How to Use IBT4 Motor Driver: Examples, Pinouts, and Specs

Design with IBT4 Motor Driver in Cirkit Designer

Design with IBT4 Motor Driver in Cirkit DesignerIntroduction

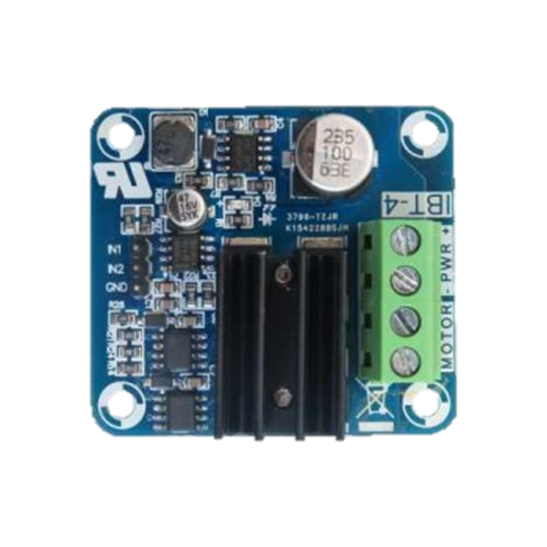

The IBT4 Motor Driver by Satisgy Electronic (Part ID: IBT-4) is a high-power motor driver module designed to control DC motors with a high current capacity. This component is widely used in robotics and automation projects to drive motors efficiently and safely. Its robust design and high current handling capabilities make it an ideal choice for applications requiring reliable motor control.

Explore Projects Built with IBT4 Motor Driver

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit DesignerExplore Projects Built with IBT4 Motor Driver

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit DesignerCommon Applications and Use Cases

- Robotics: Driving motors in robotic arms, mobile robots, and other robotic systems.

- Automation: Controlling conveyor belts, automated gates, and other automated machinery.

- Electric Vehicles: Managing the motors in electric scooters, bikes, and small electric vehicles.

- DIY Projects: Ideal for hobbyists and makers building custom motor-driven projects.

Technical Specifications

Key Technical Details

| Parameter | Value |

|---|---|

| Operating Voltage | 6V to 27V |

| Continuous Current | 43A |

| Peak Current | 100A |

| PWM Frequency | Up to 20kHz |

| Control Logic | TTL (3.3V or 5V compatible) |

| Dimensions | 60mm x 55mm x 30mm |

| Weight | 50g |

Pin Configuration and Descriptions

| Pin No. | Pin Name | Description |

|---|---|---|

| 1 | VCC | Power supply input (6V to 27V) |

| 2 | GND | Ground |

| 3 | IN1 | Control input 1 (PWM signal or logic high/low) |

| 4 | IN2 | Control input 2 (PWM signal or logic high/low) |

| 5 | EN | Enable pin (active high) |

| 6 | OUT1 | Motor output 1 |

| 7 | OUT2 | Motor output 2 |

| 8 | VCC | Power supply input (6V to 27V) |

| 9 | GND | Ground |

Usage Instructions

How to Use the Component in a Circuit

Power Supply:

- Connect the VCC pins (1 and 8) to the positive terminal of your power supply (6V to 27V).

- Connect the GND pins (2 and 9) to the ground terminal of your power supply.

Motor Connections:

- Connect the motor terminals to the OUT1 (6) and OUT2 (7) pins.

Control Inputs:

- Connect the IN1 (3) and IN2 (4) pins to your microcontroller or control circuit. These pins will receive PWM signals or logic high/low signals to control the motor direction and speed.

- Connect the EN (5) pin to a digital output pin on your microcontroller. Set this pin high to enable the motor driver.

Important Considerations and Best Practices

- Heat Dissipation: Ensure proper heat dissipation by using a heat sink or cooling fan if the motor driver is operating at high currents for extended periods.

- Power Supply: Use a power supply that can provide sufficient current for your motor to avoid voltage drops and potential damage to the motor driver.

- PWM Frequency: Use a PWM frequency up to 20kHz for smooth motor control. Higher frequencies may cause excessive heating.

- Safety: Always double-check connections before powering up the circuit to prevent short circuits and damage to the components.

Example Code for Arduino UNO

Below is an example code to control a DC motor using the IBT4 Motor Driver with an Arduino UNO:

// Define pin connections

const int EN_PIN = 9; // Enable pin

const int IN1_PIN = 10; // Control input 1

const int IN2_PIN = 11; // Control input 2

void setup() {

// Set pin modes

pinMode(EN_PIN, OUTPUT);

pinMode(IN1_PIN, OUTPUT);

pinMode(IN2_PIN, OUTPUT);

// Enable the motor driver

digitalWrite(EN_PIN, HIGH);

}

void loop() {

// Rotate motor in one direction

digitalWrite(IN1_PIN, HIGH);

digitalWrite(IN2_PIN, LOW);

delay(2000); // Run for 2 seconds

// Stop the motor

digitalWrite(IN1_PIN, LOW);

digitalWrite(IN2_PIN, LOW);

delay(1000); // Stop for 1 second

// Rotate motor in the opposite direction

digitalWrite(IN1_PIN, LOW);

digitalWrite(IN2_PIN, HIGH);

delay(2000); // Run for 2 seconds

// Stop the motor

digitalWrite(IN1_PIN, LOW);

digitalWrite(IN2_PIN, LOW);

delay(1000); // Stop for 1 second

}

Troubleshooting and FAQs

Common Issues Users Might Face

Motor Not Running:

- Check Connections: Ensure all connections are secure and correct.

- Power Supply: Verify that the power supply is providing the correct voltage and current.

- Enable Pin: Ensure the EN pin is set high to enable the motor driver.

Motor Running in One Direction Only:

- Control Signals: Check the control signals on IN1 and IN2. Ensure they are receiving the correct logic levels or PWM signals.

Overheating:

- Heat Dissipation: Ensure proper heat dissipation with a heat sink or cooling fan.

- Current Rating: Verify that the motor current does not exceed the continuous current rating of the driver.

Solutions and Tips for Troubleshooting

- Double-Check Wiring: Always double-check your wiring and connections before powering up the circuit.

- Use a Multimeter: Use a multimeter to check voltage levels and continuity in the circuit.

- Consult Datasheets: Refer to the datasheet of the IBT4 Motor Driver for detailed technical information and specifications.

By following this documentation, users can effectively utilize the IBT4 Motor Driver in their projects, ensuring reliable and efficient motor control.