How to Use NovaMax 6V 800 RPM: Examples, Pinouts, and Specs

Design with NovaMax 6V 800 RPM in Cirkit Designer

Design with NovaMax 6V 800 RPM in Cirkit DesignerIntroduction

The NovaMax 6V 800 RPM is a high-quality DC motor designed to operate at a nominal voltage of 6 volts, delivering a speed of 800 revolutions per minute (RPM). This motor is ideal for applications requiring moderate torque and speed, such as robotics, small conveyor systems, and hobbyist projects. Its compact design and reliable performance make it a versatile choice for both beginners and experienced users.

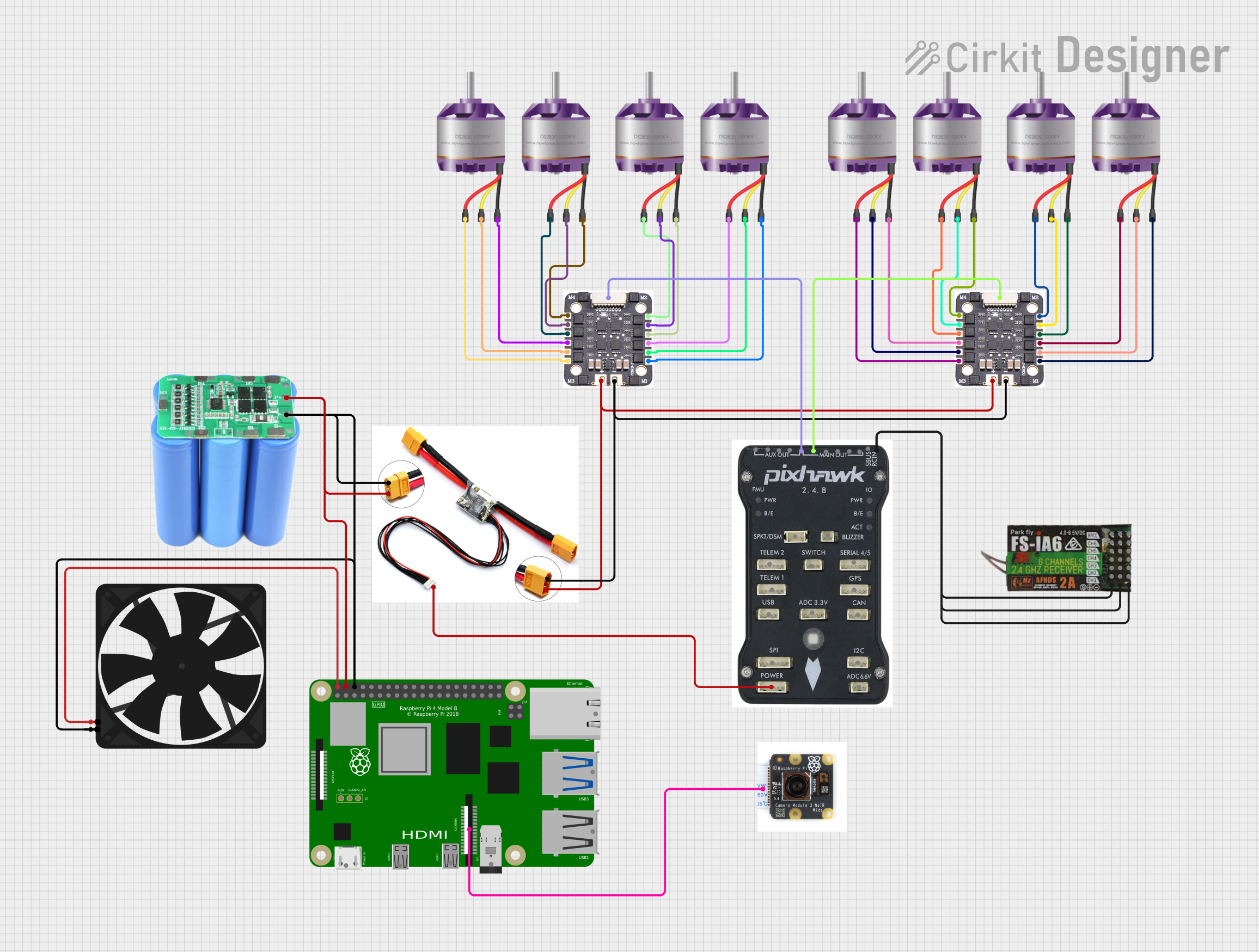

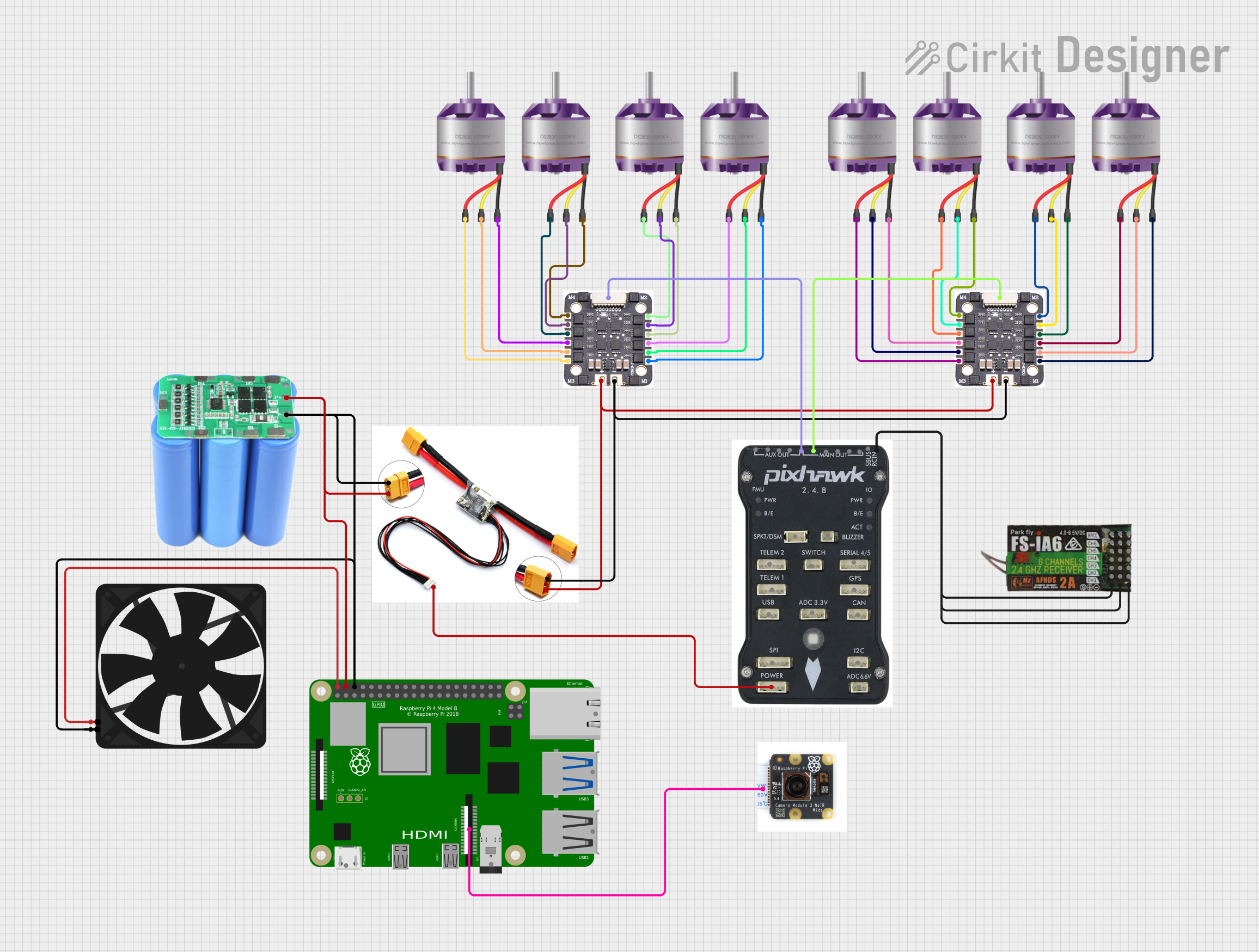

Explore Projects Built with NovaMax 6V 800 RPM

Open Project in Cirkit Designer

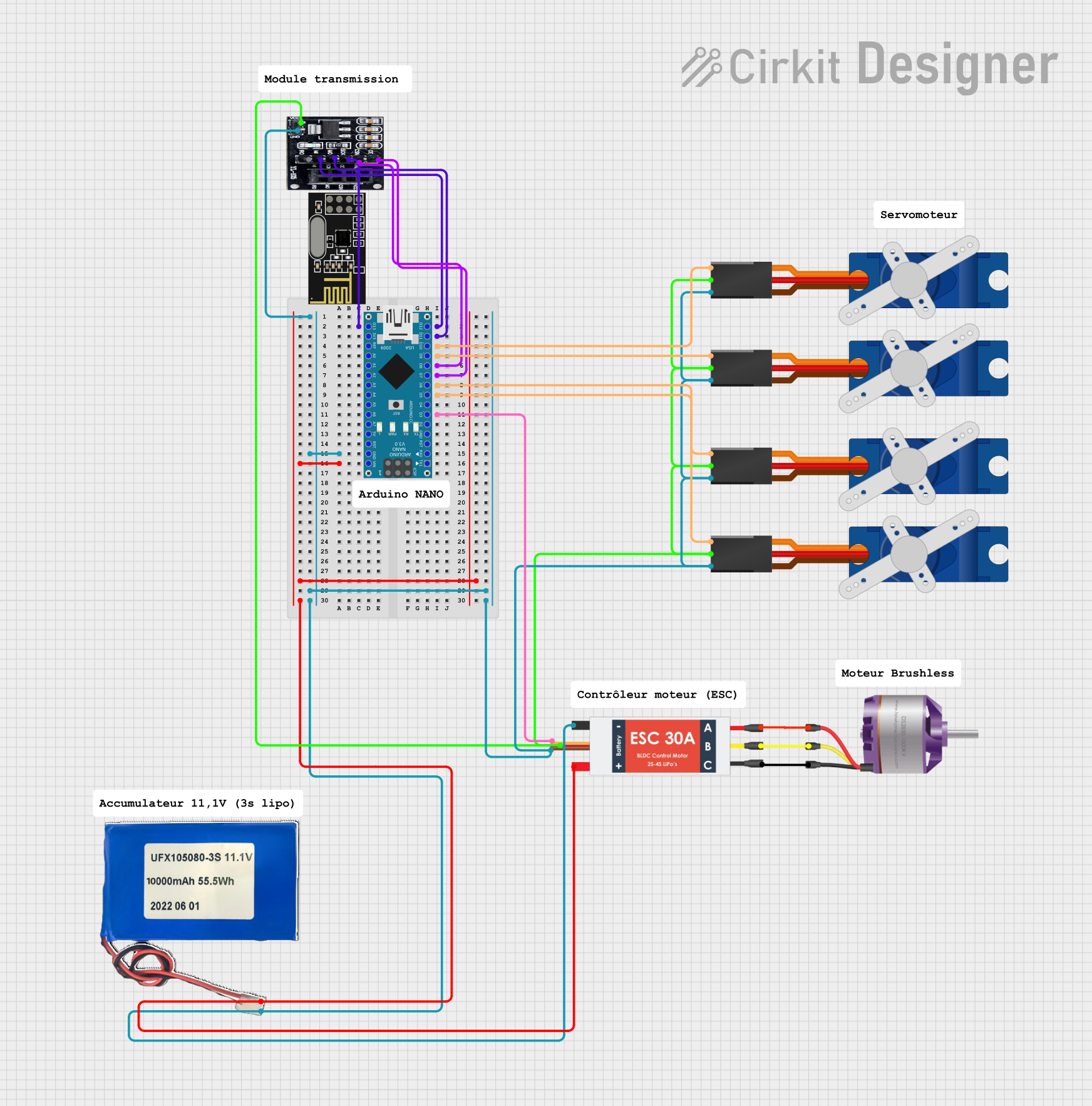

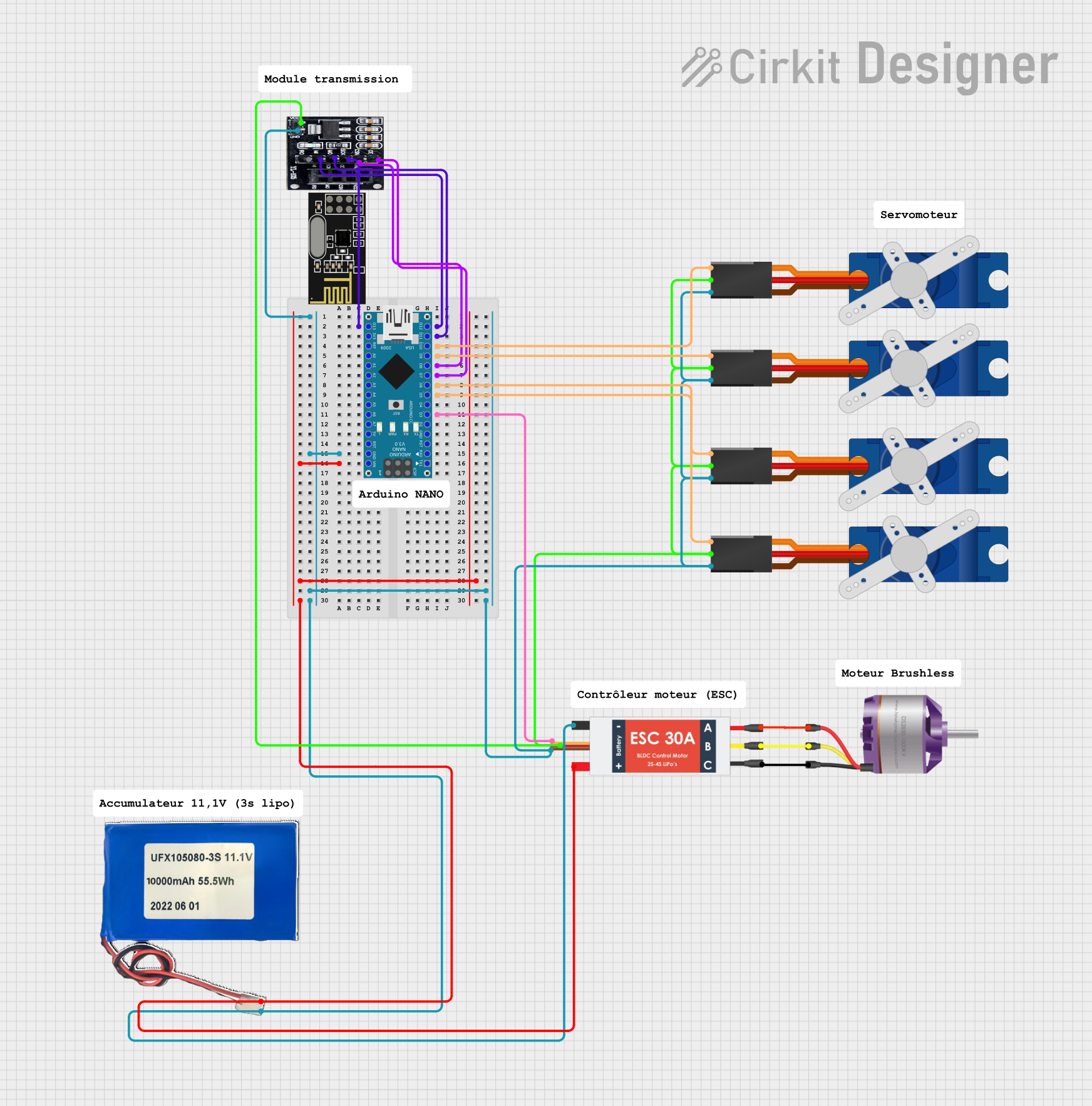

Open Project in Cirkit Designer

Open Project in Cirkit Designer

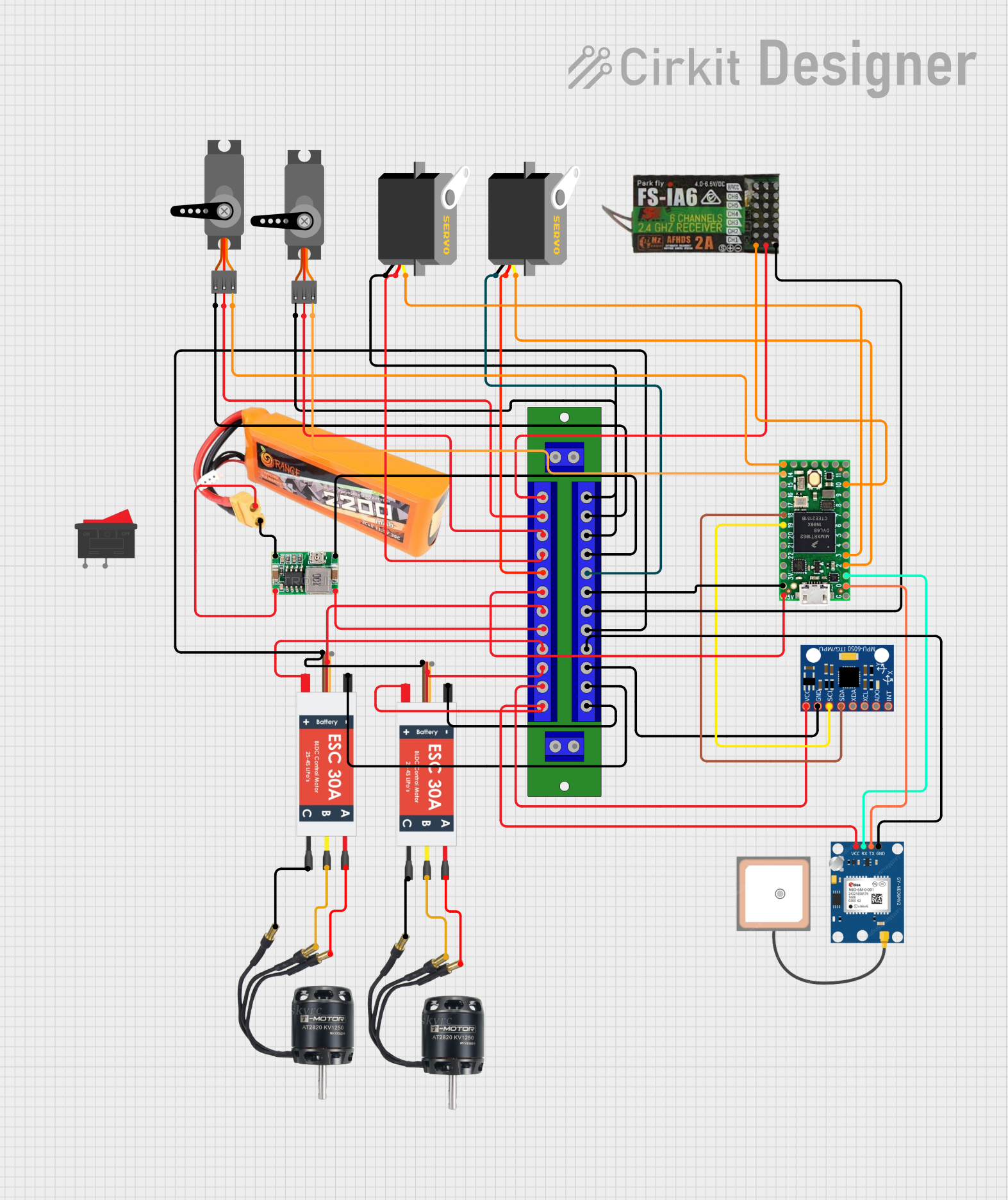

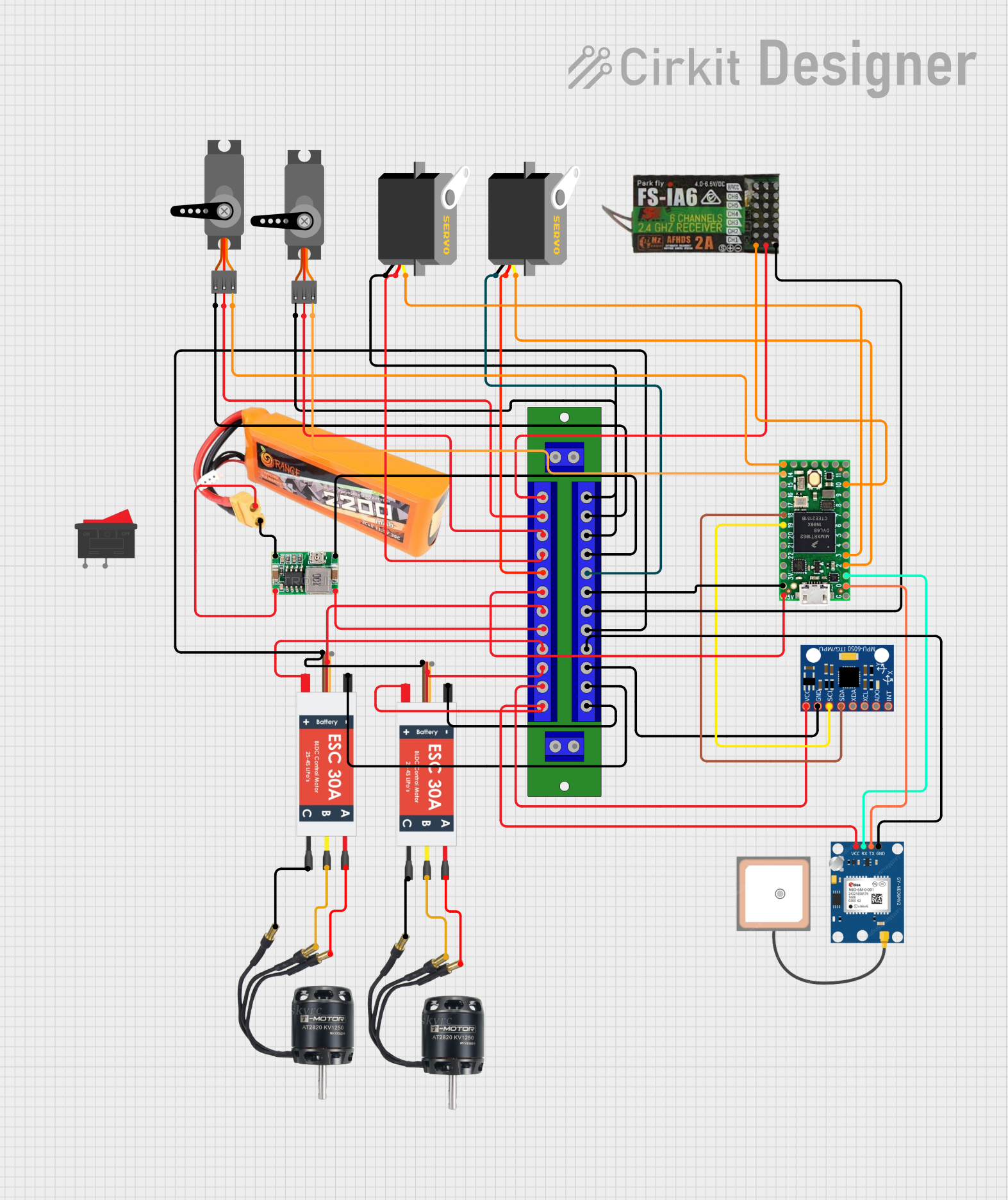

Open Project in Cirkit Designer

Open Project in Cirkit Designer

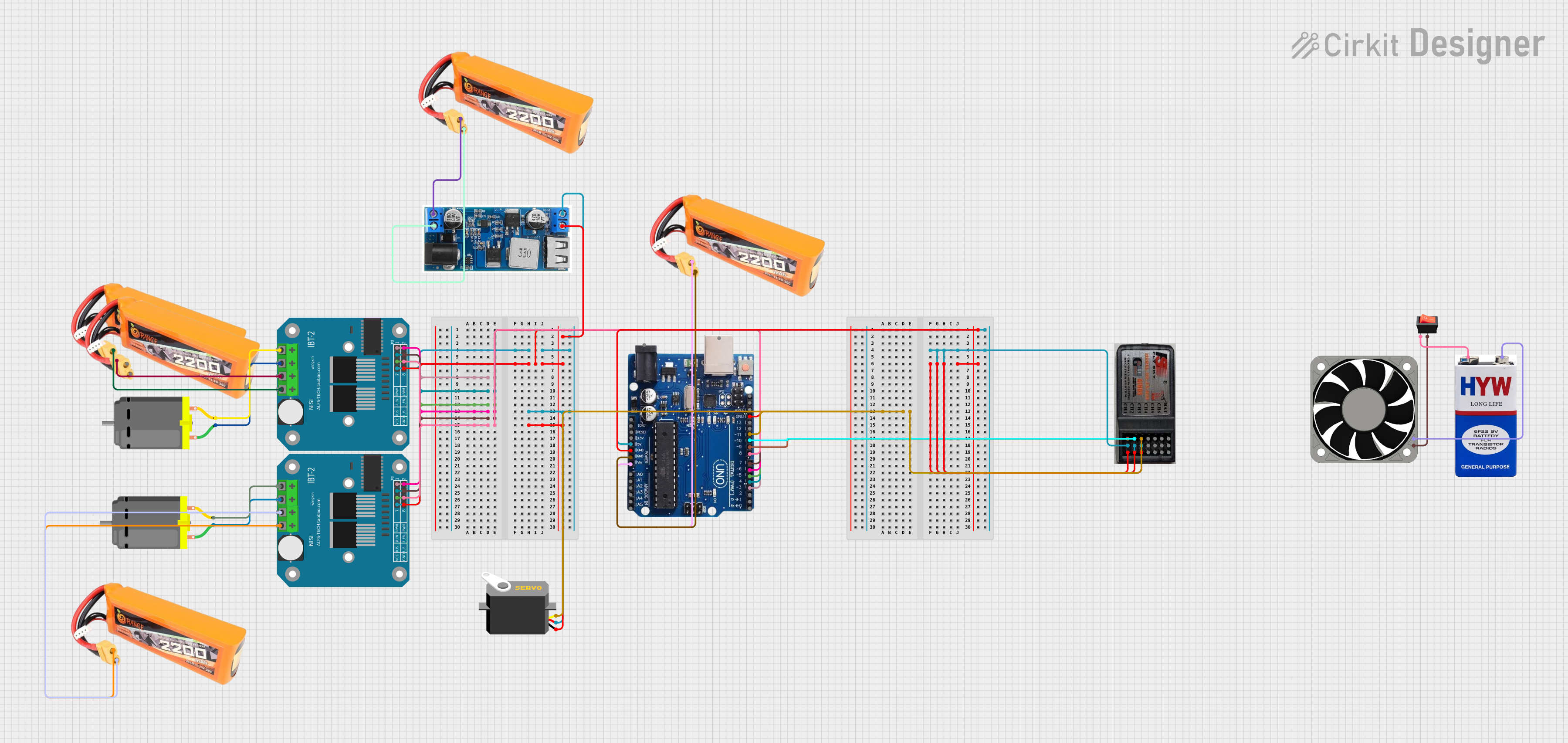

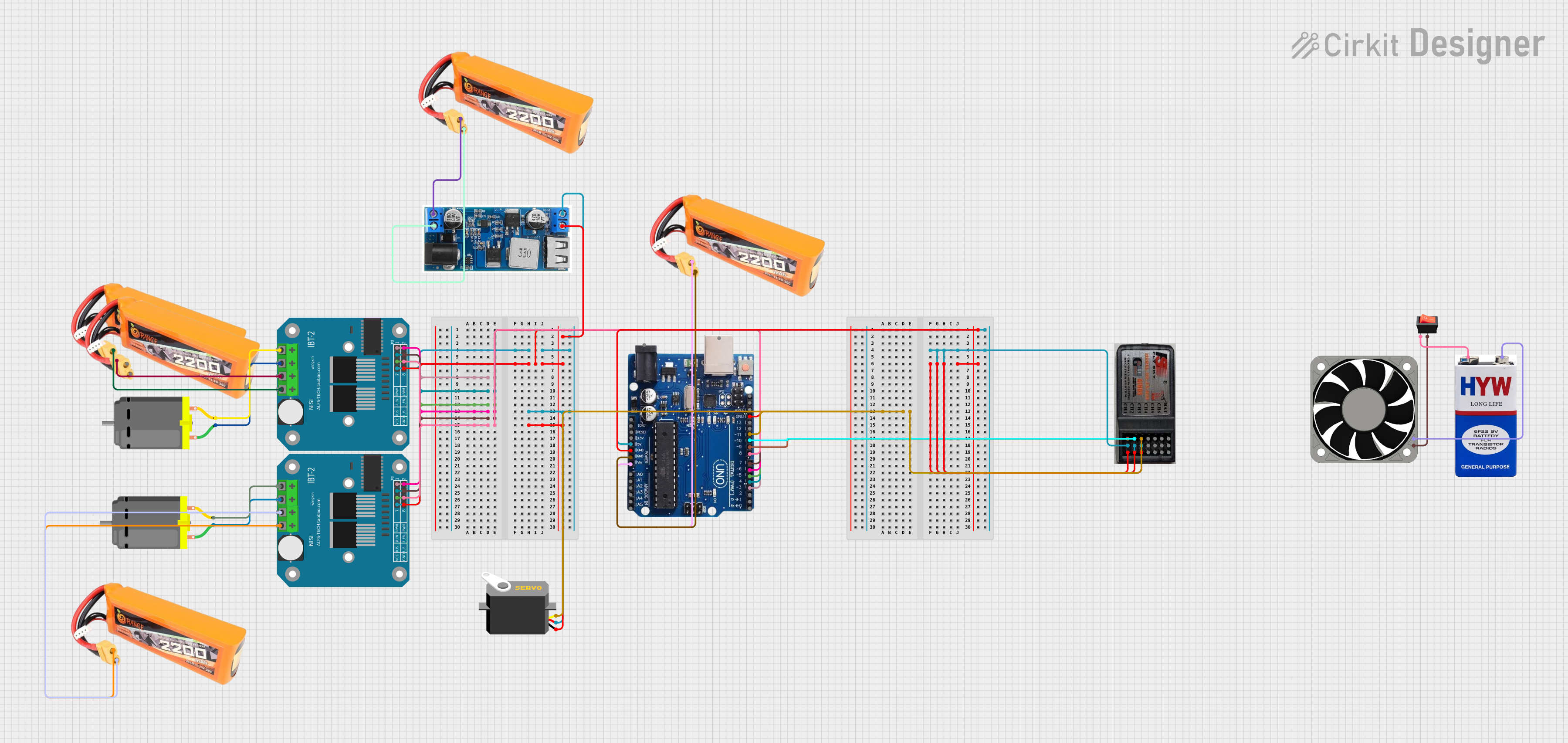

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit DesignerExplore Projects Built with NovaMax 6V 800 RPM

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit DesignerCommon Applications and Use Cases

- Robotics: Driving wheels or actuators in small robots

- Conveyor systems: Powering lightweight conveyor belts

- DIY projects: Building motorized toys or tools

- Educational purposes: Demonstrating motor principles in classrooms

- Automation: Small-scale automated systems

Technical Specifications

The NovaMax 6V 800 RPM motor is designed to provide consistent performance under a variety of conditions. Below are its key technical details:

Key Specifications

| Parameter | Value |

|---|---|

| Nominal Voltage | 6V DC |

| No-Load Speed | 800 RPM |

| Stall Torque | 0.5 Nm |

| Rated Current | 0.8 A |

| Stall Current | 2.5 A |

| Shaft Diameter | 6 mm |

| Motor Dimensions | 50 mm (L) x 30 mm (D) |

| Weight | 150 g |

| Operating Temperature | -10°C to 60°C |

Pin Configuration and Descriptions

The NovaMax 6V 800 RPM motor has two terminals for electrical connections:

| Pin/Terminal | Description |

|---|---|

| Terminal 1 | Positive terminal for power input |

| Terminal 2 | Negative terminal for power input |

Note: Reversing the polarity of the terminals will reverse the motor's rotation direction.

Usage Instructions

How to Use the NovaMax 6V 800 RPM in a Circuit

- Power Supply: Connect the motor to a 6V DC power source. Ensure the power supply can provide sufficient current (at least 2.5 A for stall conditions).

- Polarity: Connect Terminal 1 to the positive terminal of the power supply and Terminal 2 to the negative terminal. Reversing the connections will change the motor's rotation direction.

- Motor Driver: For precise control, use a motor driver (e.g., L298N or L293D) to regulate speed and direction. This is especially important when interfacing with microcontrollers like Arduino.

- Mounting: Secure the motor using appropriate brackets or mounts to prevent vibration during operation.

Important Considerations and Best Practices

- Current Limiting: Use a current-limiting resistor or motor driver to prevent damage during stall conditions.

- Heat Dissipation: Avoid prolonged operation at stall torque to prevent overheating.

- Power Supply: Ensure the power supply is stable and capable of handling the motor's peak current.

- Noise Suppression: Add capacitors (e.g., 0.1 µF) across the terminals to reduce electrical noise.

Example: Connecting to an Arduino UNO

Below is an example of how to control the NovaMax 6V 800 RPM motor using an Arduino UNO and an L298N motor driver.

Circuit Diagram

- Connect the motor terminals to the output pins of the L298N motor driver (OUT1 and OUT2).

- Connect the L298N's input pins (IN1 and IN2) to Arduino digital pins 9 and 10, respectively.

- Connect the L298N's power input to a 6V DC power source.

Arduino Code

// Define motor control pins

const int motorPin1 = 9; // IN1 on L298N

const int motorPin2 = 10; // IN2 on L298N

void setup() {

// Set motor pins as outputs

pinMode(motorPin1, OUTPUT);

pinMode(motorPin2, OUTPUT);

}

void loop() {

// Rotate motor in one direction

digitalWrite(motorPin1, HIGH);

digitalWrite(motorPin2, LOW);

delay(2000); // Run for 2 seconds

// Stop the motor

digitalWrite(motorPin1, LOW);

digitalWrite(motorPin2, LOW);

delay(1000); // Pause for 1 second

// Rotate motor in the opposite direction

digitalWrite(motorPin1, LOW);

digitalWrite(motorPin2, HIGH);

delay(2000); // Run for 2 seconds

// Stop the motor

digitalWrite(motorPin1, LOW);

digitalWrite(motorPin2, LOW);

delay(1000); // Pause for 1 second

}

Troubleshooting and FAQs

Common Issues and Solutions

Motor Does Not Spin

- Cause: Insufficient power supply or loose connections.

- Solution: Verify the power supply voltage and current. Check all connections.

Motor Spins in the Wrong Direction

- Cause: Polarity of the terminals is reversed.

- Solution: Swap the connections of Terminal 1 and Terminal 2.

Motor Overheats

- Cause: Prolonged operation at stall torque or insufficient ventilation.

- Solution: Avoid stalling the motor and ensure proper heat dissipation.

Electrical Noise Interferes with Circuit

- Cause: Motor generates electrical noise during operation.

- Solution: Add capacitors (e.g., 0.1 µF) across the motor terminals.

Motor Vibrates Excessively

- Cause: Improper mounting or unbalanced load.

- Solution: Secure the motor with appropriate mounts and balance the load.

FAQs

Q: Can I use a higher voltage power supply?

A: No, using a voltage higher than 6V may damage the motor. Always use a 6V DC power source.

Q: How can I control the motor speed?

A: Use a PWM (Pulse Width Modulation) signal from a motor driver or microcontroller to adjust the speed.

Q: Is the motor waterproof?

A: No, the NovaMax 6V 800 RPM motor is not waterproof. Avoid exposing it to water or moisture.

Q: Can I use this motor for heavy-duty applications?

A: This motor is designed for moderate torque applications. For heavy-duty tasks, consider a motor with higher torque ratings.