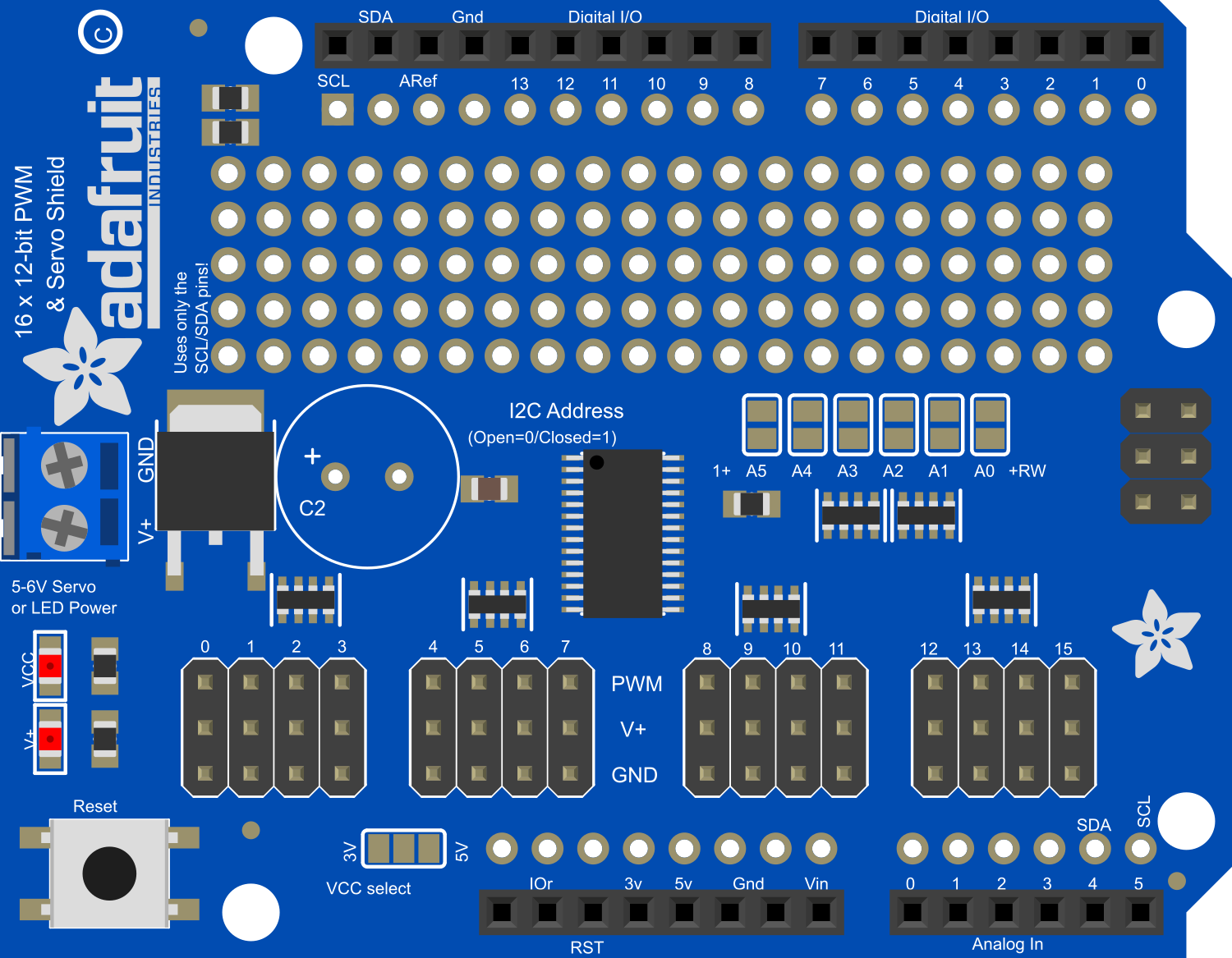

How to Use Adafruit 16-Channel 12-bit PWM Servo Shield - I2C: Examples, Pinouts, and Specs

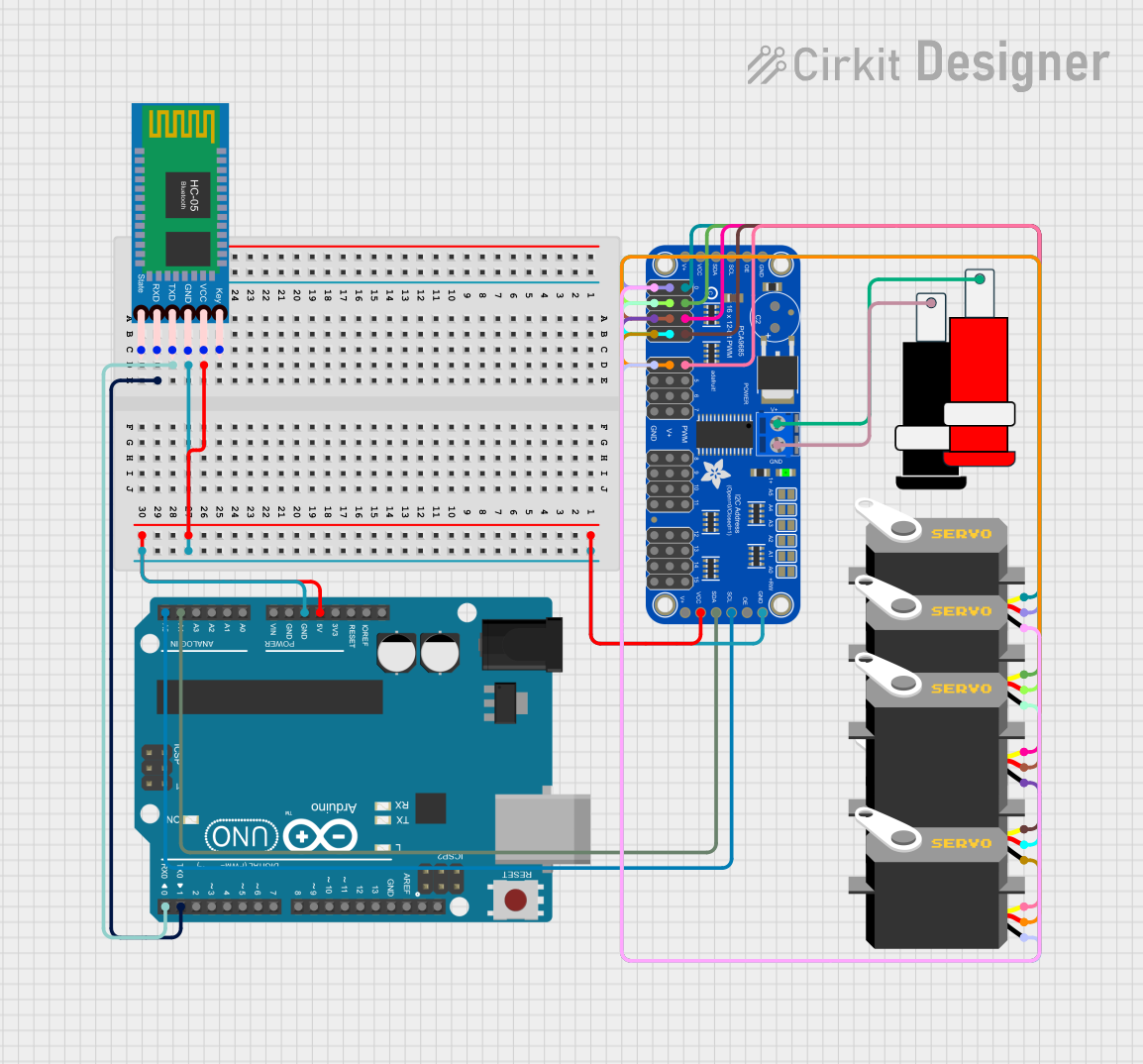

Design with Adafruit 16-Channel 12-bit PWM Servo Shield - I2C in Cirkit Designer

Design with Adafruit 16-Channel 12-bit PWM Servo Shield - I2C in Cirkit DesignerIntroduction

The Adafruit 16-Channel 12-bit PWM Servo Shield is an essential tool for hobbyists and engineers who need to control multiple servos simultaneously. This shield is designed to stack onto an Arduino UNO or similar microcontroller boards, providing an easy-to-use interface for controlling up to 16 servos with high precision thanks to its 12-bit resolution. Common applications include robotics, animatronics, custom RC vehicles, and any project requiring multiple servo controls.

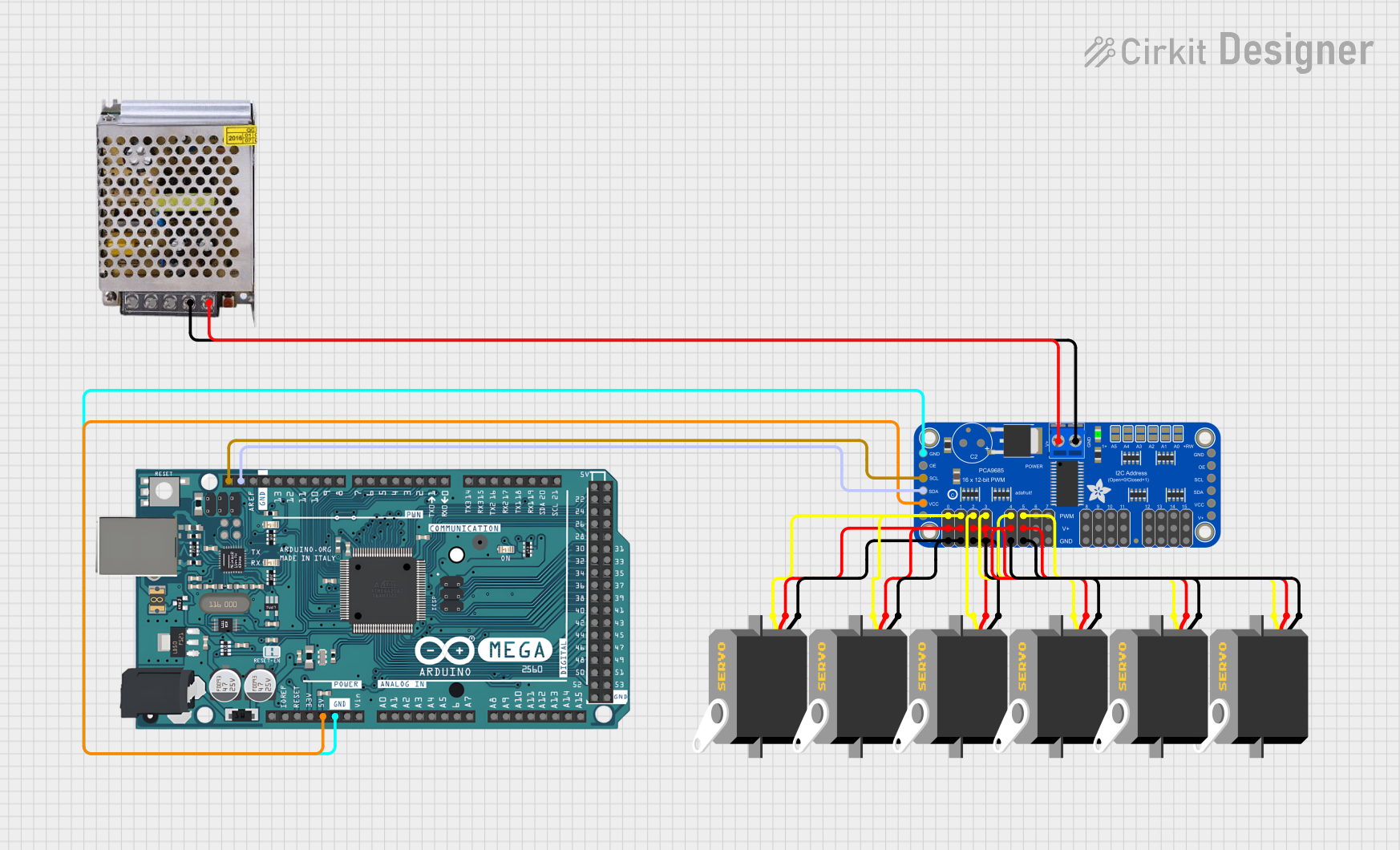

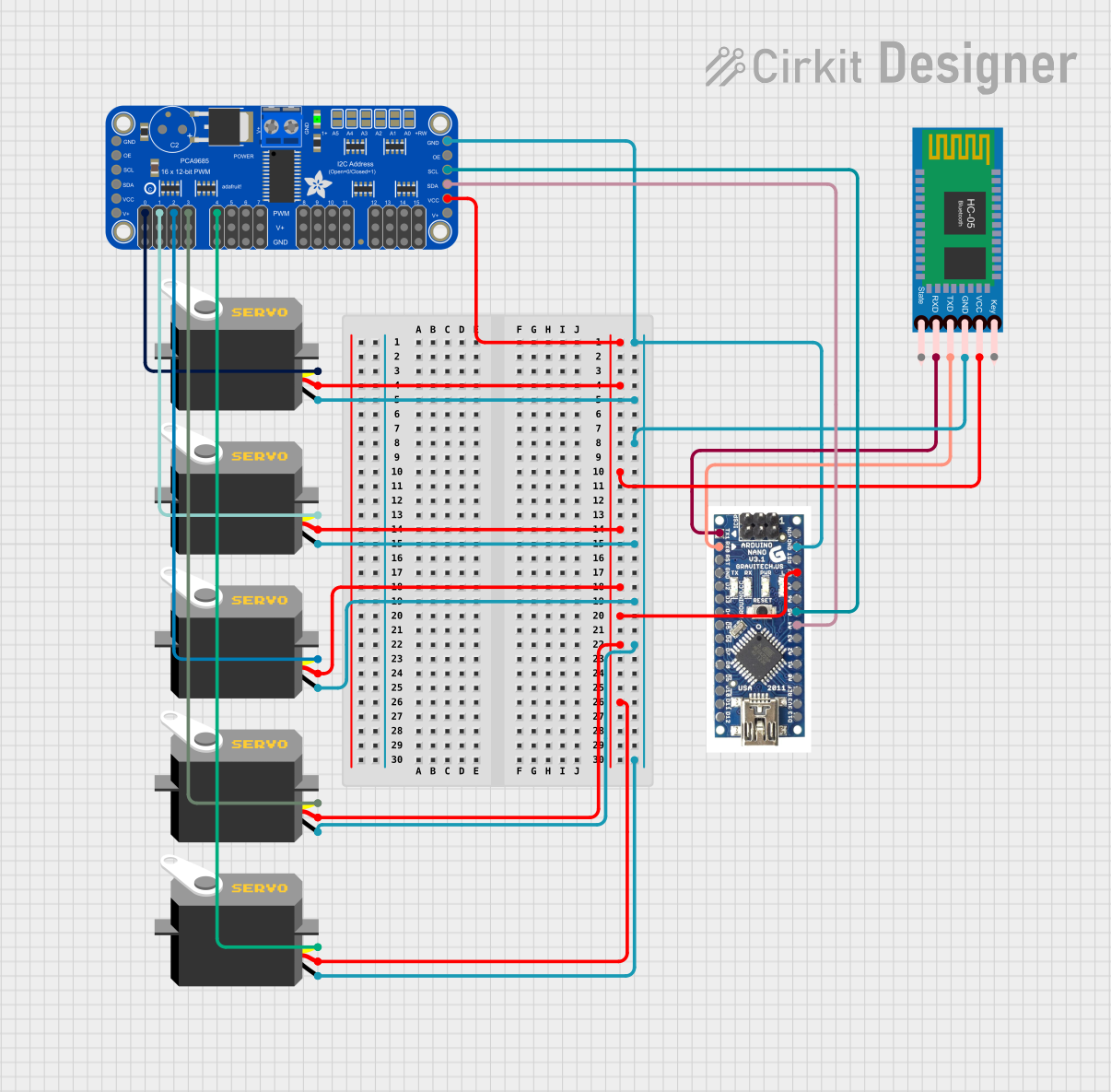

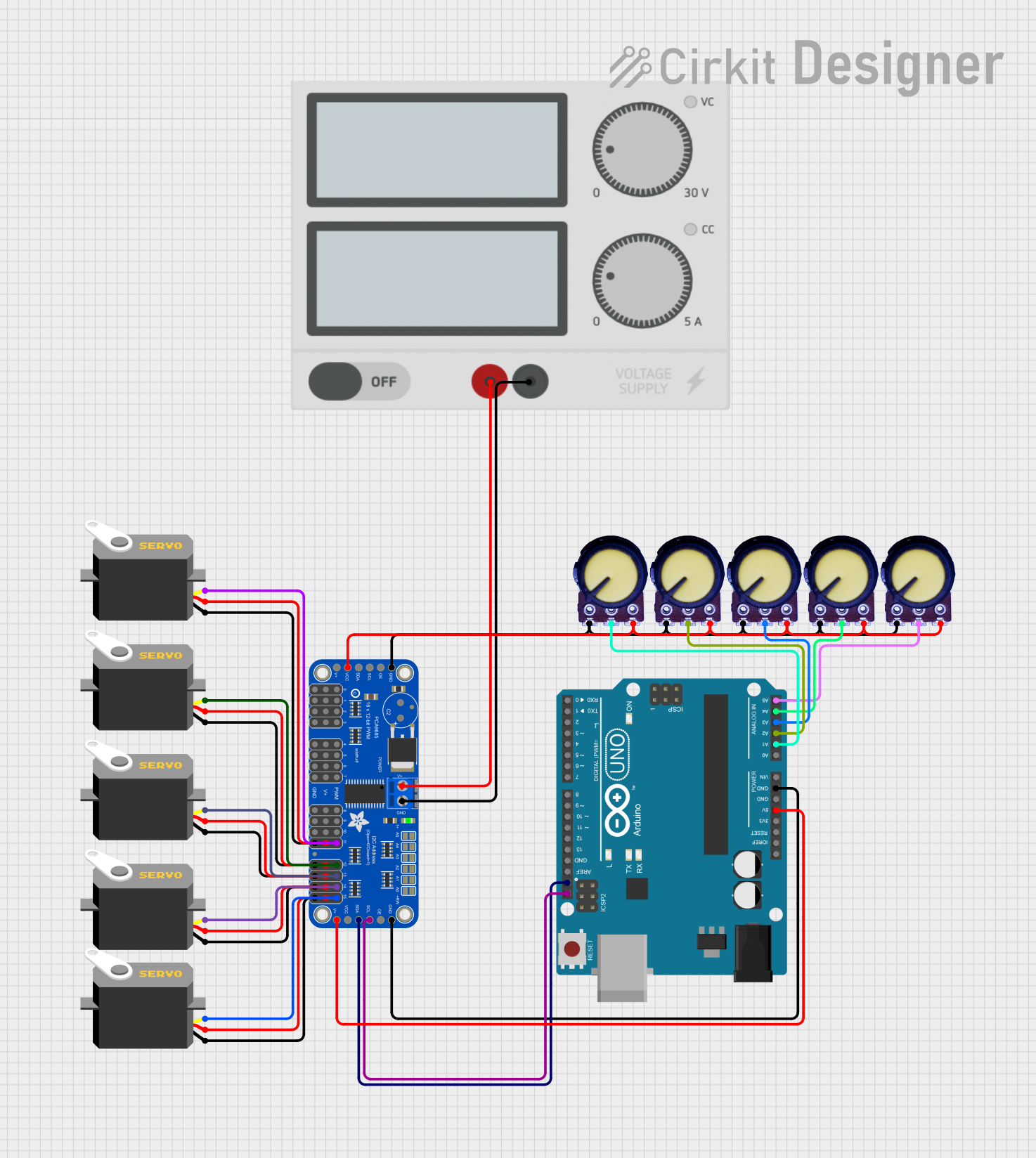

Explore Projects Built with Adafruit 16-Channel 12-bit PWM Servo Shield - I2C

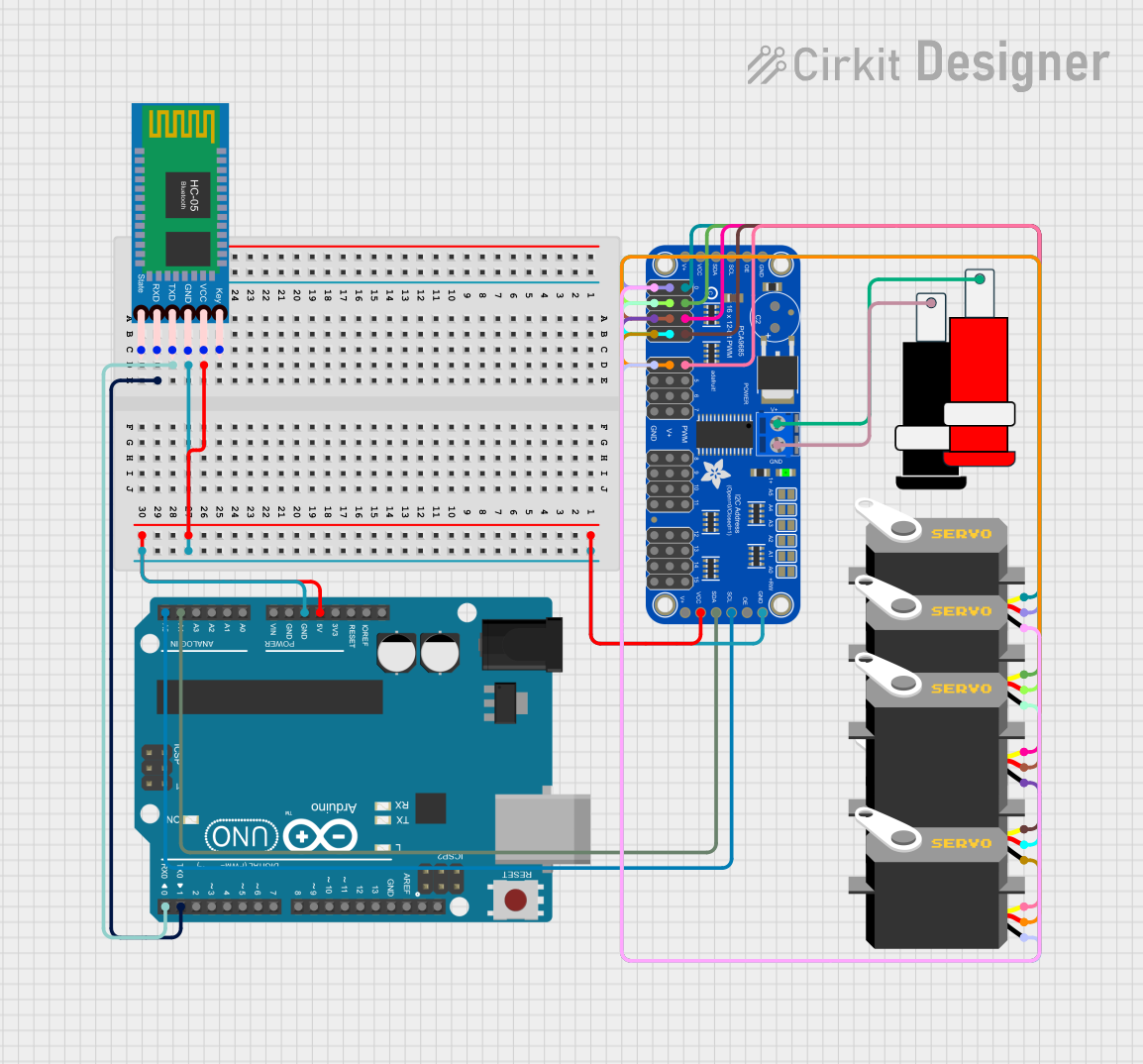

Open Project in Cirkit Designer

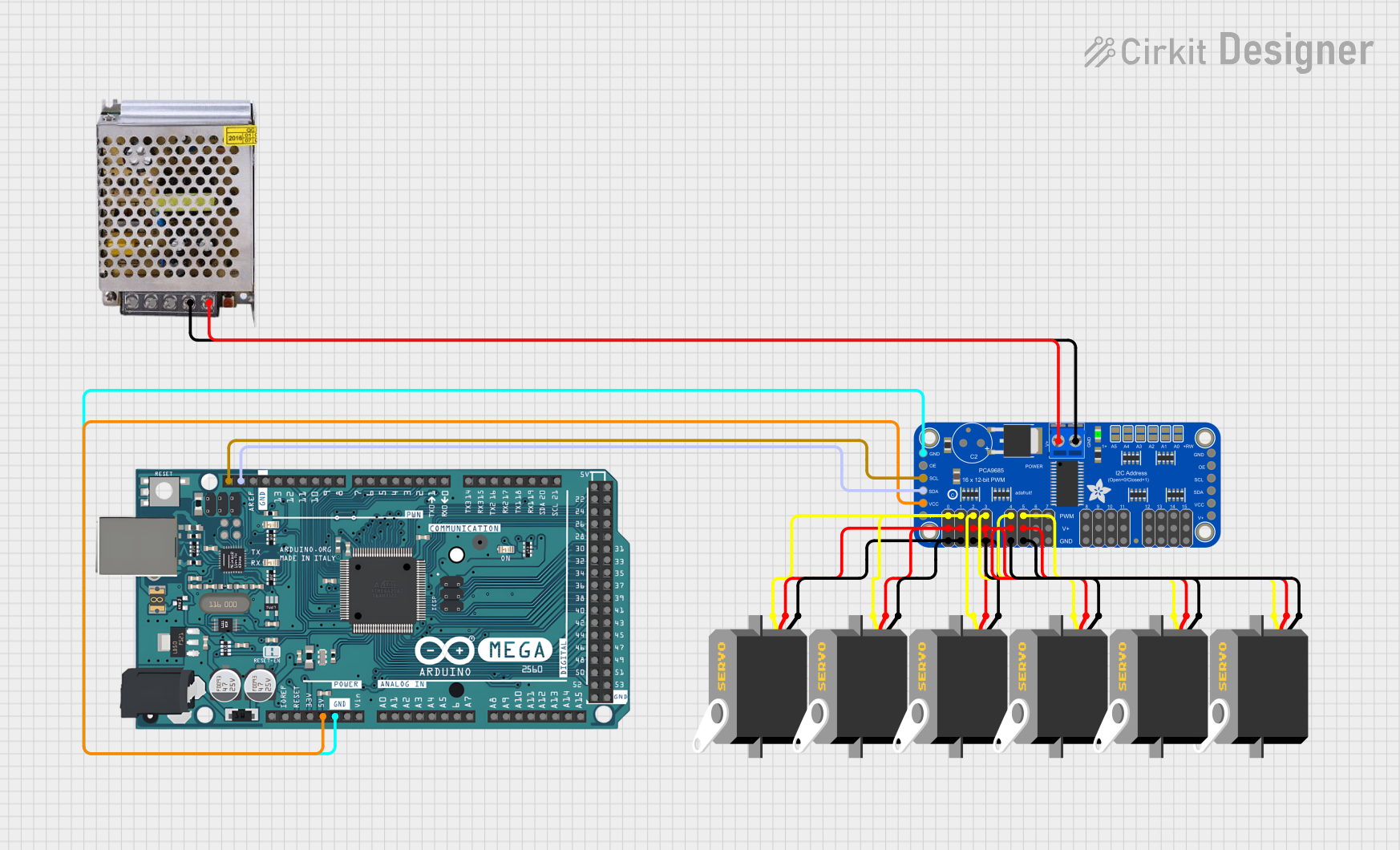

Open Project in Cirkit Designer

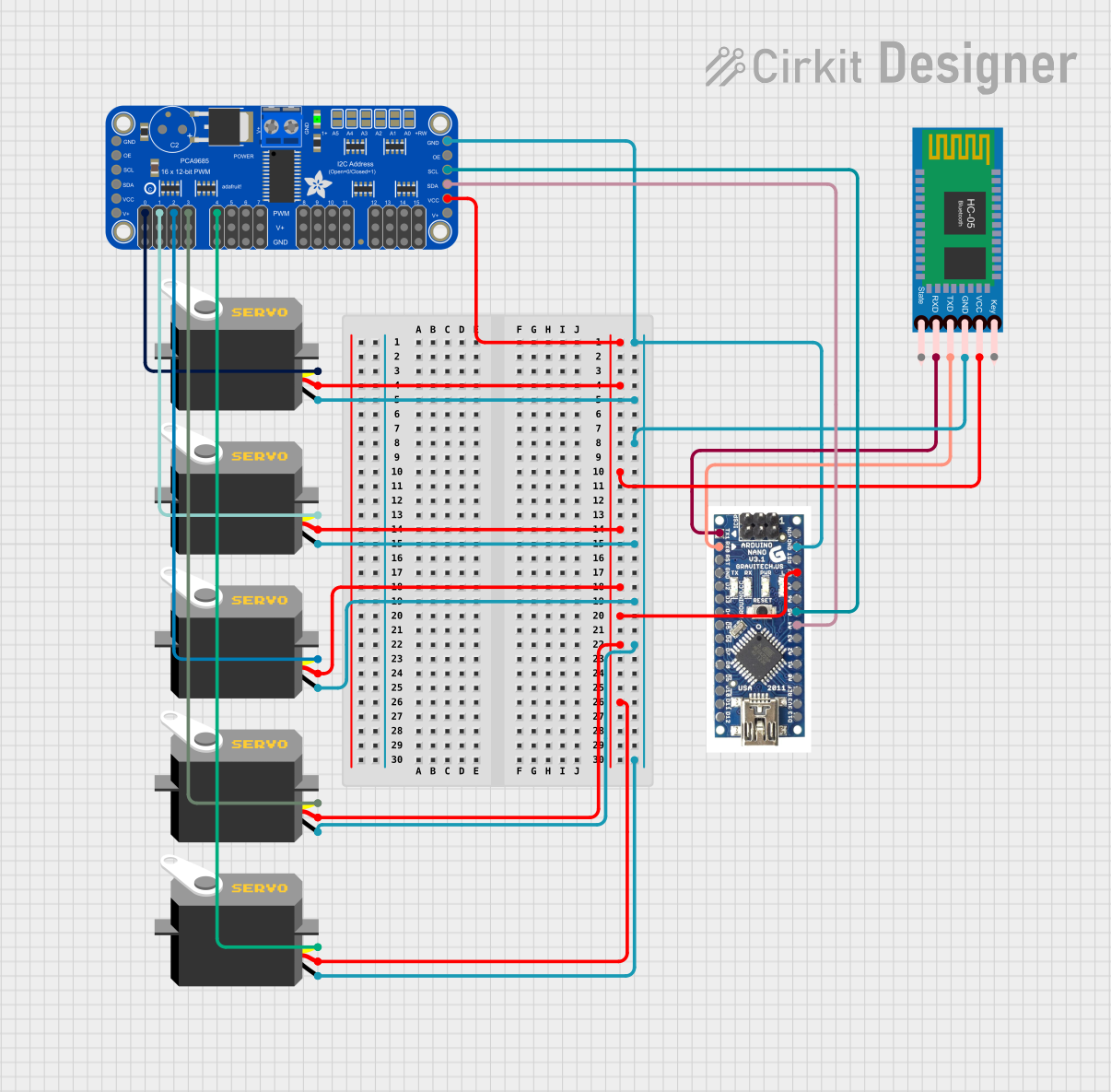

Open Project in Cirkit Designer

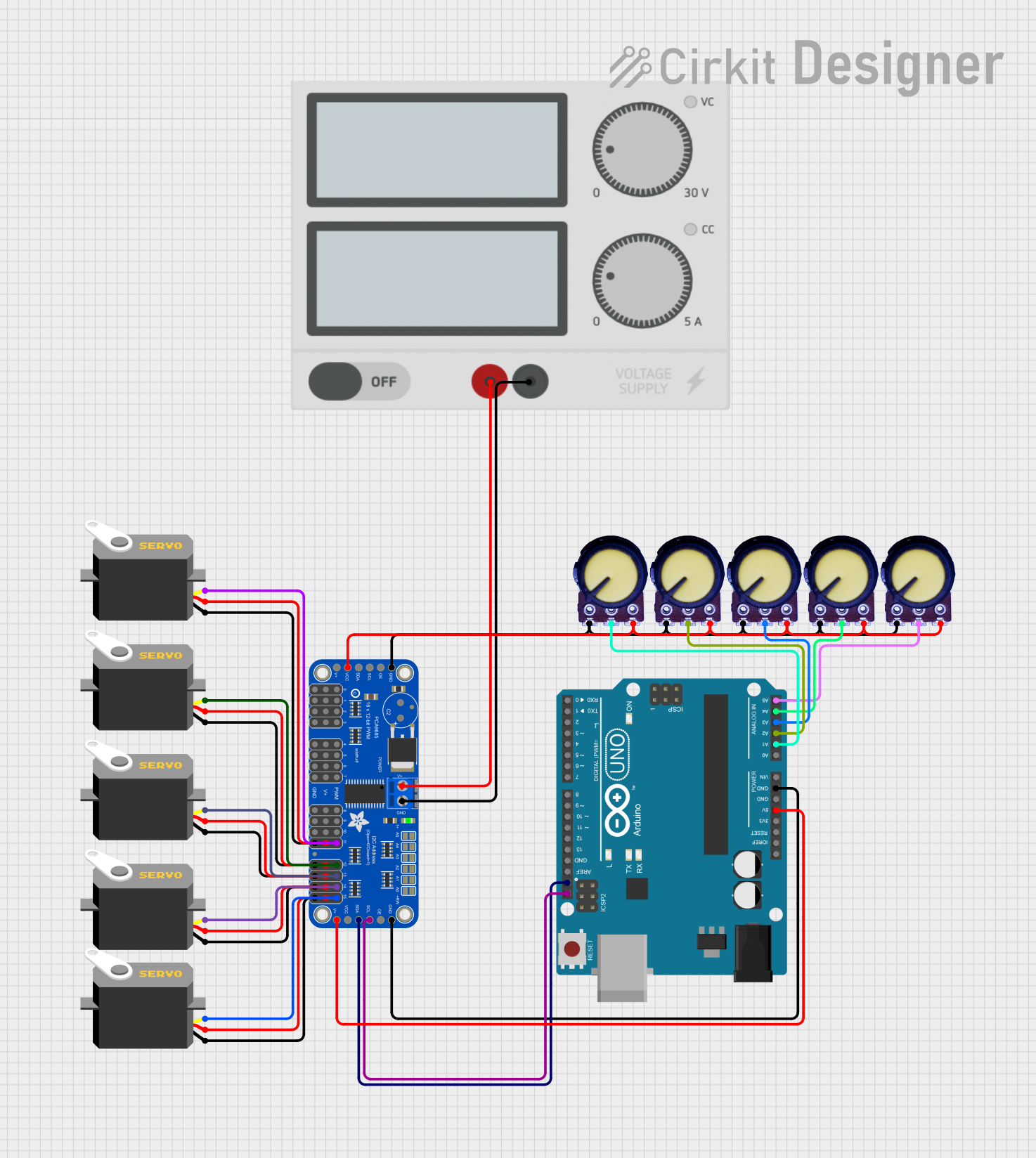

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit DesignerExplore Projects Built with Adafruit 16-Channel 12-bit PWM Servo Shield - I2C

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit DesignerTechnical Specifications

Key Technical Details

- Voltage: 5-6V (servo power), 3-5V (logic)

- Current: Depends on the servos used; the shield itself does not consume significant current

- Power Ratings: Can be powered via the Arduino board or external power supply

- Resolution: 12-bit, providing 4096 steps of PWM control

- Communication: I2C protocol

- Dimensions: 2.5" x 2.1" x 0.1" (without headers)

Pin Configuration and Descriptions

| Pin Number | Description |

|---|---|

| GND | Ground |

| V+ | Servo power supply (5-6V) |

| SCL | I2C clock line |

| SDA | I2C data line |

| A0-A5 | Address jumpers for I2C address selection |

Usage Instructions

Connecting the Shield to Arduino

Powering the Shield:

- Ensure that the shield is powered correctly; you can use the Arduino's 5V pin or an external power supply for the servos.

- Do not power high-torque servos directly from the Arduino's 5V pin.

I2C Communication:

- Connect the SCL and SDA pins to the corresponding pins on the Arduino.

- Use the A0-A5 jumpers to set the I2C address if multiple shields are used.

Attaching Servos:

- Connect your servos to the PWM output pins on the shield.

- Ensure that the servos are correctly oriented; the signal wire should match the signal pin on the shield.

Programming the Shield

- Use the Adafruit PWM Servo Driver Library to control the servos.

- Initialize the library and set the PWM frequency to 50Hz, which is typical for servos.

Example Code for Arduino UNO

#include <Wire.h>

#include <Adafruit_PWMServoDriver.h>

// Initialize the PWM driver.

Adafruit_PWMServoDriver pwm = Adafruit_PWMServoDriver();

void setup() {

pwm.begin();

pwm.setPWMFreq(50); // Set frequency to 50 Hz for servos

Wire.setClock(400000); // Use 400kHz I2C frequency

}

void loop() {

// Example: Turn servo on channel 0 to mid position

uint16_t pulseLength = map(90, 0, 180, SERVOMIN, SERVOMAX);

pwm.setPWM(0, 0, pulseLength);

delay(1000);

// Add code to control other servos as needed

}

Important Considerations and Best Practices

- Always ensure that the power supply can handle the current draw of all servos combined.

- Avoid disconnecting or connecting servos while the shield is powered to prevent damage.

- Use capacitors to smooth out power supply fluctuations if necessary.

Troubleshooting and FAQs

Common Issues

- Servos not responding: Check the power supply and I2C connections. Ensure that the correct I2C address is used.

- Jittery servo movement: This can be due to insufficient power supply or noise in the signal. Check the power supply and consider using a capacitor.

Solutions and Tips

- Power Supply: Use a dedicated power supply for the servos if they draw a lot of current.

- I2C Addressing: Make sure the I2C address is unique if using multiple shields.

- Library Usage: Always use the latest version of the Adafruit PWM Servo Driver Library for best compatibility.

FAQs

Q: Can I power the servos directly from the Arduino? A: It is not recommended to power high-torque servos directly from the Arduino due to the current limitations of the board.

Q: How do I change the I2C address? A: Solder the address jumpers A0-A5 on the shield to configure the I2C address.

Q: Can I use this shield with other microcontrollers besides Arduino? A: Yes, as long as the microcontroller supports I2C communication and you can provide the correct logic voltage.

Remember to always follow the best practices and safety guidelines when working with electronic components to ensure the longevity of your project and components.