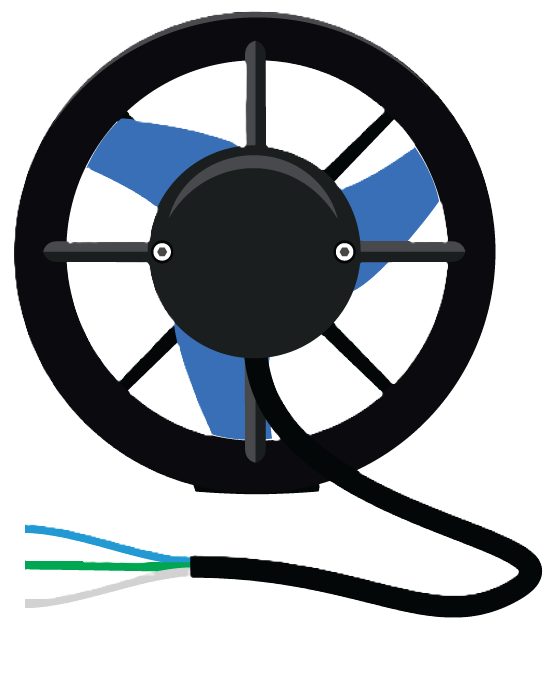

How to Use T200 Thruster: Examples, Pinouts, and Specs

Design with T200 Thruster in Cirkit Designer

Design with T200 Thruster in Cirkit DesignerIntroduction

The T200 Thruster is a high-performance brushless underwater thruster designed specifically for marine robotics applications. It is capable of providing efficient propulsion in various water environments, making it an ideal choice for remotely operated vehicles (ROVs), autonomous underwater vehicles (AUVs), and other aquatic robots. Its robust design and powerful output enable it to handle a wide range of tasks, from underwater exploration to environmental monitoring.

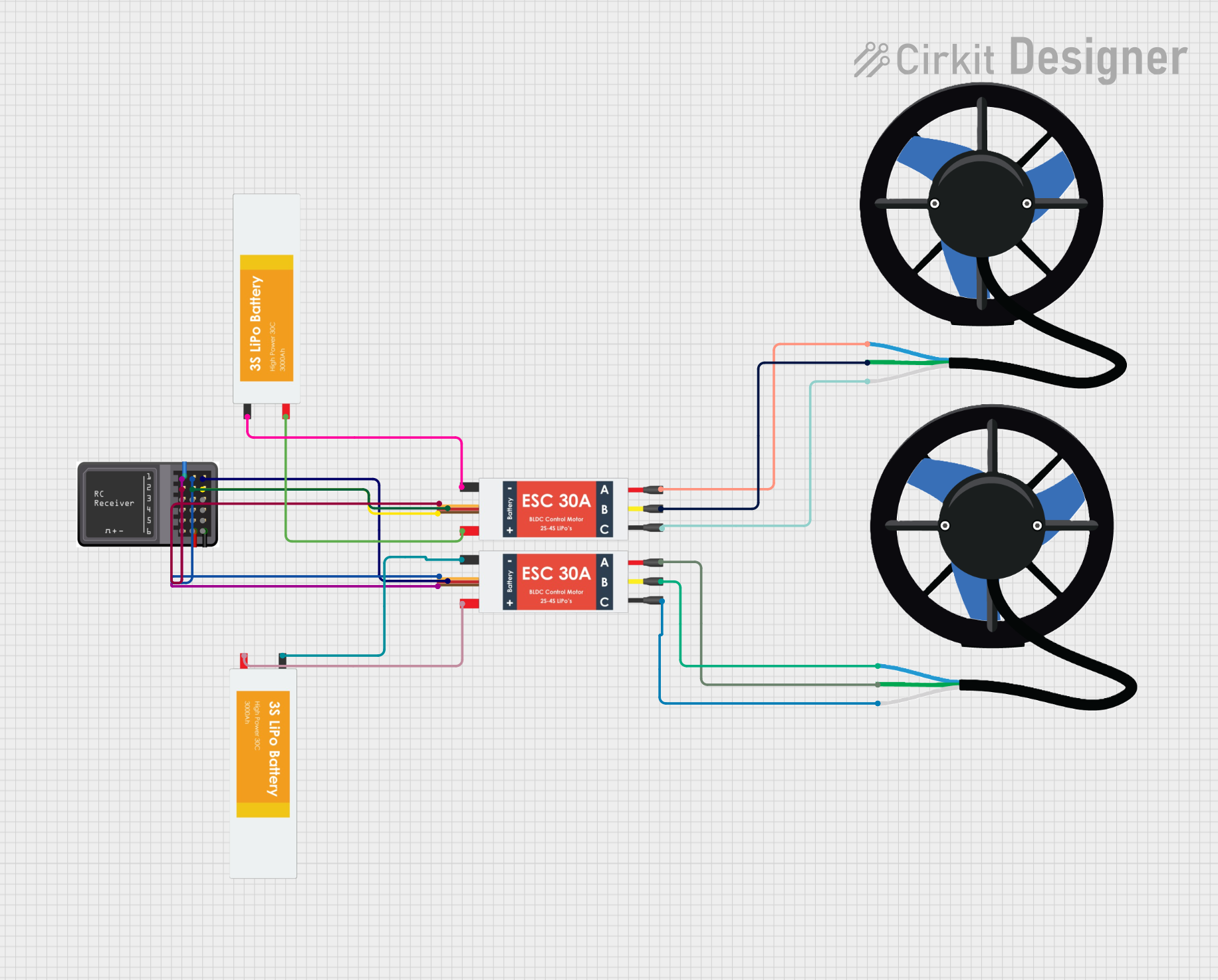

Explore Projects Built with T200 Thruster

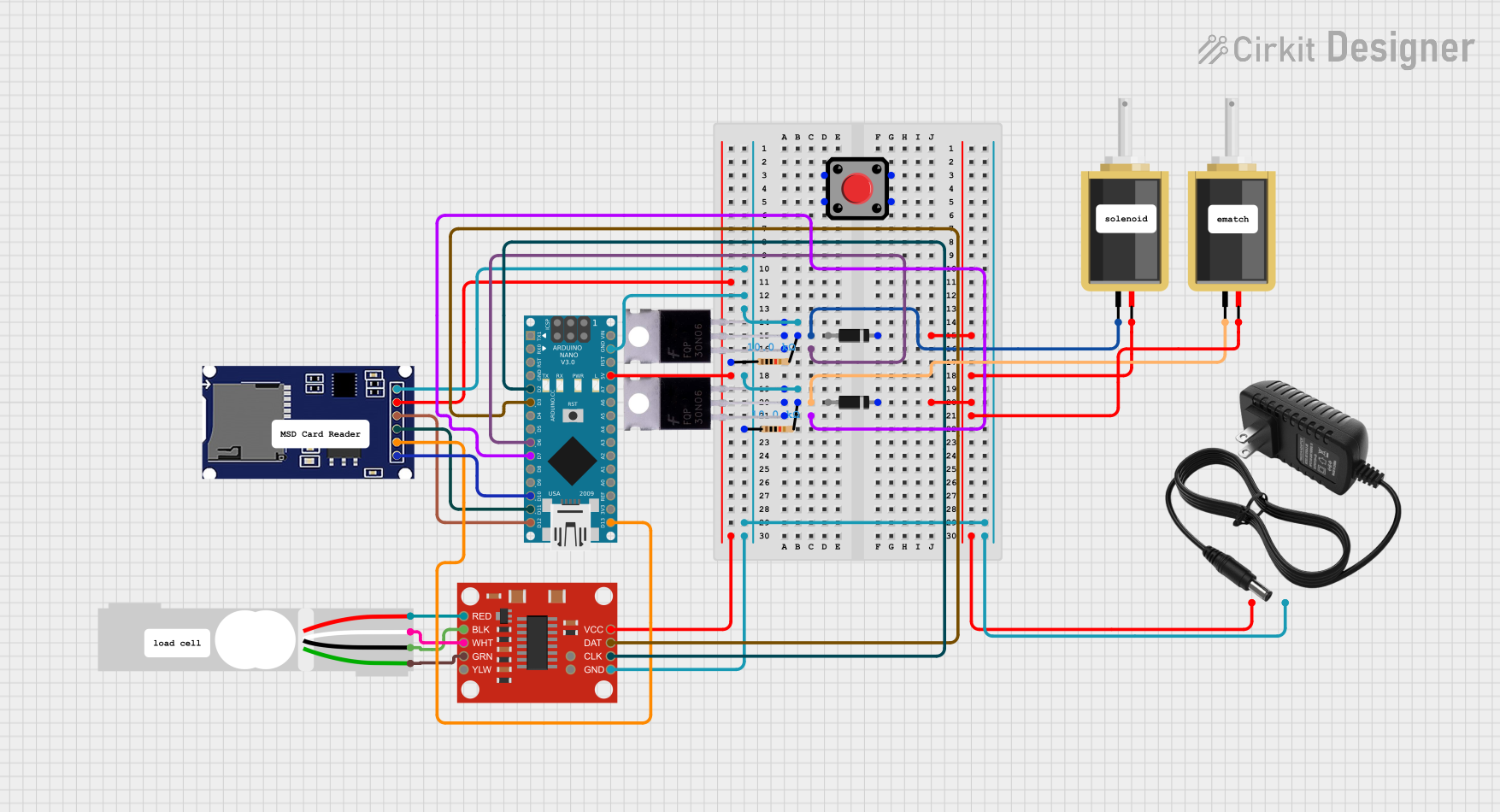

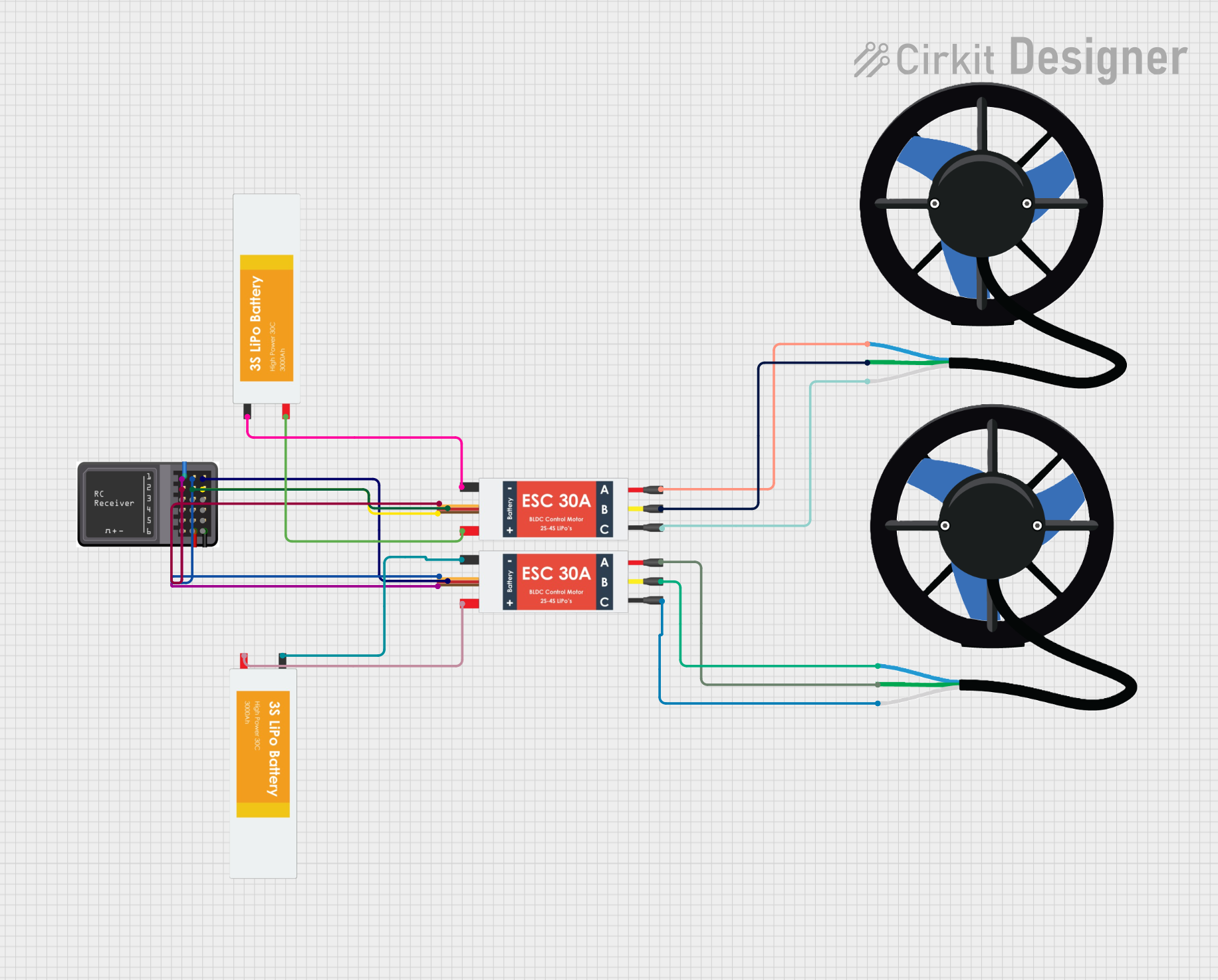

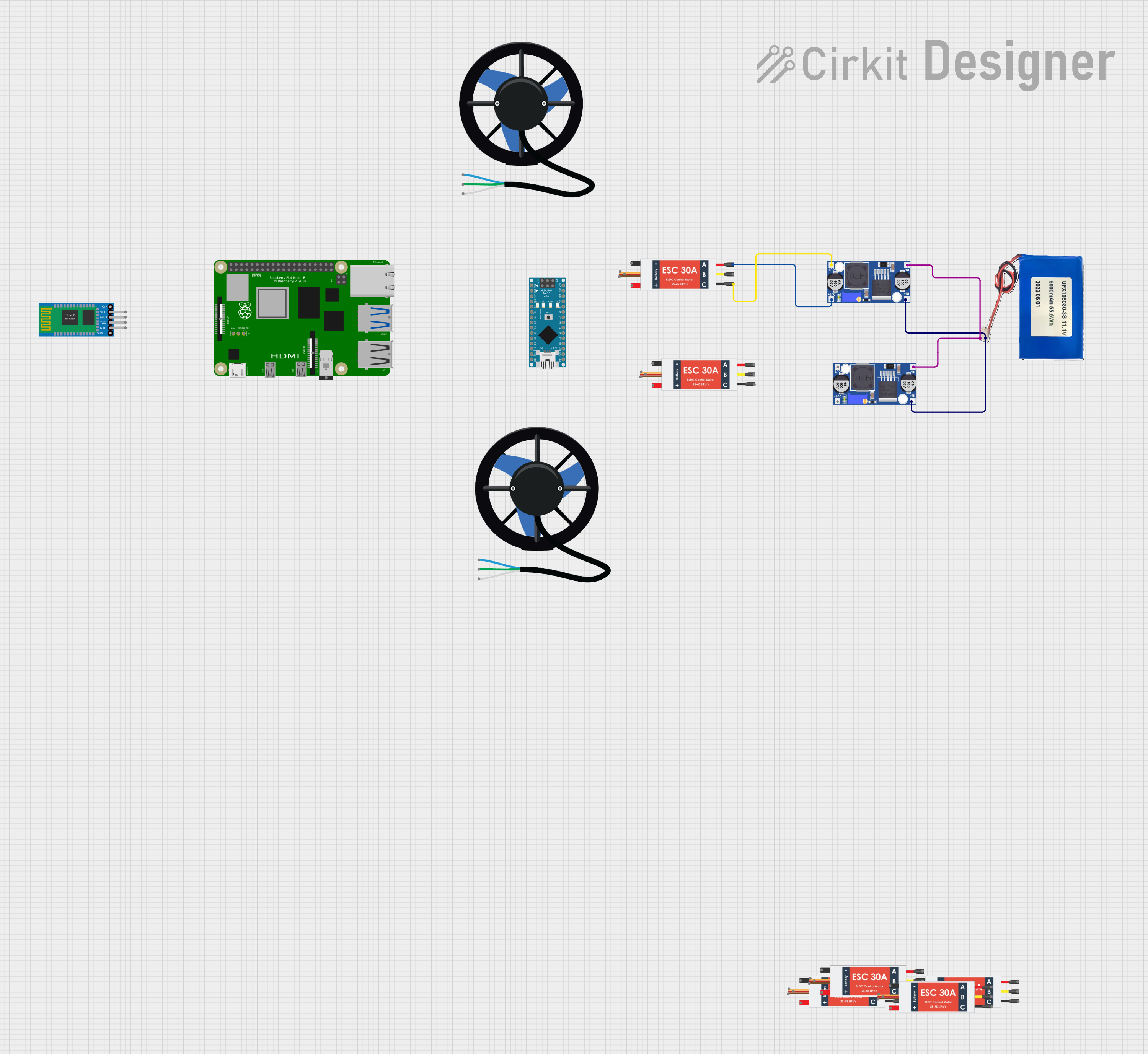

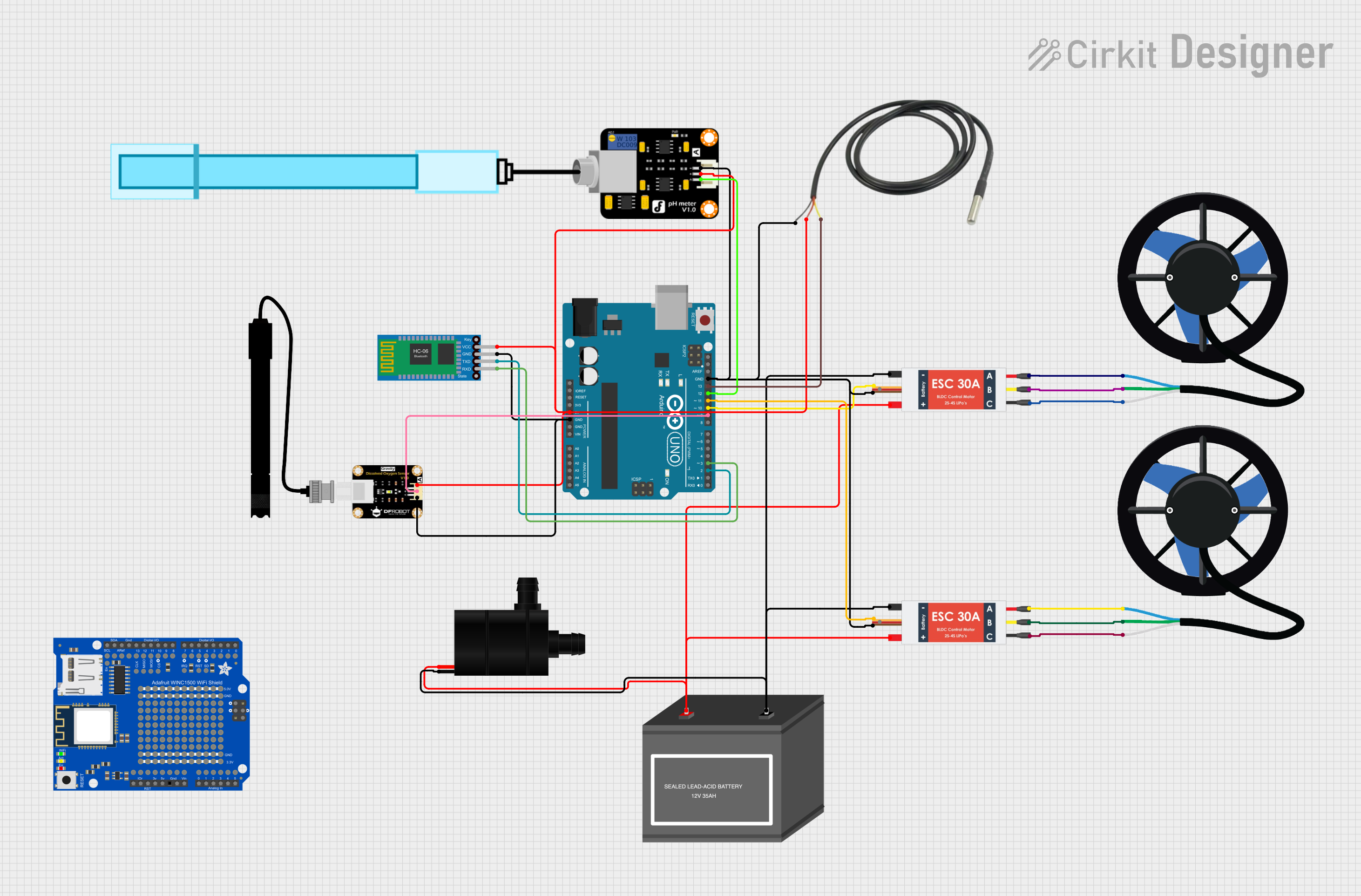

Open Project in Cirkit Designer

Open Project in Cirkit Designer

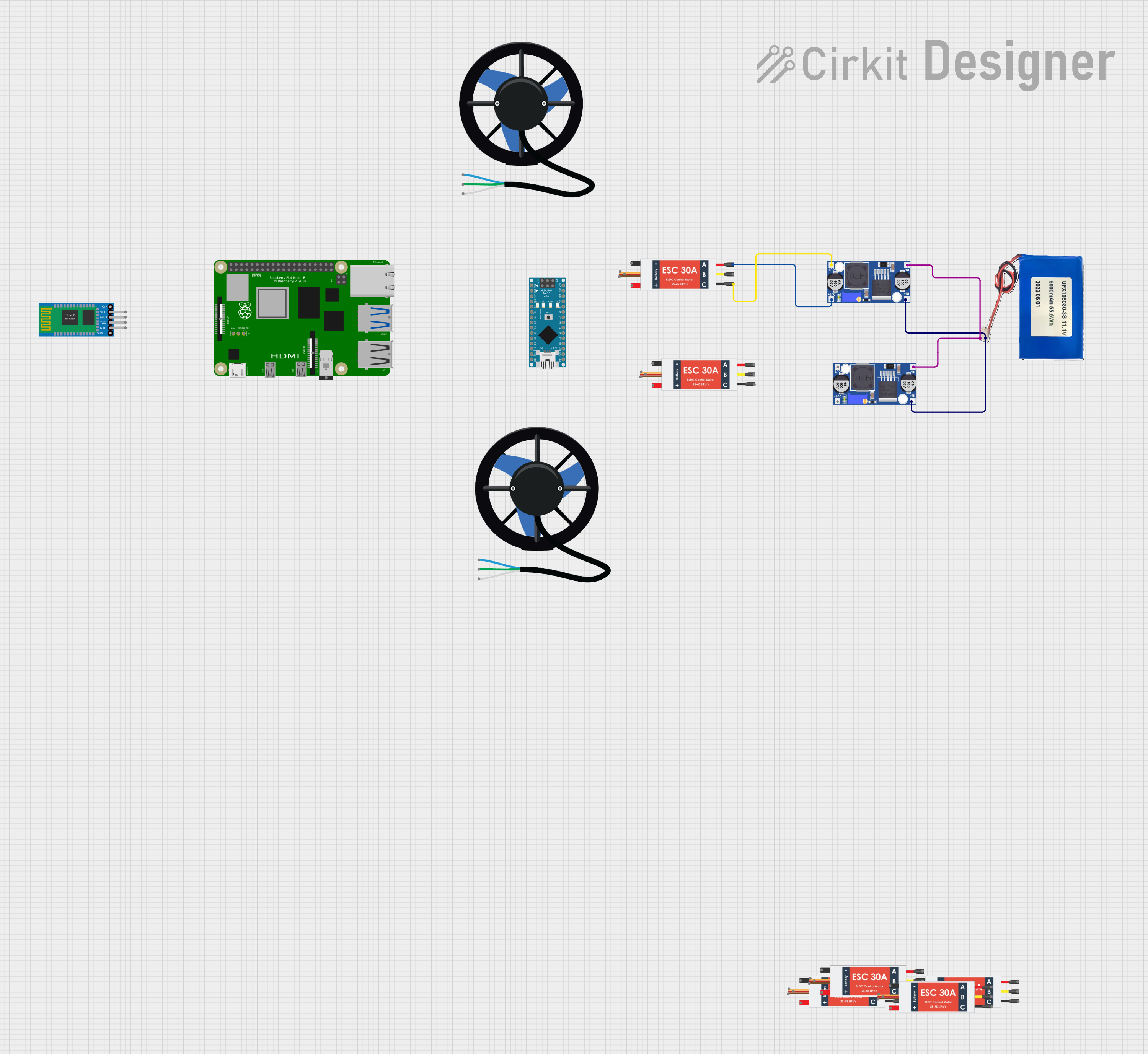

Open Project in Cirkit Designer

Open Project in Cirkit Designer

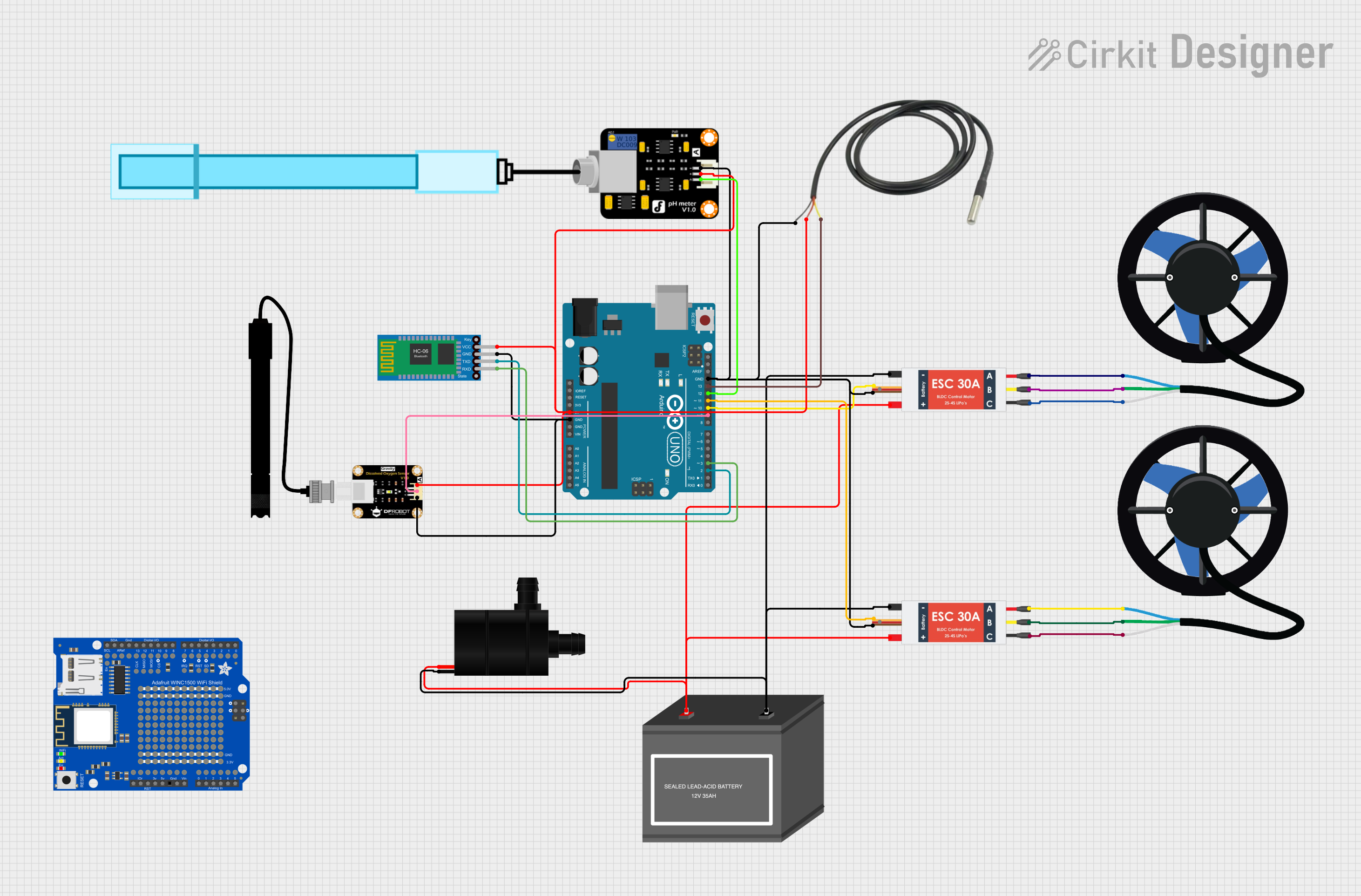

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit DesignerExplore Projects Built with T200 Thruster

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit DesignerCommon Applications and Use Cases

- Remotely Operated Vehicles (ROVs)

- Autonomous Underwater Vehicles (AUVs)

- Underwater propulsion for kayaks and small boats

- Aquatic research and data collection

- Underwater inspection and maintenance

Technical Specifications

Key Technical Details

| Specification | Value |

|---|---|

| Nominal Voltage | 16 V |

| Maximum Voltage | 20 V |

| Nominal Current | 12 A |

| Maximum Current | 25 A |

| Power Ratings | 300 W |

| Thrust | 5.1 kgf |

| Efficiency | 58% |

| RPM (Revolutions Per Minute) | 2800 RPM |

| Communication Protocol | PWM, Analog Voltage |

Pin Configuration and Descriptions

| Pin Number | Description | Notes |

|---|---|---|

| 1 | Positive Voltage (V+) | Connect to positive power supply |

| 2 | Control Signal | PWM or 0-5V analog signal |

| 3 | Negative Voltage (V-) | Connect to ground |

Usage Instructions

How to Use the T200 Thruster in a Circuit

Power Supply Connection: Connect the positive and negative leads of the thruster to a suitable power supply, ensuring that it meets the voltage and current requirements.

Control Signal: The thruster can be controlled using a PWM signal or an analog voltage between 0-5V. For PWM, a frequency of 1100 Hz is recommended.

Mounting: Secure the thruster to your vehicle or application, ensuring that it is firmly attached and that the propeller has clearance to spin freely.

Waterproofing: Ensure all electrical connections are waterproofed to prevent short circuits and damage to the thruster.

Important Considerations and Best Practices

- Always operate the thruster underwater to prevent overheating.

- Do not exceed the maximum voltage and current ratings to avoid damaging the thruster.

- Use a fuse or circuit breaker to protect against overcurrent conditions.

- Regularly inspect the propeller and shaft for debris and wear.

- When controlling the thruster with an Arduino, ensure that the control signal is within the acceptable range.

Troubleshooting and FAQs

Common Issues

- Thruster not responding: Check power supply and control signal connections. Ensure the power supply is within the specified voltage range and the control signal is correctly applied.

- Overheating: Operate the thruster underwater and avoid running it at maximum power for extended periods.

- Reduced thrust: Inspect the propeller for debris or damage. Ensure the thruster is properly mounted and aligned.

Solutions and Tips for Troubleshooting

- Verify all connections are secure and properly insulated.

- Use a multimeter to check for the correct voltage at the thruster's terminals.

- If using PWM control, ensure the signal frequency and duty cycle are within the specified range.

FAQs

Q: Can the T200 Thruster be used in saltwater? A: Yes, the T200 Thruster is designed to operate in both freshwater and saltwater environments.

Q: What is the recommended battery for the T200 Thruster? A: A battery that can provide a voltage between 16V to 20V and can handle the current draw up to 25A is recommended, such as a high-capacity LiPo battery.

Q: How do I reverse the direction of the thruster? A: Reversing the direction can be achieved by reversing the polarity of the control signal.

Example Arduino Code for T200 Thruster Control

// T200 Thruster control using Arduino UNO

#include <Servo.h>

Servo thruster; // Create a servo object to control the T200 Thruster

void setup() {

thruster.attach(9); // Attach the thruster to pin 9

// Ensure the pin is capable of PWM output

}

void loop() {

int thrust = 1500; // Set thrust (1100 to 1900 for full reverse to full forward)

thruster.writeMicroseconds(thrust); // Send PWM signal to thruster

// Additional code to control the thrust based on your application's needs

}

Note: The writeMicroseconds function is used to provide more precise control over the PWM signal sent to the thruster. The value 1500 corresponds to the neutral position where the thruster is stopped. Values below 1500 will cause the thruster to reverse, and values above 1500 will cause the thruster to move forward. The range is typically from 1100 (full reverse) to 1900 (full forward), but you should calibrate these values for your specific setup.