How to Use 3-Phase A/C GENARTOR: Examples, Pinouts, and Specs

Design with 3-Phase A/C GENARTOR in Cirkit Designer

Design with 3-Phase A/C GENARTOR in Cirkit DesignerIntroduction

The 3-Phase A/C Generator (Manufacturer: Cirkit, Part ID: 3-Phase A/C GENARTOR) is a device designed to convert mechanical energy into electrical energy through the principle of electromagnetic induction. It generates three alternating currents that are phase-shifted by 120 degrees, ensuring a stable and efficient power supply. This type of generator is widely used in industrial, commercial, and renewable energy applications due to its high efficiency and ability to deliver consistent power.

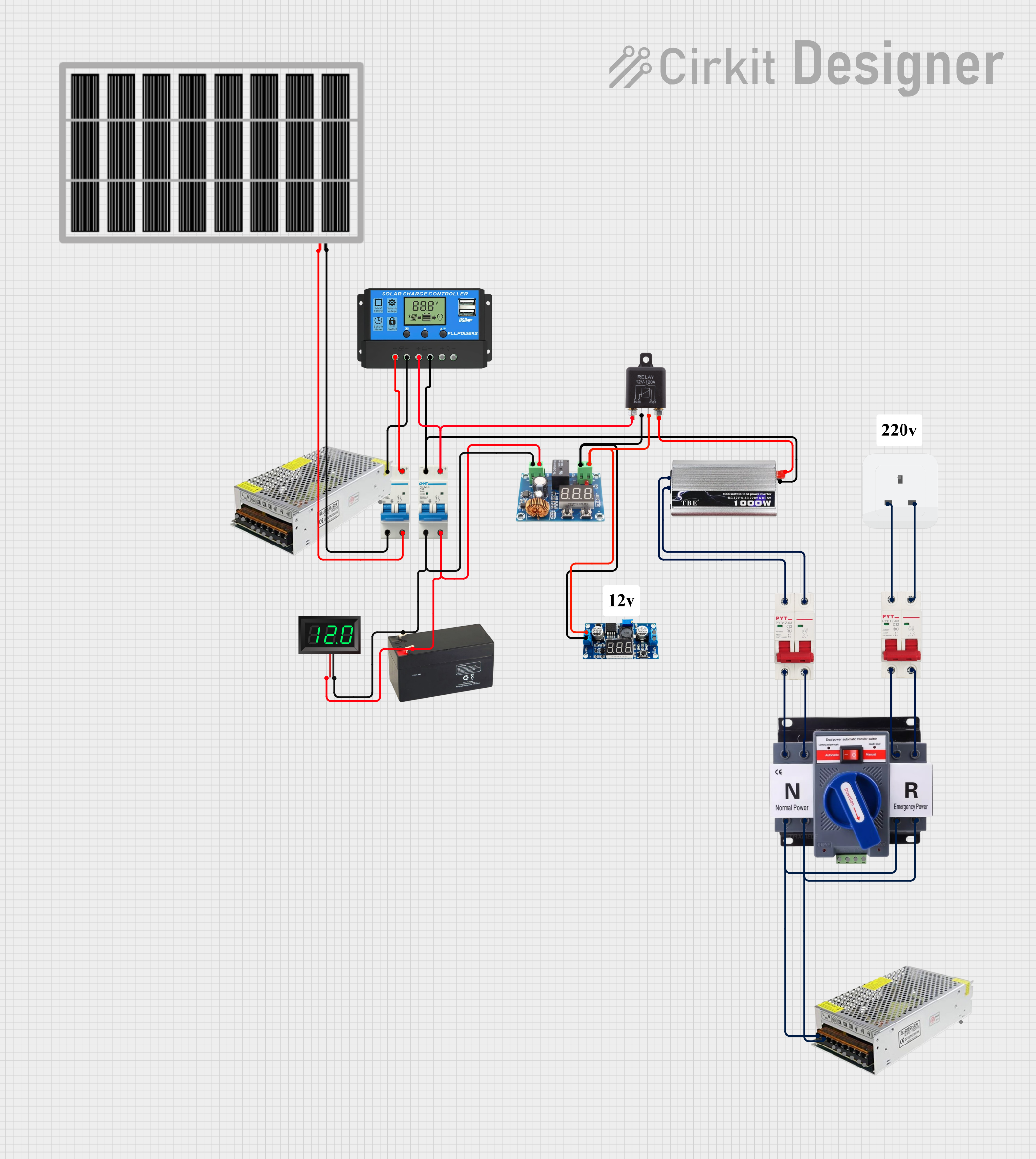

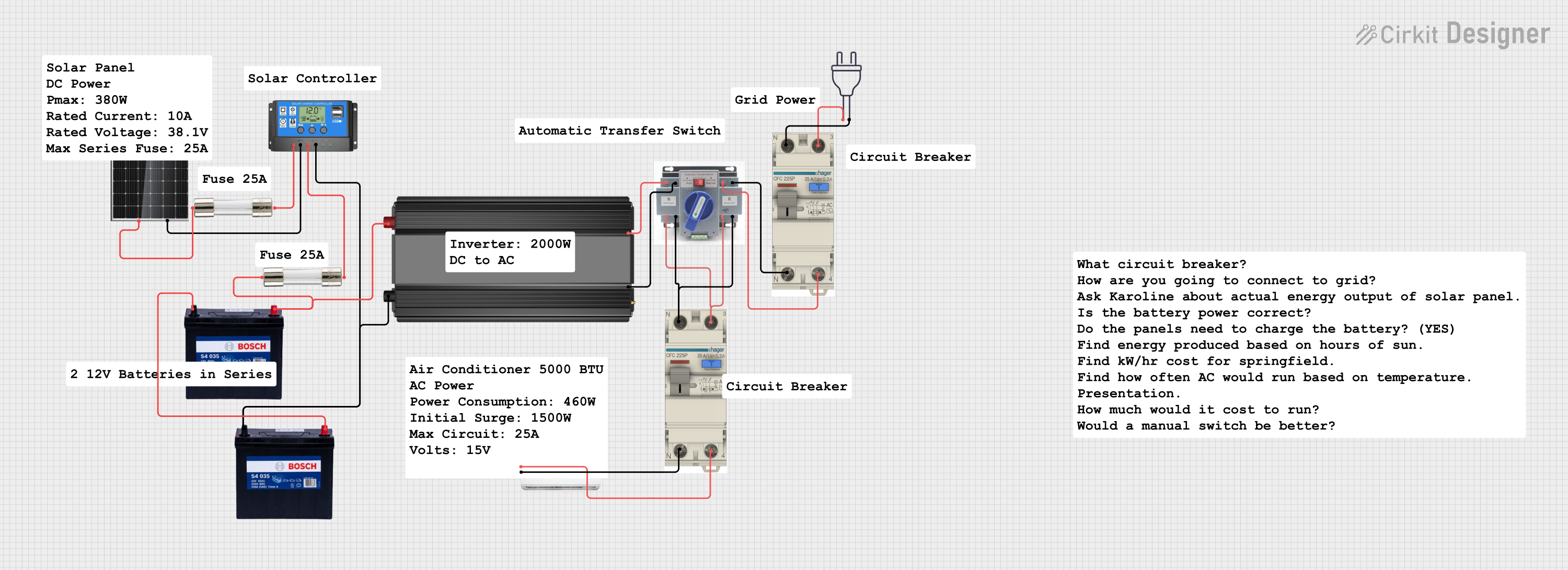

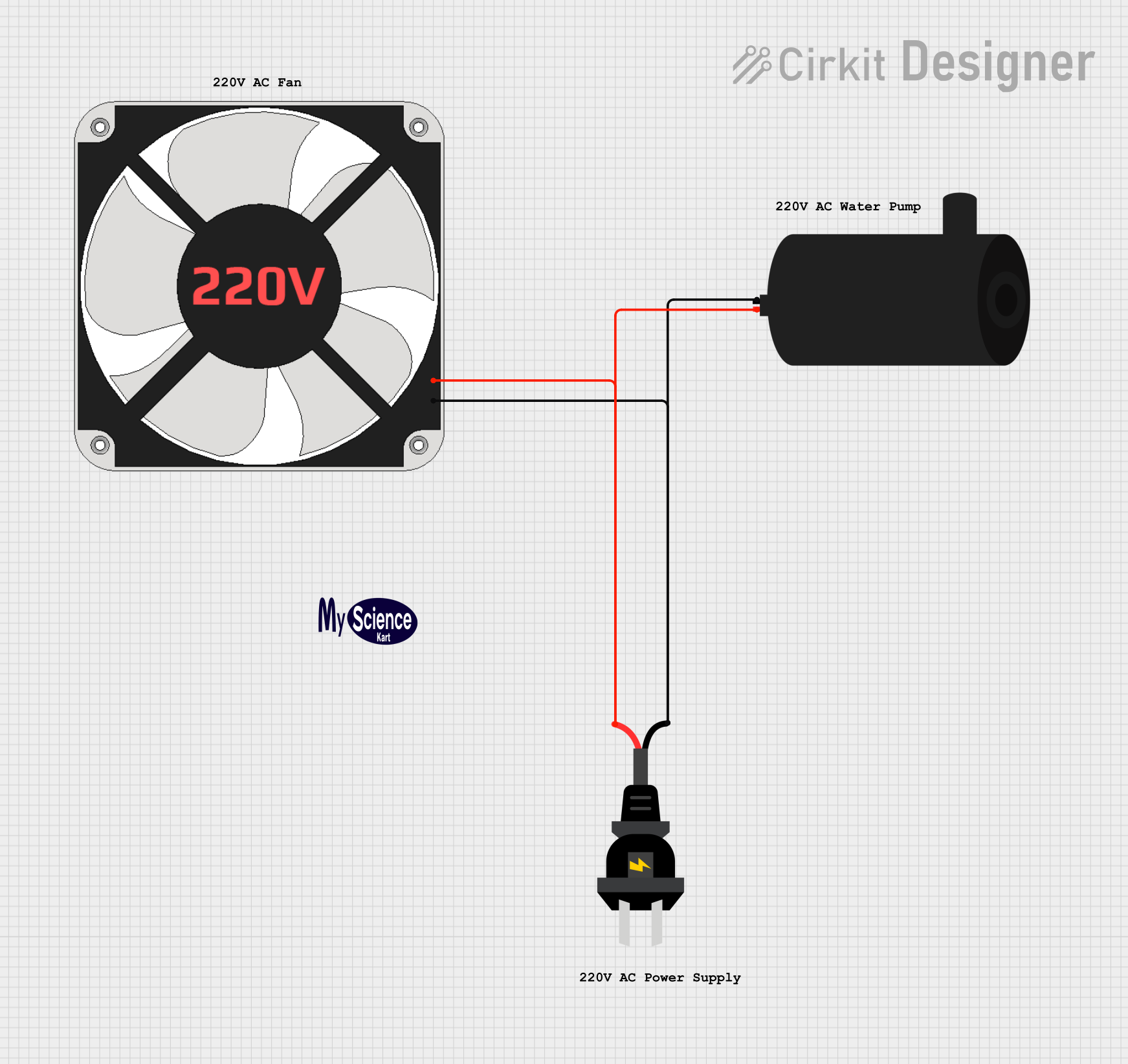

Explore Projects Built with 3-Phase A/C GENARTOR

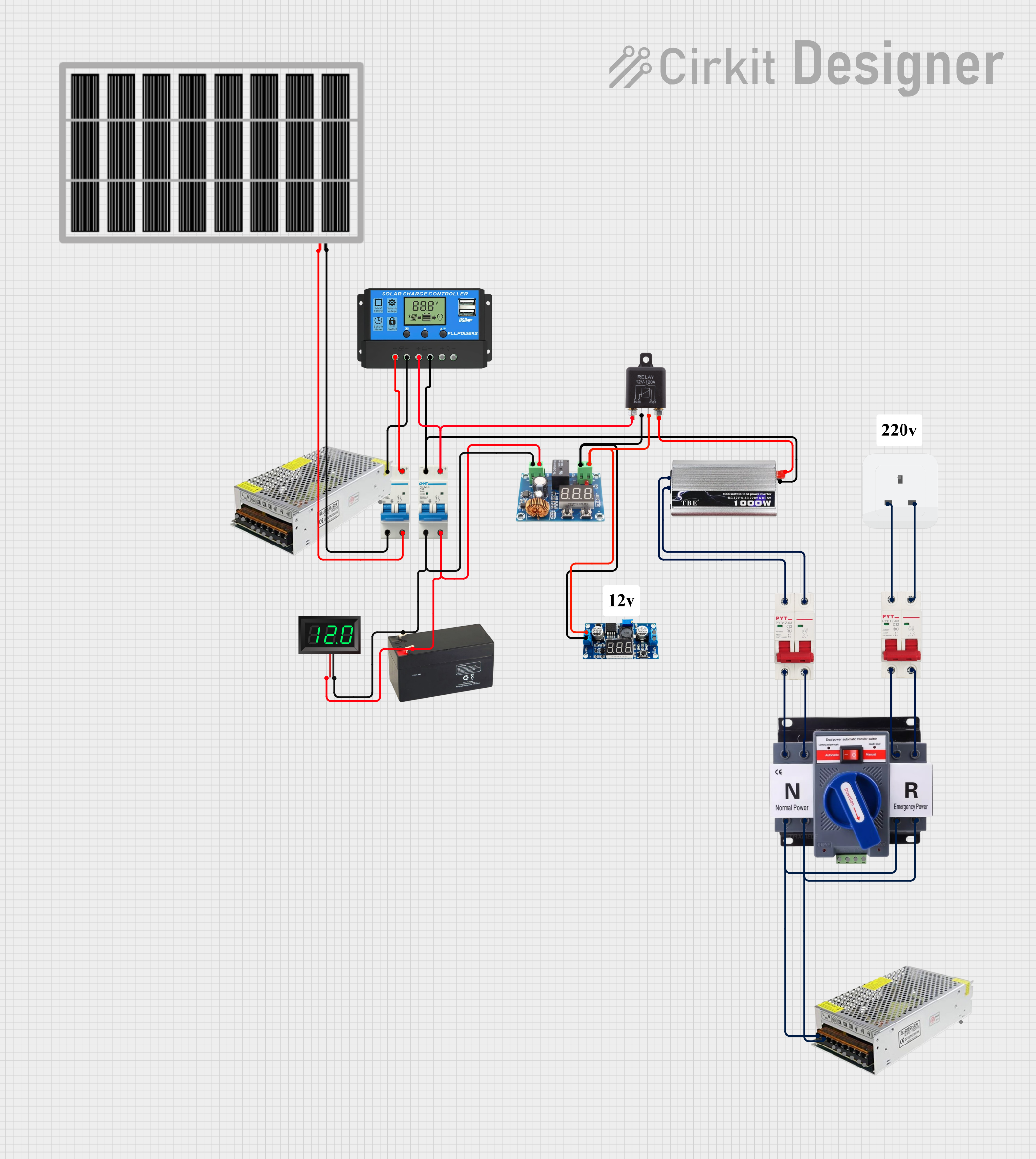

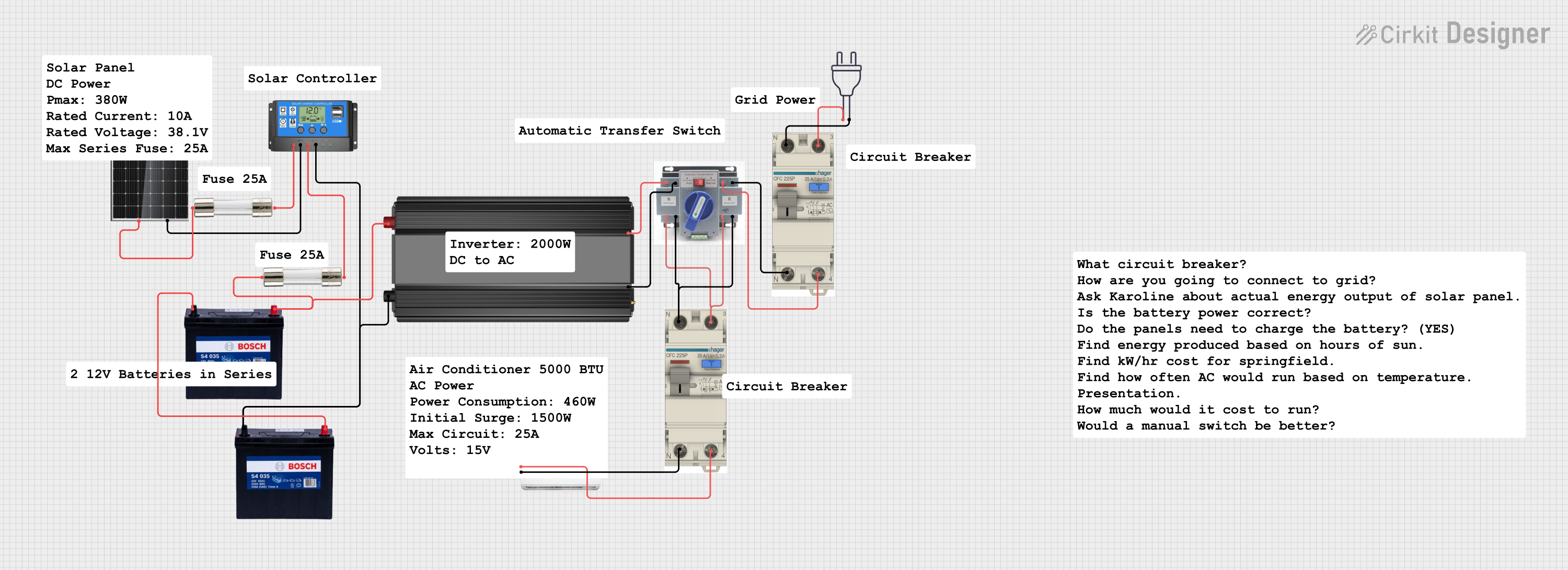

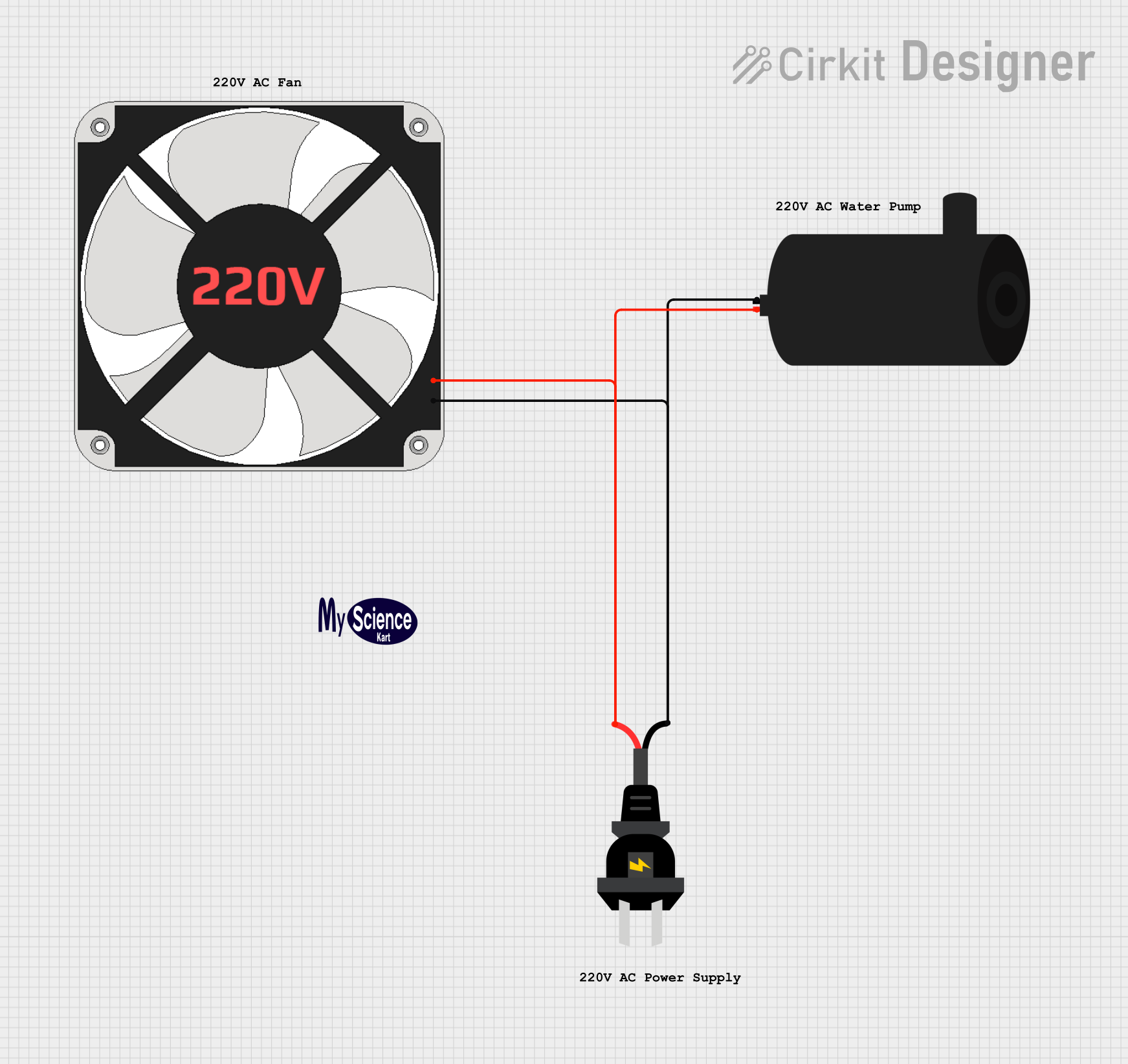

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit DesignerExplore Projects Built with 3-Phase A/C GENARTOR

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit DesignerCommon Applications and Use Cases

- Industrial Power Supply: Used in factories and manufacturing plants to power heavy machinery.

- Renewable Energy Systems: Commonly integrated into wind turbines and hydroelectric systems.

- Commercial Power Backup: Provides reliable backup power for commercial buildings.

- Electric Vehicles: Used in regenerative braking systems to convert kinetic energy into electrical energy.

- Power Grids: Supplies electricity to the grid in large-scale power generation systems.

Technical Specifications

The following table outlines the key technical specifications of the 3-Phase A/C Generator:

| Parameter | Specification |

|---|---|

| Manufacturer | Cirkit |

| Part ID | 3-Phase A/C GENARTOR |

| Output Voltage Range | 220V - 480V (depending on model) |

| Output Frequency | 50Hz / 60Hz |

| Power Rating | 5 kW - 500 kW (model-dependent) |

| Phase Configuration | 3-phase |

| Efficiency | Up to 95% |

| Operating Temperature | -20°C to 60°C |

| Cooling Method | Air-cooled or liquid-cooled |

| Rotor Type | Synchronous or asynchronous |

| Insulation Class | Class F |

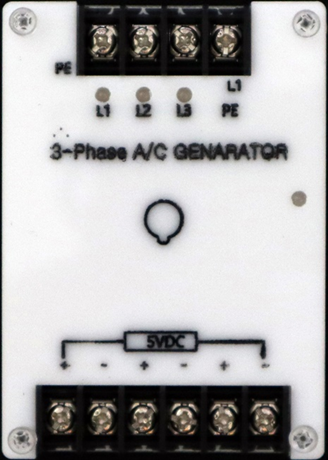

Pin Configuration and Descriptions

The 3-Phase A/C Generator typically has the following terminal connections:

| Terminal | Description |

|---|---|

| L1 | Phase 1 output |

| L2 | Phase 2 output |

| L3 | Phase 3 output |

| N | Neutral terminal (optional, model-dependent) |

| GND | Ground terminal for safety |

| Exciter+ | Positive terminal for excitation system |

| Exciter- | Negative terminal for excitation system |

Usage Instructions

How to Use the Component in a Circuit

- Mechanical Input: Connect the generator to a mechanical energy source, such as a turbine, engine, or motor. Ensure the mechanical input matches the generator's rated speed (RPM) for optimal performance.

- Electrical Connections:

- Connect the three-phase output terminals (L1, L2, L3) to the load or power distribution system.

- If required, connect the neutral (N) terminal for single-phase loads.

- Ensure the ground (GND) terminal is properly connected to the earth for safety.

- Excitation System:

- For synchronous generators, connect the exciter terminals (Exciter+ and Exciter-) to the excitation system to provide the necessary magnetic field.

- Startup:

- Gradually increase the mechanical input speed to the rated RPM.

- Monitor the output voltage and frequency to ensure they are within the specified range.

- Load Connection:

- Once the generator is running stably, connect the load to the output terminals.

- Avoid sudden load changes to prevent voltage and frequency fluctuations.

Important Considerations and Best Practices

- Load Balancing: Ensure the load is evenly distributed across all three phases to prevent overheating and inefficiency.

- Overload Protection: Use circuit breakers or fuses to protect the generator from overloading.

- Regular Maintenance: Periodically inspect the generator for wear and tear, clean the cooling system, and check the insulation resistance.

- Safety Precautions: Always disconnect the generator from the load and mechanical input before performing maintenance.

- Synchronization: When connecting the generator to a power grid, ensure proper synchronization of voltage, frequency, and phase.

Arduino UNO Integration

While the 3-Phase A/C Generator is not directly compatible with an Arduino UNO due to its high voltage and current, you can use sensors and modules to monitor its performance. For example, you can use a voltage sensor and current sensor to measure the generator's output and display the data on the Arduino.

Example Code for Monitoring Voltage and Current

// Example code to monitor voltage and current of a 3-Phase A/C Generator

// using an Arduino UNO and appropriate sensors.

// Define sensor input pins

const int voltageSensorPin = A0; // Voltage sensor connected to analog pin A0

const int currentSensorPin = A1; // Current sensor connected to analog pin A1

// Variables to store sensor readings

float voltage = 0.0;

float current = 0.0;

void setup() {

Serial.begin(9600); // Initialize serial communication

pinMode(voltageSensorPin, INPUT);

pinMode(currentSensorPin, INPUT);

}

void loop() {

// Read voltage sensor value and convert to actual voltage

int voltageRaw = analogRead(voltageSensorPin);

voltage = (voltageRaw / 1023.0) * 500.0; // Adjust based on sensor specs

// Read current sensor value and convert to actual current

int currentRaw = analogRead(currentSensorPin);

current = (currentRaw / 1023.0) * 50.0; // Adjust based on sensor specs

// Print voltage and current readings to the Serial Monitor

Serial.print("Voltage: ");

Serial.print(voltage);

Serial.println(" V");

Serial.print("Current: ");

Serial.print(current);

Serial.println(" A");

delay(1000); // Wait for 1 second before next reading

}

Troubleshooting and FAQs

Common Issues and Solutions

Low or No Output Voltage:

- Cause: Insufficient mechanical input speed or faulty excitation system.

- Solution: Check the mechanical input and ensure it matches the rated RPM. Inspect the excitation system for faults.

Overheating:

- Cause: Overloading, poor ventilation, or unbalanced load.

- Solution: Reduce the load, improve ventilation, and ensure the load is balanced across all phases.

Voltage Fluctuations:

- Cause: Sudden load changes or unstable mechanical input.

- Solution: Avoid sudden load changes and ensure a stable mechanical input.

Excessive Noise or Vibration:

- Cause: Misalignment of the mechanical input or worn bearings.

- Solution: Realign the mechanical input and replace worn bearings.

FAQs

Can the generator be used for single-phase loads?

- Yes, by connecting the load between one phase and the neutral terminal (if available).

What is the recommended maintenance schedule?

- Perform a basic inspection every 500 operating hours and a comprehensive maintenance check every 2,000 hours.

Can this generator be used in off-grid systems?

- Yes, it is suitable for off-grid applications when paired with an appropriate control system and energy storage.

Is synchronization required for standalone operation?

- No, synchronization is only required when connecting to a power grid.

By following this documentation, users can effectively utilize the Cirkit 3-Phase A/C Generator for a wide range of applications while ensuring safety and optimal performance.