How to Use CNC SHIELD V3: Examples, Pinouts, and Specs

Design with CNC SHIELD V3 in Cirkit Designer

Design with CNC SHIELD V3 in Cirkit DesignerIntroduction

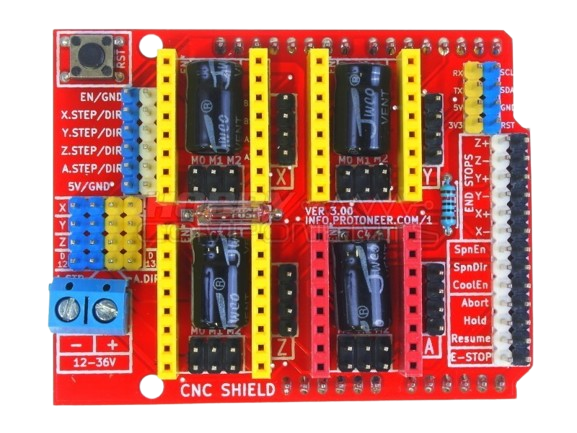

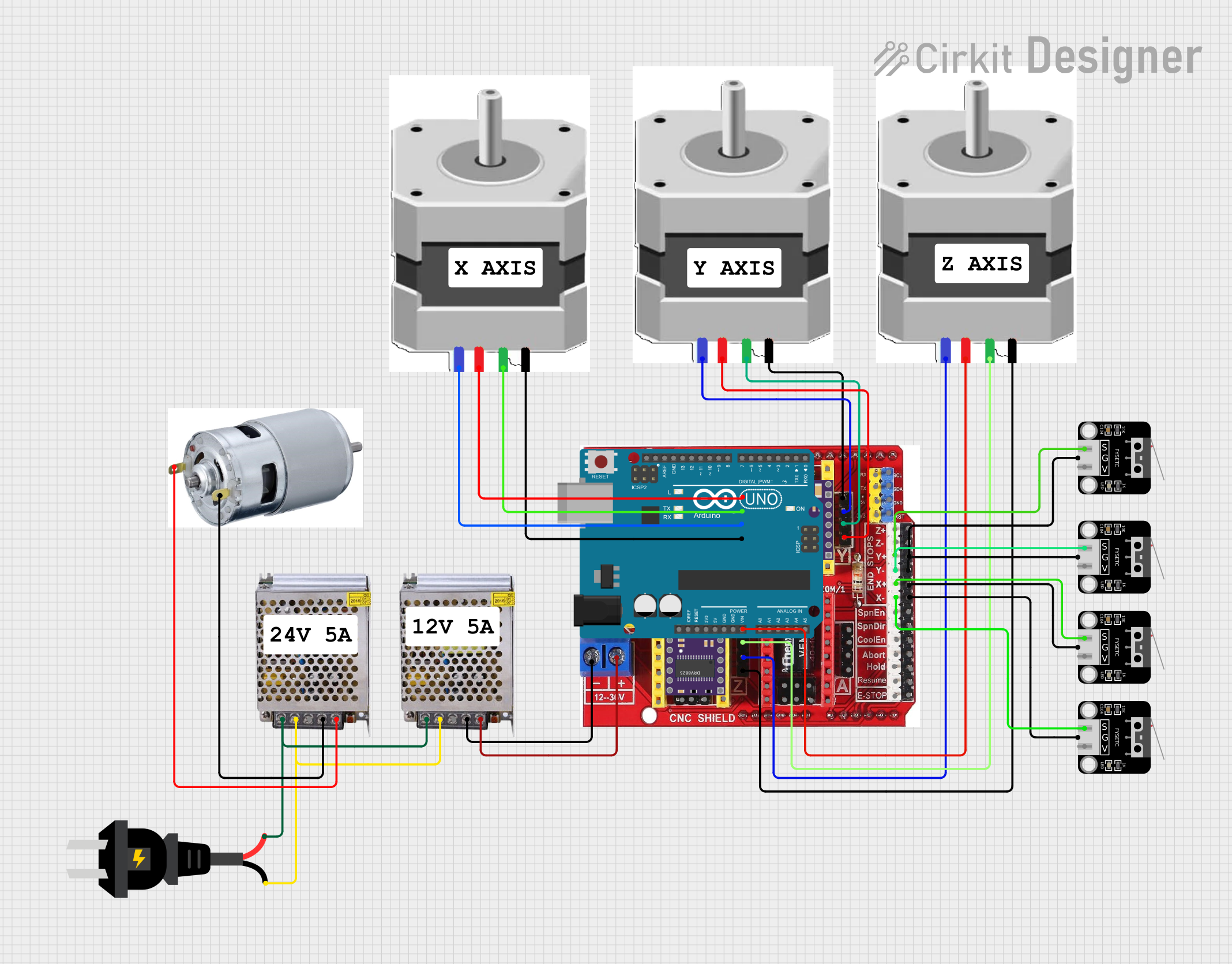

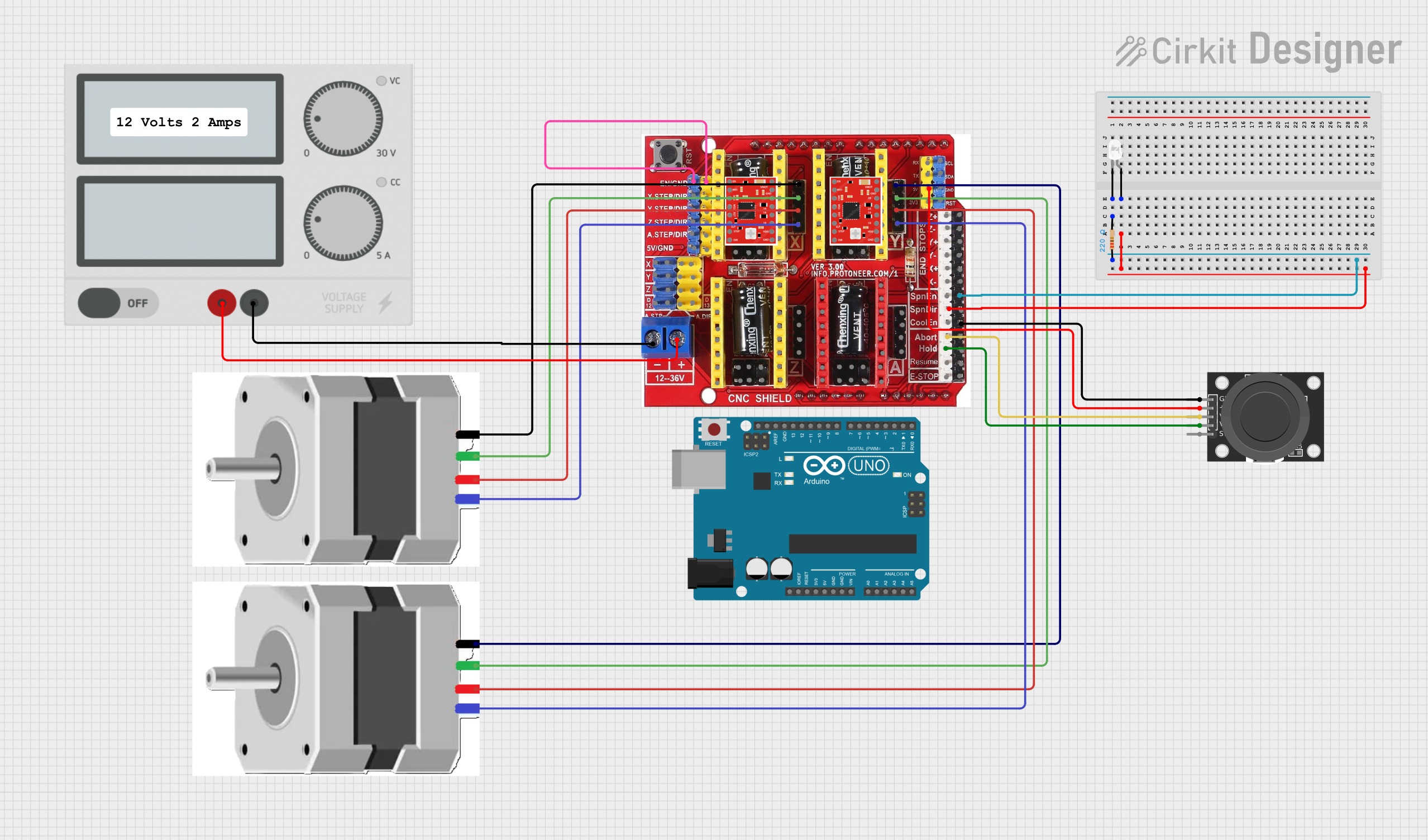

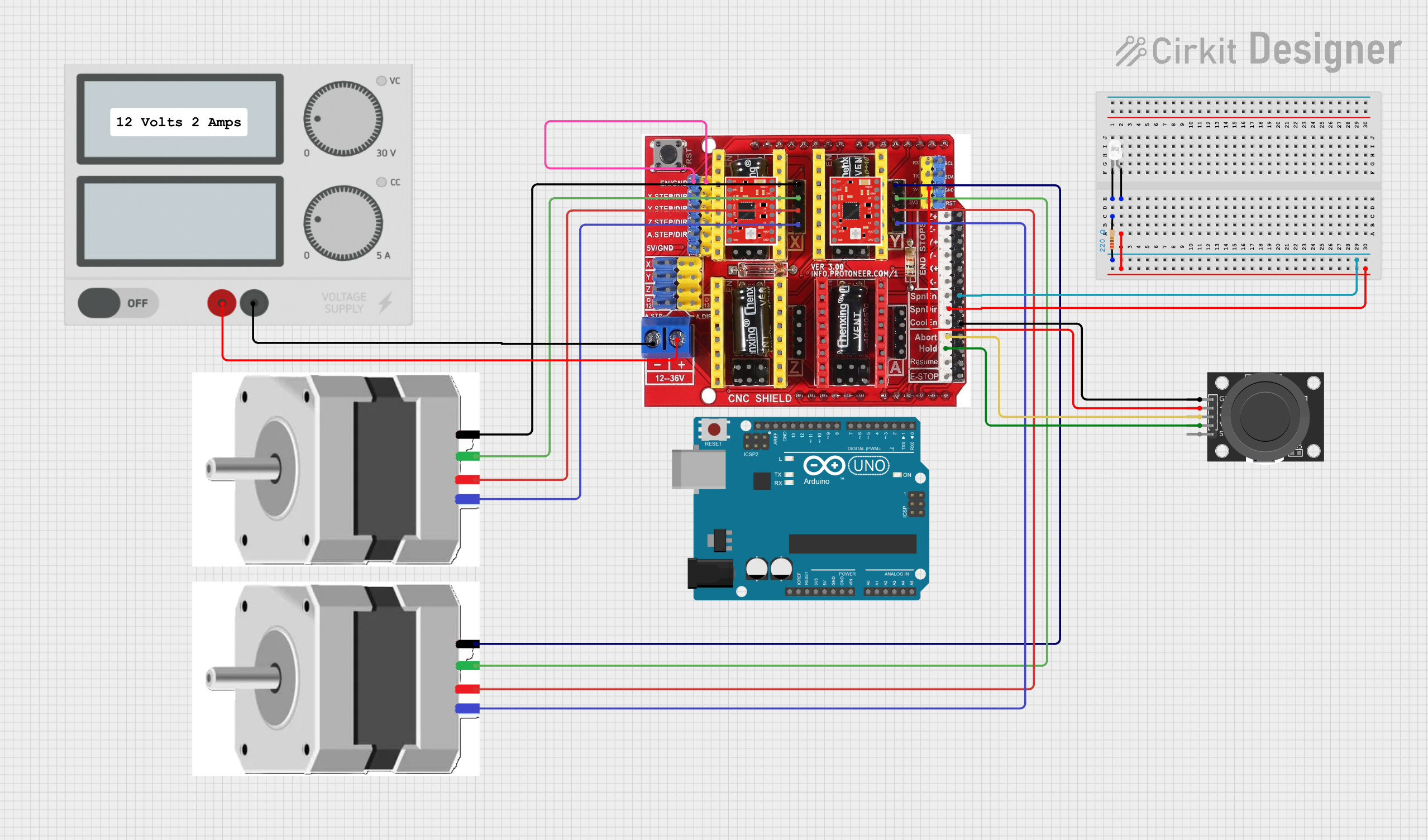

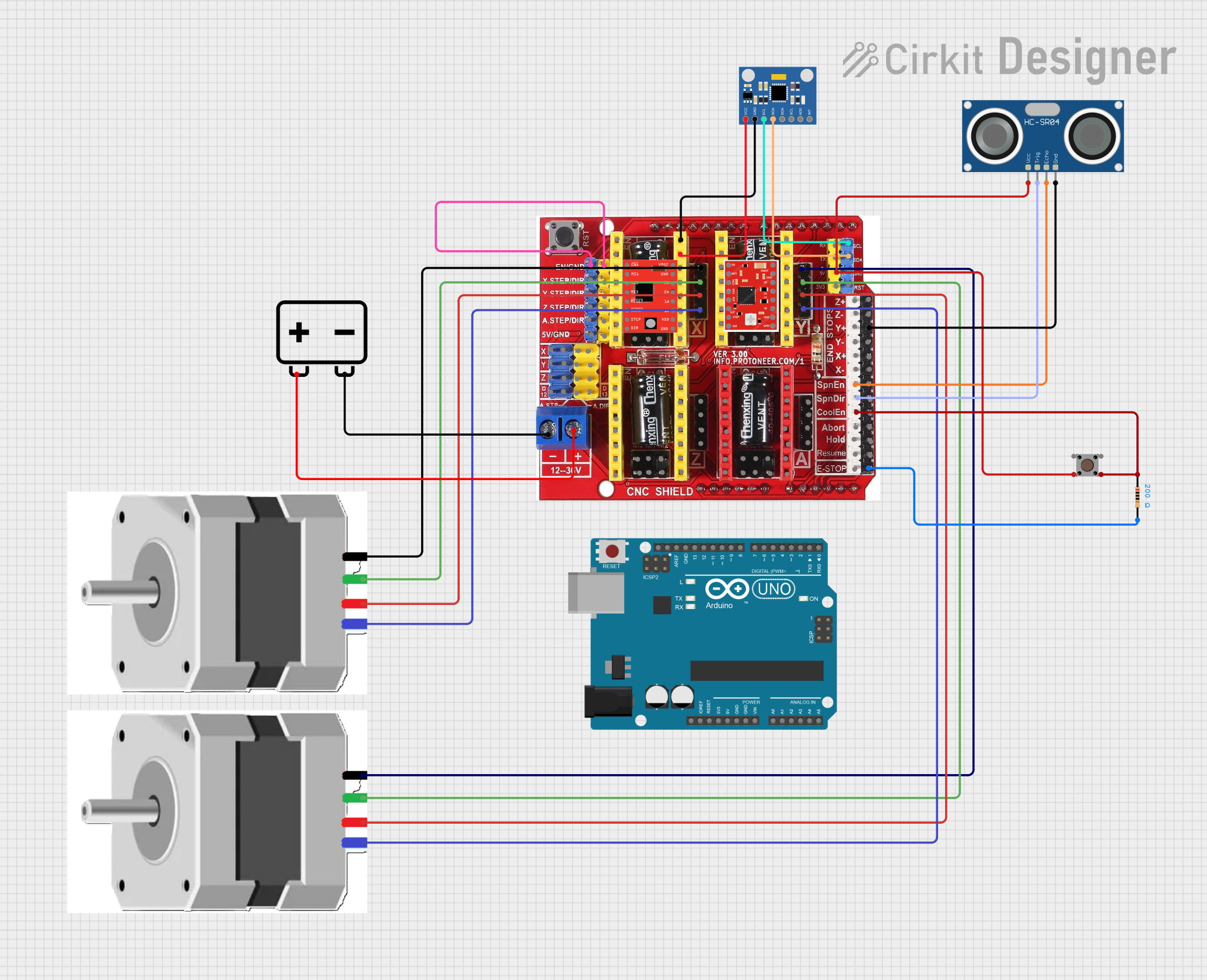

The CNC SHIELD V3 by INFO PROTONER (Part ID: CNC SHIELD) is a versatile control board designed for CNC machines, 3D printers, and laser engravers. It provides an easy-to-use platform for controlling stepper motors, connecting endstops, and interfacing with various firmware such as GRBL. This shield is compatible with Arduino boards, making it a popular choice for DIY projects and professional applications alike.

Explore Projects Built with CNC SHIELD V3

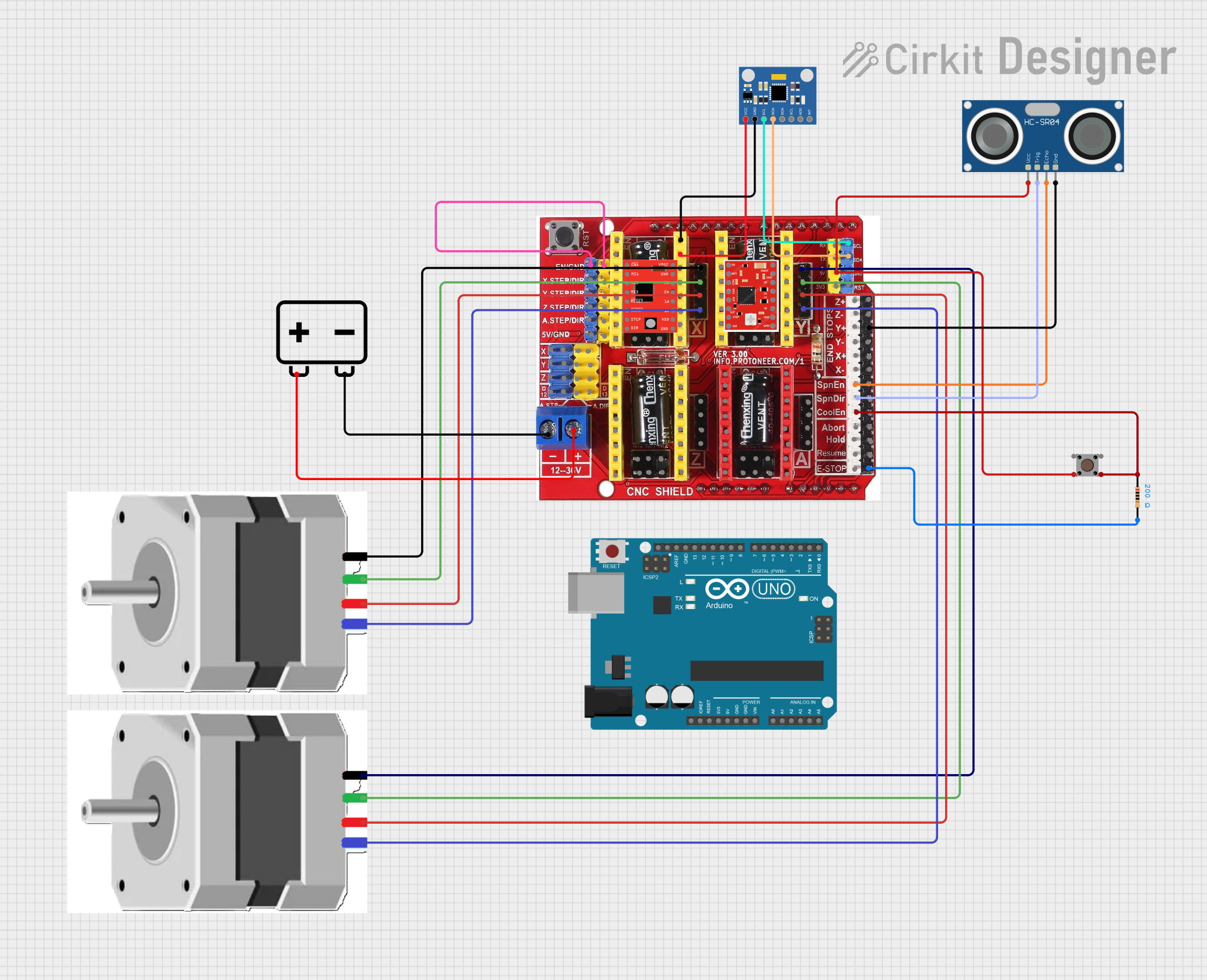

Open Project in Cirkit Designer

Open Project in Cirkit Designer

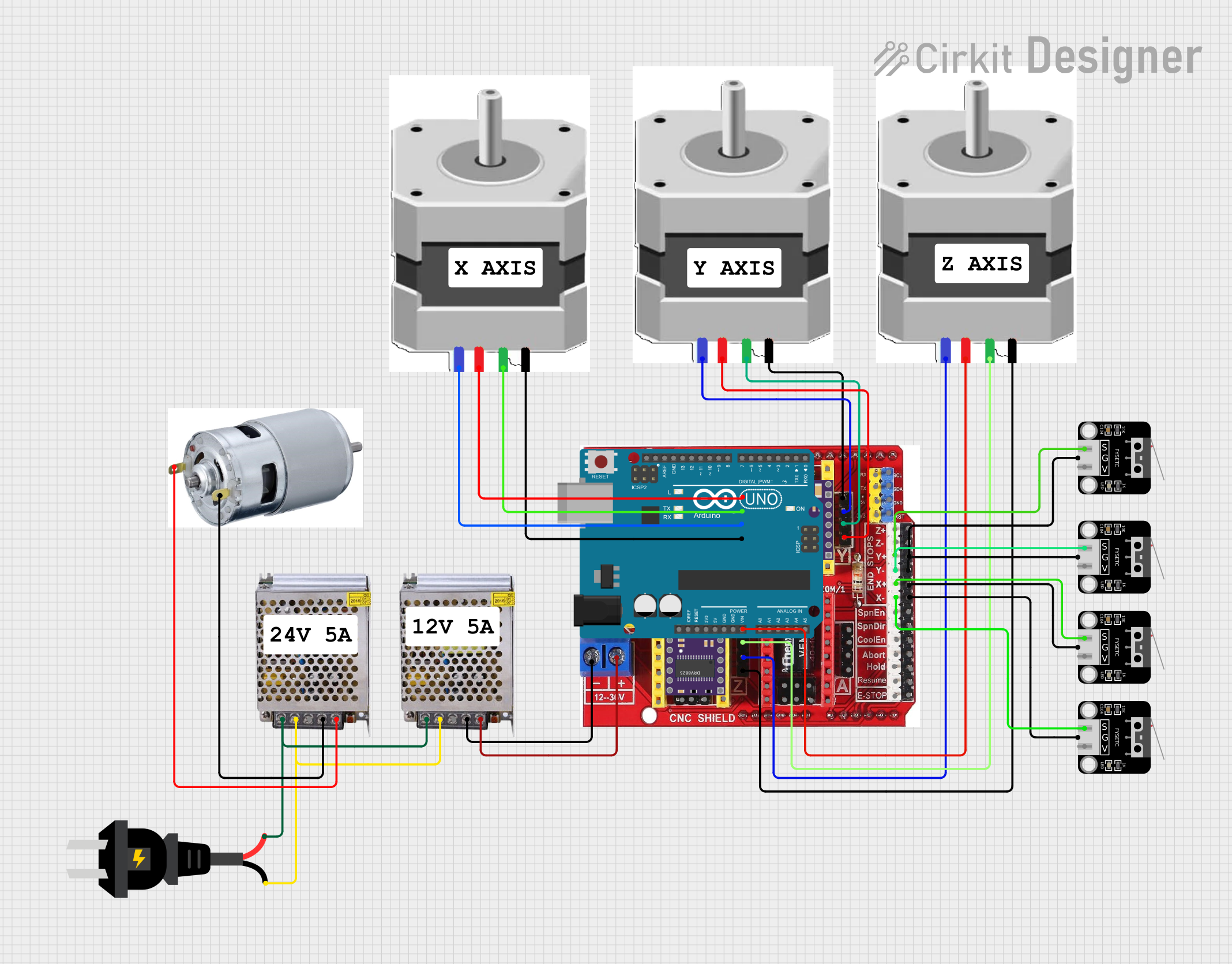

Open Project in Cirkit Designer

Open Project in Cirkit Designer

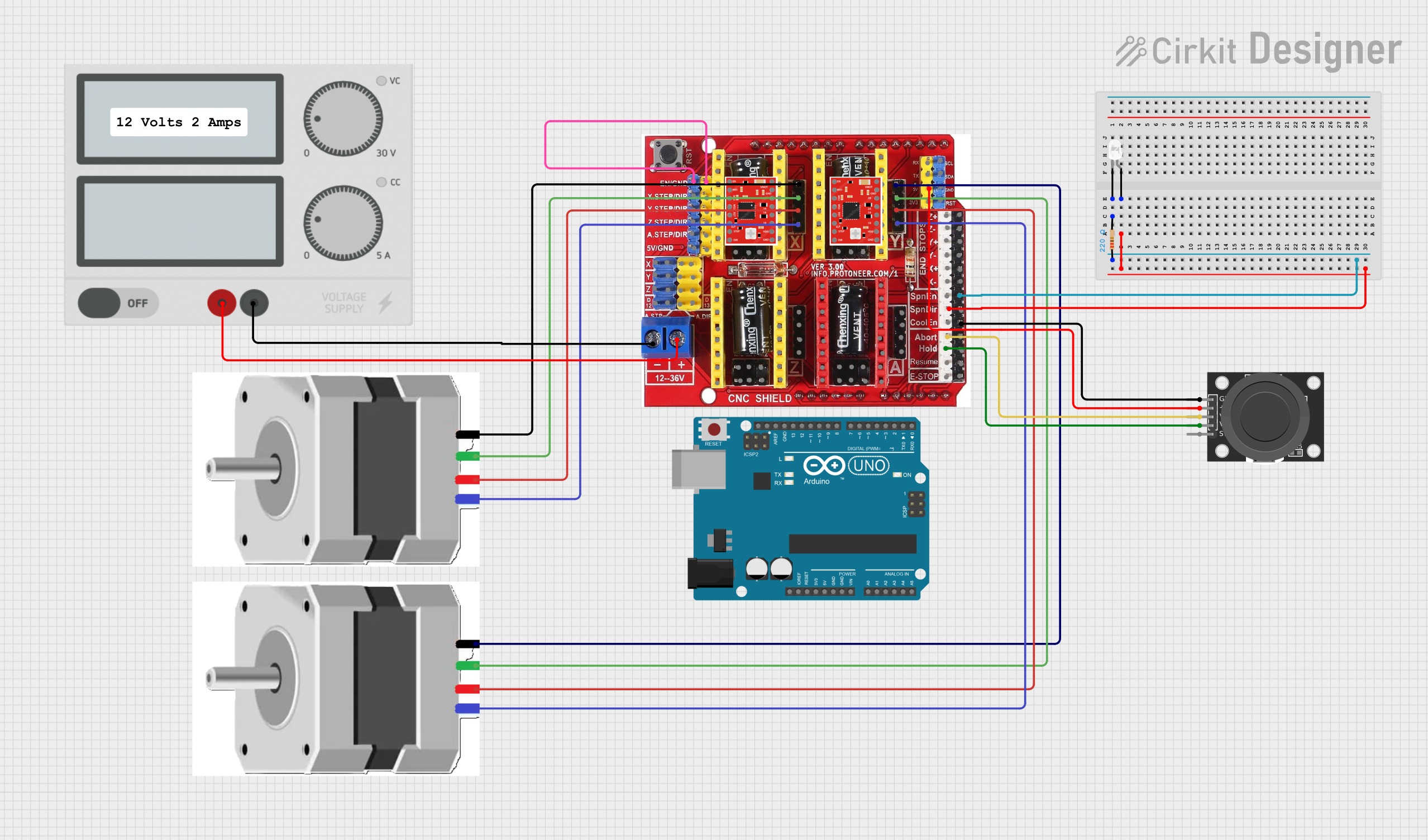

Open Project in Cirkit Designer

Open Project in Cirkit Designer

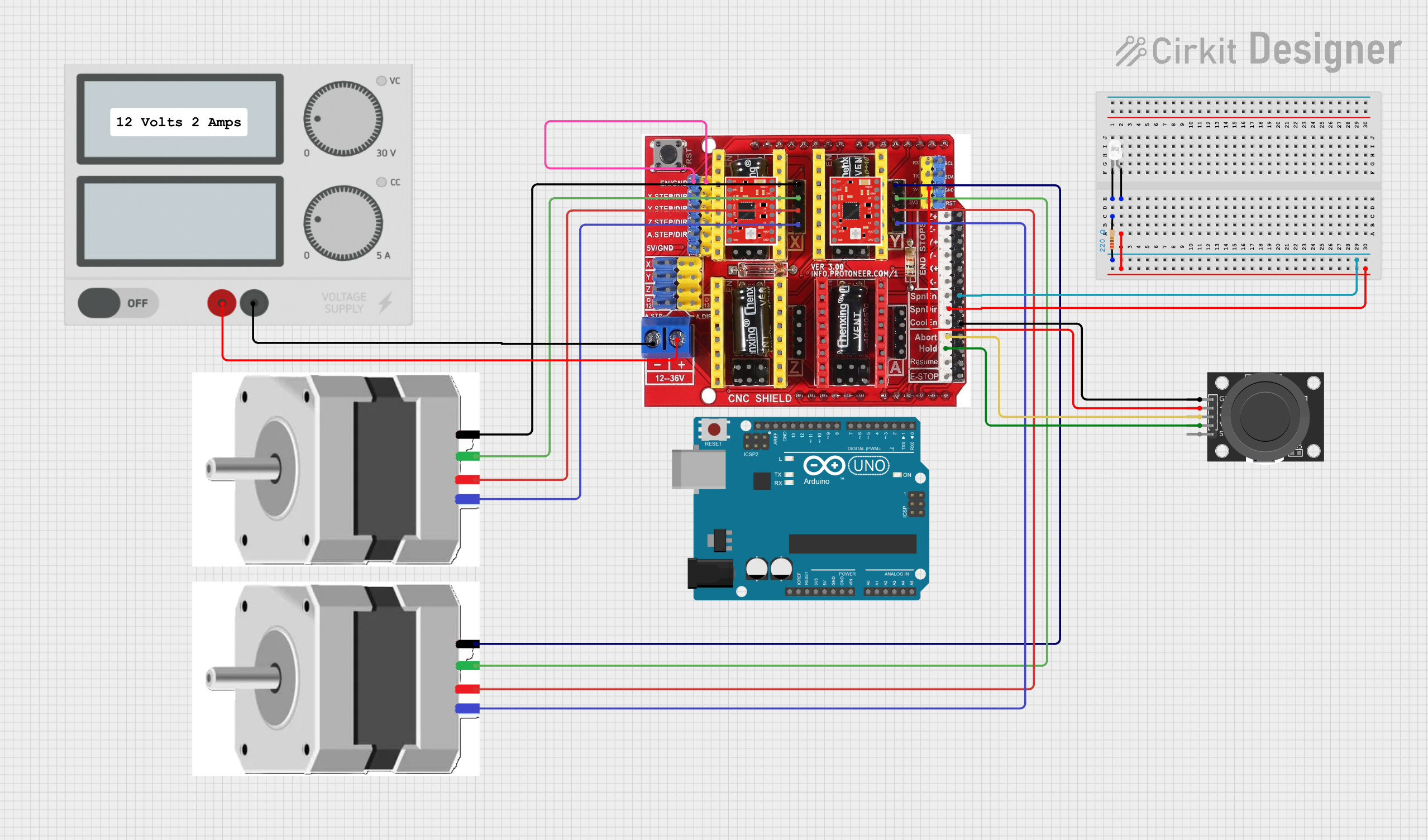

Open Project in Cirkit Designer

Open Project in Cirkit DesignerExplore Projects Built with CNC SHIELD V3

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit DesignerCommon Applications and Use Cases

- CNC milling machines

- 3D printers

- Laser engravers

- Robotics and automation projects

- Educational and prototyping purposes

Technical Specifications

The CNC SHIELD V3 is designed to simplify the control of stepper motors and other peripherals in CNC and related applications. Below are its key technical details:

Key Technical Details

- Input Voltage: 12V to 36V DC (via external power supply)

- Stepper Motor Drivers Supported: A4988, DRV8825, or compatible drivers

- Number of Axes: 4 (X, Y, Z, and A for dual Y-axis or rotary axis)

- Microstepping Support: Configurable via jumpers (Full, 1/2, 1/4, 1/8, 1/16, etc.)

- Endstop Connections: 6 (2 per axis for X, Y, and Z)

- Firmware Compatibility: GRBL (open-source CNC firmware)

- Dimensions: 69mm x 54mm

- Arduino Compatibility: Designed to stack on Arduino UNO R3

Pin Configuration and Descriptions

The CNC SHIELD V3 features a straightforward pin layout for easy integration. Below is a detailed table of the pin configuration:

| Pin Name | Description |

|---|---|

| X-STEP, Y-STEP, Z-STEP, A-STEP | Step signal input for X, Y, Z, and A axes stepper motors. |

| X-DIR, Y-DIR, Z-DIR, A-DIR | Direction signal input for X, Y, Z, and A axes stepper motors. |

| EN (Enable) | Enables or disables all stepper motor drivers. |

| X+, X-, Y+, Y-, Z+, Z- | Endstop connections for X, Y, and Z axes (positive and negative limits). |

| Spindle Enable (SPN EN) | Controls spindle motor on/off. |

| Spindle Direction (SPN DIR) | Controls spindle motor direction. |

| Coolant Enable (Cool EN) | Controls coolant system on/off. |

| VCC, GND | Power supply pins for logic and stepper motor drivers. |

| Motor Power (12-36V) | External power input for stepper motors. |

Usage Instructions

The CNC SHIELD V3 is designed to be user-friendly and easy to integrate into CNC and related projects. Follow the steps below to use the shield effectively:

Step 1: Hardware Setup

- Stack the Shield: Place the CNC SHIELD V3 on top of an Arduino UNO R3, ensuring the pins align correctly.

- Install Stepper Drivers: Insert A4988 or DRV8825 stepper motor drivers into the designated sockets. Ensure proper orientation (refer to the markings on the shield).

- Connect Stepper Motors: Attach the stepper motors to the X, Y, Z, and A motor outputs.

- Connect Endstops: Wire the endstop switches to the corresponding X, Y, and Z endstop pins.

- Power the Shield: Connect an external power supply (12V to 36V DC) to the motor power input.

Step 2: Software Setup

- Install GRBL Firmware: Upload the GRBL firmware to the Arduino UNO using the Arduino IDE.

- Configure GRBL Settings: Use a GRBL-compatible software (e.g., Universal Gcode Sender) to configure settings such as steps per mm, feed rates, and acceleration.

- Connect to PC: Use a USB cable to connect the Arduino UNO to your computer.

Step 3: Testing and Calibration

- Test Motor Movement: Use GRBL commands (e.g.,

$X,$H,G0 X10) to test motor movement and ensure proper operation. - Calibrate Axes: Adjust the stepper driver current and microstepping settings as needed for smooth operation.

Example Arduino Code

Below is an example of how to control the CNC SHIELD V3 using GRBL firmware. Note that GRBL handles most of the low-level control, so direct Arduino programming is not typically required.

// Example: Sending GRBL commands via Arduino Serial Monitor

// Ensure GRBL firmware is uploaded to the Arduino UNO

void setup() {

Serial.begin(115200); // Set baud rate to match GRBL firmware

delay(1000); // Wait for GRBL to initialize

Serial.println("$X"); // Unlock GRBL

Serial.println("G21"); // Set units to millimeters

Serial.println("G90"); // Set to absolute positioning

Serial.println("G0 X10 Y10 Z5"); // Move to X=10mm, Y=10mm, Z=5mm

}

void loop() {

// No code needed in loop for GRBL control

}

Important Considerations and Best Practices

- Cooling: Use heatsinks and/or a cooling fan for stepper motor drivers to prevent overheating.

- Power Supply: Ensure the external power supply matches the voltage and current requirements of your stepper motors.

- Microstepping: Configure microstepping jumpers based on your application's precision and torque requirements.

- Endstop Polarity: Verify the polarity of endstop switches to avoid incorrect triggering.

Troubleshooting and FAQs

Common Issues and Solutions

Stepper Motors Not Moving

- Cause: Incorrect wiring or loose connections.

- Solution: Double-check motor wiring and ensure drivers are properly seated.

Overheating Stepper Drivers

- Cause: Excessive current or insufficient cooling.

- Solution: Adjust the current limit on the stepper driver and add heatsinks or a fan.

GRBL Not Responding

- Cause: Incorrect baud rate or firmware not uploaded.

- Solution: Verify the baud rate (115200 by default) and re-upload GRBL firmware.

Endstops Not Working

- Cause: Miswired or faulty endstop switches.

- Solution: Check wiring and test switches with a multimeter.

FAQs

Q: Can I use the CNC SHIELD V3 with an Arduino Mega?

A: The CNC SHIELD V3 is designed for the Arduino UNO form factor. While it may be possible to adapt it for use with an Arduino Mega, additional wiring and configuration would be required.

Q: What stepper motors are compatible with this shield?

A: The shield supports most bipolar stepper motors that operate within the voltage and current limits of the A4988 or DRV8825 drivers.

Q: How do I reset the GRBL settings?

A: Send the $RST=* command via a GRBL-compatible software to reset all settings to default.

Q: Can I control a spindle motor with this shield?

A: Yes, the shield includes pins for spindle enable and direction control, which can be used with a compatible spindle motor and driver.

By following this documentation, you can effectively use the CNC SHIELD V3 in your CNC, 3D printing, or laser engraving projects.