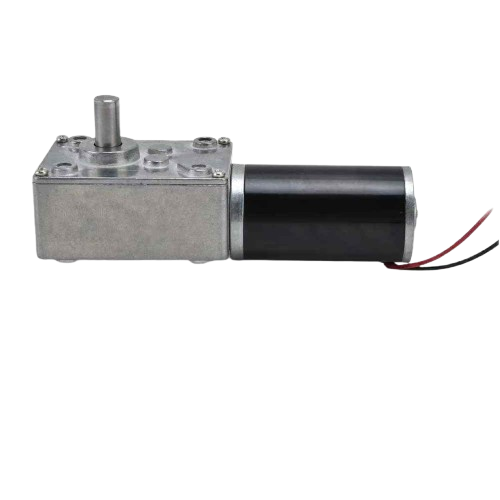

How to Use มอเตอร์เกียร์ DC 12V 27 RPM: Examples, Pinouts, and Specs

Design with มอเตอร์เกียร์ DC 12V 27 RPM in Cirkit Designer

Design with มอเตอร์เกียร์ DC 12V 27 RPM in Cirkit DesignerIntroduction

The มอเตอร์เกียร์ DC 12V 27 RPM is a 12-volt DC gear motor designed to deliver high torque at low speeds, with a rotational speed of 27 revolutions per minute (RPM). This motor is ideal for applications requiring precise and powerful motion control, such as robotics, conveyor systems, and automated mechanisms. Its robust design and reliable performance make it a popular choice for hobbyists and professionals alike.

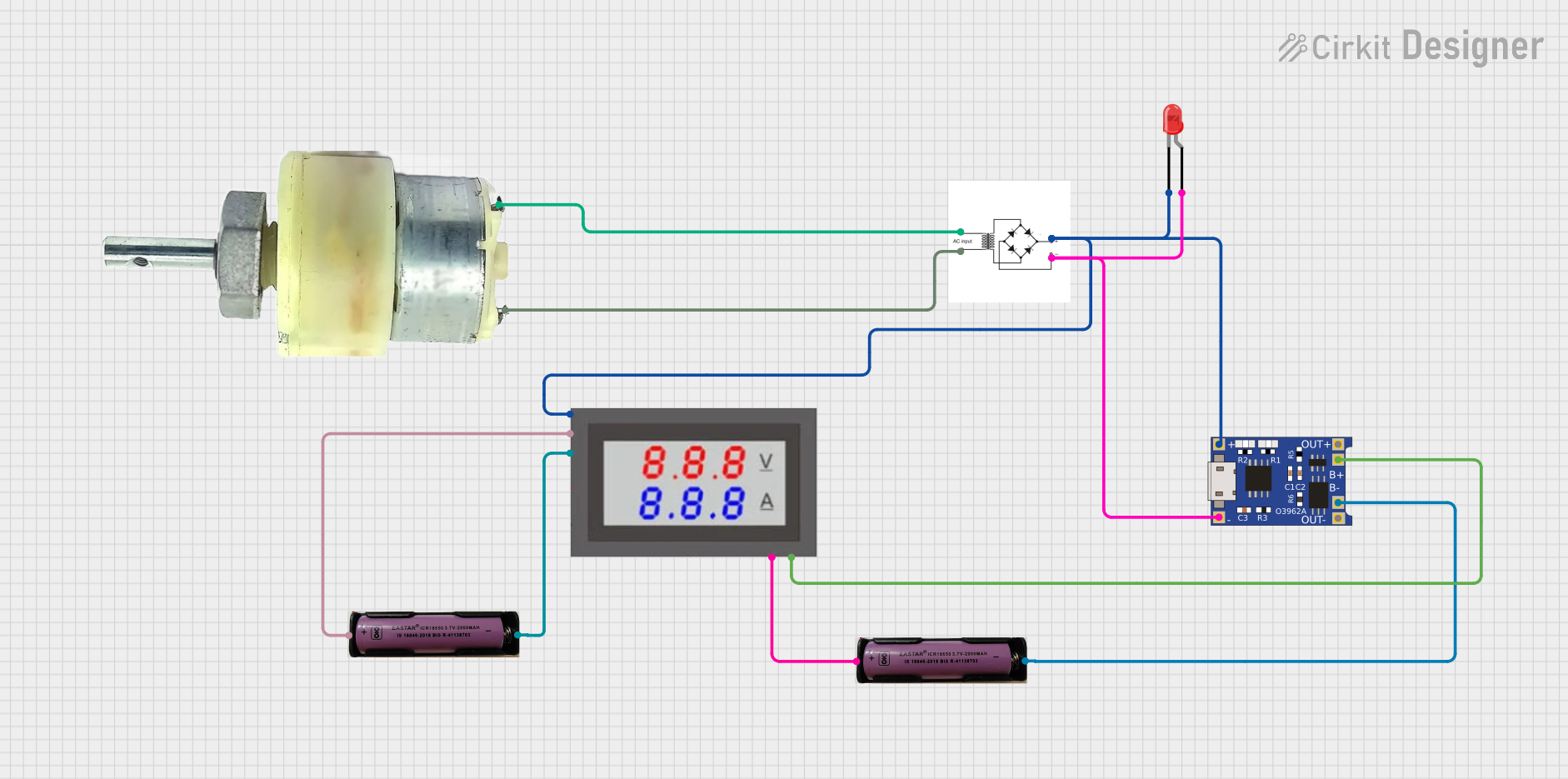

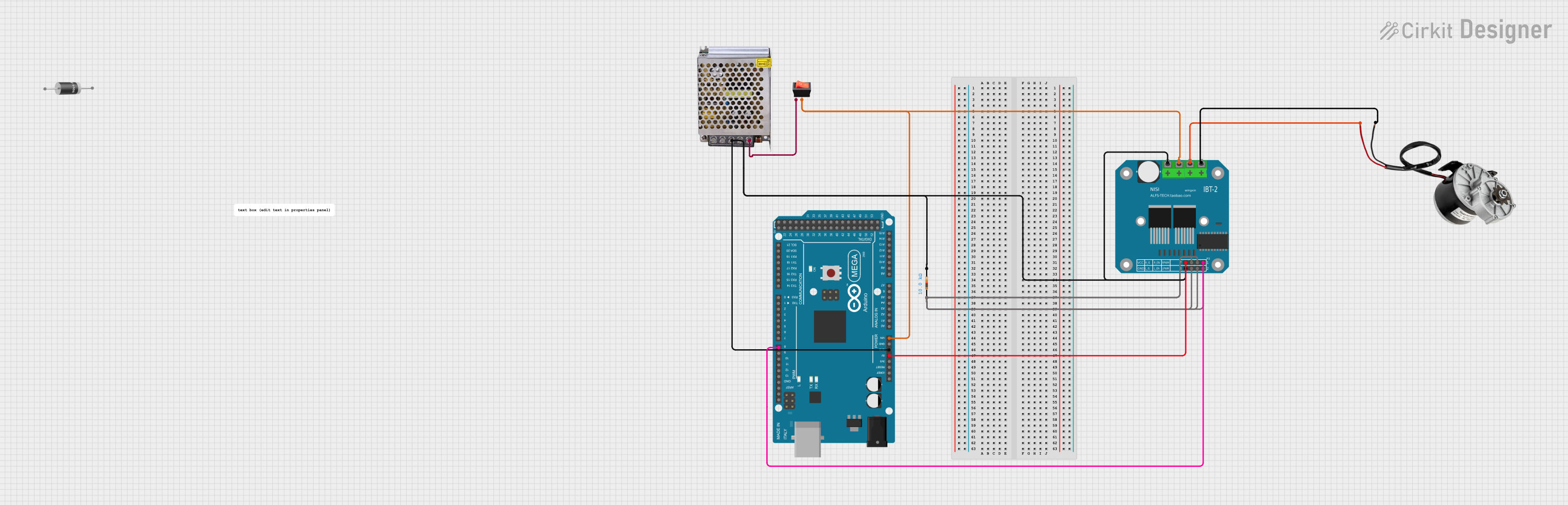

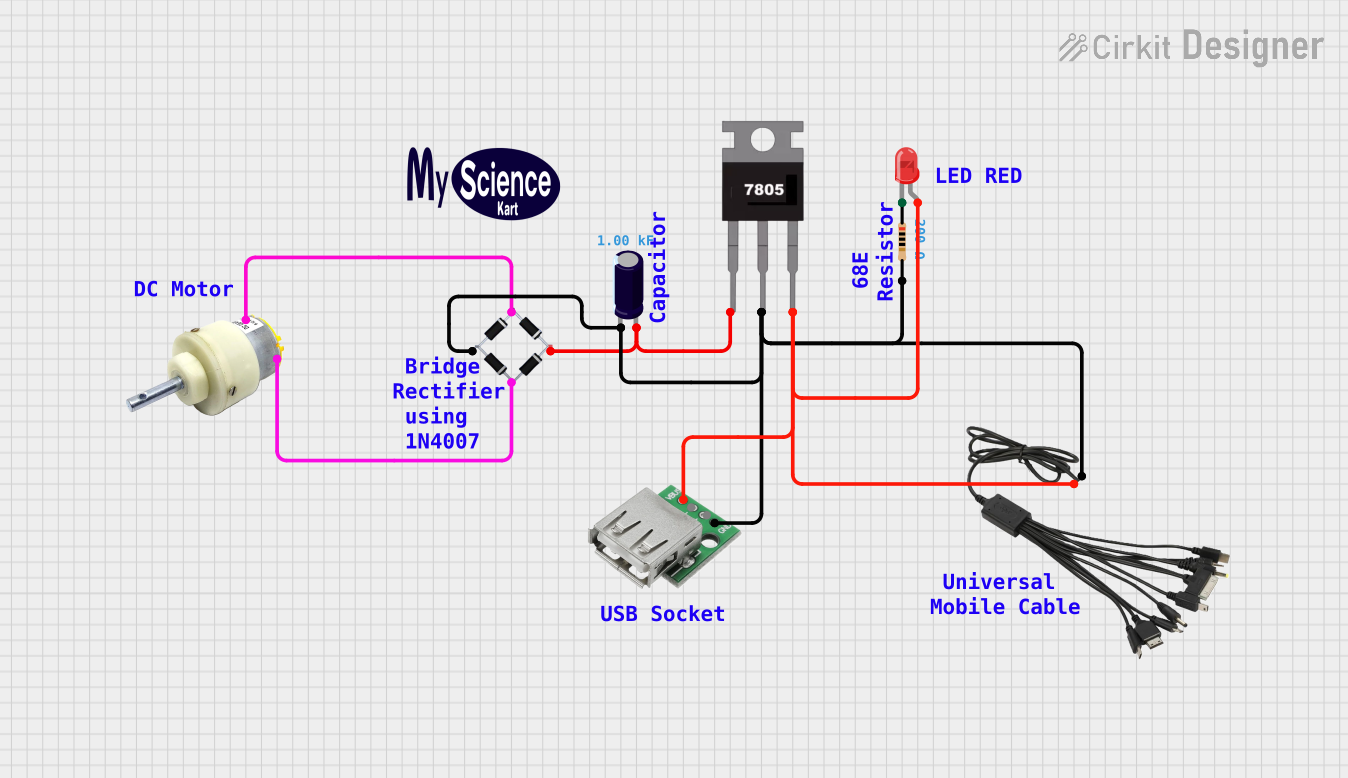

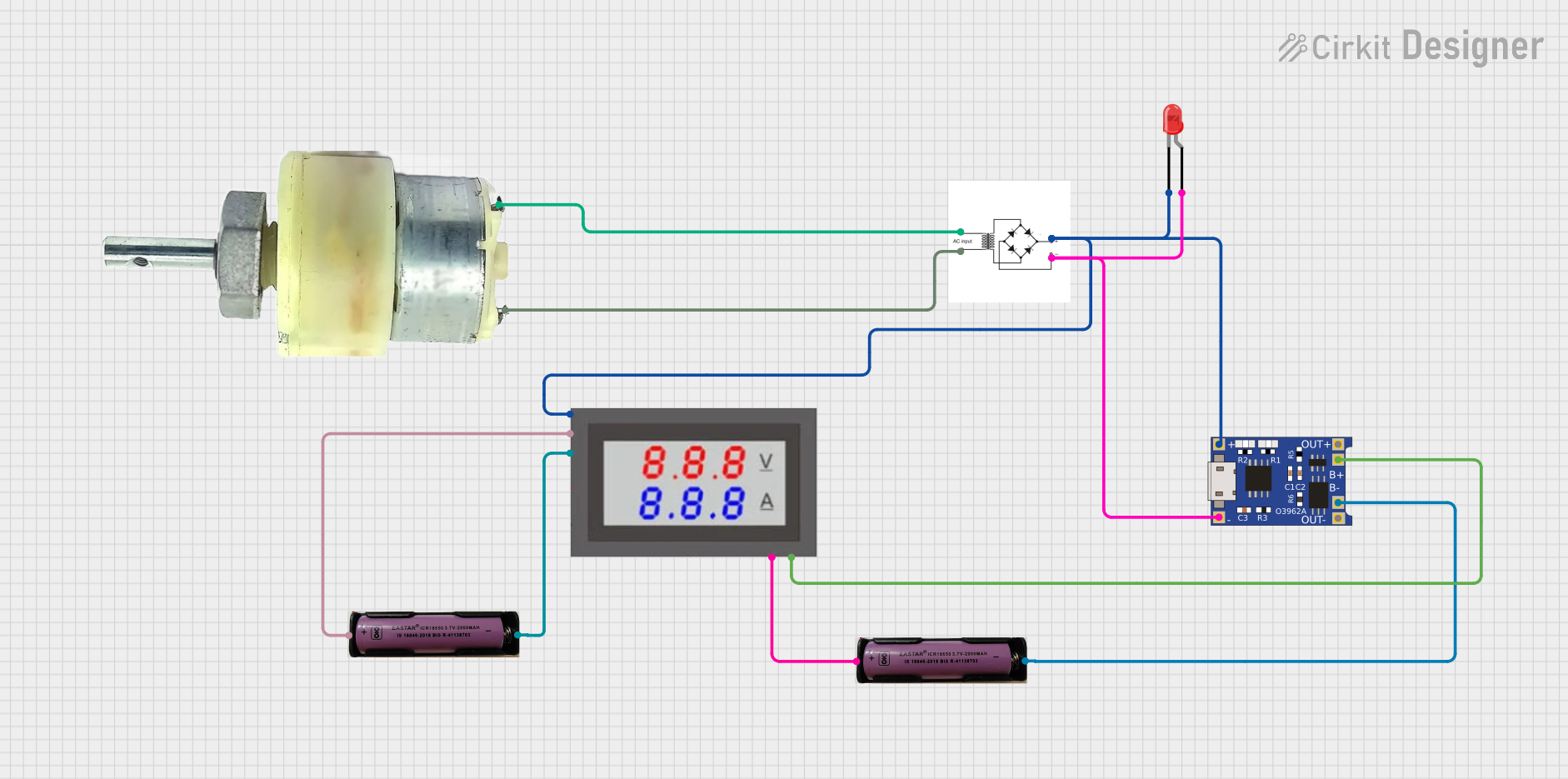

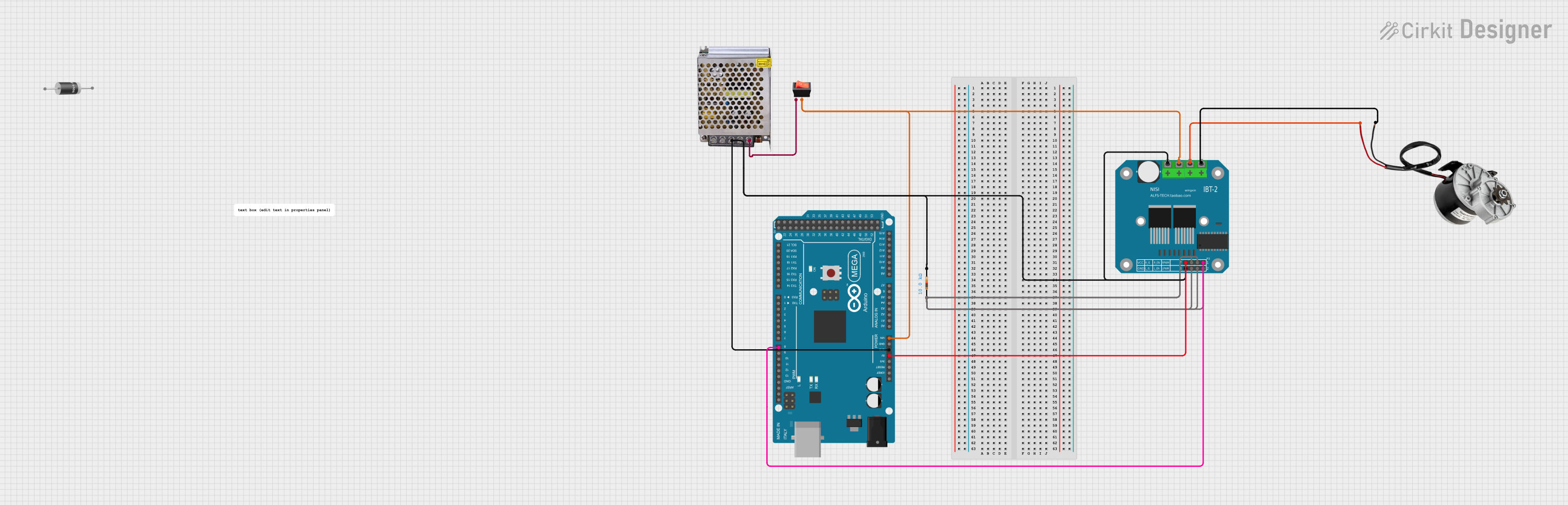

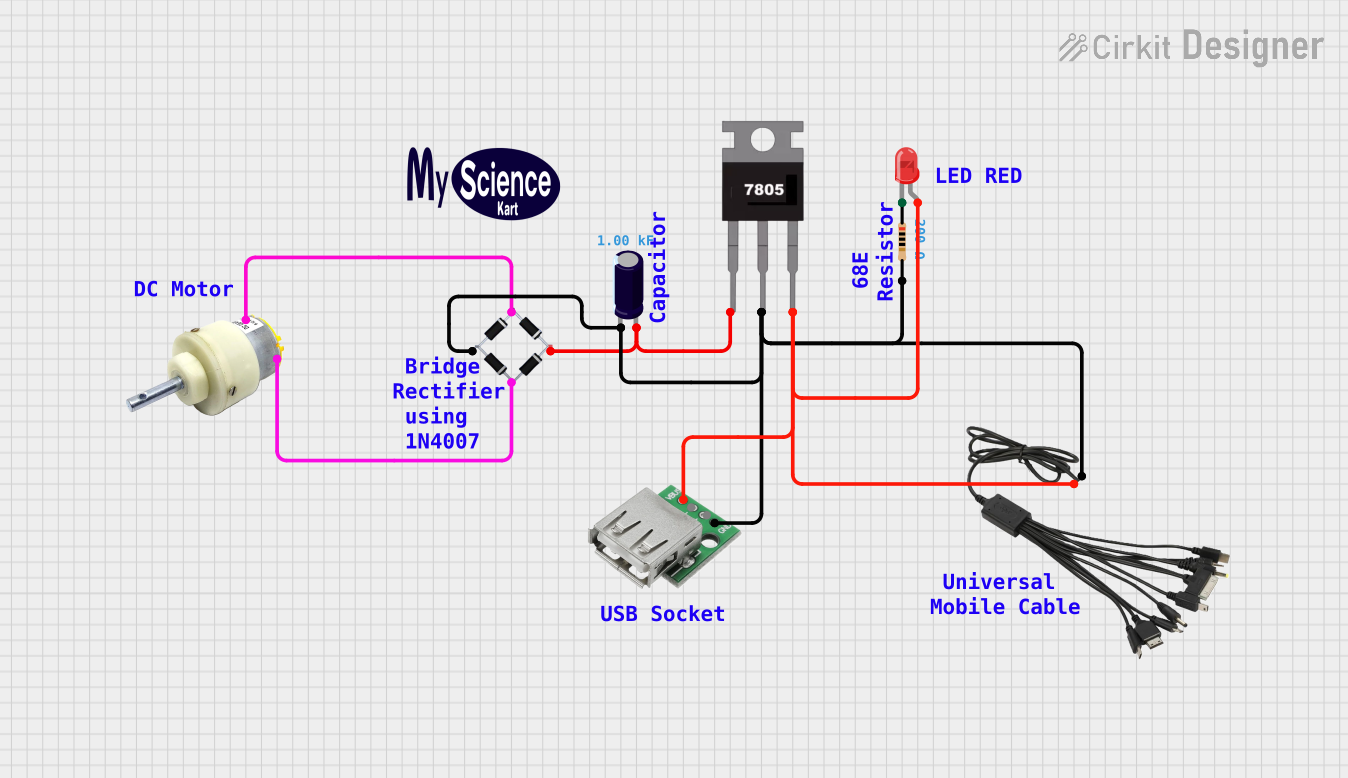

Explore Projects Built with มอเตอร์เกียร์ DC 12V 27 RPM

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit DesignerExplore Projects Built with มอเตอร์เกียร์ DC 12V 27 RPM

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit DesignerCommon Applications

- Robotics (e.g., robotic arms, mobile robots)

- Conveyor belts and material handling systems

- Automated door mechanisms

- DIY projects requiring controlled rotational motion

- Small-scale industrial automation

Technical Specifications

Below are the key technical details of the มอเตอร์เกียร์ DC 12V 27 RPM:

| Parameter | Value |

|---|---|

| Operating Voltage | 12V DC |

| No-Load Speed | 27 RPM |

| Torque | High (varies by load) |

| Current (No Load) | ~200 mA |

| Current (Stall) | ~1.2 A |

| Gear Ratio | ~1:200 |

| Shaft Diameter | 6 mm |

| Shaft Length | 15 mm |

| Motor Dimensions | 37 mm (diameter) x 70 mm (length) |

| Weight | ~200 g |

Pin Configuration and Descriptions

The motor typically has two terminals for electrical connections:

| Pin/Terminal | Description |

|---|---|

| Terminal 1 | Positive terminal (+12V DC) |

| Terminal 2 | Negative terminal (Ground or -12V DC) |

Note: Reversing the polarity of the terminals will reverse the motor's rotation direction.

Usage Instructions

How to Use the Component in a Circuit

- Power Supply: Connect the motor to a 12V DC power source. Ensure the power supply can provide sufficient current (at least 1.5 A) to handle the motor's stall current.

- Polarity Control: Use an H-bridge motor driver (e.g., L298N or L293D) to control the motor's direction and speed. The H-bridge allows you to reverse the polarity and adjust the voltage supplied to the motor.

- Speed Control: Implement Pulse Width Modulation (PWM) using a microcontroller (e.g., Arduino UNO) to control the motor's speed.

- Mounting: Secure the motor using appropriate brackets or mounts to prevent vibration or misalignment during operation.

Important Considerations and Best Practices

- Avoid Overloading: Do not exceed the motor's rated torque to prevent overheating or damage.

- Heat Dissipation: Ensure proper ventilation or heat sinking if the motor operates continuously under high load.

- Power Supply: Use a regulated power supply to avoid voltage spikes that could damage the motor.

- Noise Suppression: Add capacitors (e.g., 0.1 µF) across the motor terminals to reduce electrical noise.

Example: Connecting to an Arduino UNO

Below is an example of how to control the motor's speed and direction using an Arduino UNO and an L298N motor driver.

Circuit Diagram

- Connect the motor terminals to the L298N motor driver's output pins (e.g., OUT1 and OUT2).

- Connect the L298N's input pins (e.g., IN1 and IN2) to Arduino digital pins.

- Connect the L298N's enable pin (e.g., ENA) to an Arduino PWM pin.

Arduino Code

// Define motor control pins

const int IN1 = 7; // Motor direction pin 1

const int IN2 = 8; // Motor direction pin 2

const int ENA = 9; // Motor speed control (PWM pin)

void setup() {

// Set motor control pins as outputs

pinMode(IN1, OUTPUT);

pinMode(IN2, OUTPUT);

pinMode(ENA, OUTPUT);

}

void loop() {

// Rotate motor forward at 50% speed

digitalWrite(IN1, HIGH); // Set direction

digitalWrite(IN2, LOW);

analogWrite(ENA, 128); // Set speed (0-255)

delay(5000); // Run for 5 seconds

// Rotate motor backward at 75% speed

digitalWrite(IN1, LOW); // Reverse direction

digitalWrite(IN2, HIGH);

analogWrite(ENA, 192); // Set speed (0-255)

delay(5000); // Run for 5 seconds

// Stop the motor

digitalWrite(IN1, LOW);

digitalWrite(IN2, LOW);

analogWrite(ENA, 0); // Set speed to 0

delay(2000); // Wait for 2 seconds before repeating

}

Troubleshooting and FAQs

Common Issues and Solutions

Motor Does Not Spin

- Cause: Insufficient power supply or loose connections.

- Solution: Verify that the power supply provides 12V and sufficient current. Check all connections.

Motor Spins in the Wrong Direction

- Cause: Polarity of the motor terminals is reversed.

- Solution: Swap the connections of the motor terminals or adjust the H-bridge control signals.

Motor Overheats

- Cause: Excessive load or prolonged operation at high current.

- Solution: Reduce the load or provide adequate cooling.

Electrical Noise Interference

- Cause: Motor generates electrical noise during operation.

- Solution: Add capacitors (e.g., 0.1 µF) across the motor terminals to suppress noise.

FAQs

- Can I use a lower voltage to power the motor?

- Yes, but the motor's speed and torque will decrease proportionally.

- What is the maximum load the motor can handle?

- The maximum load depends on the torque rating. Avoid exceeding the stall torque to prevent damage.

- Can I control this motor without a motor driver?

- While possible, it is not recommended. A motor driver provides better control and protection for the motor and power supply.

This concludes the documentation for the มอเตอร์เกียร์ DC 12V 27 RPM.