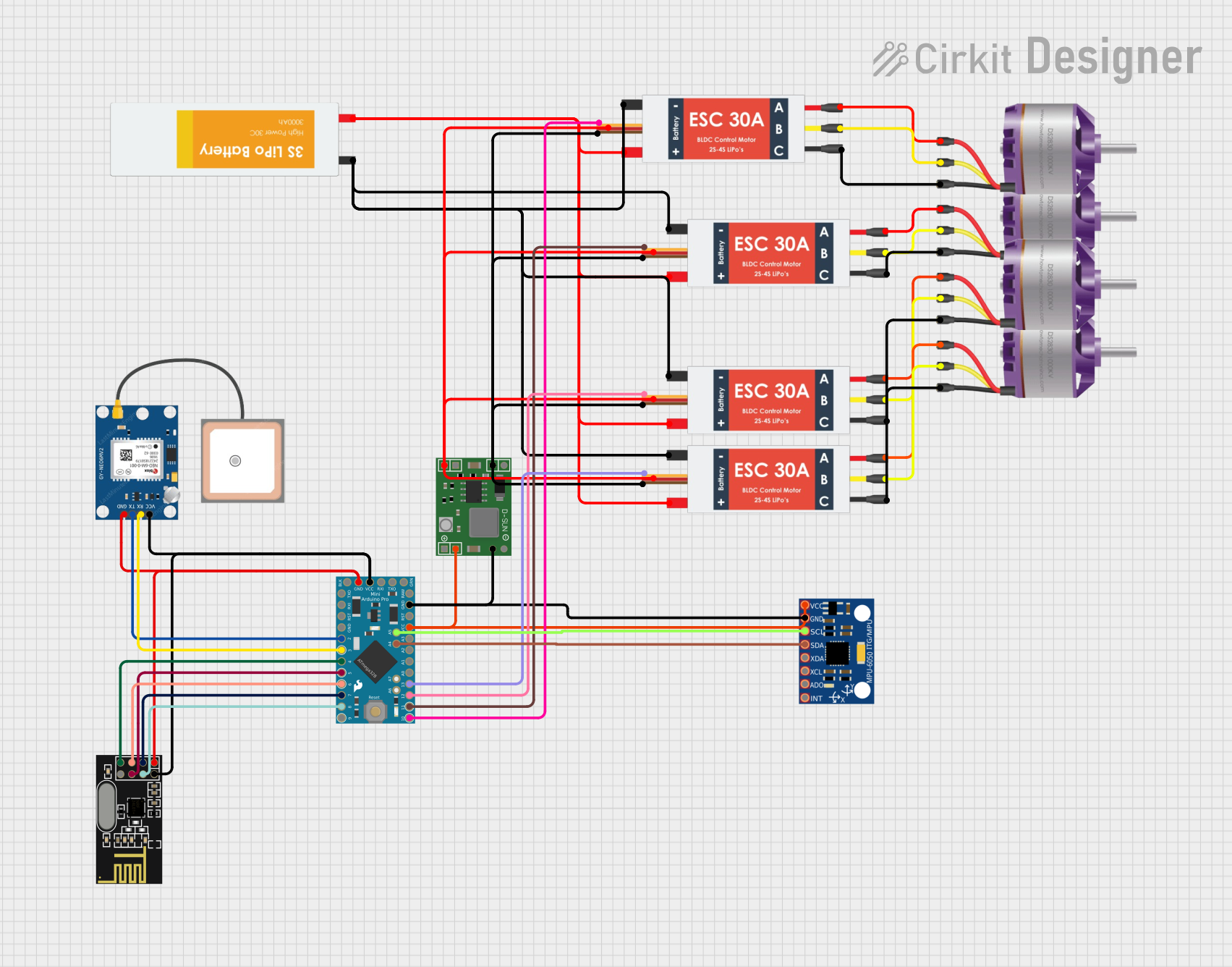

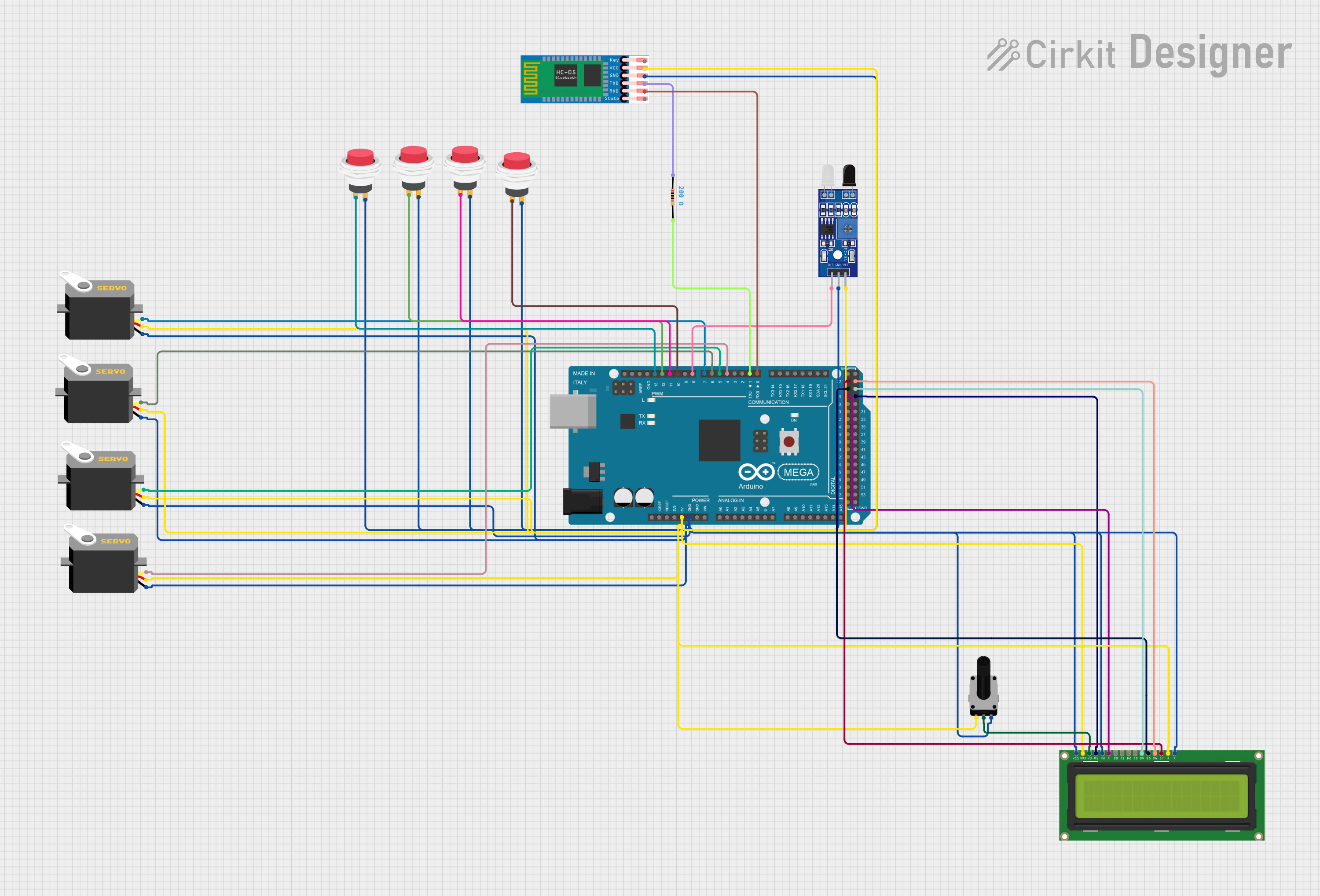

Explore Projects Built with Propeller Microcontroller

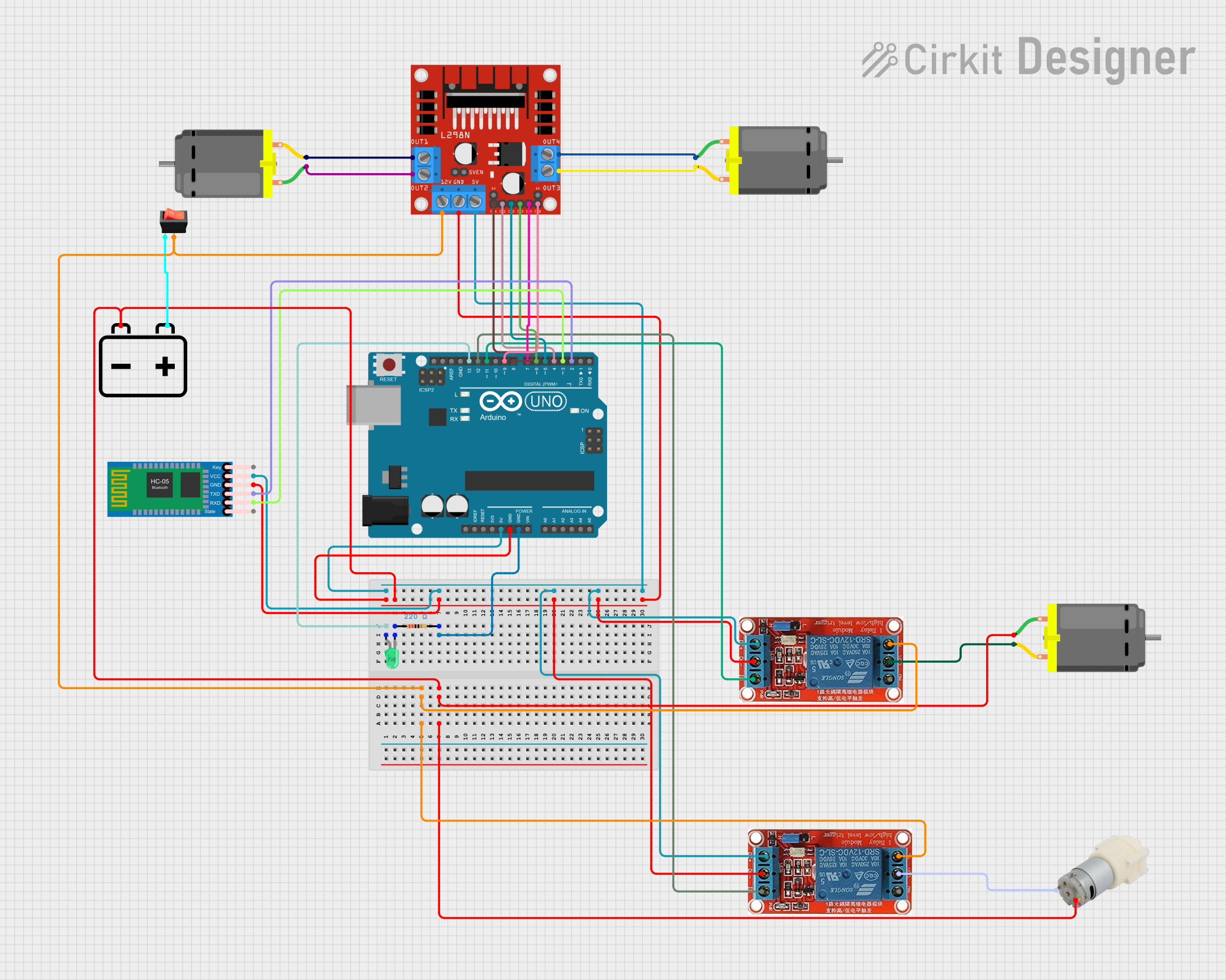

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

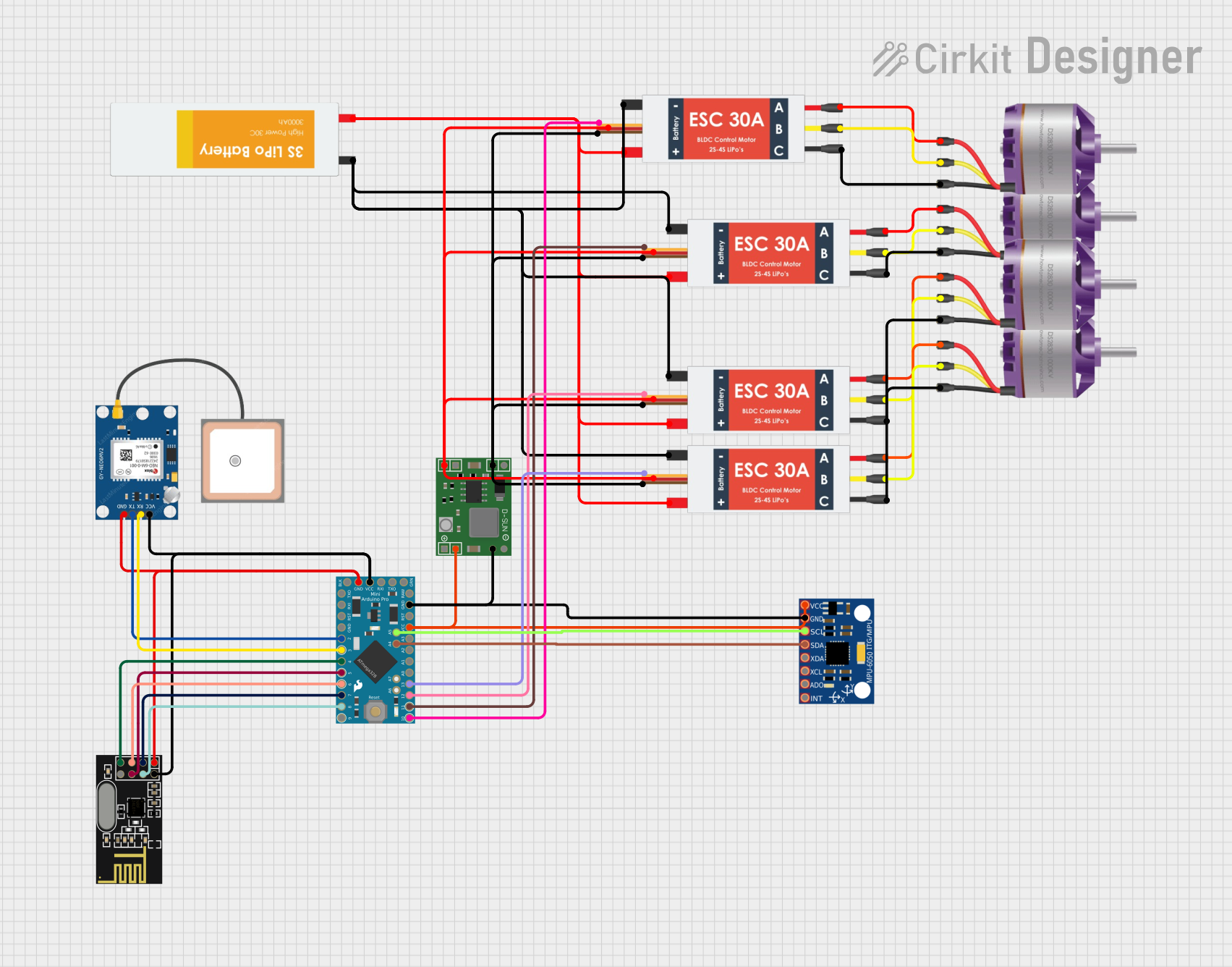

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit DesignerExplore Projects Built with Propeller Microcontroller

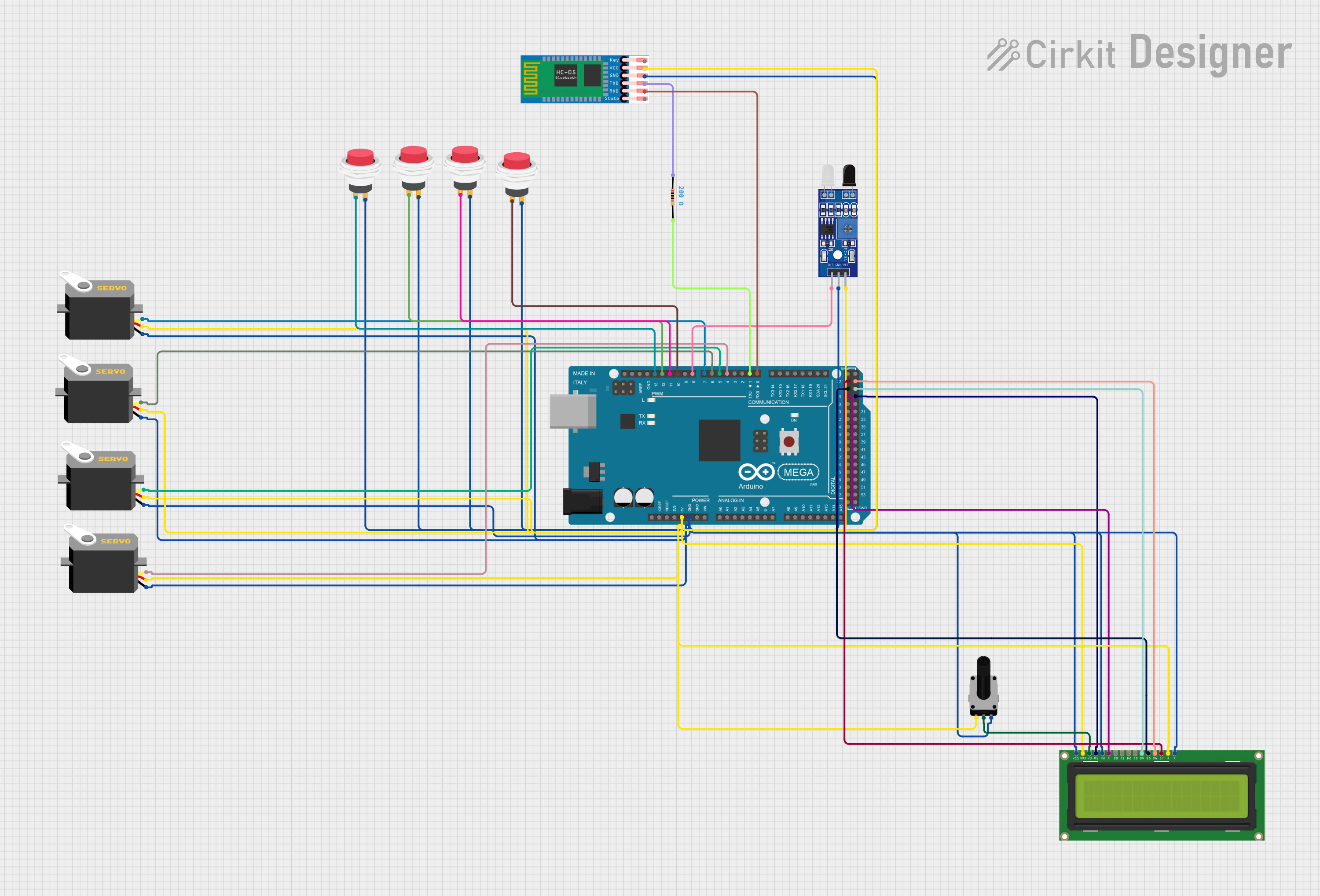

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit DesignerCommon Applications and Use Cases

- Robotics and automation systems

- Real-time signal processing

- Audio and video processing

- Industrial control systems

- Educational projects and prototyping

- Internet of Things (IoT) devices

Technical Specifications

The Propeller Microcontroller (PBX32A) is designed to deliver high performance and flexibility. Below are its key technical specifications:

General Specifications

| Parameter | Value |

|---|---|

| Manufacturer | Propeller |

| Part ID | PBX32A |

| Number of Cores | 8 |

| Clock Speed | Up to 80 MHz per core |

| Program Memory | 32 KB |

| RAM | 32 KB |

| Operating Voltage | 3.3 V |

| I/O Voltage | 3.3 V (5 V tolerant inputs) |

| GPIO Pins | 32 |

| Communication Protocols | UART, SPI, I2C |

| Power Consumption | ~80 mA (typical) |

| Package Type | QFP-44 |

Pin Configuration and Descriptions

The PBX32A microcontroller has 44 pins, with 32 general-purpose I/O (GPIO) pins. Below is the pin configuration:

| Pin Number | Pin Name | Description |

|---|---|---|

| 1-32 | P0-P31 | General-purpose I/O pins |

| 33 | VDD | Power supply (3.3 V) |

| 34 | VSS | Ground |

| 35 | RESn | Active-low reset pin |

| 36 | XI | Crystal oscillator input |

| 37 | XO | Crystal oscillator output |

| 38 | VIO | I/O voltage reference (3.3 V) |

| 39 | BOEn | EEPROM boot enable (active low) |

| 40 | TEST | Test pin (leave unconnected in normal use) |

| 41-44 | NC | Not connected |

Usage Instructions

The Propeller Microcontroller is designed for ease of use in a variety of applications. Below are the steps and best practices for using the PBX32A in a circuit.

How to Use the Component in a Circuit

- Power Supply: Connect the VDD pin to a 3.3 V power source and the VSS pin to ground. Ensure a stable power supply to avoid erratic behavior.

- Clock Source: Connect a crystal oscillator (e.g., 5 MHz) to the XI and XO pins. Alternatively, use an external clock signal on the XI pin.

- GPIO Configuration: Use the P0-P31 pins for input/output operations. Configure these pins in software as needed for your application.

- Communication: Use the UART, SPI, or I2C protocols for interfacing with other devices. Ensure proper pull-up resistors for I2C communication.

- Reset: Connect the RESn pin to a push-button or external reset circuit for manual resets.

Important Considerations and Best Practices

- Voltage Levels: Ensure all I/O signals are within the 3.3 V range. While inputs are 5 V tolerant, outputs are not.

- Decoupling Capacitors: Place decoupling capacitors (e.g., 0.1 µF) close to the VDD and VSS pins to filter noise.

- Boot Configuration: Use the BOEn pin to enable or disable booting from an external EEPROM.

- Programming: Use the Propeller Tool software to write and upload code to the microcontroller.

Example Code for Arduino UNO Integration

Although the Propeller Microcontroller is not directly programmable via Arduino IDE, it can communicate with an Arduino UNO using UART. Below is an example of how to send data from an Arduino UNO to the PBX32A:

// Arduino UNO code to send data to the Propeller Microcontroller via UART

void setup() {

Serial.begin(9600); // Initialize UART communication at 9600 baud

}

void loop() {

Serial.println("Hello, Propeller!"); // Send a message to the Propeller

delay(1000); // Wait for 1 second before sending the next message

}

On the Propeller side, you can use its UART library to receive and process the data.

Troubleshooting and FAQs

Common Issues and Solutions

Microcontroller Not Responding

- Cause: Incorrect power supply or missing decoupling capacitors.

- Solution: Verify the power supply is 3.3 V and add decoupling capacitors near the VDD and VSS pins.

Communication Failure

- Cause: Mismatched baud rates or incorrect wiring.

- Solution: Ensure the baud rate settings match on both devices and check the wiring.

GPIO Pins Not Functioning

- Cause: Pins not configured correctly in software.

- Solution: Double-check the pin configuration in your code.

Overheating

- Cause: Excessive current draw or short circuits.

- Solution: Check for short circuits and ensure the current draw is within the microcontroller's limits.

FAQs

Q: Can the PBX32A run multiple programs simultaneously?

A: Yes, the PBX32A has 8 cores, allowing it to run up to 8 independent threads simultaneously.

Q: Is the PBX32A compatible with 5 V logic?

A: The GPIO inputs are 5 V tolerant, but outputs operate at 3.3 V. Use level shifters if needed.

Q: What software is used to program the PBX32A?

A: The Propeller Tool software is the official IDE for programming the PBX32A.

Q: Can I use the PBX32A without an external crystal oscillator?

A: Yes, the PBX32A has an internal RC oscillator, but using an external crystal provides better timing accuracy.