How to Use Servo Plug: Examples, Pinouts, and Specs

Design with Servo Plug in Cirkit Designer

Design with Servo Plug in Cirkit DesignerIntroduction

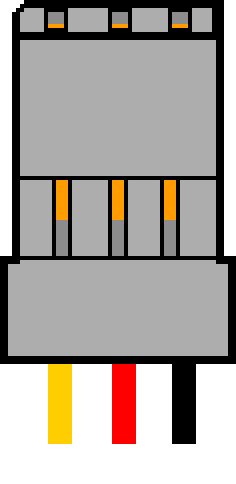

The Servo Plug is a connector used to interface servos with a power source or control system. It is commonly found in remote-controlled (RC) vehicles, robotics, and various automation projects. The plug typically consists of three pins: power, ground, and signal, which are essential for controlling the servo motor's position.

Explore Projects Built with Servo Plug

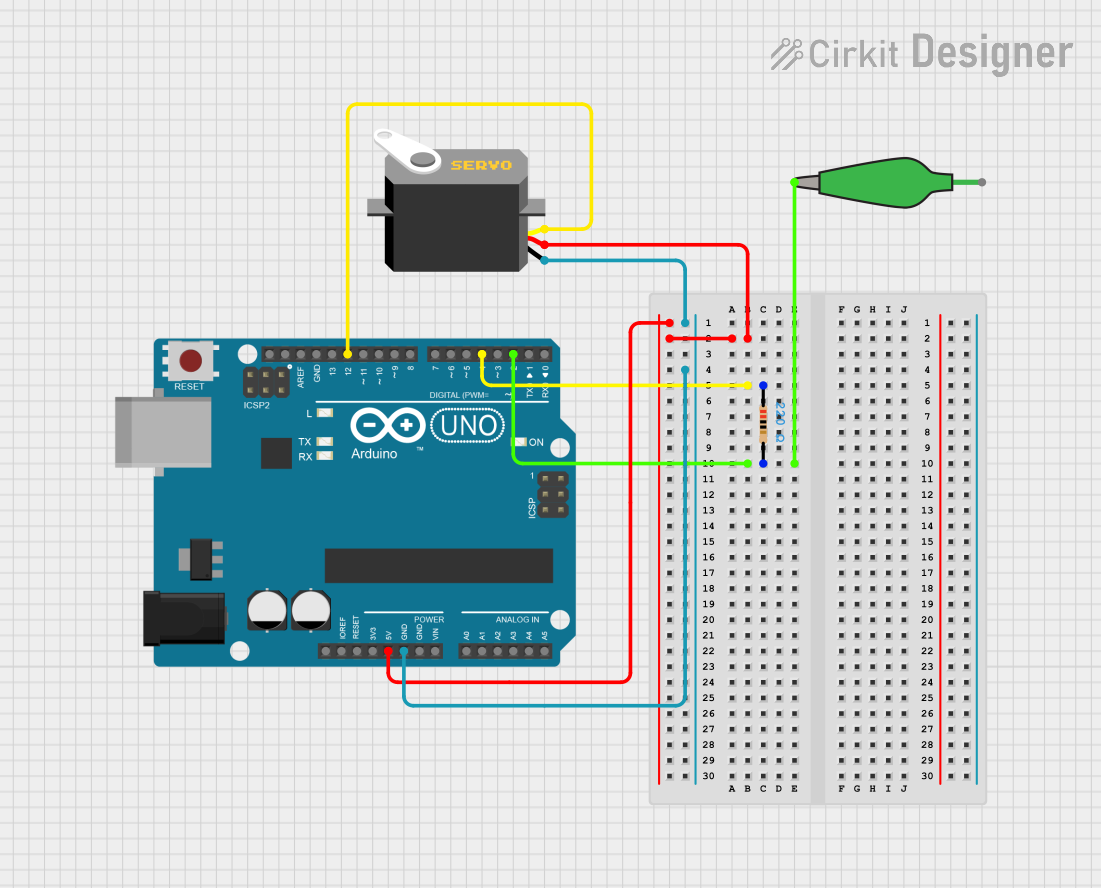

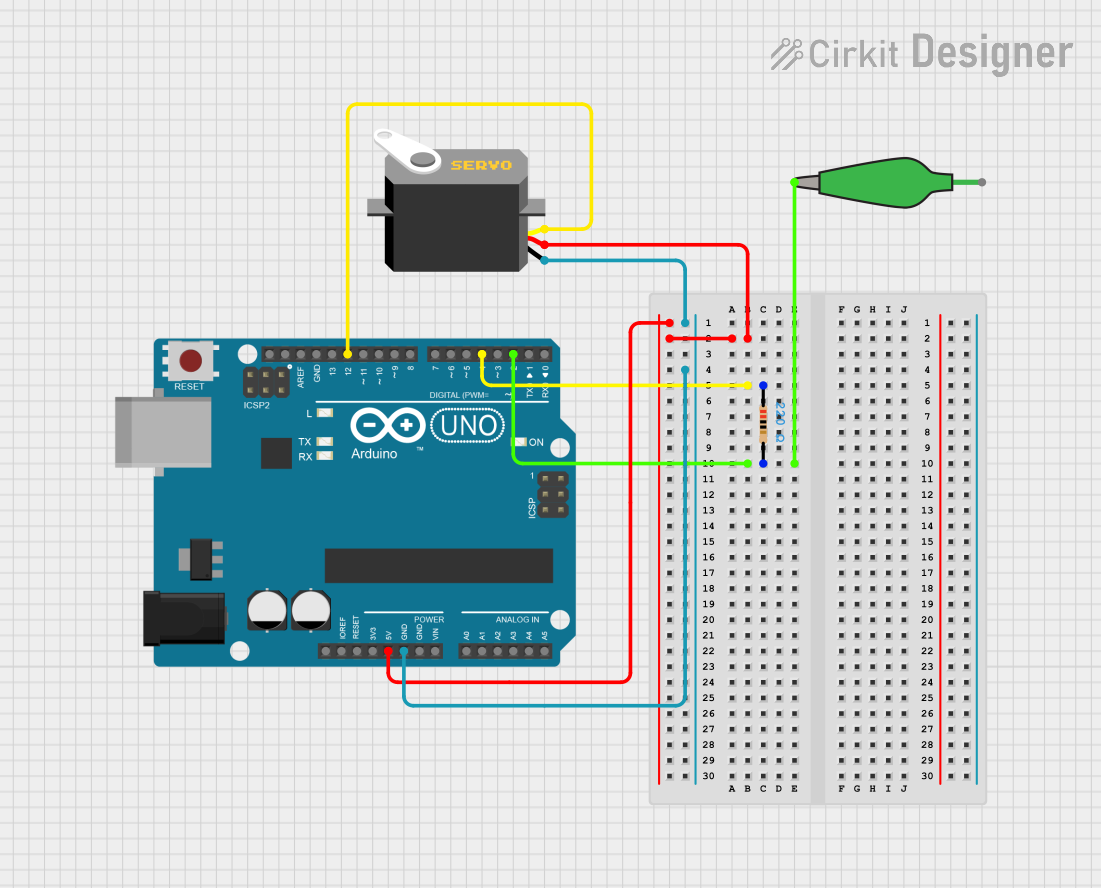

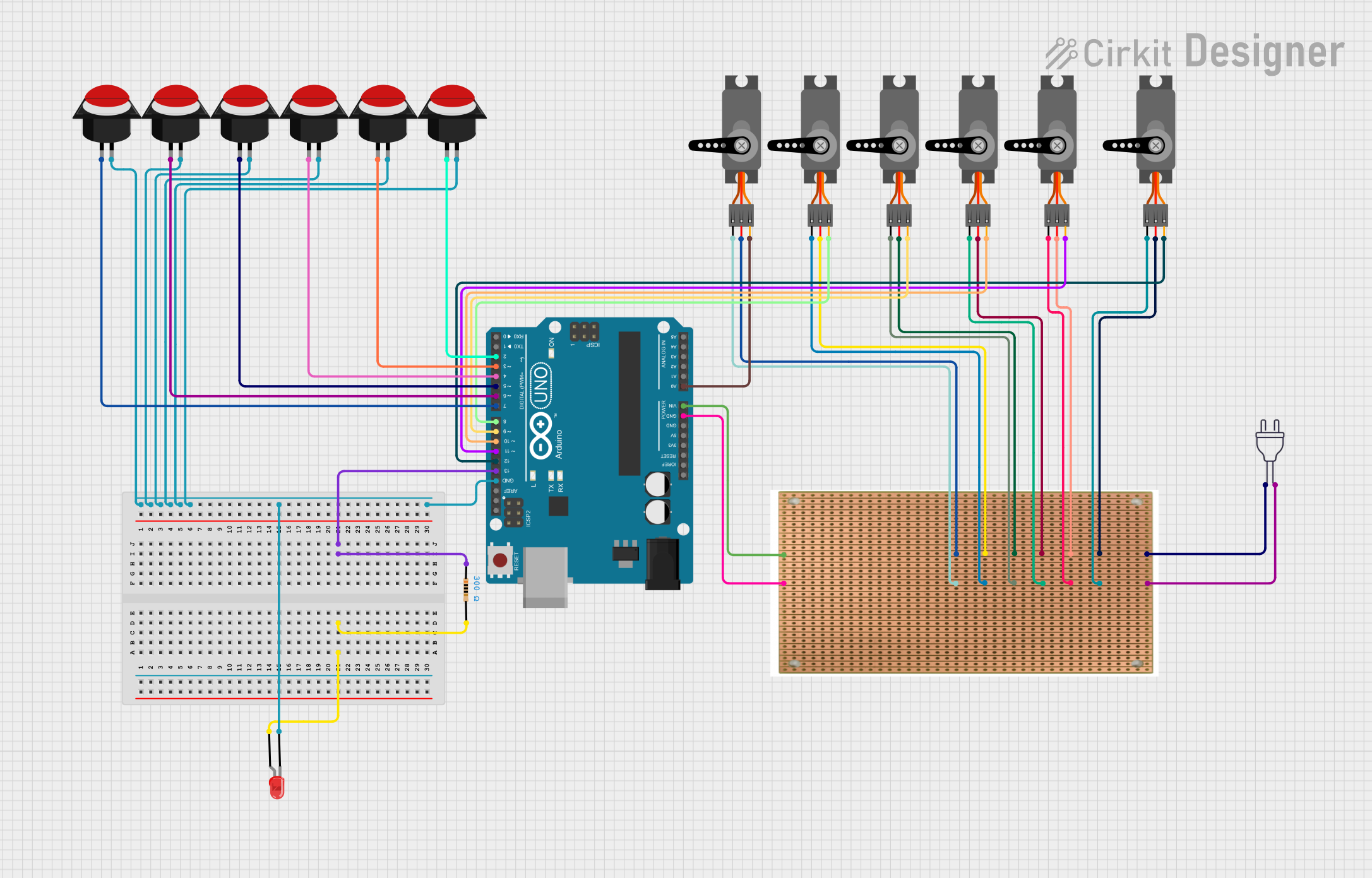

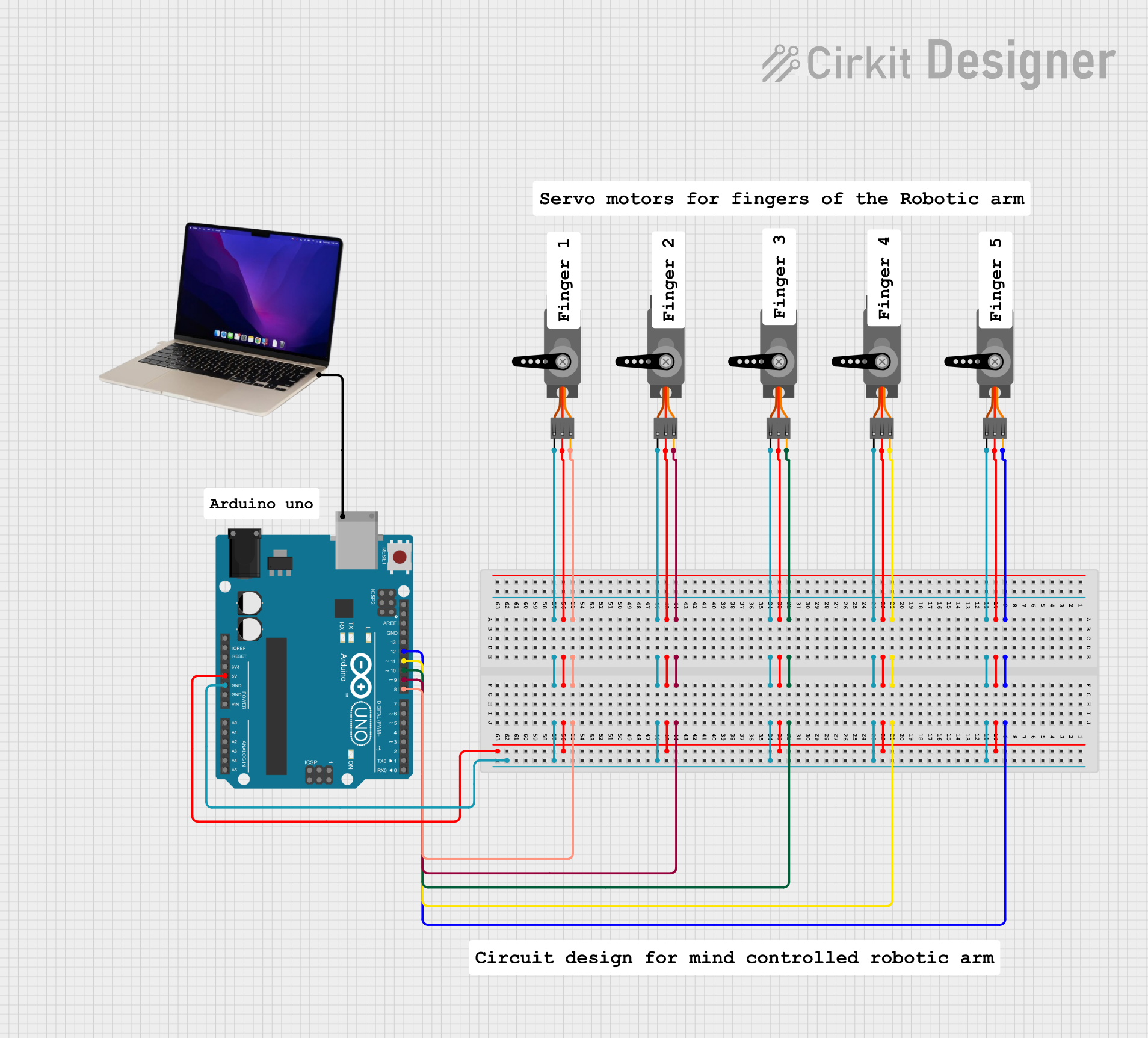

Open Project in Cirkit Designer

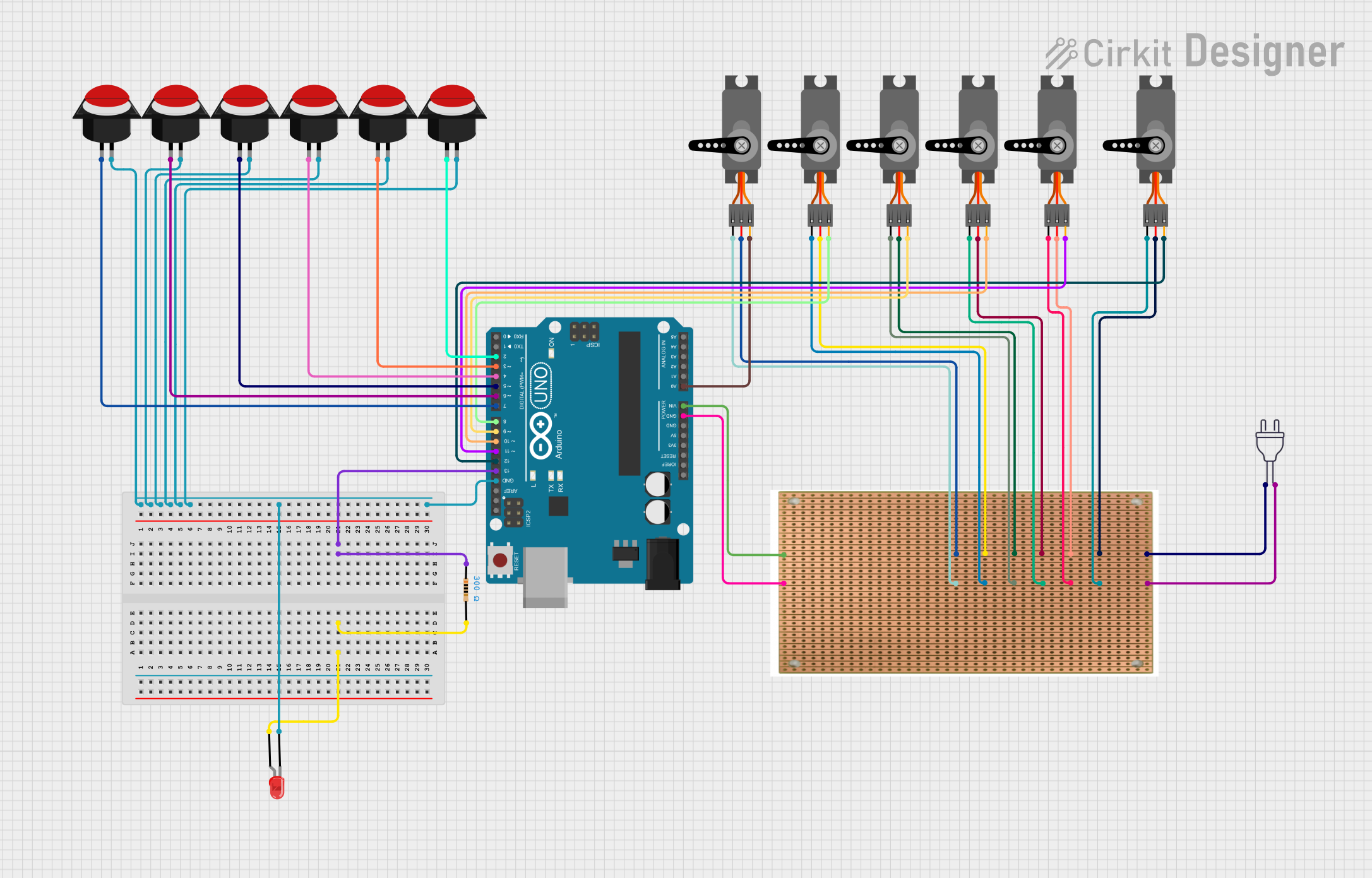

Open Project in Cirkit Designer

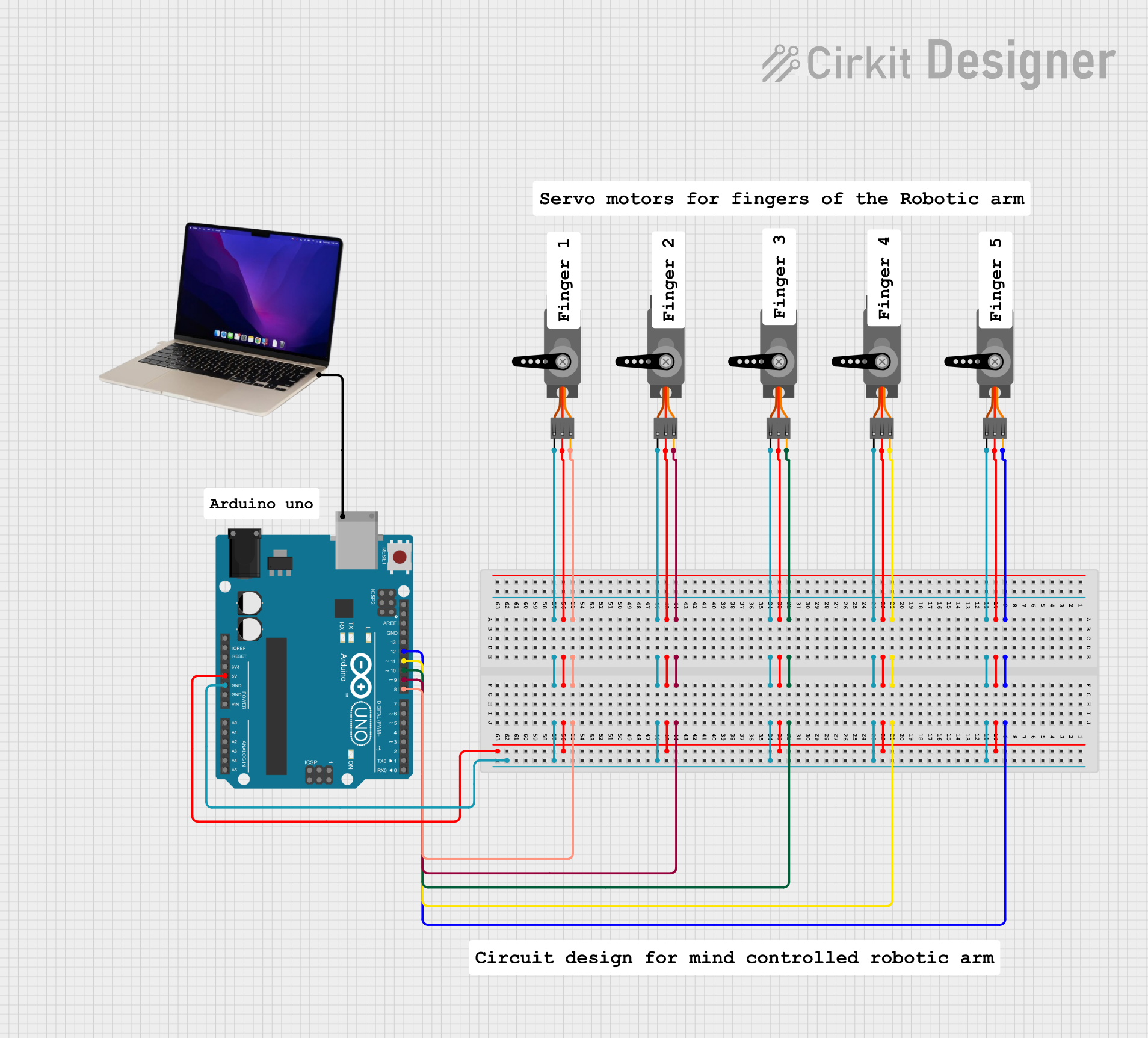

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit DesignerExplore Projects Built with Servo Plug

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit DesignerTechnical Specifications

Key Technical Details

| Parameter | Value |

|---|---|

| Voltage Rating | 4.8V to 6.0V |

| Current Rating | Up to 3A |

| Pin Count | 3 |

| Connector Type | Male/Female |

| Wire Gauge | 22 AWG |

| Insulation Type | PVC |

Pin Configuration and Descriptions

| Pin Number | Pin Name | Description |

|---|---|---|

| 1 | Signal | PWM signal for controlling the servo |

| 2 | VCC | Power supply (4.8V to 6.0V) |

| 3 | GND | Ground |

Usage Instructions

How to Use the Servo Plug in a Circuit

- Identify the Pins: Ensure you correctly identify the signal, VCC, and GND pins on the servo plug.

- Connect to Power Source: Connect the VCC pin to a power source that provides 4.8V to 6.0V.

- Connect to Ground: Connect the GND pin to the ground of your power source.

- Connect to Control System: Connect the Signal pin to the PWM output of your control system (e.g., Arduino).

Important Considerations and Best Practices

- Voltage Compatibility: Ensure the power supply voltage is within the specified range (4.8V to 6.0V) to avoid damaging the servo.

- Current Capacity: Use wires with appropriate current ratings (22 AWG recommended) to handle the servo's current draw.

- Secure Connections: Ensure all connections are secure to prevent intermittent operation or disconnection during use.

- Avoid Overloading: Do not exceed the current rating of the servo plug to prevent overheating and potential failure.

Example: Connecting a Servo to an Arduino UNO

#include <Servo.h> // Include the Servo library

Servo myServo; // Create a Servo object

void setup() {

myServo.attach(9); // Attach the servo to pin 9 on the Arduino

}

void loop() {

myServo.write(90); // Set the servo to the 90-degree position

delay(1000); // Wait for 1 second

myServo.write(0); // Set the servo to the 0-degree position

delay(1000); // Wait for 1 second

}

Troubleshooting and FAQs

Common Issues and Solutions

Servo Not Moving:

- Check Connections: Ensure all connections (signal, VCC, GND) are secure and correctly oriented.

- Verify Power Supply: Ensure the power supply voltage is within the specified range (4.8V to 6.0V).

Intermittent Operation:

- Inspect Wiring: Check for loose or frayed wires that might cause intermittent connections.

- Check Power Source: Ensure the power source can supply sufficient current for the servo.

Servo Jittering:

- Signal Quality: Ensure the PWM signal is stable and within the correct frequency range.

- Power Stability: Use a capacitor across the power supply to filter out noise and stabilize the voltage.

FAQs

Q1: Can I use a higher voltage power supply with the servo plug?

- A1: No, using a higher voltage than specified (4.8V to 6.0V) can damage the servo motor.

Q2: What type of wire should I use with the servo plug?

- A2: It is recommended to use 22 AWG wire for optimal current handling and flexibility.

Q3: Can I connect multiple servos to a single power source?

- A3: Yes, but ensure the power source can supply sufficient current for all connected servos.

Q4: How do I know if my servo is receiving the correct PWM signal?

- A4: Use an oscilloscope to verify the PWM signal's frequency and duty cycle match the servo's requirements.

By following this documentation, users can effectively utilize the Servo Plug in their projects, ensuring reliable and efficient operation of their servo motors.