How to Use Power Window Motor 12V: Examples, Pinouts, and Specs

Design with Power Window Motor 12V in Cirkit Designer

Design with Power Window Motor 12V in Cirkit DesignerIntroduction

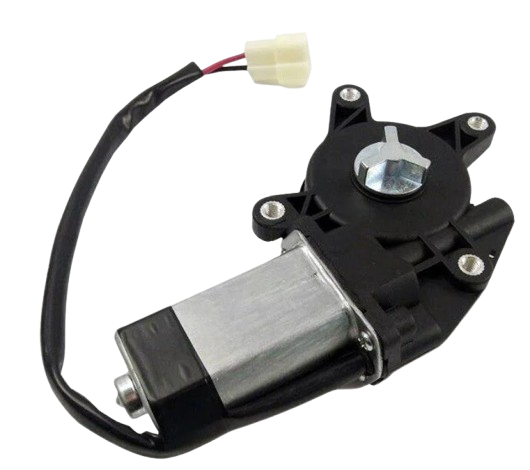

The Power Window Motor 12V is an electric motor designed to automate the raising and lowering of window glass in vehicles. It operates on a 12V DC power supply, making it compatible with most automotive electrical systems. This motor is a critical component in modern power window systems, providing smooth and reliable operation.

Explore Projects Built with Power Window Motor 12V

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit DesignerExplore Projects Built with Power Window Motor 12V

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit DesignerCommon Applications and Use Cases

- Automotive power window systems in cars, trucks, and buses.

- Custom vehicle projects requiring automated window movement.

- Robotics and DIY projects involving linear or rotational motion.

- Industrial applications requiring small-scale motorized actuation.

Technical Specifications

The following table outlines the key technical details of the Power Window Motor 12V:

| Parameter | Specification |

|---|---|

| Operating Voltage | 12V DC |

| Current Draw (No Load) | ~2A |

| Current Draw (Full Load) | ~10A |

| Stall Current | ~15A |

| Rated Torque | 10-15 Nm (varies by model) |

| Speed (No Load) | ~50-100 RPM |

| Motor Type | Brushed DC Motor |

| Operating Temperature | -20°C to 60°C |

| Weight | ~1.5-2.5 kg |

Pin Configuration and Descriptions

The Power Window Motor 12V typically has two terminals for operation. The table below describes the pin configuration:

| Pin/Terminal | Description |

|---|---|

| Terminal 1 | Positive terminal (+12V DC input) |

| Terminal 2 | Negative terminal (Ground or -12V input) |

Note: Reversing the polarity of the terminals will reverse the motor's direction, allowing for both upward and downward window movement.

Usage Instructions

How to Use the Component in a Circuit

- Power Supply: Connect the motor to a 12V DC power source capable of supplying sufficient current (at least 15A for stall conditions).

- Polarity Control: Use a DPDT (Double Pole Double Throw) switch or an H-bridge motor driver to control the direction of the motor. This allows for both raising and lowering the window.

- Fuse Protection: Install a fuse rated for 15A-20A in series with the motor to protect against overcurrent conditions.

- Mounting: Securely mount the motor to the vehicle's door frame or desired location using appropriate brackets and screws.

Important Considerations and Best Practices

- Current Handling: Ensure the power supply and wiring can handle the motor's peak current (stall current of ~15A).

- Heat Dissipation: Avoid prolonged operation under heavy load to prevent overheating.

- Polarity Reversal: Use a motor driver or switch to safely reverse polarity without damaging the motor.

- Lubrication: Periodically check and lubricate the motor's moving parts to ensure smooth operation.

- Noise Reduction: Use rubber mounts or dampers to minimize vibration and noise during operation.

Example: Controlling the Motor with an Arduino UNO

The Power Window Motor 12V can be controlled using an Arduino UNO and an H-bridge motor driver (e.g., L298N). Below is an example code to control the motor's direction and speed:

// Arduino code to control a 12V Power Window Motor using an L298N motor driver

// Define motor control pins

const int motorPin1 = 5; // IN1 on L298N

const int motorPin2 = 6; // IN2 on L298N

const int enablePin = 9; // ENA on L298N (PWM pin)

// Setup function

void setup() {

pinMode(motorPin1, OUTPUT); // Set motorPin1 as output

pinMode(motorPin2, OUTPUT); // Set motorPin2 as output

pinMode(enablePin, OUTPUT); // Set enablePin as output

}

// Function to rotate motor forward

void motorForward(int speed) {

digitalWrite(motorPin1, HIGH); // Set IN1 high

digitalWrite(motorPin2, LOW); // Set IN2 low

analogWrite(enablePin, speed); // Set motor speed (0-255)

}

// Function to rotate motor backward

void motorBackward(int speed) {

digitalWrite(motorPin1, LOW); // Set IN1 low

digitalWrite(motorPin2, HIGH); // Set IN2 high

analogWrite(enablePin, speed); // Set motor speed (0-255)

}

// Function to stop the motor

void motorStop() {

digitalWrite(motorPin1, LOW); // Set IN1 low

digitalWrite(motorPin2, LOW); // Set IN2 low

analogWrite(enablePin, 0); // Set motor speed to 0

}

// Loop function

void loop() {

motorForward(200); // Rotate motor forward at 200/255 speed

delay(2000); // Run for 2 seconds

motorStop(); // Stop the motor

delay(1000); // Wait for 1 second

motorBackward(200); // Rotate motor backward at 200/255 speed

delay(2000); // Run for 2 seconds

motorStop(); // Stop the motor

delay(1000); // Wait for 1 second

}

Note: Ensure the motor driver is capable of handling the motor's current requirements.

Troubleshooting and FAQs

Common Issues and Solutions

Motor Does Not Operate:

- Cause: Insufficient power supply or loose connections.

- Solution: Verify the power supply voltage and current. Check all connections.

Motor Runs in One Direction Only:

- Cause: Faulty H-bridge driver or incorrect wiring.

- Solution: Check the H-bridge connections and ensure proper polarity control.

Motor Overheats:

- Cause: Prolonged operation under heavy load or insufficient ventilation.

- Solution: Allow the motor to cool down and avoid overloading. Ensure proper ventilation.

Excessive Noise or Vibration:

- Cause: Loose mounting or worn-out components.

- Solution: Tighten all mounting screws and inspect the motor for wear.

FAQs

Q1: Can I use a 24V power supply with this motor?

A1: No, the motor is designed for 12V operation. Using a higher voltage may damage the motor.

Q2: How do I reverse the motor's direction?

A2: Reverse the polarity of the terminals or use an H-bridge motor driver to control the direction electronically.

Q3: Can this motor be used for non-automotive applications?

A3: Yes, it can be used in robotics, DIY projects, and other applications requiring a 12V DC motor.

Q4: What type of lubrication should I use?

A4: Use a light machine oil or automotive-grade grease for lubrication.

Q5: How do I calculate the required power supply rating?

A5: Ensure the power supply can handle the motor's stall current (~15A) and provide a stable 12V output.