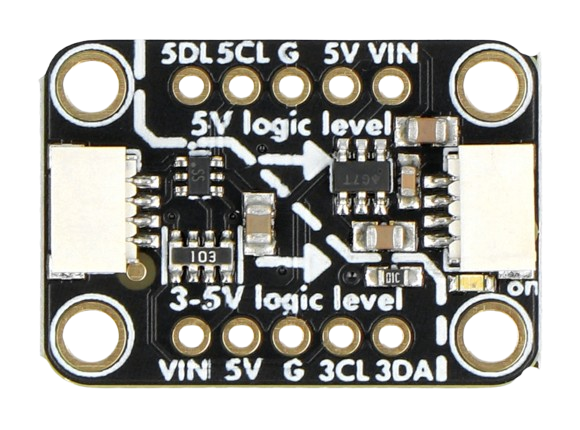

How to Use Level Shifter Breakout STEMMA QT Adafruit 5637: Examples, Pinouts, and Specs

Design with Level Shifter Breakout STEMMA QT Adafruit 5637 in Cirkit Designer

Design with Level Shifter Breakout STEMMA QT Adafruit 5637 in Cirkit DesignerIntroduction

The Level Shifter Breakout STEMMA QT (Adafruit 5637) is a compact and versatile level shifter breakout board designed to facilitate communication between devices operating at different logic voltage levels. It is particularly useful for interfacing 3.3V logic devices with 5V logic devices, ensuring compatibility and reliable data transfer. The board features a bi-directional level shifting circuit and includes STEMMA QT connectors for easy plug-and-play integration.

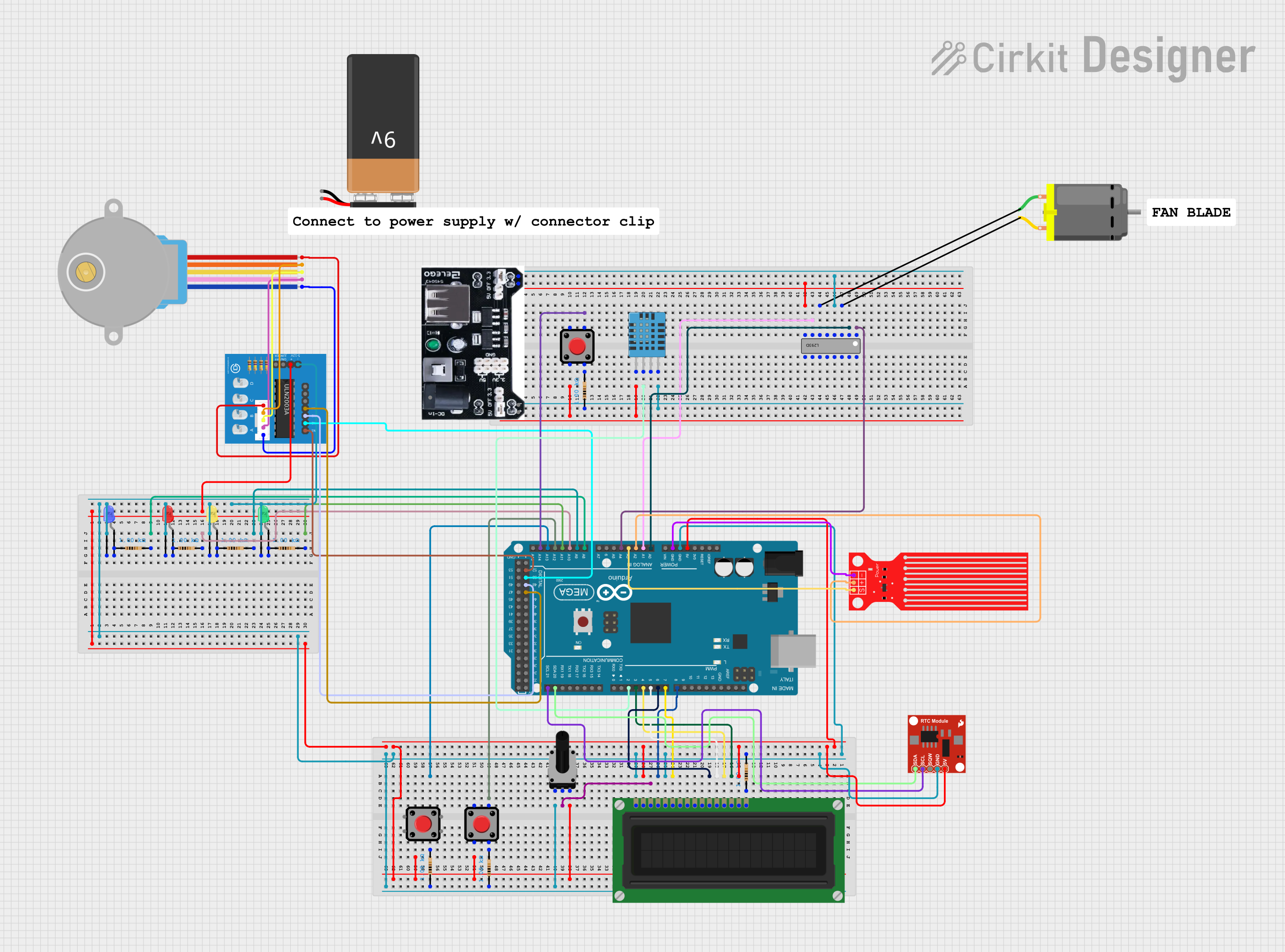

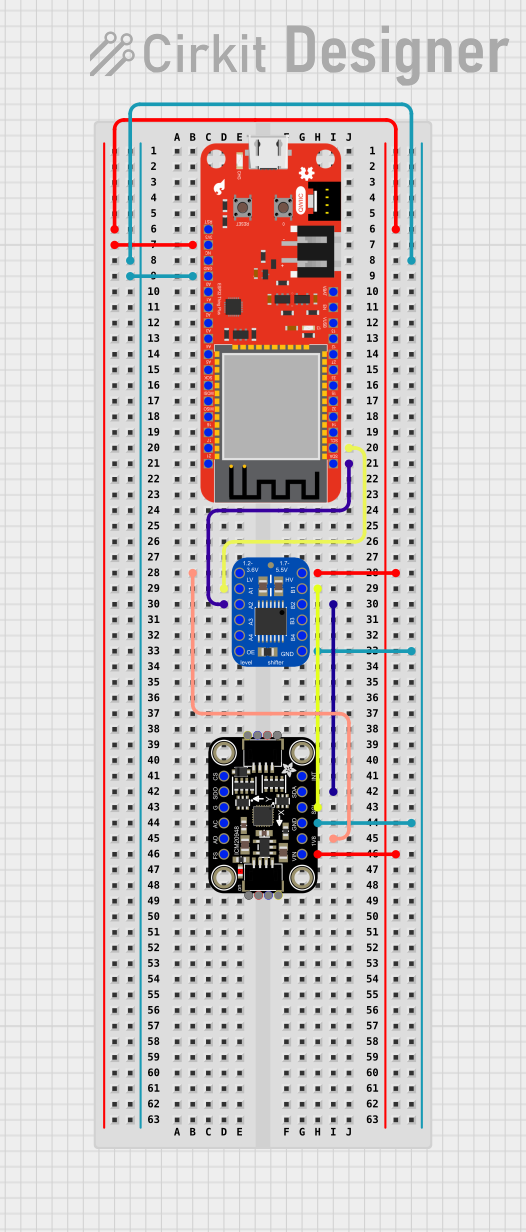

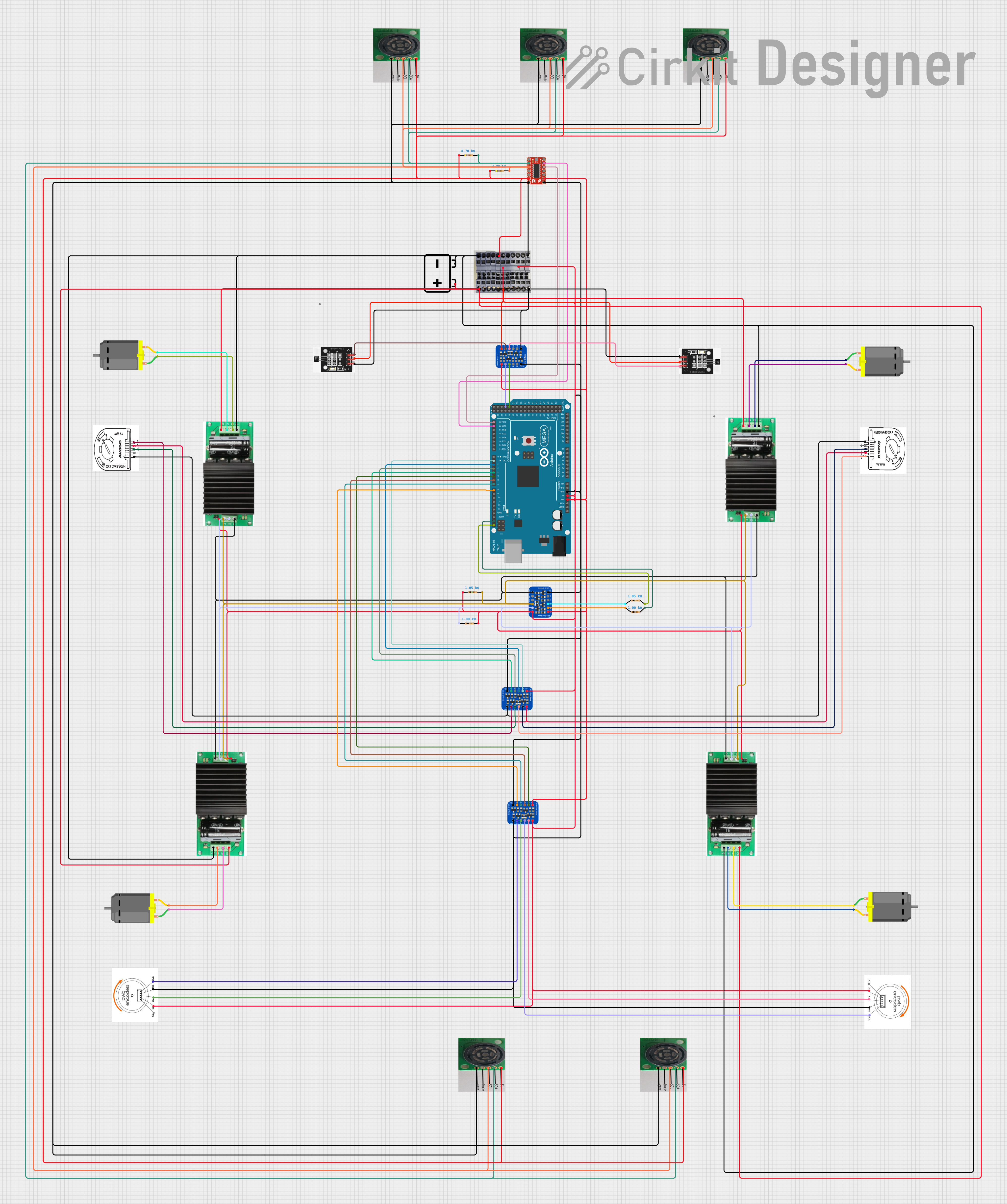

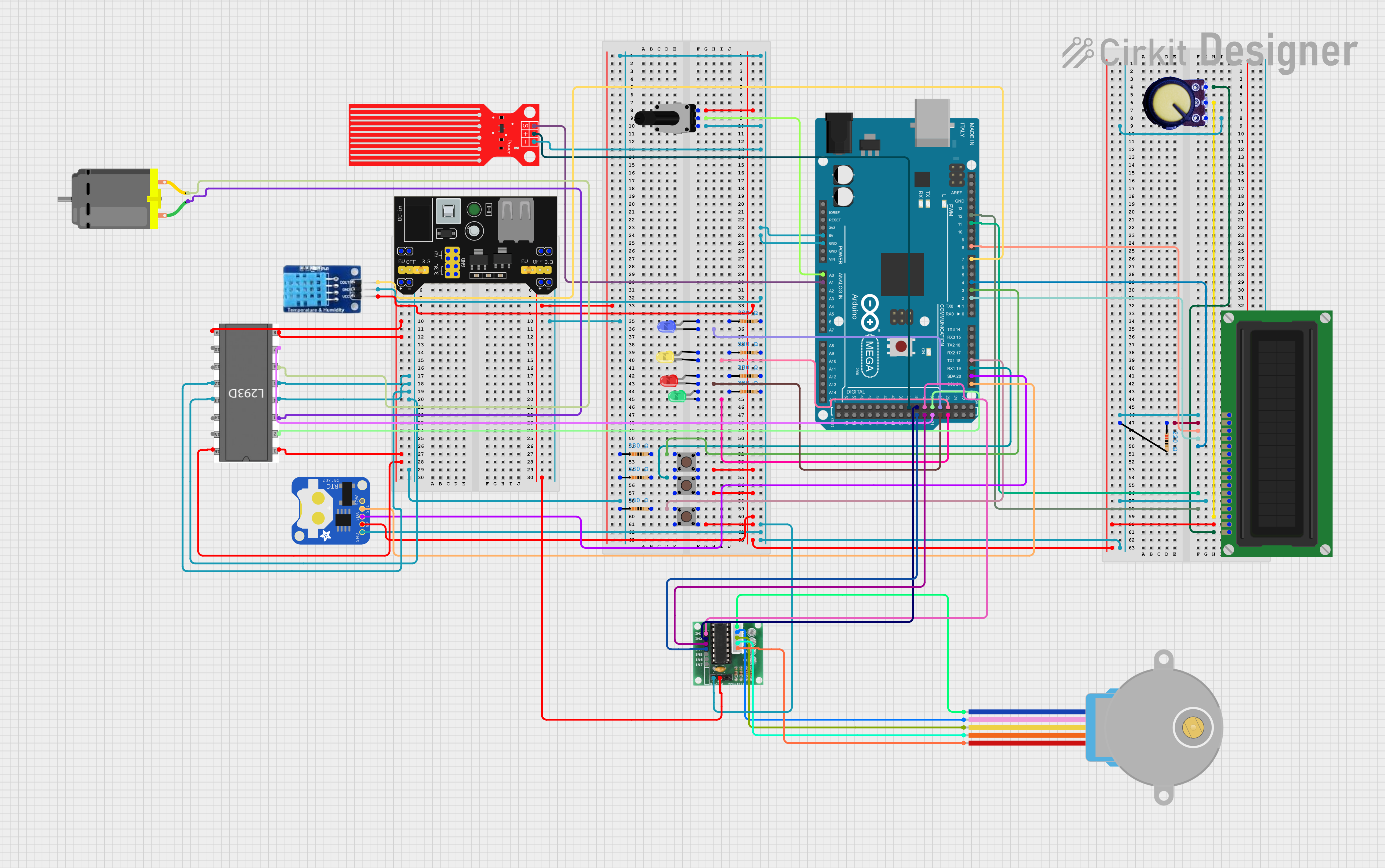

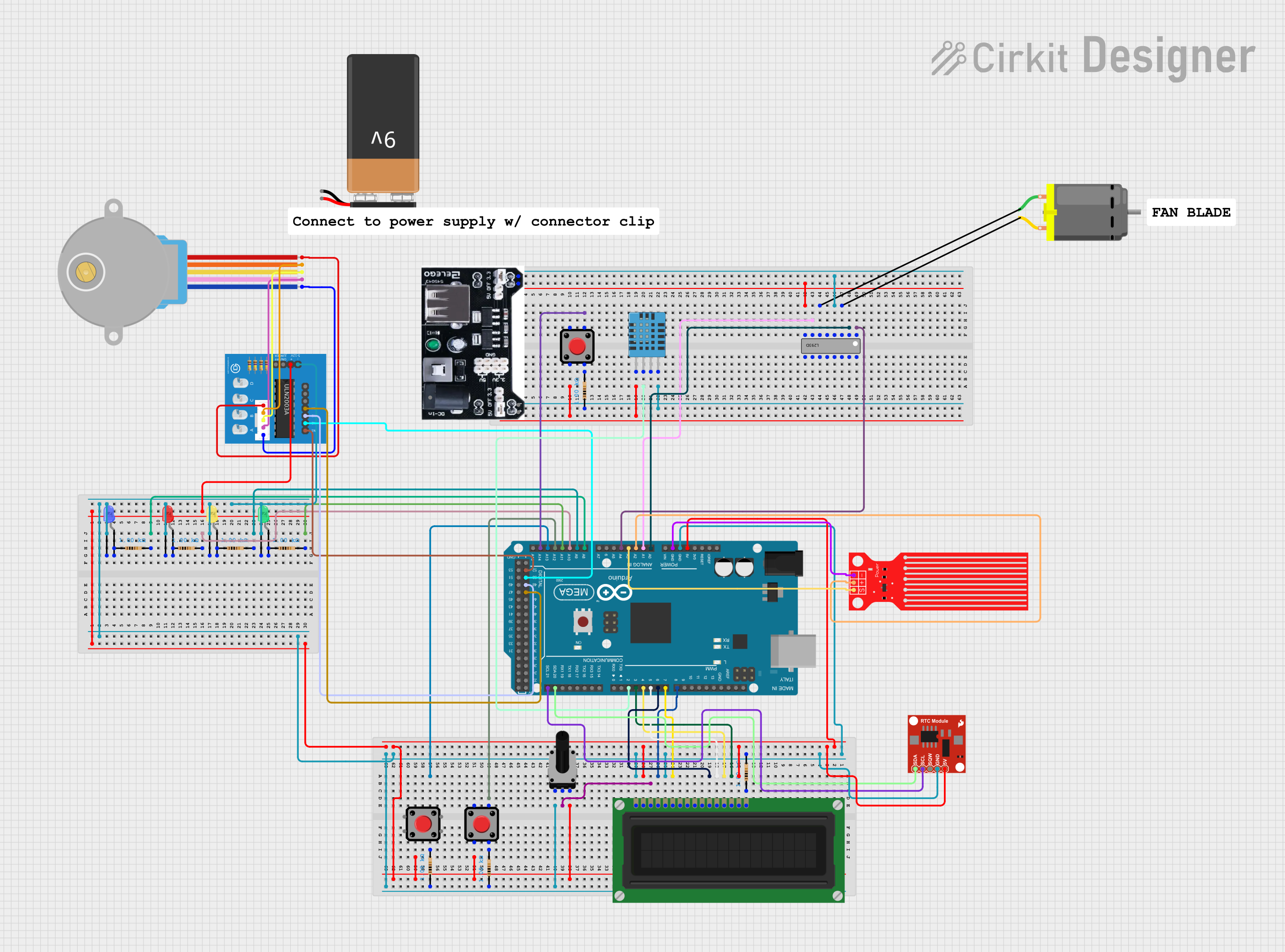

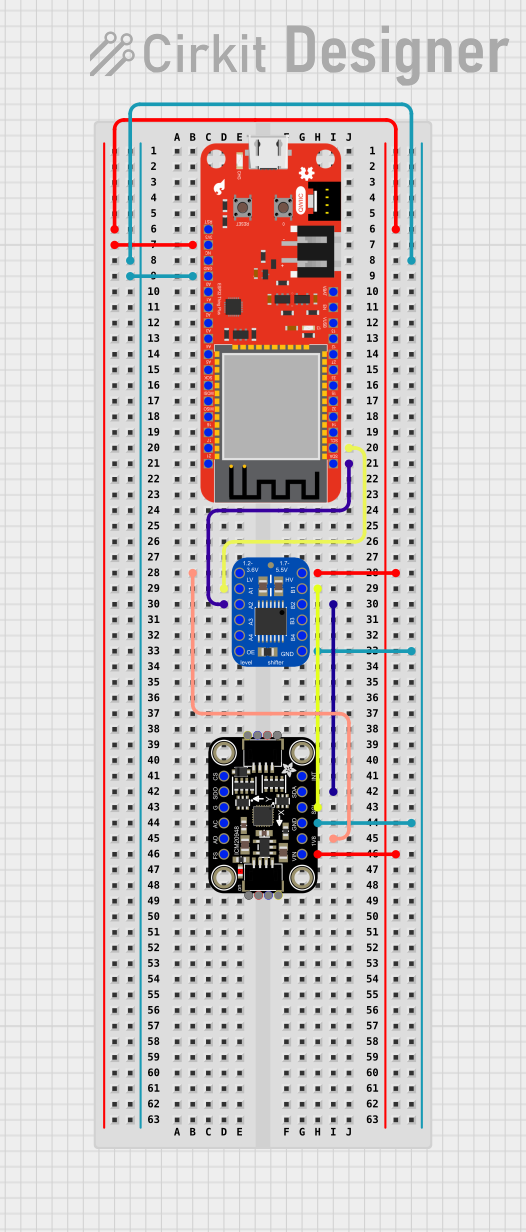

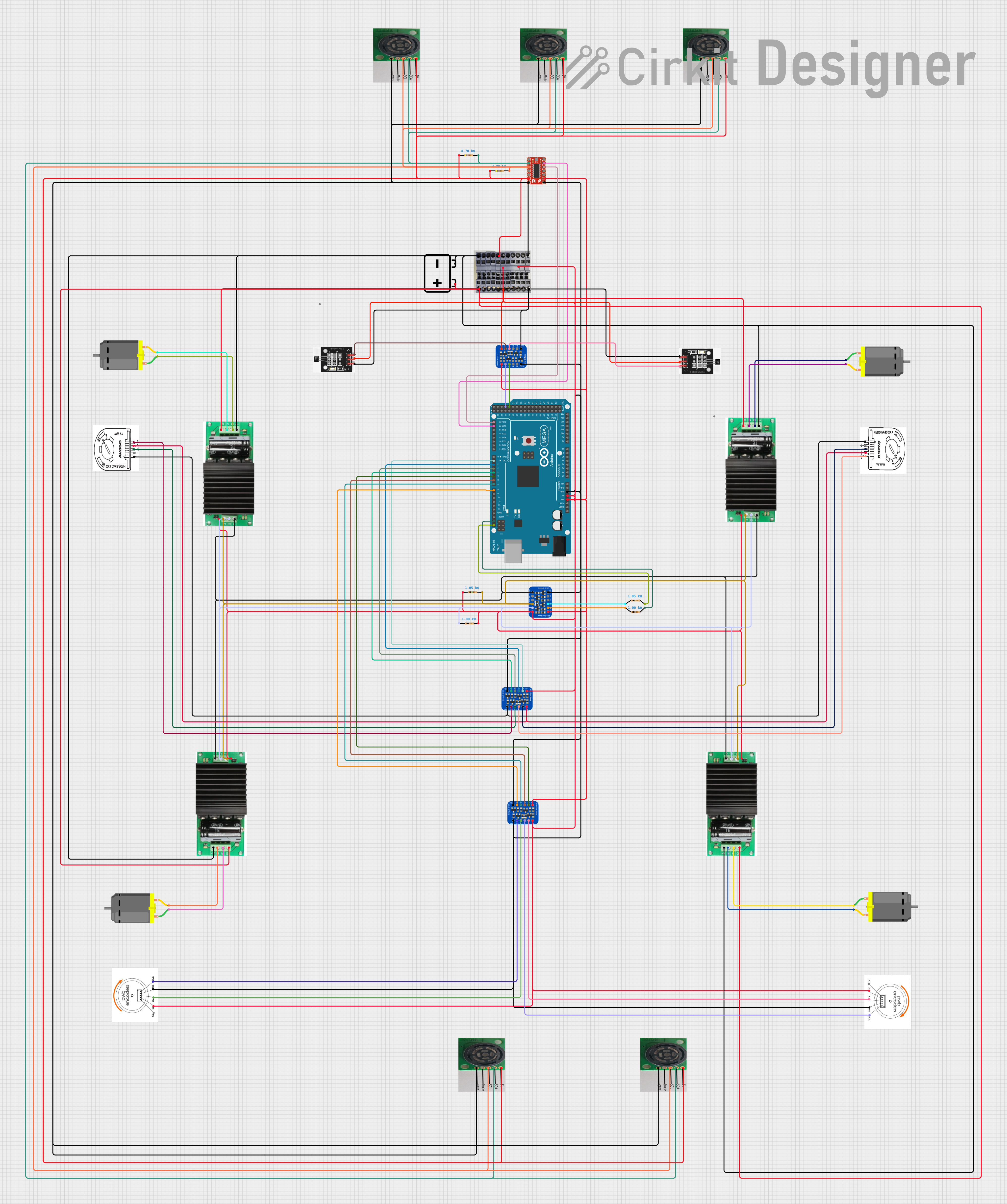

Explore Projects Built with Level Shifter Breakout STEMMA QT Adafruit 5637

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit DesignerExplore Projects Built with Level Shifter Breakout STEMMA QT Adafruit 5637

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit DesignerCommon Applications and Use Cases

- Interfacing 3.3V microcontrollers (e.g., Raspberry Pi, ESP32) with 5V peripherals (e.g., sensors, displays).

- Bridging communication between I2C devices operating at different voltage levels.

- Prototyping and testing circuits with mixed voltage requirements.

- Educational projects and hobbyist electronics.

Technical Specifications

Key Technical Details

- Operating Voltage (High Side): 5V (typical)

- Operating Voltage (Low Side): 3.3V (typical)

- Logic Level Compatibility: 1.8V to 5V

- Communication Protocols Supported: I2C, UART, SPI, GPIO

- Connectors: STEMMA QT (Qwiic-compatible) for I2C

- Dimensions: 25mm x 17mm x 4mm

- Weight: ~1g

Pin Configuration and Descriptions

The Adafruit 5637 breakout board has the following pinout:

| Pin Name | Description |

|---|---|

| VIN | Power input for the high-side voltage (typically 5V). |

| GND | Ground connection. |

| LV | Power input for the low-side voltage (typically 3.3V). |

| HV | High-side voltage reference for level shifting (connect to VIN). |

| A1, A2, A3, A4 | Low-side logic pins for bi-directional level shifting. |

| B1, B2, B3, B4 | High-side logic pins corresponding to A1, A2, A3, and A4. |

| STEMMA QT IN | I2C input connector for easy daisy-chaining with other STEMMA QT devices. |

| STEMMA QT OUT | I2C output connector for chaining additional devices. |

Usage Instructions

How to Use the Component in a Circuit

Power Connections:

- Connect the VIN pin to the high-side voltage source (e.g., 5V).

- Connect the LV pin to the low-side voltage source (e.g., 3.3V).

- Connect the GND pin to the ground of your circuit.

Logic Connections:

- Use the A1-A4 pins for the low-voltage side (e.g., 3.3V logic).

- Use the corresponding B1-B4 pins for the high-voltage side (e.g., 5V logic).

- For I2C communication, connect the SDA and SCL lines to any of the A or B pins as needed.

STEMMA QT Integration:

- Use the STEMMA QT connectors to easily integrate the breakout board into an I2C bus with other compatible devices.

Important Considerations and Best Practices

- Ensure that the VIN and LV voltages are within the supported range (1.8V to 5V).

- Always connect the GND pin to the common ground of your circuit to avoid communication issues.

- For I2C applications, ensure proper pull-up resistors are present on the SDA and SCL lines if not already included in your setup.

- Avoid exceeding the maximum current rating of the board to prevent damage.

Example: Using with Arduino UNO

Below is an example of how to use the Adafruit 5637 to interface a 3.3V sensor with a 5V Arduino UNO via I2C.

Circuit Connections

- Connect VIN to the Arduino's 5V pin.

- Connect LV to the sensor's 3.3V power pin.

- Connect GND to the common ground.

- Connect A1 to the sensor's SDA pin and B1 to the Arduino's SDA pin.

- Connect A2 to the sensor's SCL pin and B2 to the Arduino's SCL pin.

Arduino Code Example

#include <Wire.h>

// I2C address of the 3.3V sensor

#define SENSOR_ADDRESS 0x40

void setup() {

Wire.begin(); // Initialize I2C communication

Serial.begin(9600); // Start serial communication for debugging

// Check if the sensor is connected

Wire.beginTransmission(SENSOR_ADDRESS);

if (Wire.endTransmission() == 0) {

Serial.println("Sensor detected!");

} else {

Serial.println("Sensor not detected. Check connections.");

}

}

void loop() {

// Example: Read data from the sensor

Wire.beginTransmission(SENSOR_ADDRESS);

Wire.write(0x00); // Command to read data (depends on the sensor)

Wire.endTransmission();

Wire.requestFrom(SENSOR_ADDRESS, 2); // Request 2 bytes of data

if (Wire.available() == 2) {

int data = Wire.read() << 8 | Wire.read(); // Combine two bytes

Serial.print("Sensor Data: ");

Serial.println(data);

}

delay(1000); // Wait 1 second before the next read

}

Troubleshooting and FAQs

Common Issues and Solutions

No Communication Between Devices:

- Ensure that the GND pin is connected to the common ground of all devices.

- Verify that the VIN and LV voltages are correctly supplied.

- Check the wiring between the A and B pins for proper connections.

I2C Devices Not Detected:

- Confirm that the pull-up resistors are present on the SDA and SCL lines.

- Use an I2C scanner sketch to verify the device address.

Unstable or Intermittent Communication:

- Ensure that the power supply is stable and within the specified voltage range.

- Check for loose connections or damaged wires.

FAQs

Q: Can I use this board for SPI communication?

A: Yes, the Adafruit 5637 supports SPI communication. Connect the SPI lines (MOSI, MISO, SCK, CS) to the appropriate A and B pins.

Q: What is the maximum data rate supported?

A: The board supports data rates up to 400kHz for I2C and similar speeds for other protocols, depending on the circuit design.

Q: Can I daisy-chain multiple level shifters?

A: Yes, you can daisy-chain multiple level shifters using the STEMMA QT connectors for I2C communication.

Q: Is this board compatible with 1.8V logic?

A: Yes, the board supports logic levels as low as 1.8V on the low side. Ensure proper voltage is supplied to the LV pin.