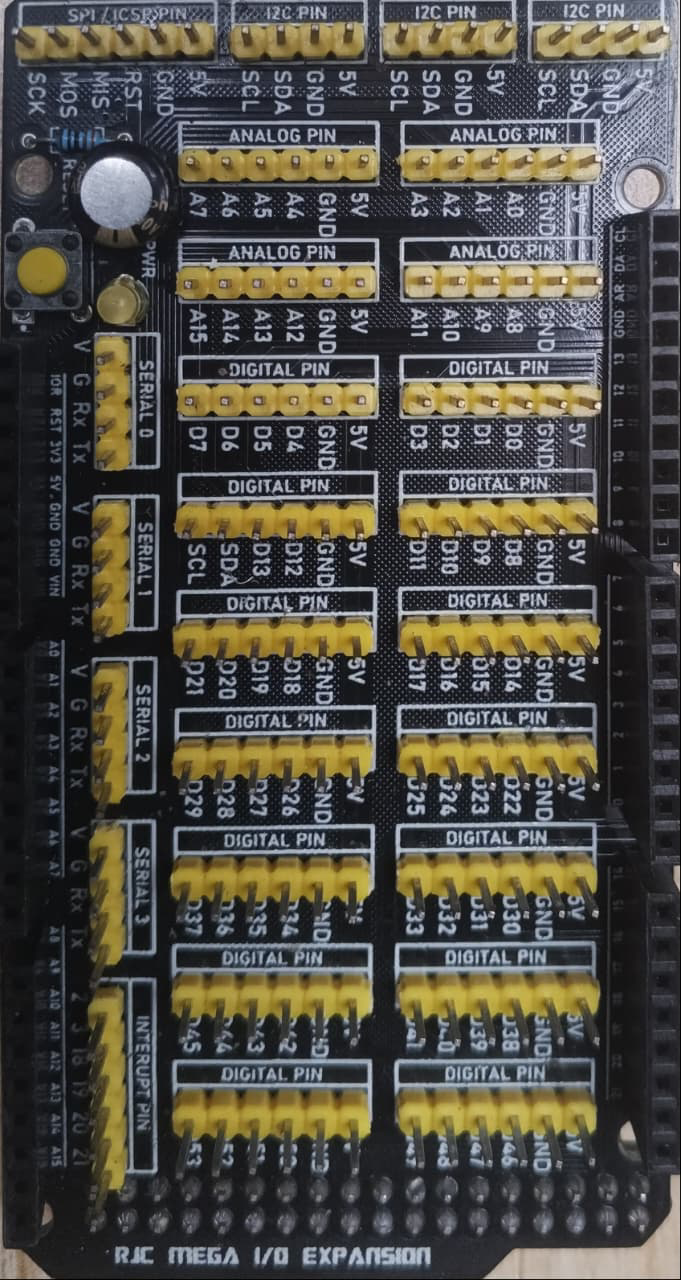

How to Use mega_proto_screw: Examples, Pinouts, and Specs

Design with mega_proto_screw in Cirkit Designer

Design with mega_proto_screw in Cirkit DesignerIntroduction

The Mega Proto Screw is a versatile and durable fastening component designed specifically for prototyping and DIY electronics projects. Its large size, wide head, and robust threading make it ideal for securing components, circuit boards, and other hardware during the prototyping phase. The screw's design ensures easy handling and reliable fastening, even in demanding applications.

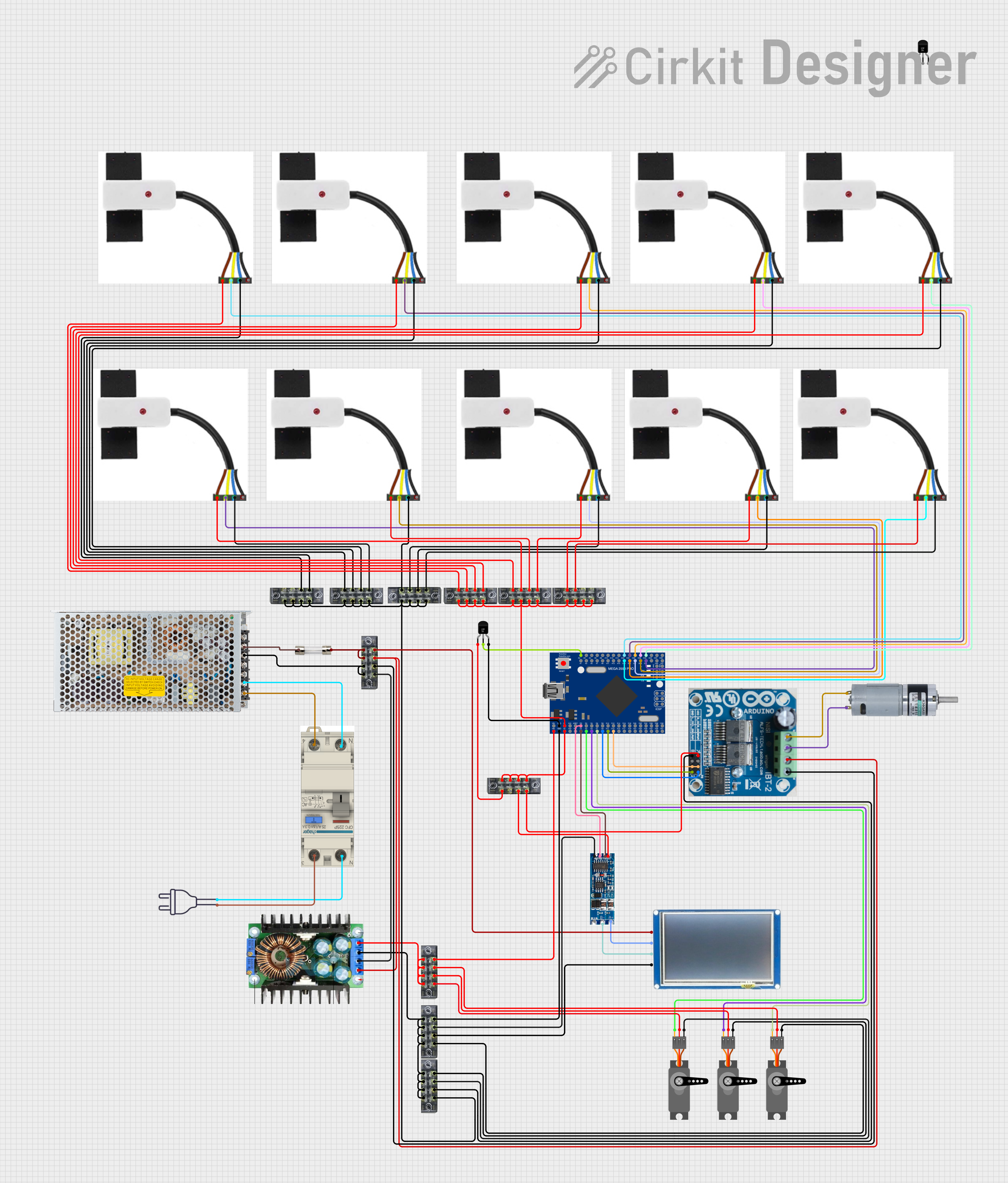

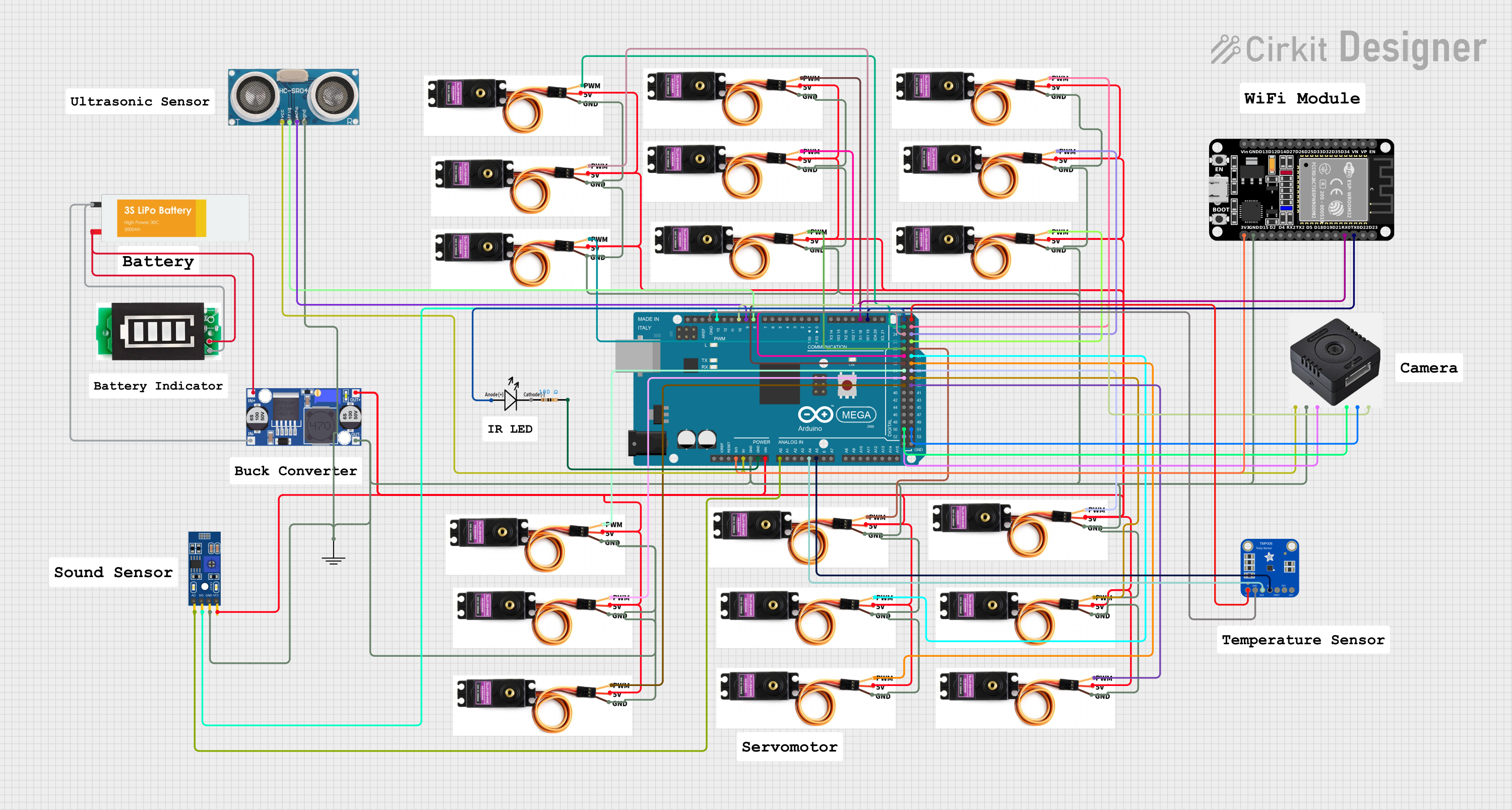

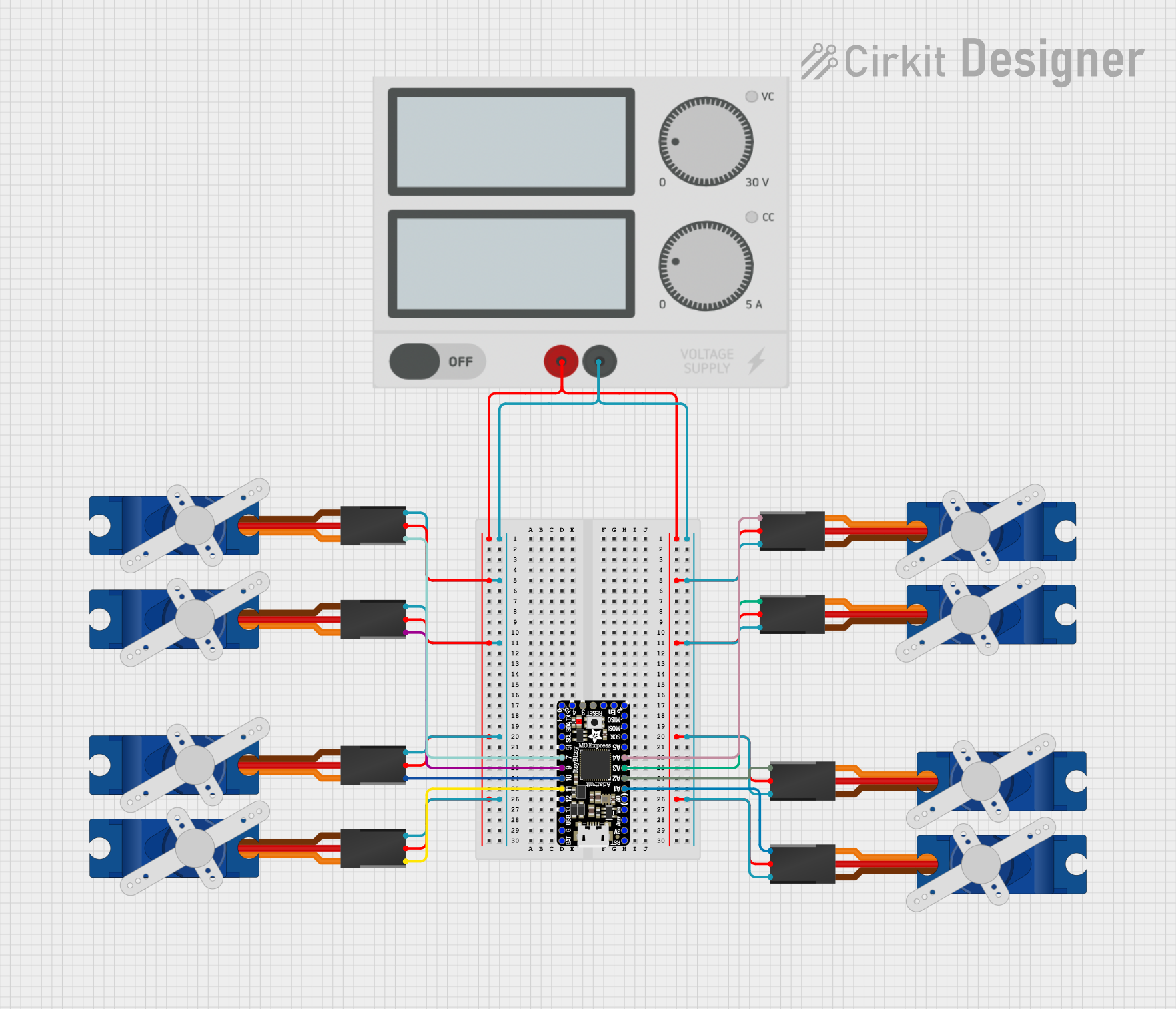

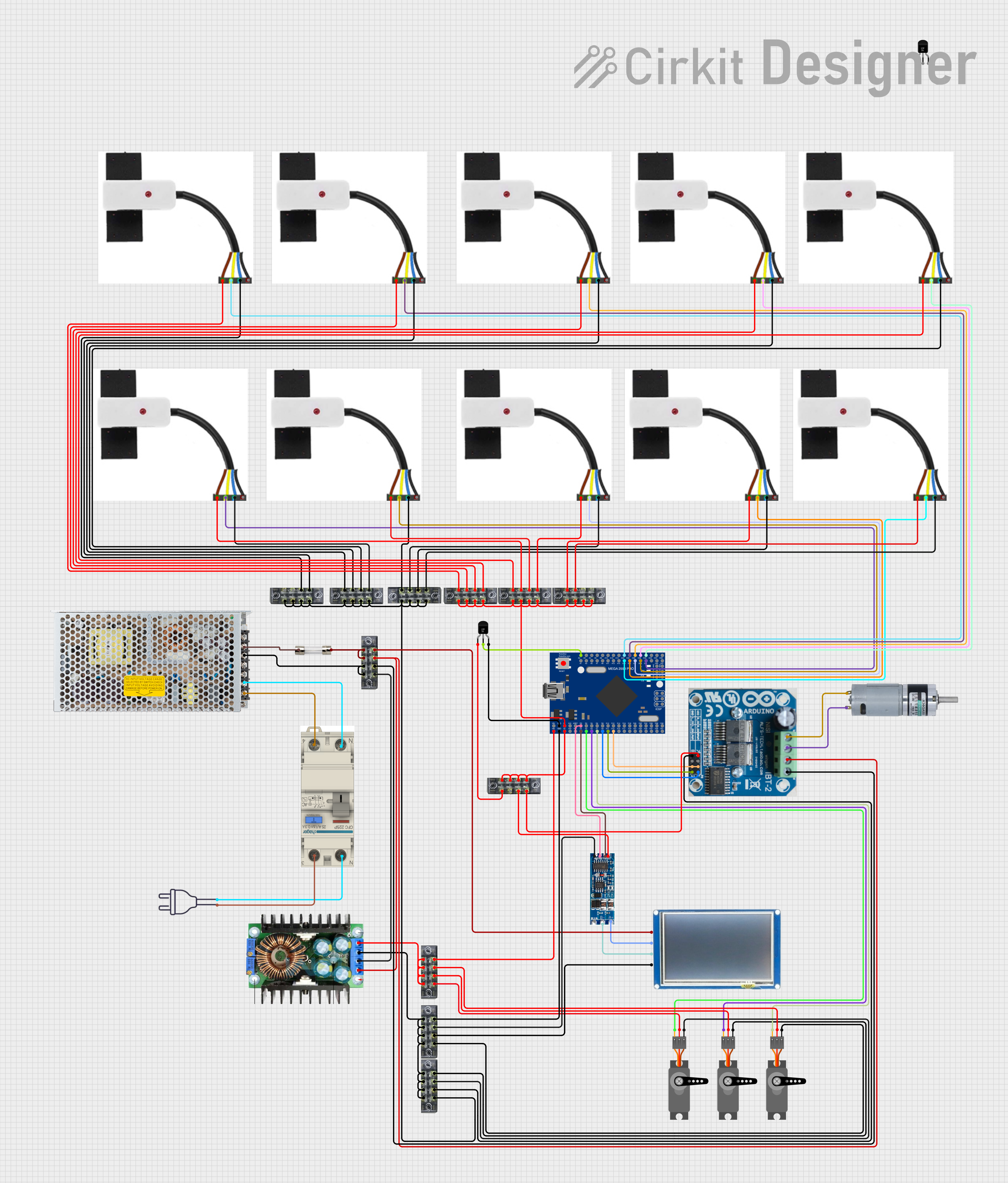

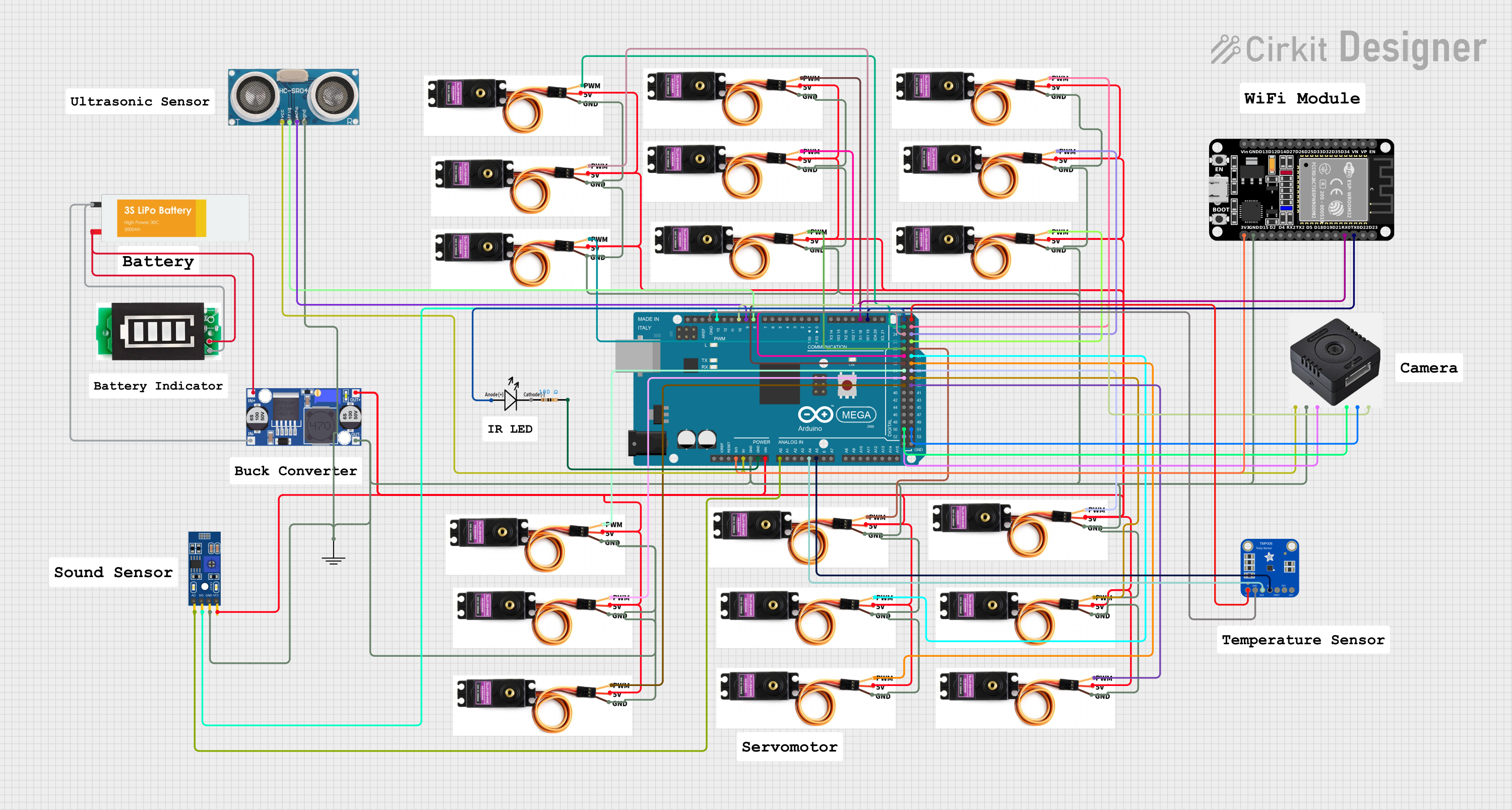

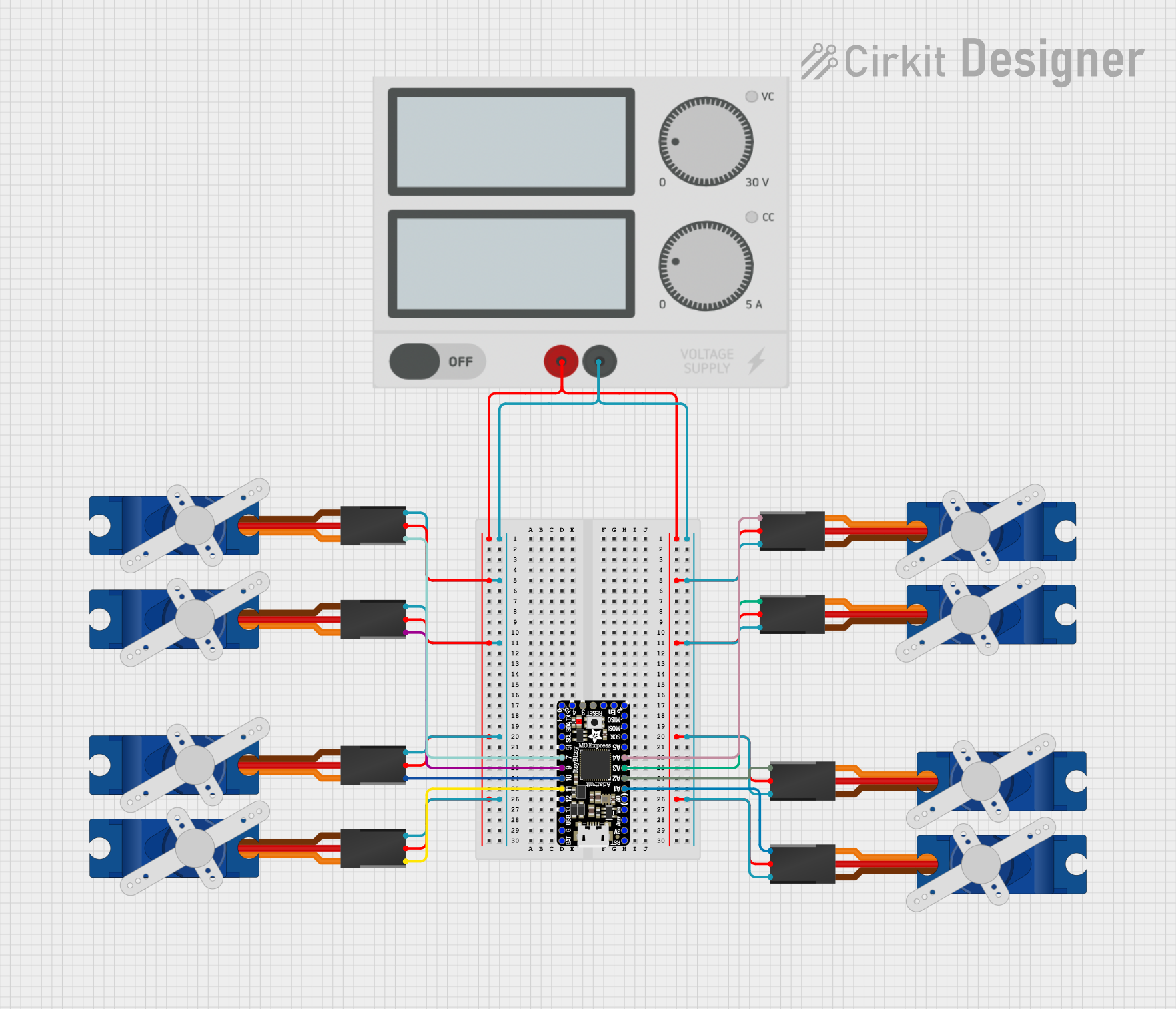

Explore Projects Built with mega_proto_screw

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit DesignerExplore Projects Built with mega_proto_screw

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit DesignerCommon Applications and Use Cases

- Securing printed circuit boards (PCBs) to enclosures or mounting plates.

- Fastening components in prototyping setups.

- Use in DIY electronics projects where strong and reusable fastening is required.

- Temporary assembly of mechanical and electronic systems for testing purposes.

Technical Specifications

The Mega Proto Screw is designed to meet the needs of prototyping and electronics enthusiasts. Below are its key technical details:

| Parameter | Specification |

|---|---|

| Material | Stainless Steel |

| Thread Type | Coarse Thread |

| Thread Diameter | 4 mm |

| Thread Length | 20 mm |

| Head Type | Wide Flat Head |

| Drive Type | Phillips (Cross) |

| Corrosion Resistance | Yes (Rust-Resistant Coating) |

| Weight | 5 grams per screw |

Pin Configuration and Descriptions

The Mega Proto Screw does not have electrical pins, as it is a mechanical component. However, its design features are optimized for prototyping use:

| Feature | Description |

|---|---|

| Wide Head | Provides a large surface area for secure fastening. |

| Robust Thread | Ensures strong grip and prevents loosening over time. |

| Phillips Drive | Compatible with standard Phillips screwdrivers. |

Usage Instructions

The Mega Proto Screw is straightforward to use and can be applied in a variety of prototyping scenarios. Follow the steps below for optimal performance:

Select the Appropriate Screwdriver

Use a Phillips screwdriver that matches the screw's drive size to avoid stripping the head.Align the Components

Ensure the components you are fastening are properly aligned. For example, if securing a PCB, align the mounting holes with the enclosure or standoff.Insert the Screw

Place the screw through the aligned holes and begin turning it clockwise using the screwdriver.Tighten Securely

Tighten the screw until it is snug, but avoid over-tightening, as this may damage the components or strip the threads.Check Stability

Verify that the components are securely fastened and do not wobble or shift.

Important Considerations and Best Practices

- Avoid Over-Tightening: Excessive force can damage delicate components or strip the screw threads.

- Use with Standoffs: When securing PCBs, consider using standoffs to maintain proper spacing and prevent short circuits.

- Corrosion Resistance: While the screw is rust-resistant, avoid prolonged exposure to harsh environments to maintain its integrity.

- Reuse: The Mega Proto Screw is designed for reuse. Handle it carefully to preserve the threading and head.

Example: Securing a PCB in a Prototyping Enclosure

If you are using the Mega Proto Screw to secure a PCB in an enclosure, follow these steps:

- Place the PCB on standoffs inside the enclosure.

- Align the screw holes on the PCB with the standoffs.

- Insert the Mega Proto Screw through the PCB and into the standoff.

- Tighten the screw until the PCB is firmly secured.

Troubleshooting and FAQs

Common Issues and Solutions

| Issue | Possible Cause | Solution |

|---|---|---|

| Screw does not tighten properly | Misaligned components or stripped threads | Realign components or replace the screw. |

| Screw head is damaged | Incorrect screwdriver size used | Use the correct Phillips screwdriver. |

| Components are loose after fastening | Screw not tightened enough | Tighten the screw further, but avoid over-tightening. |

| Screw rusts over time | Exposure to harsh environments | Use in a dry environment or apply additional rust protection. |

FAQs

Q: Can the Mega Proto Screw be used with plastic enclosures?

A: Yes, the screw is compatible with plastic enclosures. However, ensure that the plastic is strong enough to handle the screw's threading without cracking.

Q: Is the Mega Proto Screw reusable?

A: Yes, the screw is designed for reuse. Handle it carefully to avoid damaging the threads or head.

Q: What is the maximum torque the screw can handle?

A: The maximum torque depends on the material being fastened. For most applications, standard hand-tightening with a screwdriver is sufficient.

Q: Can I use the Mega Proto Screw in outdoor projects?

A: While the screw is rust-resistant, prolonged exposure to outdoor conditions may reduce its lifespan. Consider additional protective coatings for outdoor use.

By following this documentation, you can effectively use the Mega Proto Screw in your prototyping and DIY projects.