How to Use 775 motor: Examples, Pinouts, and Specs

Design with 775 motor in Cirkit Designer

Design with 775 motor in Cirkit DesignerIntroduction

The 775 motor is a high-power, brushed DC electric motor commonly utilized in a wide range of applications including robotics, radio-controlled vehicles, power tools, and industrial machinery. Its robust design and high torque output make it a preferred choice for projects requiring a durable and reliable motor solution.

Explore Projects Built with 775 motor

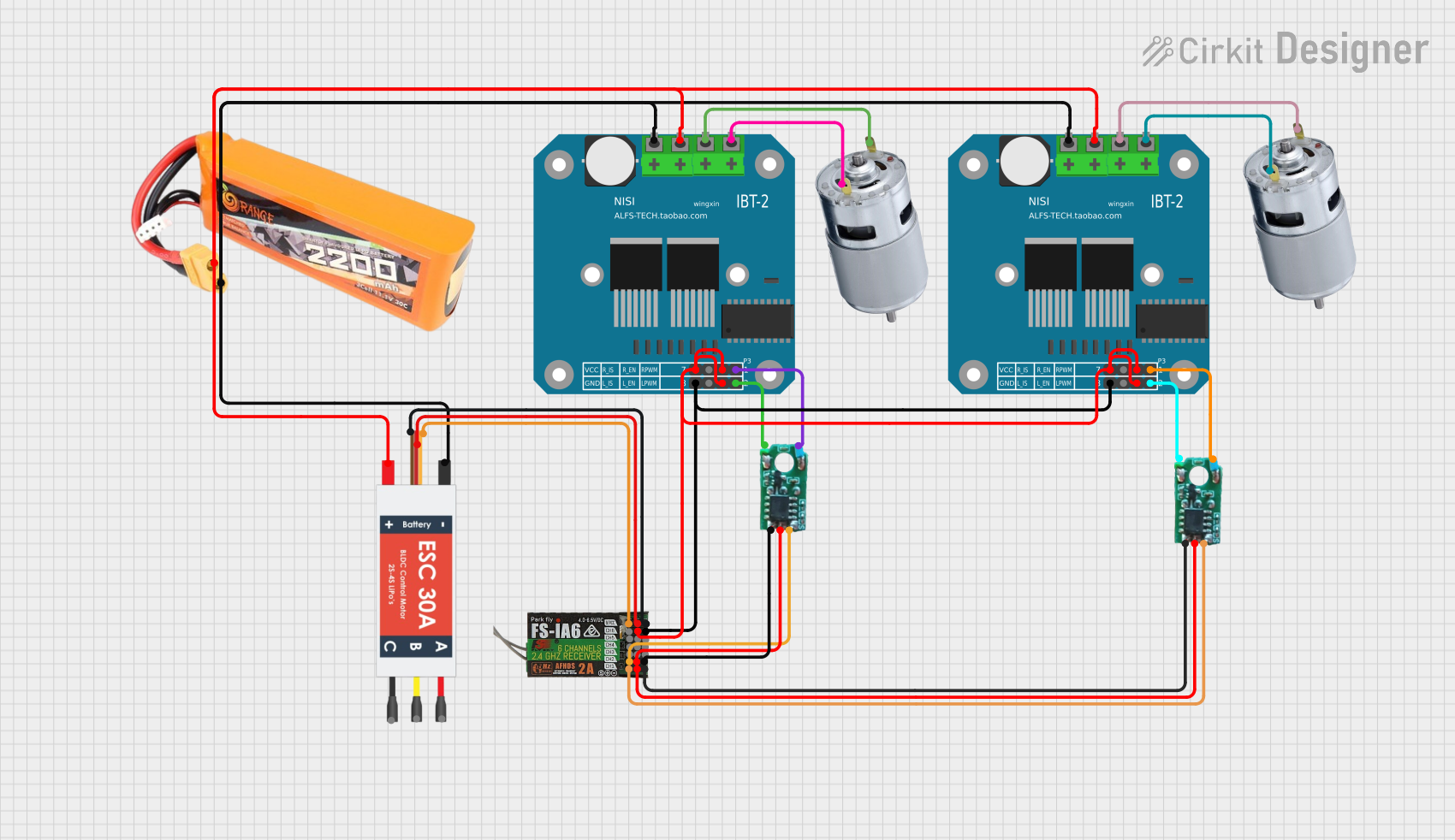

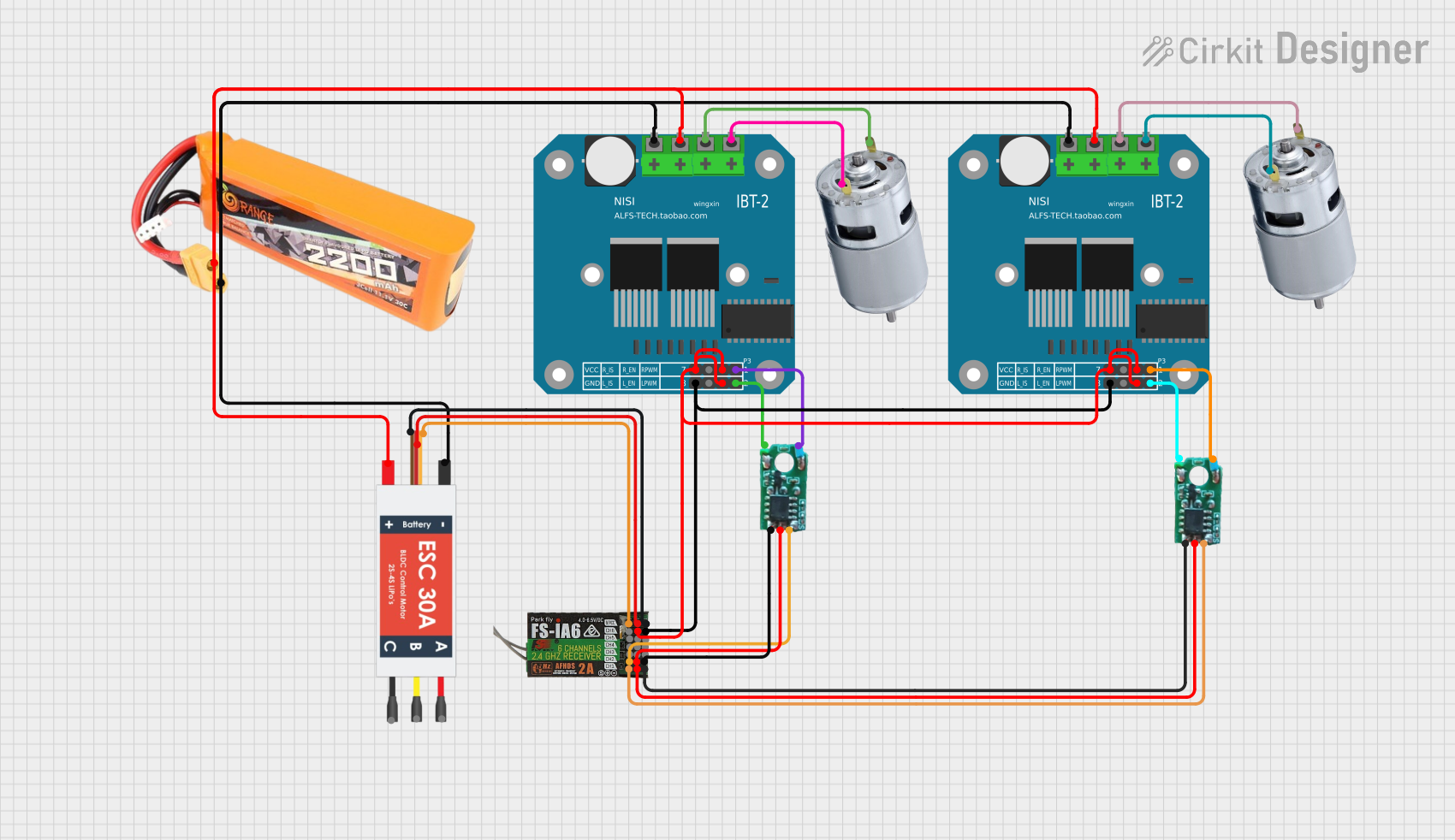

Open Project in Cirkit Designer

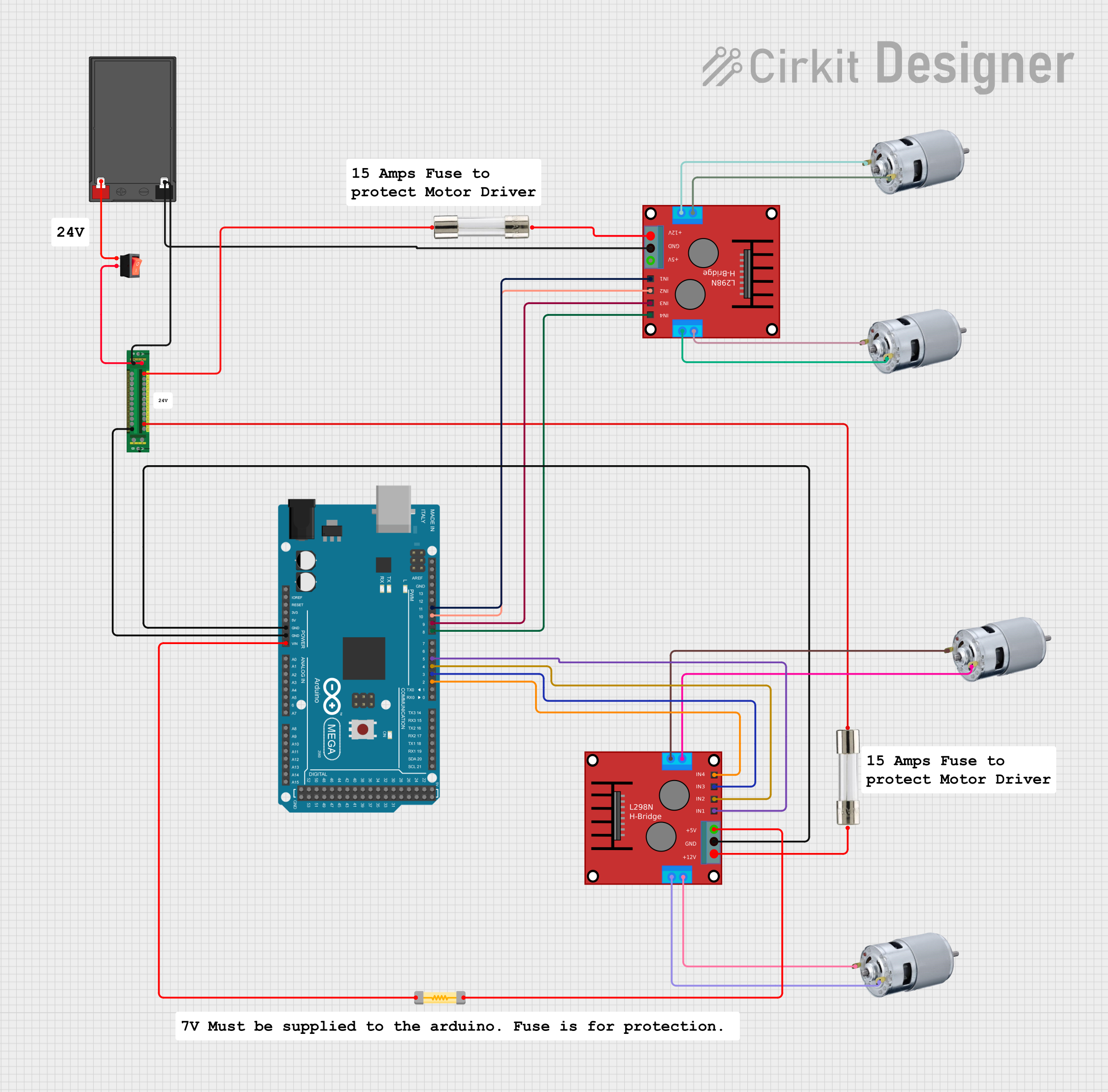

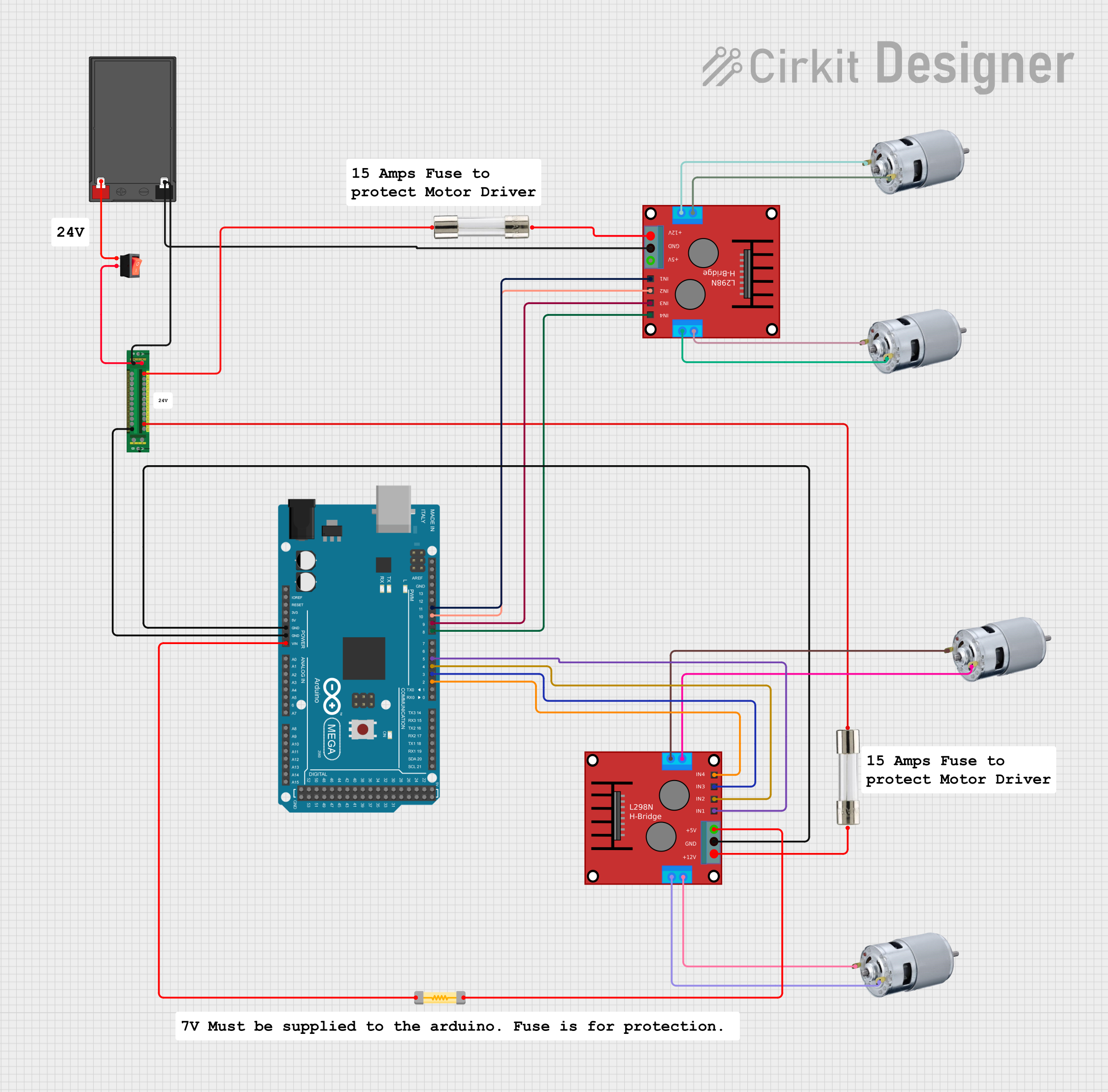

Open Project in Cirkit Designer

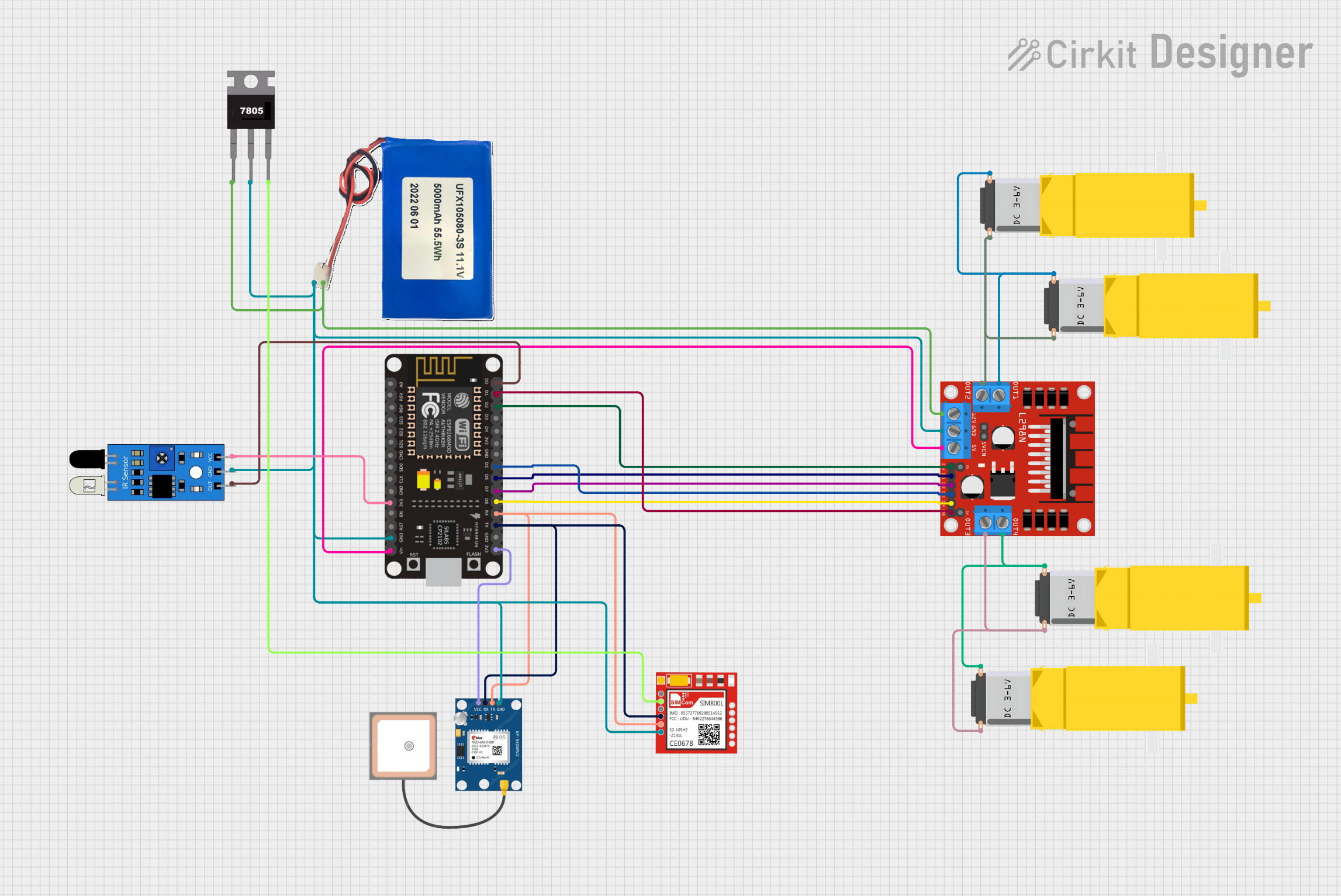

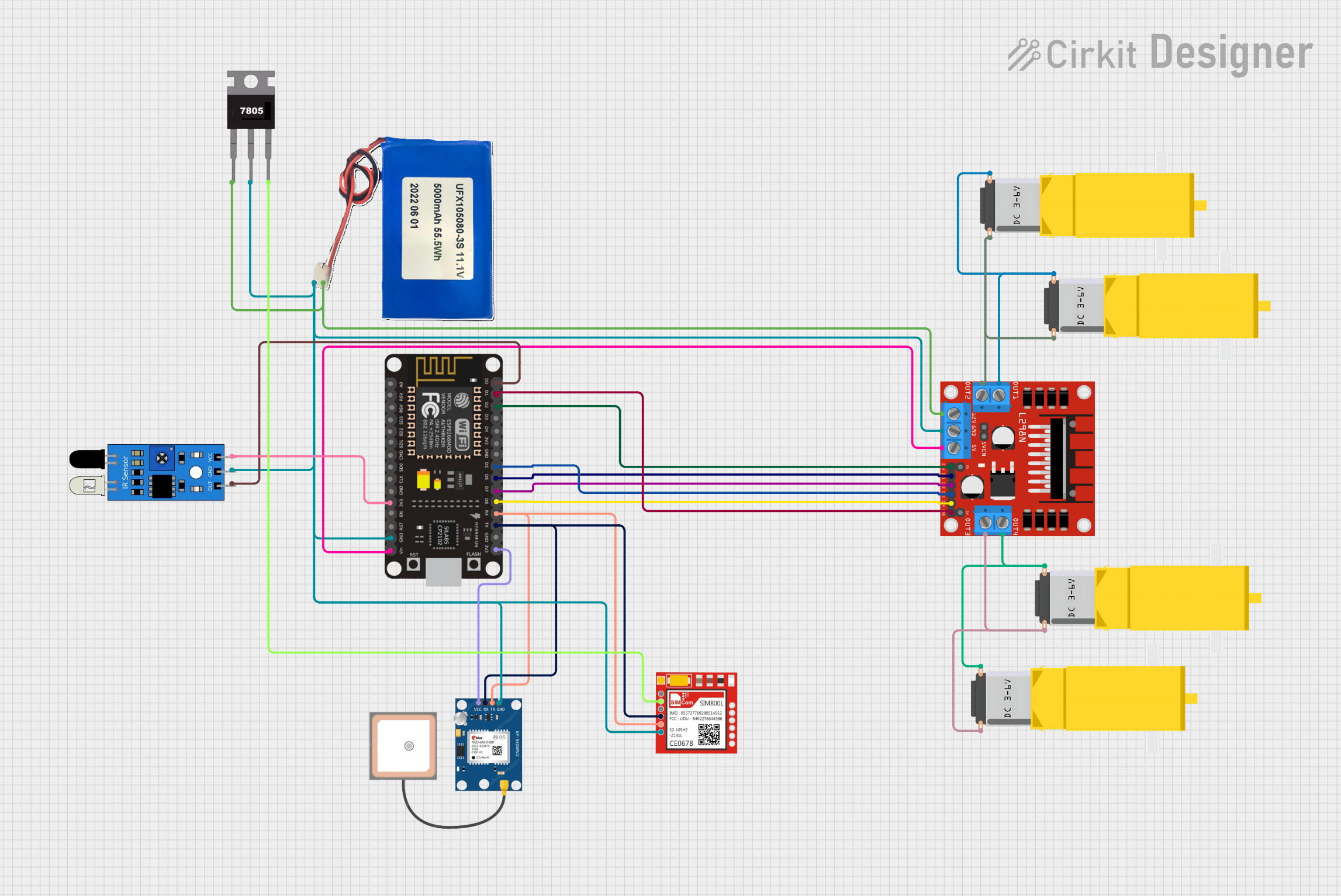

Open Project in Cirkit Designer

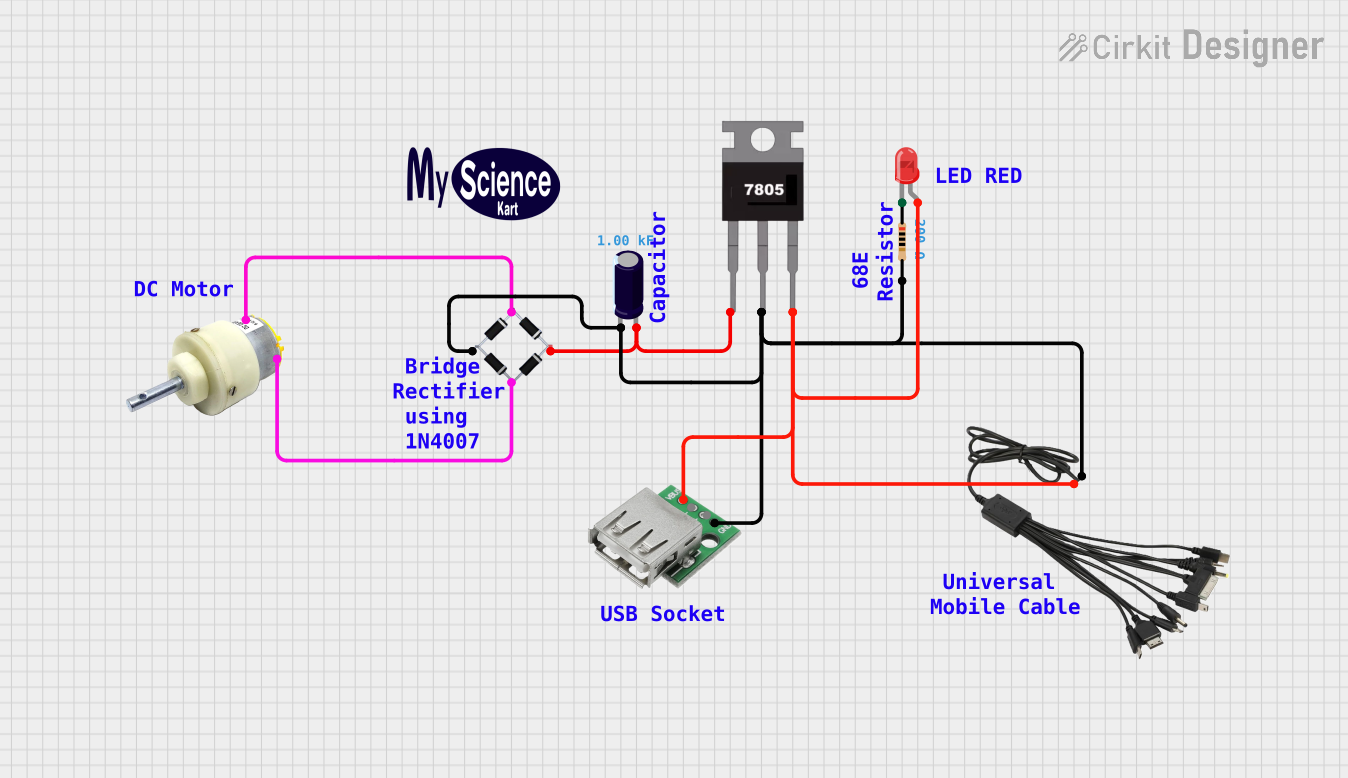

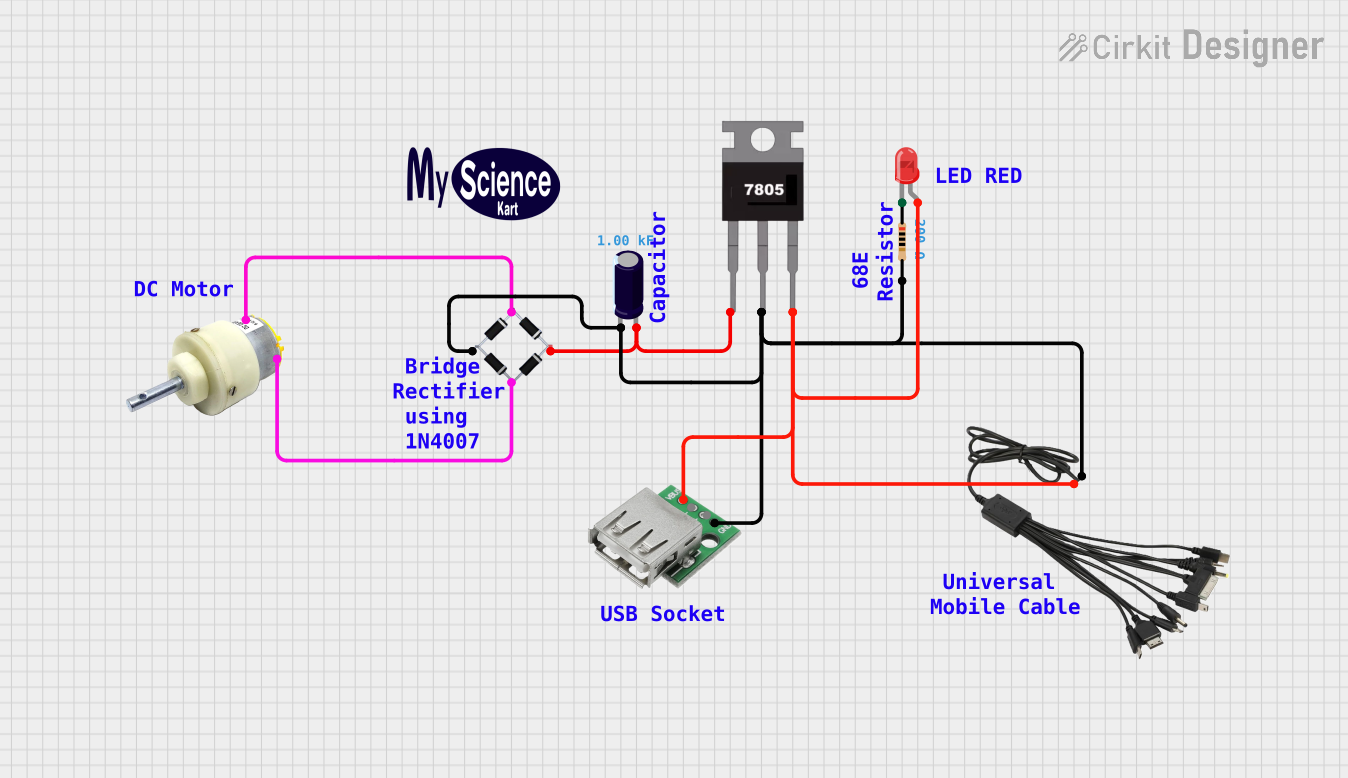

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit DesignerExplore Projects Built with 775 motor

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit DesignerCommon Applications and Use Cases

- Robotics: Actuation of robotic arms, wheels, and tracks.

- Radio-Controlled (RC) Vehicles: Propulsion of cars, boats, and drones.

- Power Tools: Drives for drills, saws, and sanders.

- Industrial Machinery: Automation equipment and conveyor systems.

Technical Specifications

Key Technical Details

- Nominal Voltage: 12V DC (operating range typically 6-20V)

- No-Load Speed: Approximately 7000-12000 RPM

- No-Load Current: 1.2A

- Rated Load Current: ~5A

- Stall Current: 20A-30A (varies by specific model)

- Power Ratings: 100W-250W (varies by specific model)

- Torque: Varies by specific model, typically around 0.5-2 Nm

- Efficiency: Varies by specific model, generally around 70-80%

- Operating Temperature: -10°C to +60°C

Pin Configuration and Descriptions

| Pin No. | Description | Notes |

|---|---|---|

| 1 | Positive Terminal | Connect to positive voltage supply |

| 2 | Negative Terminal | Connect to ground or negative voltage supply |

Usage Instructions

How to Use the 775 Motor in a Circuit

- Power Supply: Ensure that the power supply can handle the motor's nominal voltage and stall current without overheating or shutting down.

- Motor Driver: Use an appropriate motor driver capable of handling the motor's current requirements.

- PWM Control: For speed control, use a PWM signal from a microcontroller to the motor driver.

- Mounting: Secure the motor firmly to prevent vibrations and ensure proper alignment with the load.

- Ventilation: Ensure adequate ventilation around the motor to prevent overheating during prolonged use.

Important Considerations and Best Practices

- Current Limiting: Implement current limiting to protect the motor from excessive current draw, especially at startup or stall.

- Diode Protection: Use flyback diodes across the motor terminals to protect the driver from voltage spikes.

- Gear Reduction: Consider using gear reduction if high torque at lower speeds is required.

- Safety: Always disconnect the power supply before making changes to the motor connections.

Troubleshooting and FAQs

Common Issues

- Motor Does Not Start: Check power supply and wiring connections. Ensure the motor driver is functioning correctly.

- Excessive Noise or Vibration: Verify that the motor is mounted securely. Check for any obstructions or misalignments.

- Overheating: Ensure proper ventilation and check for overloading or excessive duty cycles.

Solutions and Tips for Troubleshooting

- Motor Does Not Start: Confirm that the voltage at the motor terminals is within the operating range. Inspect the motor driver and control signals.

- Excessive Noise or Vibration: Realign the motor or load. Add dampening materials if necessary.

- Overheating: Reduce the load or duty cycle. Improve airflow or add additional cooling mechanisms.

FAQs

Q: Can I run the 775 motor at a higher voltage than rated? A: Operating the motor above its rated voltage can increase performance but may reduce its lifespan and increase the risk of overheating.

Q: What is the lifespan of a 775 motor? A: The lifespan varies based on usage, but typically these motors can last for several thousand hours of operation under normal conditions.

Q: How do I reverse the direction of the motor? A: Reverse the polarity of the power supply to the motor terminals.

Q: Can I control the 775 motor with an Arduino? A: Yes, you can control the motor using an Arduino by connecting it through a suitable motor driver and using PWM signals for speed control.

Example Arduino Code for Motor Control

// Define motor control pins

const int pwmPin = 3; // PWM control (speed)

const int dirPin = 4; // Direction control

void setup() {

pinMode(pwmPin, OUTPUT);

pinMode(dirPin, OUTPUT);

}

void loop() {

// Set motor direction

digitalWrite(dirPin, HIGH); // Set to LOW to reverse direction

// Set motor speed (0-255)

analogWrite(pwmPin, 128); // Set to desired PWM value (50% duty cycle)

// Add your code to change speed or direction based on your application needs

}

Note: The above code assumes the use of a motor driver compatible with PWM control. Always ensure that the motor driver can handle the current and voltage requirements of the 775 motor.