How to Use IR2110: Examples, Pinouts, and Specs

Design with IR2110 in Cirkit Designer

Design with IR2110 in Cirkit DesignerIntroduction

The IR2110, manufactured by Infineon Technologies AG (Part ID: INFINEON), is a high-voltage, high-speed power MOSFET and IGBT driver. It features independent high-side and low-side output channels, making it ideal for driving the gates of power transistors in half-bridge and full-bridge configurations. The IR2110 provides level shifting and isolation, ensuring efficient and reliable switching in power electronics applications.

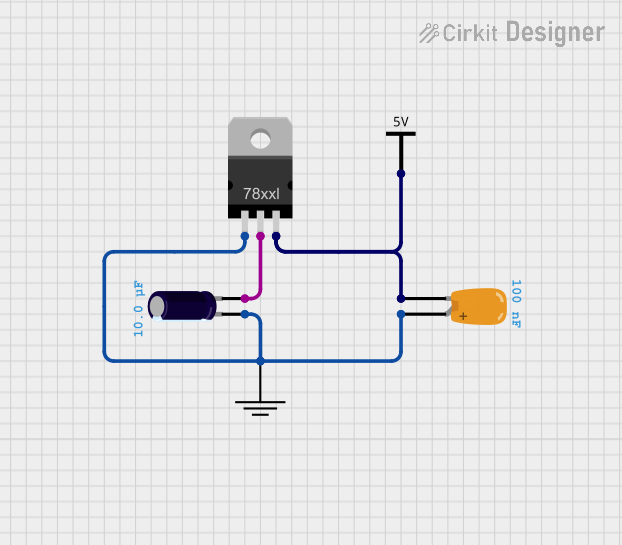

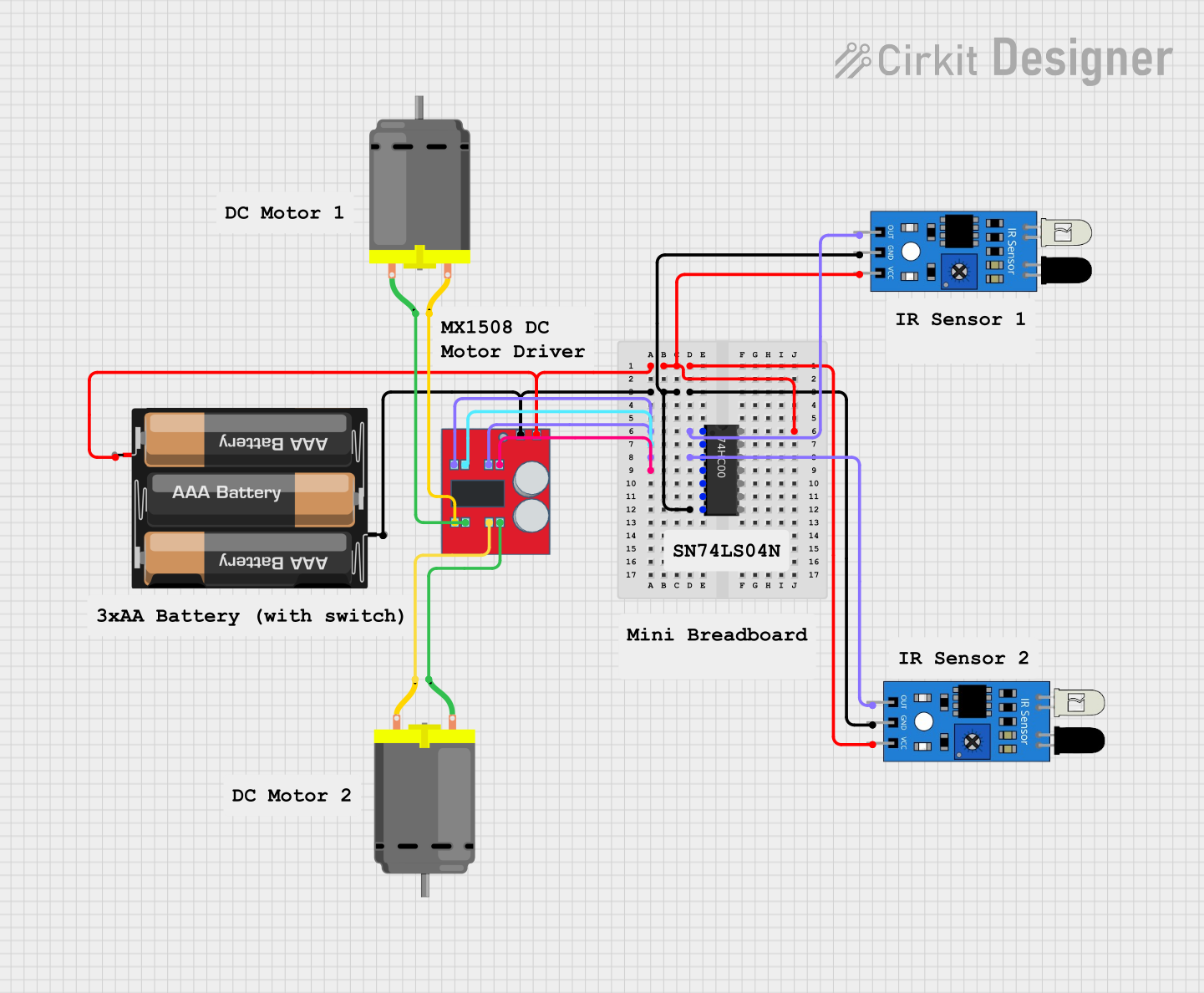

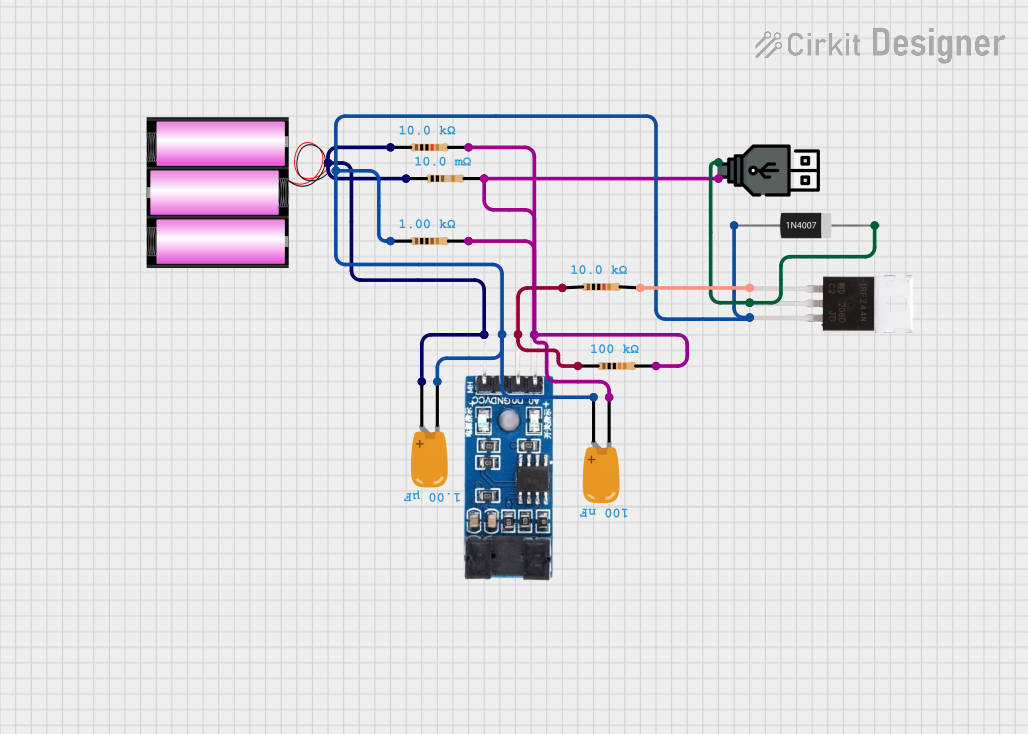

Explore Projects Built with IR2110

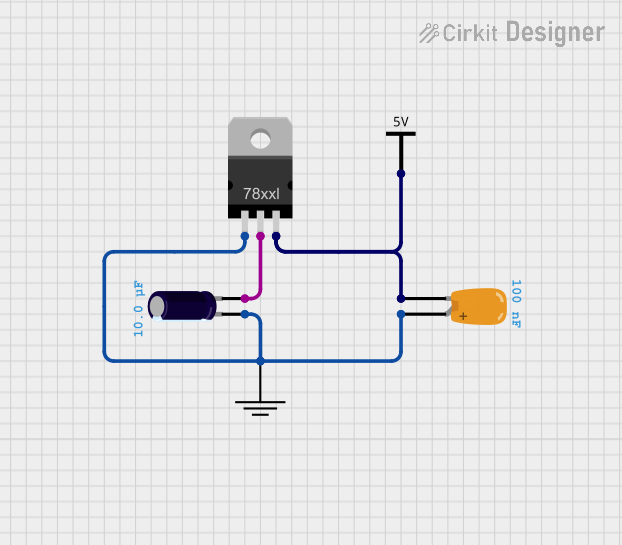

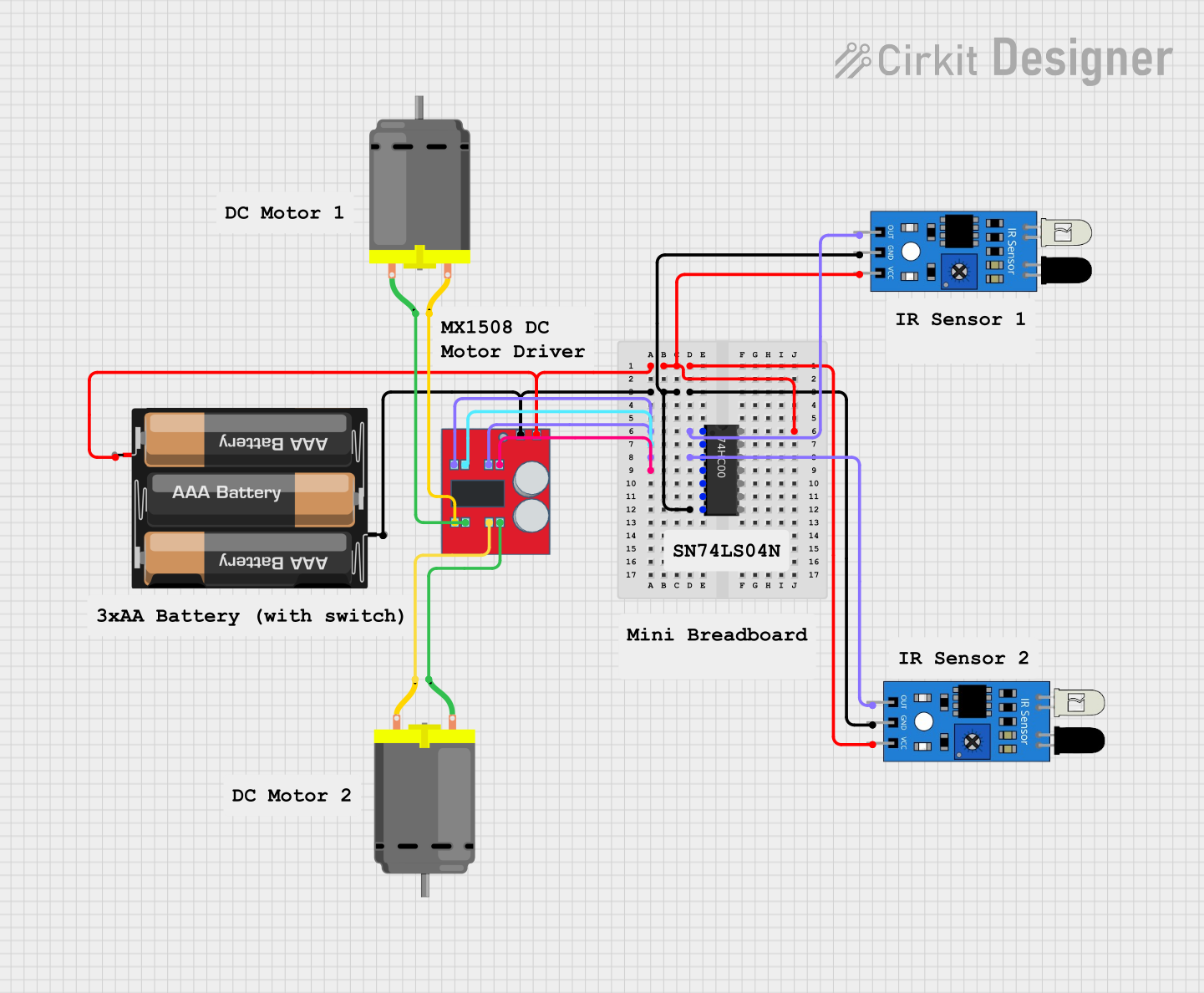

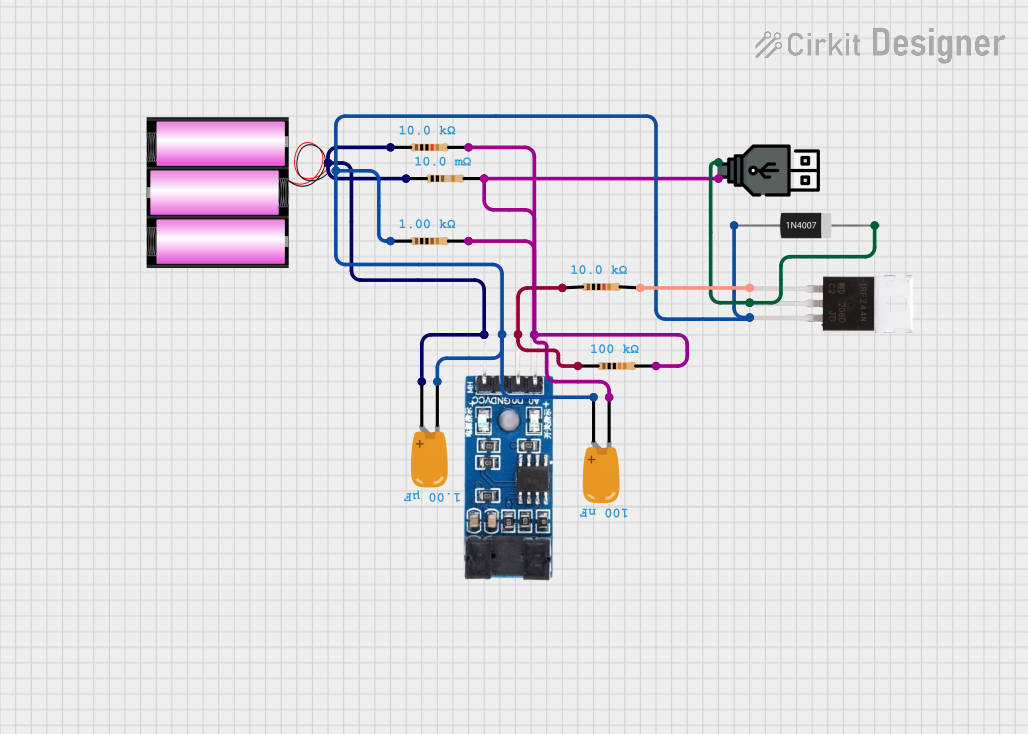

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit DesignerExplore Projects Built with IR2110

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit DesignerCommon Applications

- DC-DC converters

- Motor control systems

- Inverters for renewable energy systems (e.g., solar inverters)

- Uninterruptible Power Supplies (UPS)

- High-frequency switching power supplies

Technical Specifications

Key Technical Details

| Parameter | Value |

|---|---|

| Supply Voltage (Vcc) | 10V to 20V |

| High-Side Floating Supply Voltage (Vb) | Up to 600V |

| Output Current (Peak) | 2A (source), 2A (sink) |

| Gate Drive Voltage | 10V to 20V |

| Propagation Delay (typical) | 120 ns |

| Operating Temperature Range | -40°C to +125°C |

| Package Options | DIP-14, SOIC-14 |

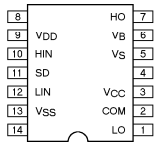

Pin Configuration and Descriptions

The IR2110 is available in a 14-pin package. Below is the pinout and description:

| Pin No. | Pin Name | Description |

|---|---|---|

| 1 | Vcc | Logic supply voltage (10V to 20V). |

| 2 | HIN | Logic input for high-side gate driver. Active high. |

| 3 | LIN | Logic input for low-side gate driver. Active high. |

| 4 | COM | Logic ground. |

| 5 | VSS | Low-side return. |

| 6 | LO | Low-side gate drive output. |

| 7 | VS | High-side floating supply return. |

| 8 | HO | High-side gate drive output. |

| 9 | VB | High-side floating supply voltage. |

| 10-14 | NC | Not connected (varies by package). |

Usage Instructions

How to Use the IR2110 in a Circuit

Power Supply Configuration:

- Connect the Vcc pin to a stable 10V-20V supply.

- Use a bootstrap capacitor between VB and VS to provide the high-side floating supply voltage.

Input Signals:

- Provide logic-level signals (e.g., from a microcontroller) to the HIN and LIN pins to control the high-side and low-side drivers, respectively.

- Ensure proper dead-time between HIN and LIN signals to avoid shoot-through.

Gate Drive Outputs:

- Connect the HO pin to the gate of the high-side MOSFET/IGBT and the LO pin to the gate of the low-side MOSFET/IGBT.

- Use appropriate gate resistors to limit inrush current and control switching speed.

Bootstrap Capacitor:

- Select a bootstrap capacitor (typically 0.1 µF to 1 µF) based on the gate charge of the high-side MOSFET/IGBT.

Grounding:

- Connect the COM pin to the logic ground and the VSS pin to the low-side return.

Important Considerations and Best Practices

- Dead-Time Management: Ensure sufficient dead-time between high-side and low-side switching to prevent shoot-through.

- Bootstrap Capacitor Sizing: Choose a capacitor with low ESR and sufficient capacitance to maintain the high-side supply voltage during switching.

- Thermal Management: Ensure proper heat dissipation, especially in high-frequency or high-current applications.

- Input Signal Integrity: Use clean, noise-free logic signals to drive the HIN and LIN pins.

Example: Using IR2110 with Arduino UNO

Below is an example of how to control the IR2110 using an Arduino UNO to drive a half-bridge circuit:

// Example: Controlling IR2110 with Arduino UNO

// This code generates complementary PWM signals with dead-time for a half-bridge circuit.

const int HIN_PIN = 9; // High-side input connected to Arduino pin 9

const int LIN_PIN = 10; // Low-side input connected to Arduino pin 10

void setup() {

pinMode(HIN_PIN, OUTPUT); // Set HIN pin as output

pinMode(LIN_PIN, OUTPUT); // Set LIN pin as output

}

void loop() {

digitalWrite(HIN_PIN, HIGH); // Turn on high-side MOSFET

digitalWrite(LIN_PIN, LOW); // Ensure low-side MOSFET is off

delayMicroseconds(10); // Dead-time (adjust as needed)

digitalWrite(HIN_PIN, LOW); // Turn off high-side MOSFET

digitalWrite(LIN_PIN, HIGH); // Turn on low-side MOSFET

delayMicroseconds(10); // Dead-time (adjust as needed)

}

Troubleshooting and FAQs

Common Issues and Solutions

High-Side Driver Not Working:

- Check the bootstrap capacitor connection and ensure it is properly sized.

- Verify that the VB pin voltage is sufficiently higher than the VS pin voltage.

Excessive Heat:

- Ensure proper dead-time between high-side and low-side switching.

- Use appropriate gate resistors to limit switching losses.

No Output Signal:

- Verify the input signals (HIN and LIN) are within the logic voltage range.

- Check the Vcc supply voltage and ensure it is stable.

Shoot-Through in MOSFETs:

- Increase the dead-time between HIN and LIN signals.

- Verify the gate drive signals with an oscilloscope.

FAQs

Q1: Can the IR2110 drive both N-channel and P-channel MOSFETs?

A1: The IR2110 is designed to drive N-channel MOSFETs or IGBTs in half-bridge or full-bridge configurations. It is not suitable for P-channel MOSFETs.

Q2: What is the maximum switching frequency of the IR2110?

A2: The maximum switching frequency depends on the load capacitance and gate charge of the MOSFET/IGBT. Typically, it can operate up to several hundred kHz.

Q3: How do I calculate the bootstrap capacitor value?

A3: The bootstrap capacitor value can be calculated using the formula:

[

C_{boot} \geq \frac{Q_g}{\Delta V}

]

Where ( Q_g ) is the total gate charge of the high-side MOSFET/IGBT, and ( \Delta V ) is the allowable voltage drop across the capacitor.

Q4: Can I use the IR2110 for three-phase motor control?

A4: Yes, the IR2110 can be used in three-phase motor control applications by using three IR2110 drivers to control the six MOSFETs/IGBTs in the inverter.

This concludes the documentation for the IR2110.