How to Use L298N MOTOR DRIVER: Examples, Pinouts, and Specs

Design with L298N MOTOR DRIVER in Cirkit Designer

Design with L298N MOTOR DRIVER in Cirkit DesignerIntroduction

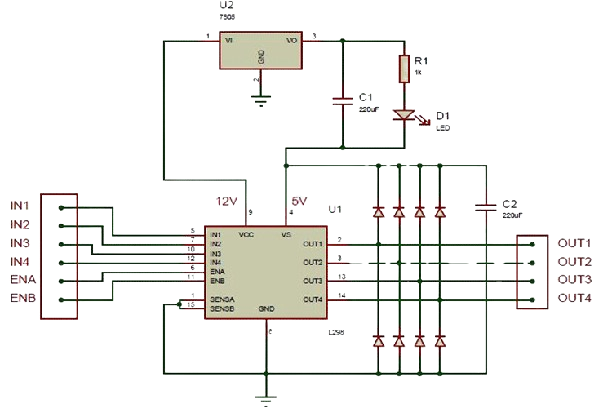

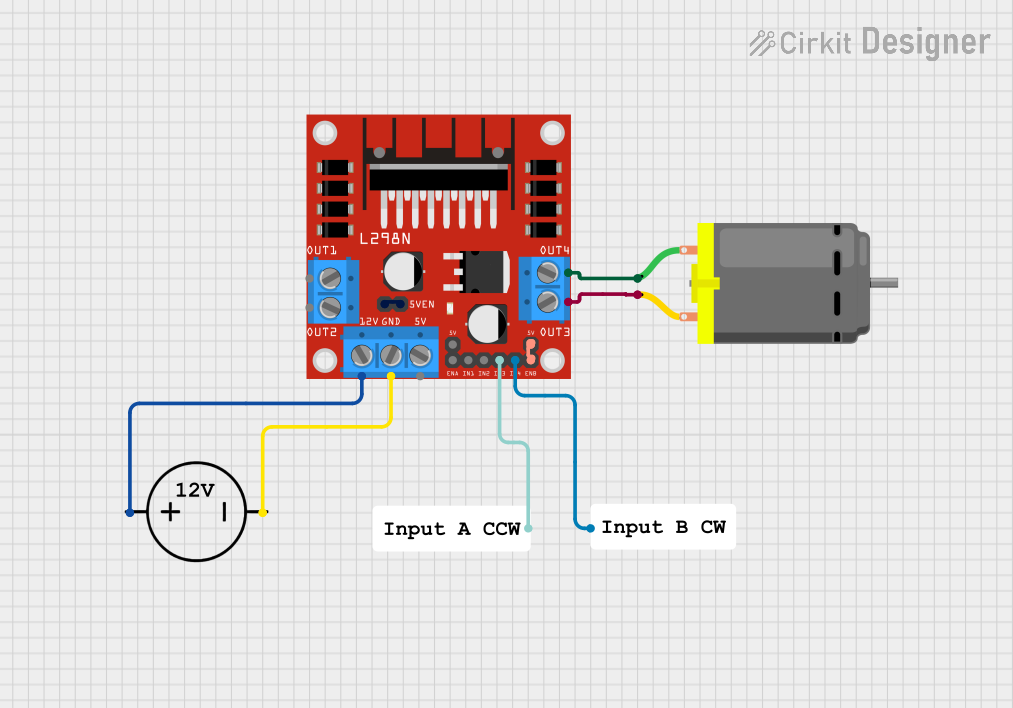

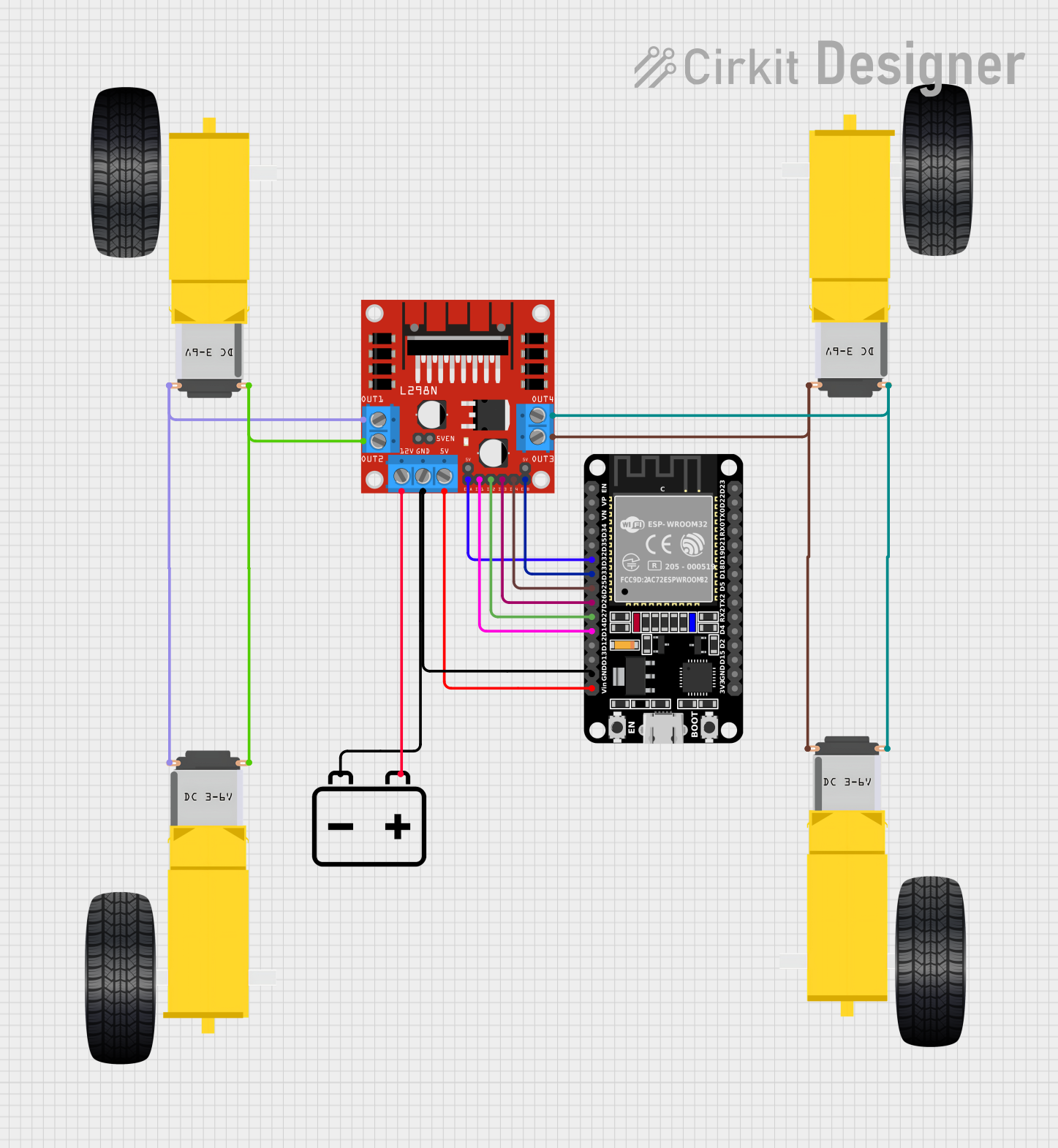

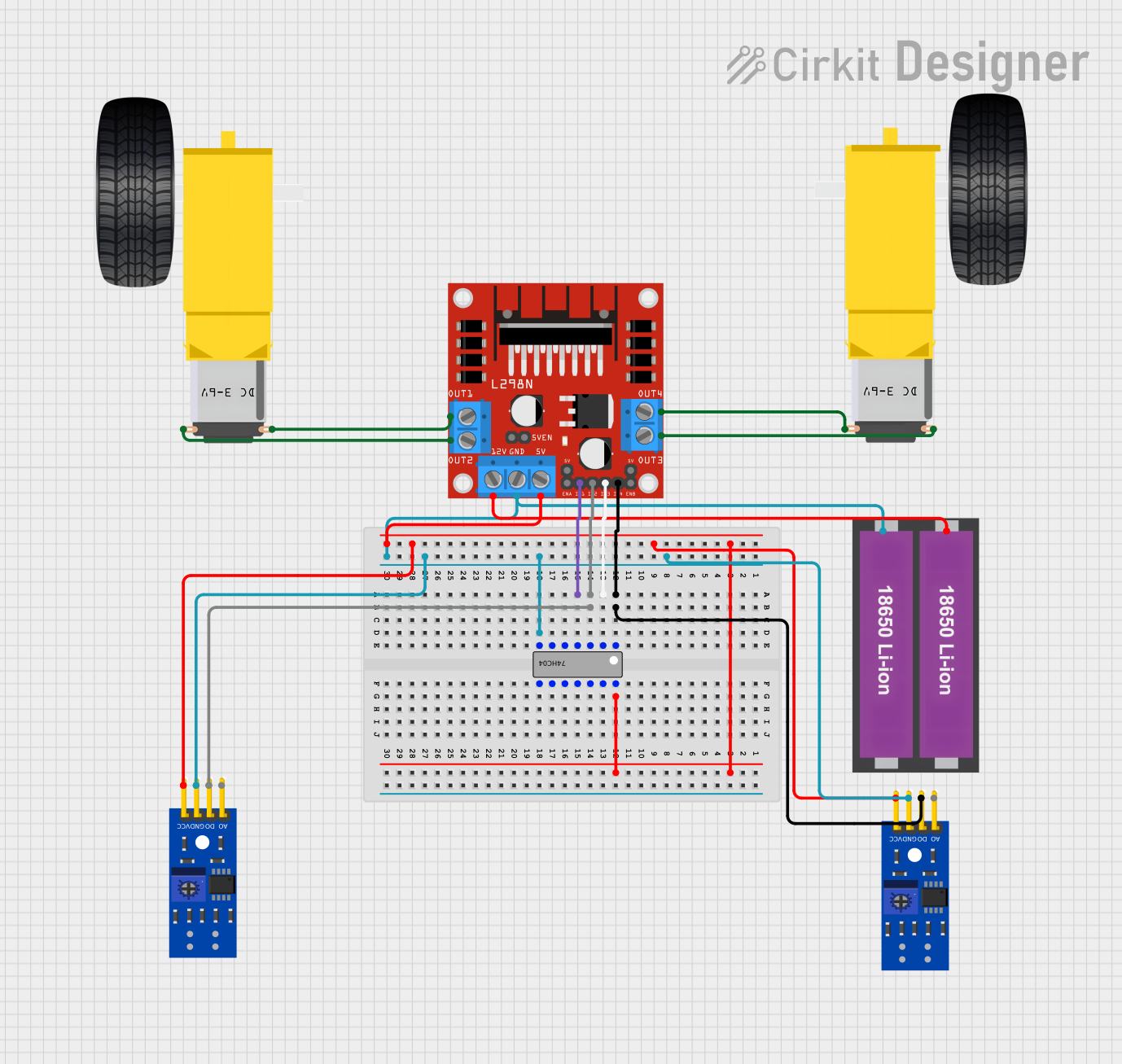

The L298N motor driver is a versatile dual H-bridge motor driver integrated circuit (IC) capable of controlling the speed and direction of two DC motors or one stepper motor. It is widely used in robotics, automation projects, and various applications where precise motor control is required.

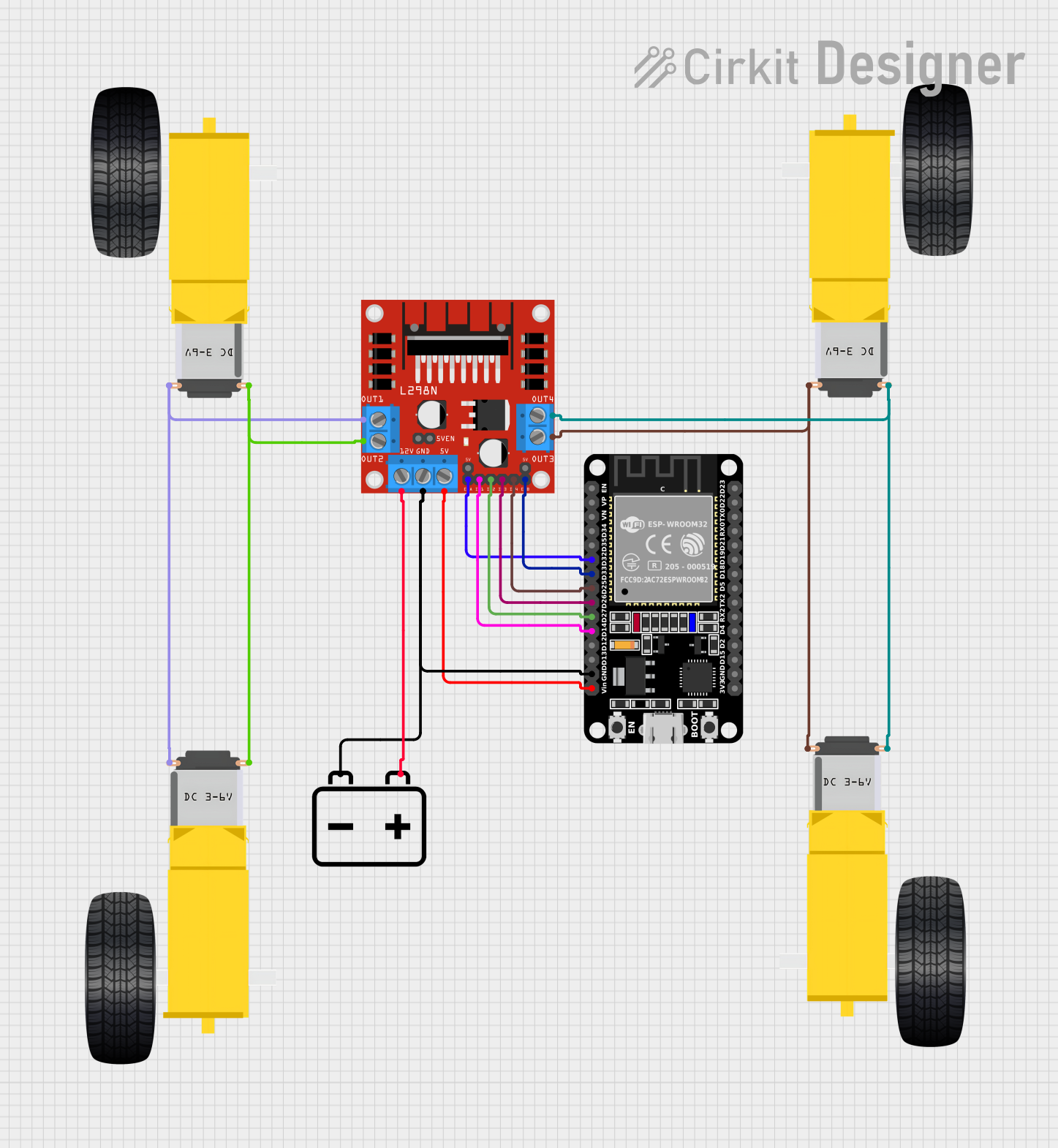

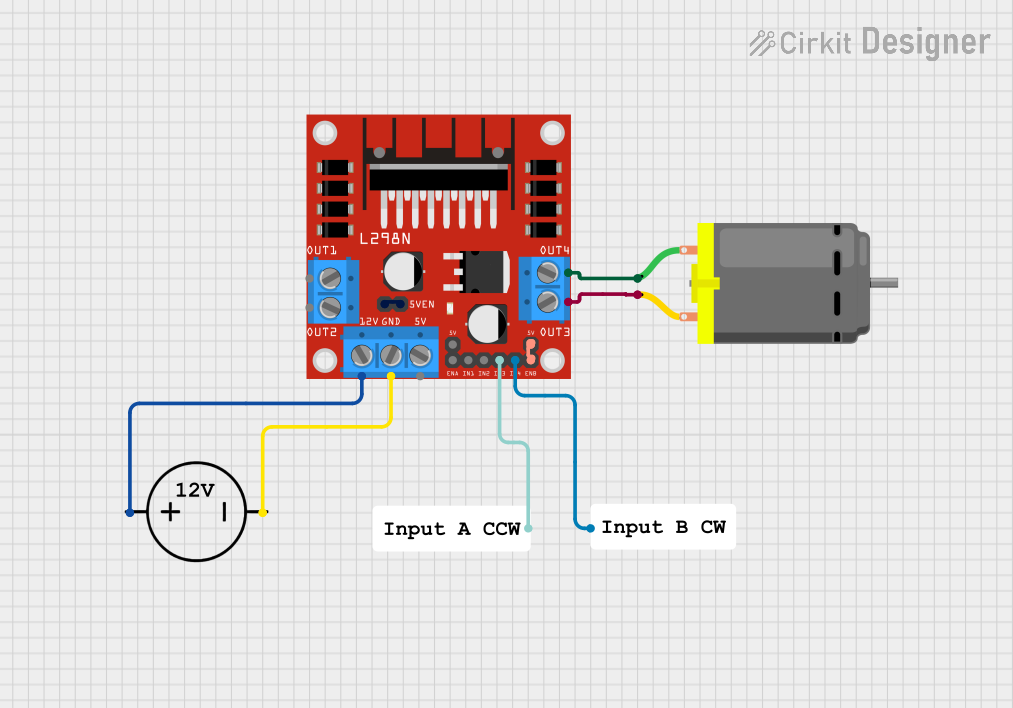

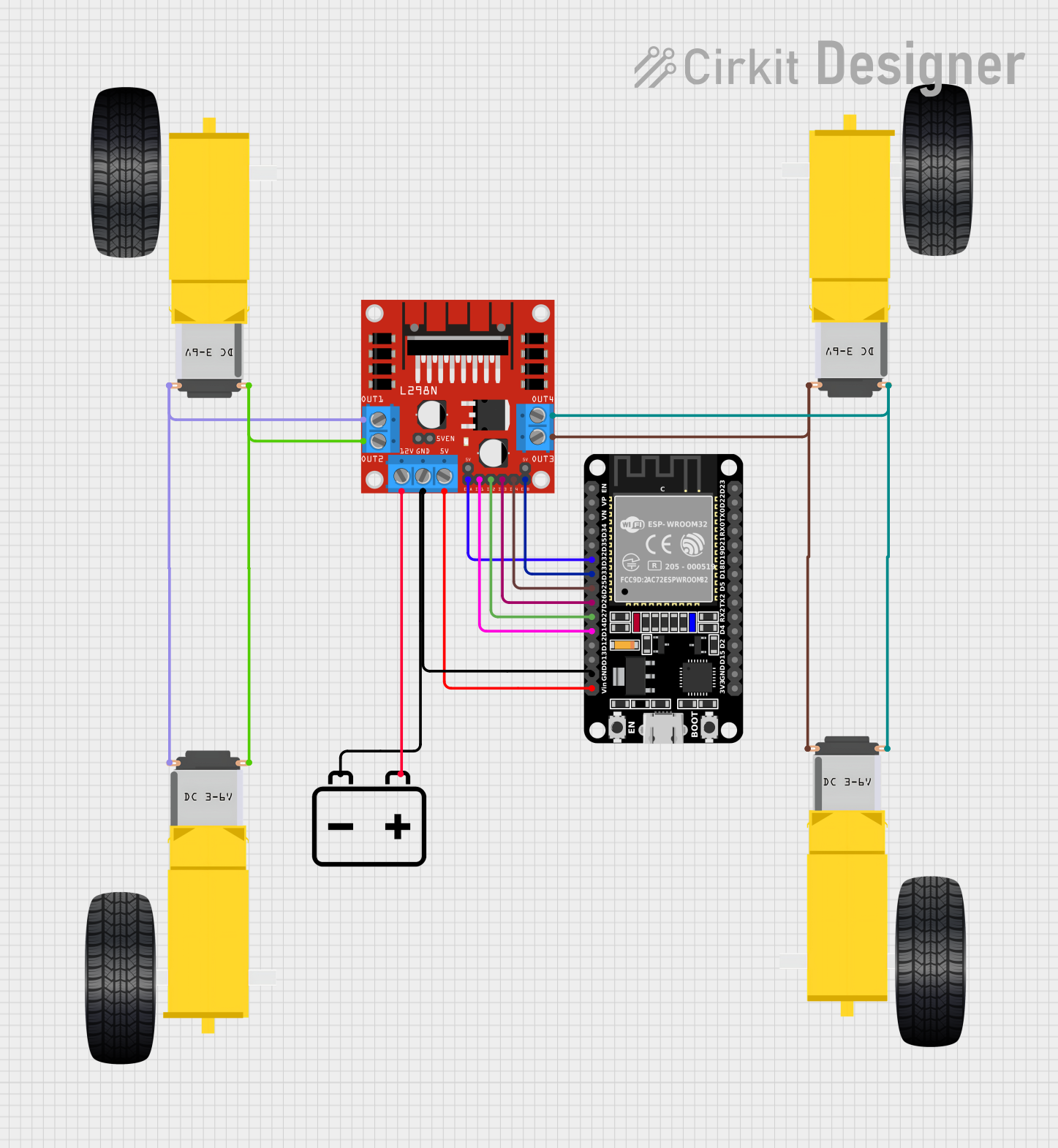

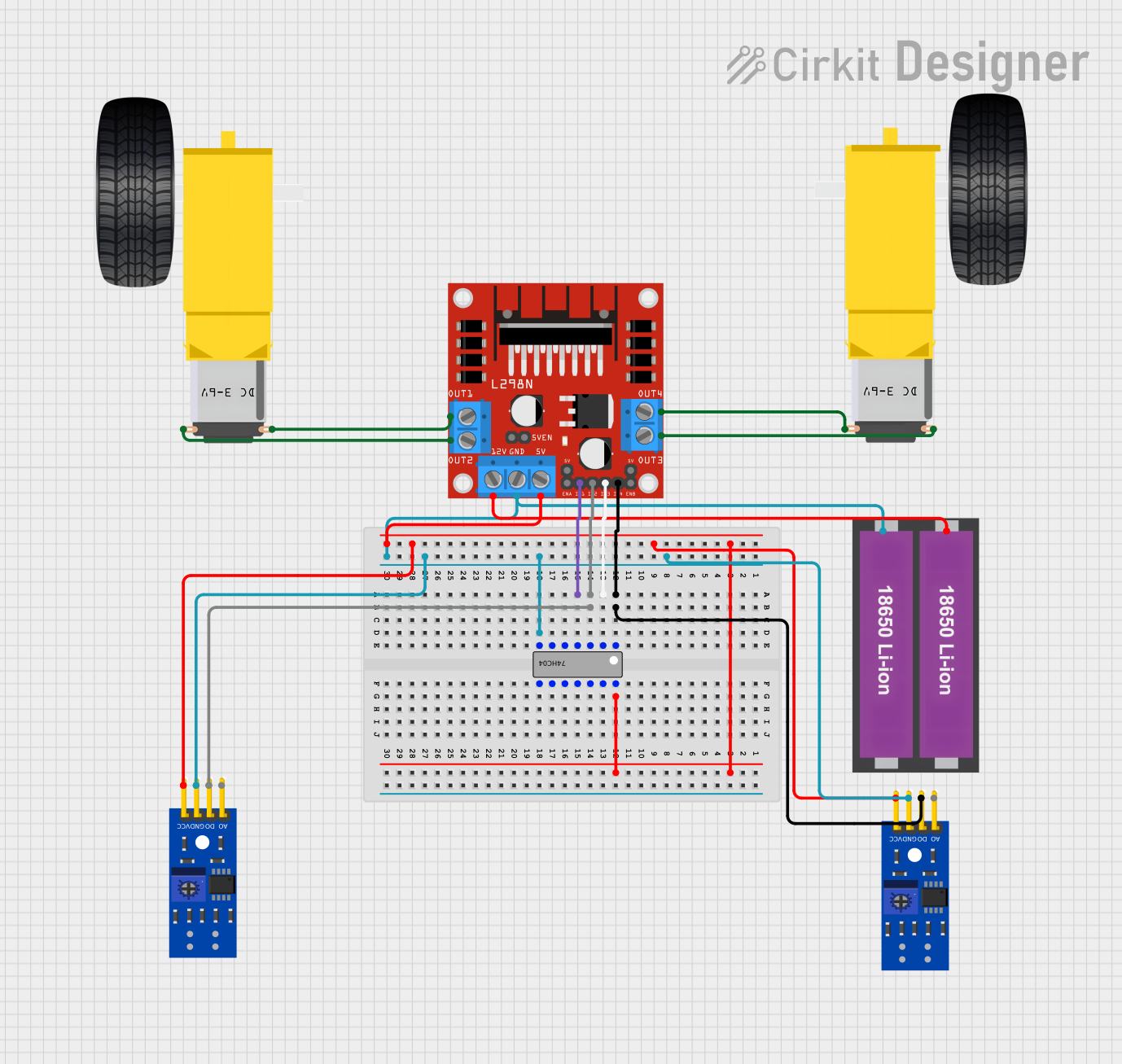

Explore Projects Built with L298N MOTOR DRIVER

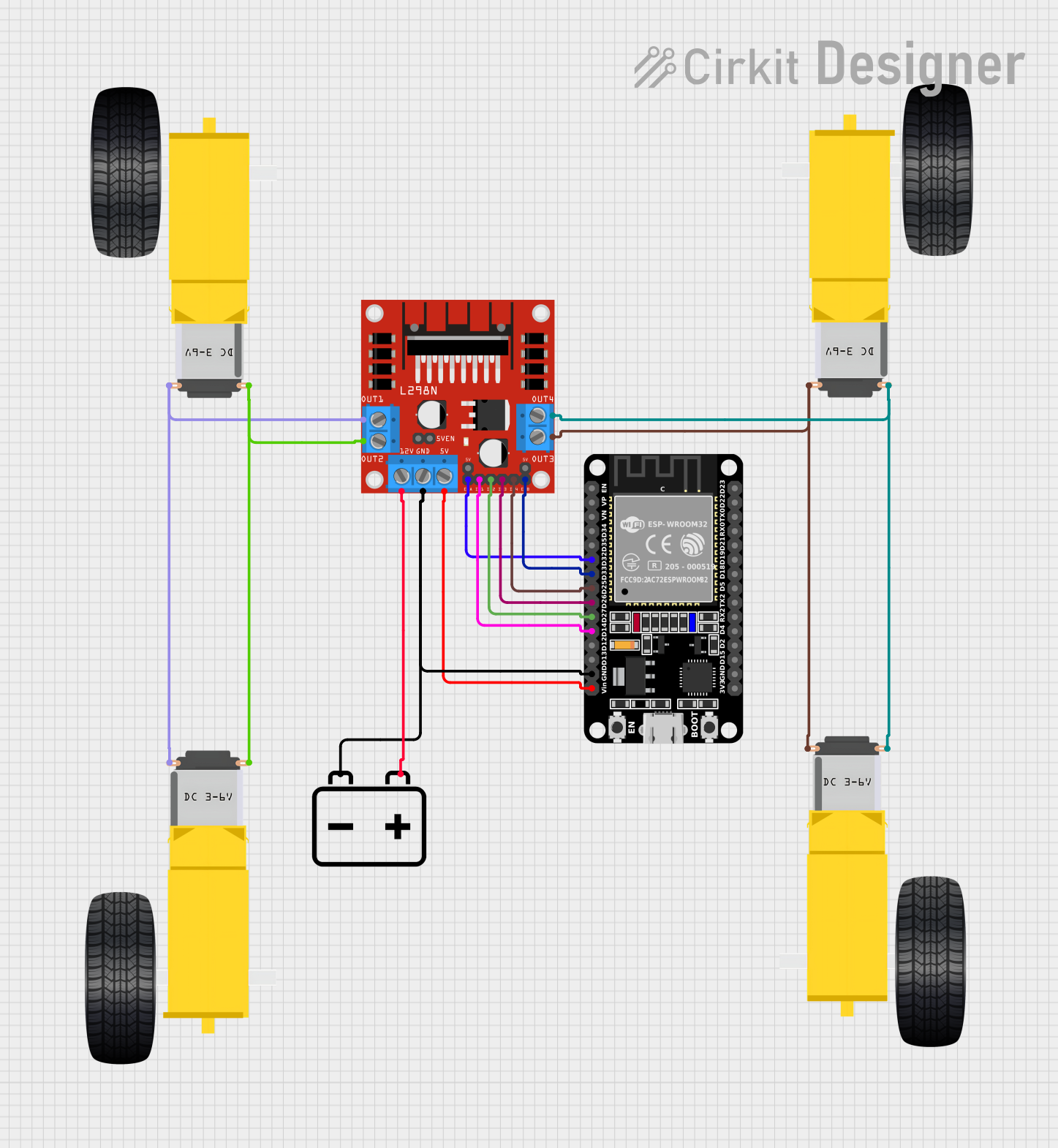

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit DesignerExplore Projects Built with L298N MOTOR DRIVER

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit DesignerCommon Applications and Use Cases

- Robotics

- CNC machines

- Automated guided vehicles (AGVs)

- Home automation systems

- DIY electronic projects

Technical Specifications

Key Technical Details

- Operating Voltage: 5V to 35V

- Logic Voltage: 5V

- Continuous Output Current: 2A per channel (3A peak)

- Power Dissipation: 25W

Pin Configuration and Descriptions

| Pin Number | Pin Name | Description |

|---|---|---|

| 1 | OUT1 | Motor A output 1 |

| 2 | OUT2 | Motor A output 2 |

| 3 | VS | Motor power supply (up to 35V) |

| 4 | GND | Ground |

| 5 | OUT3 | Motor B output 1 |

| 6 | OUT4 | Motor B output 2 |

| 7 | VSS | Logic power supply (5V) |

| 8 | ENA | Enable motor A / PWM speed control for motor A |

| 9 | IN1 | Input 1 for motor A direction control |

| 10 | IN2 | Input 2 for motor A direction control |

| 11 | IN3 | Input 3 for motor B direction control |

| 12 | IN4 | Input 4 for motor B direction control |

| 13 | ENB | Enable motor B / PWM speed control for motor B |

| 14 | CS | Current sensing output (optional) |

Usage Instructions

How to Use the Component in a Circuit

- Connect the motor power supply (VS) to the motors' voltage source, ensuring it does not exceed 35V.

- Connect the logic power supply (VSS) to a 5V source.

- Connect the ground pin (GND) to the common ground of the power supplies.

- Connect the motors to the OUT1/OUT2 and OUT3/OUT4 for motor A and B, respectively.

- Use the ENA and ENB pins to enable the motors and control their speed using PWM signals.

- Control the direction of the motors by setting the IN1/IN2 and IN3/IN4 pins to high or low.

Important Considerations and Best Practices

- Always use a separate power supply for the motors to prevent noise and voltage drops on the logic side.

- Use heat sinks if operating near the maximum current rating to prevent overheating.

- Ensure that the power supply can handle the motors' current requirements.

- Use flyback diodes if necessary to protect against voltage spikes when the motors turn off.

Example Connection to an Arduino UNO

// Define the L298N control pins

const int enA = 9;

const int in1 = 8;

const int in2 = 7;

const int enB = 3;

const int in3 = 5;

const int in4 = 4;

void setup() {

// Set all the motor control pins to outputs

pinMode(enA, OUTPUT);

pinMode(enB, OUTPUT);

pinMode(in1, OUTPUT);

pinMode(in2, OUTPUT);

pinMode(in3, OUTPUT);

pinMode(in4, OUTPUT);

}

void loop() {

// Turn on motor A & B

digitalWrite(in1, HIGH);

digitalWrite(in2, LOW);

digitalWrite(in3, HIGH);

digitalWrite(in4, LOW);

// Set speed to 200 out of possible range 0-255

analogWrite(enA, 200);

analogWrite(enB, 200);

// Wait 2 seconds

delay(2000);

// Change motor directions

digitalWrite(in1, LOW);

digitalWrite(in2, HIGH);

digitalWrite(in3, LOW);

digitalWrite(in4, HIGH);

// Wait 2 seconds

delay(2000);

// Turn off motors

digitalWrite(enA, LOW);

digitalWrite(enB, LOW);

}

Troubleshooting and FAQs

Common Issues Users Might Face

- Motor not running: Check power supply connections, ensure the enable pins (ENA/ENB) are set to high, and verify that the input pins (IN1-IN4) are correctly configured.

- Overheating: Ensure proper heat sinking and that the current does not exceed the rated specifications.

- Inconsistent motor speed: Check for PWM signal integrity and ensure a stable power supply.

Solutions and Tips for Troubleshooting

- Use a multimeter to check for proper voltage levels at the power supply and the motor outputs.

- If using PWM for speed control, ensure the PWM frequency is within the acceptable range for the L298N.

- Double-check wiring, especially the ground connections, to ensure they are secure and have a good connection.

FAQs

Q: Can I control a stepper motor with the L298N? A: Yes, the L298N can control a bipolar stepper motor by using the two H-bridges to control the two coils.

Q: What is the maximum current the L298N can handle? A: The L298N can handle up to 2A per channel continuously, with peak currents of 3A.

Q: Do I need to use external diodes with the L298N? A: The L298N has built-in diodes for back EMF protection. However, additional external diodes may be used for extra protection.

Q: How do I use the current sensing feature? A: The CS pin can be connected to an analog input on a microcontroller to measure the voltage proportional to the motor current.