How to Use motor driver: Examples, Pinouts, and Specs

Design with motor driver in Cirkit Designer

Design with motor driver in Cirkit DesignerIntroduction

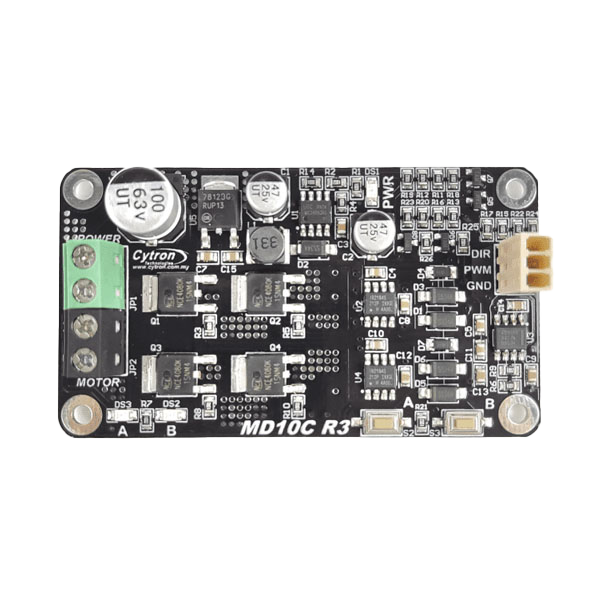

The Cytron MD10C is a robust and versatile motor driver designed to control DC motors with high efficiency and precision. It acts as an interface between a microcontroller (e.g., Arduino, Raspberry Pi) and a DC motor, enabling users to regulate the motor's speed and direction. The MD10C is particularly well-suited for applications requiring high current and voltage handling, such as robotics, automation systems, and motorized vehicles.

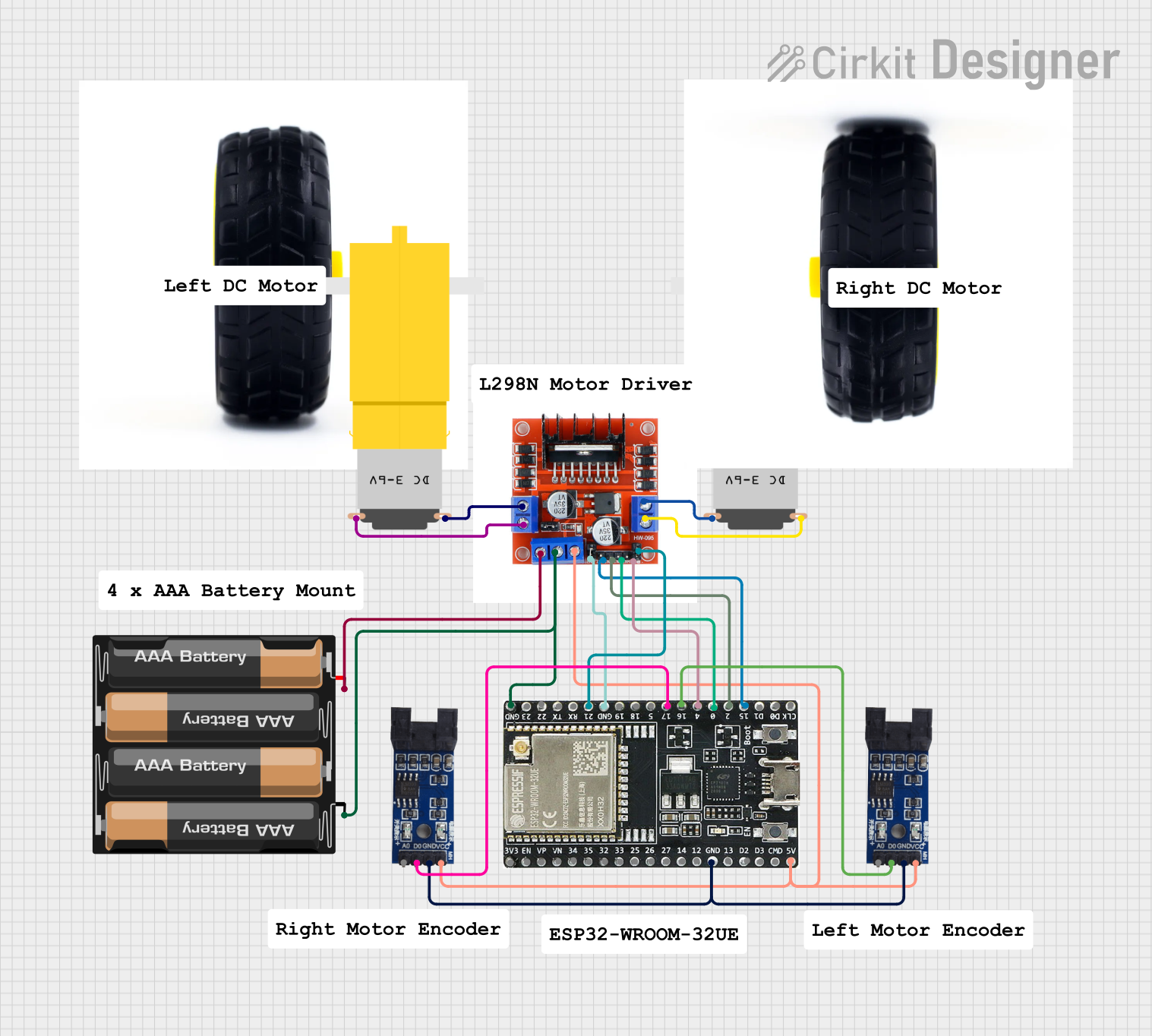

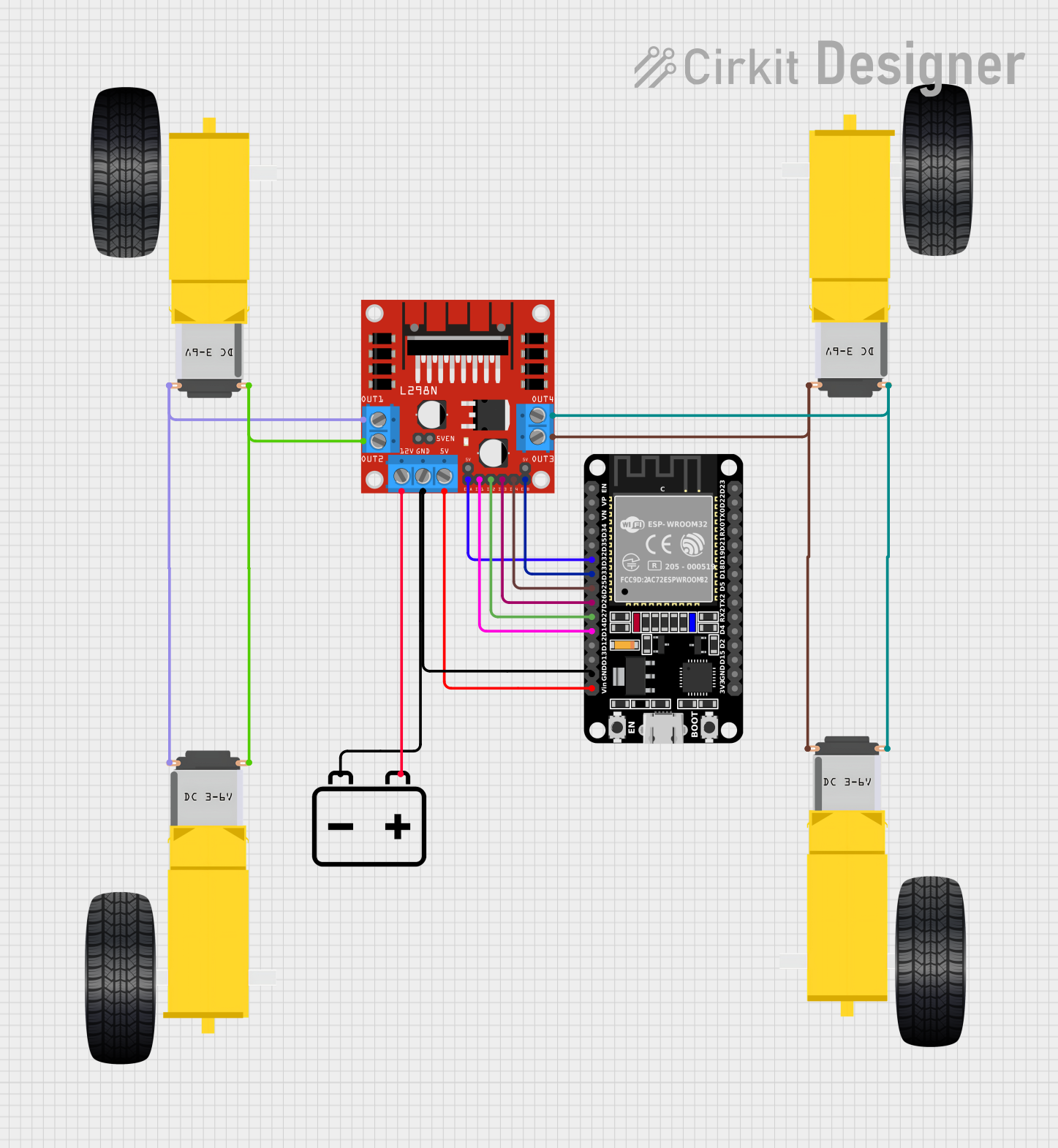

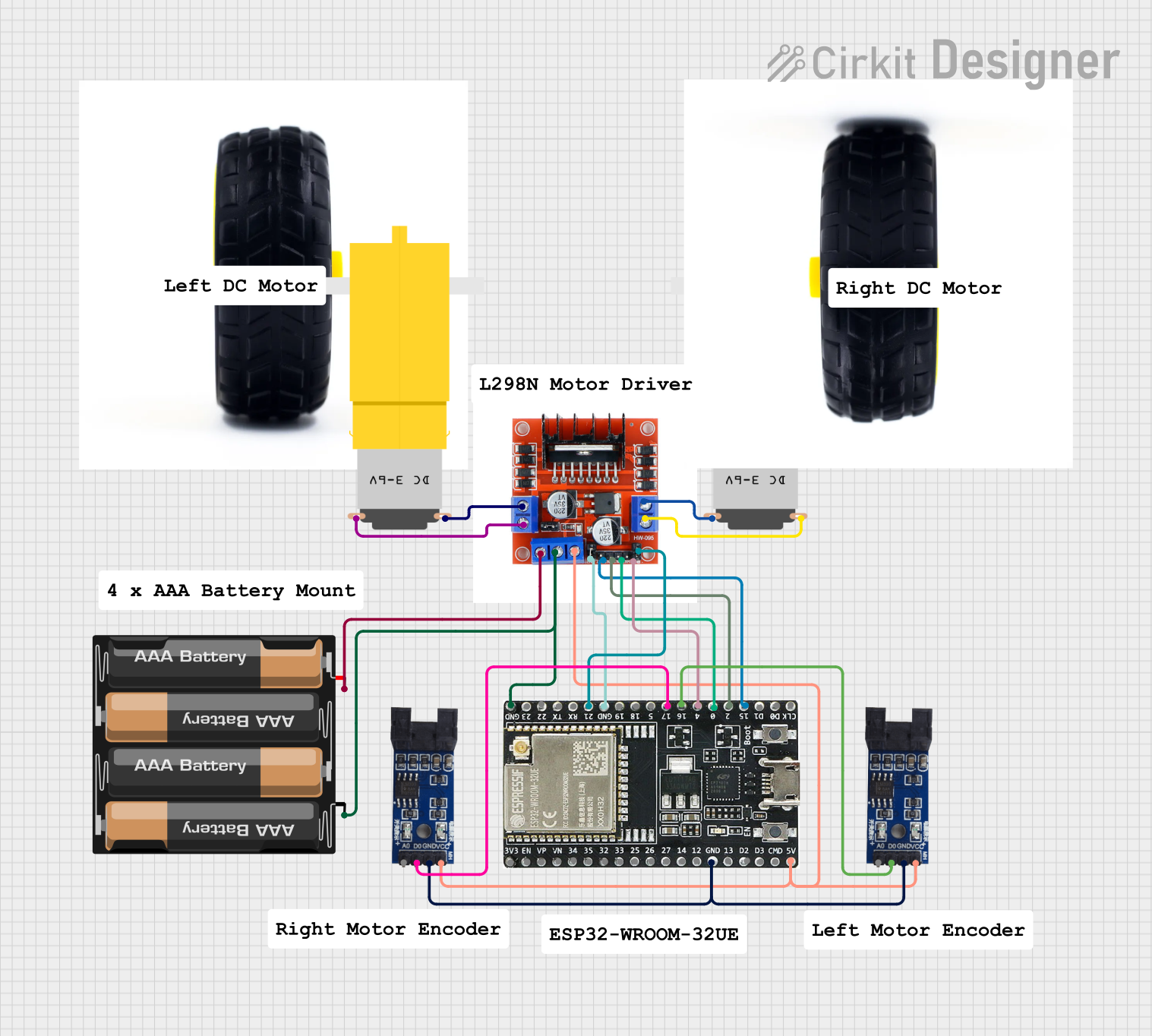

Explore Projects Built with motor driver

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit DesignerExplore Projects Built with motor driver

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit DesignerCommon Applications

- Robotics and automation systems

- Electric vehicles and motorized carts

- Conveyor belts and industrial machinery

- DIY projects involving DC motor control

Technical Specifications

The Cytron MD10C motor driver is designed to handle a wide range of DC motor control requirements. Below are its key technical specifications:

| Parameter | Specification |

|---|---|

| Operating Voltage | 7V to 30V DC |

| Continuous Current | Up to 10A |

| Peak Current | 30A (for 10 seconds) |

| Control Signal Voltage | 3.3V or 5V logic compatible |

| PWM Frequency | Up to 20 kHz |

| Motor Direction Control | Forward and Reverse |

| Protection Features | Overcurrent, Overtemperature, and Reverse Polarity |

Pin Configuration and Descriptions

The MD10C features a simple pinout for easy integration into your circuit. Below is the pin configuration:

| Pin Name | Type | Description |

|---|---|---|

| VM | Power Input | Connect to the positive terminal of the motor power supply (7V to 30V). |

| GND | Power Ground | Connect to the ground of the motor power supply and the microcontroller. |

| PWM | Input Signal | Pulse Width Modulation (PWM) input for speed control (3.3V or 5V logic). |

| DIR | Input Signal | Direction control input: HIGH for forward, LOW for reverse (3.3V or 5V logic). |

| MOTOR+ | Motor Output | Connect to the positive terminal of the DC motor. |

| MOTOR- | Motor Output | Connect to the negative terminal of the DC motor. |

Usage Instructions

How to Use the MD10C in a Circuit

- Power Supply: Connect the VM pin to a DC power supply (7V to 30V) and the GND pin to the ground of the power supply.

- Motor Connection: Connect the MOTOR+ and MOTOR- pins to the terminals of the DC motor.

- Control Signals:

- Connect the PWM pin to a PWM-capable pin on your microcontroller for speed control.

- Connect the DIR pin to a digital output pin on your microcontroller for direction control.

- Logic Voltage Compatibility: Ensure the control signals (PWM and DIR) are compatible with 3.3V or 5V logic levels.

Important Considerations

- Heat Dissipation: The MD10C can handle high currents, so ensure proper ventilation or use a heatsink if operating near the maximum current rating.

- Power Supply: Use a power supply capable of providing sufficient current for your motor to avoid voltage drops.

- PWM Frequency: For optimal performance, use a PWM frequency between 10 kHz and 20 kHz.

Example: Using MD10C with Arduino UNO

Below is an example Arduino sketch to control a DC motor using the MD10C:

// Define pin connections

const int pwmPin = 9; // PWM pin connected to MD10C's PWM input

const int dirPin = 8; // Direction pin connected to MD10C's DIR input

void setup() {

// Set pin modes

pinMode(pwmPin, OUTPUT);

pinMode(dirPin, OUTPUT);

}

void loop() {

// Rotate motor forward at 50% speed

digitalWrite(dirPin, HIGH); // Set direction to forward

analogWrite(pwmPin, 128); // Set speed (128/255 = 50%)

delay(3000); // Run for 3 seconds

// Rotate motor in reverse at 75% speed

digitalWrite(dirPin, LOW); // Set direction to reverse

analogWrite(pwmPin, 192); // Set speed (192/255 = 75%)

delay(3000); // Run for 3 seconds

}

Best Practices

- Always double-check your wiring before powering the circuit to avoid damage to the motor driver or other components.

- Use a fuse or circuit breaker to protect the motor driver and motor from overcurrent conditions.

- Avoid sudden changes in direction at high speeds to prevent mechanical stress on the motor.

Troubleshooting and FAQs

Common Issues and Solutions

Motor Not Running

- Cause: Incorrect wiring or insufficient power supply.

- Solution: Verify all connections and ensure the power supply meets the voltage and current requirements.

Motor Running in the Wrong Direction

- Cause: DIR pin logic level is incorrect.

- Solution: Check the DIR pin signal and ensure it matches the desired direction.

Motor Speed Not Changing

- Cause: PWM signal not being generated or incorrect frequency.

- Solution: Verify the PWM signal from the microcontroller using an oscilloscope or multimeter.

Overheating

- Cause: Prolonged operation at high current without proper cooling.

- Solution: Add a heatsink or improve ventilation around the motor driver.

FAQs

Q: Can I use the MD10C with a 3.3V microcontroller?

A: Yes, the MD10C is compatible with both 3.3V and 5V logic levels.Q: What is the maximum motor voltage I can use?

A: The MD10C supports motor voltages between 7V and 30V.Q: Can I control two motors with one MD10C?

A: No, the MD10C is designed to control a single DC motor.Q: Is the MD10C suitable for stepper motors?

A: No, the MD10C is specifically designed for DC motors, not stepper motors.

By following this documentation, you can effectively integrate the Cytron MD10C motor driver into your projects for precise and reliable motor control.