How to Use Gear Motor with integrated Encoder: Examples, Pinouts, and Specs

Design with Gear Motor with integrated Encoder in Cirkit Designer

Design with Gear Motor with integrated Encoder in Cirkit DesignerIntroduction

A gear motor with an integrated encoder by Naroote is a compact and efficient solution for precise motion control in various applications. This component combines a geared electric motor with a rotary encoder, providing both the mechanical power to drive a system and the capability to monitor and control the position, speed, or direction of the motor shaft. Common applications include robotics, automated machinery, conveyor systems, and any application where precise motor control is required.

Explore Projects Built with Gear Motor with integrated Encoder

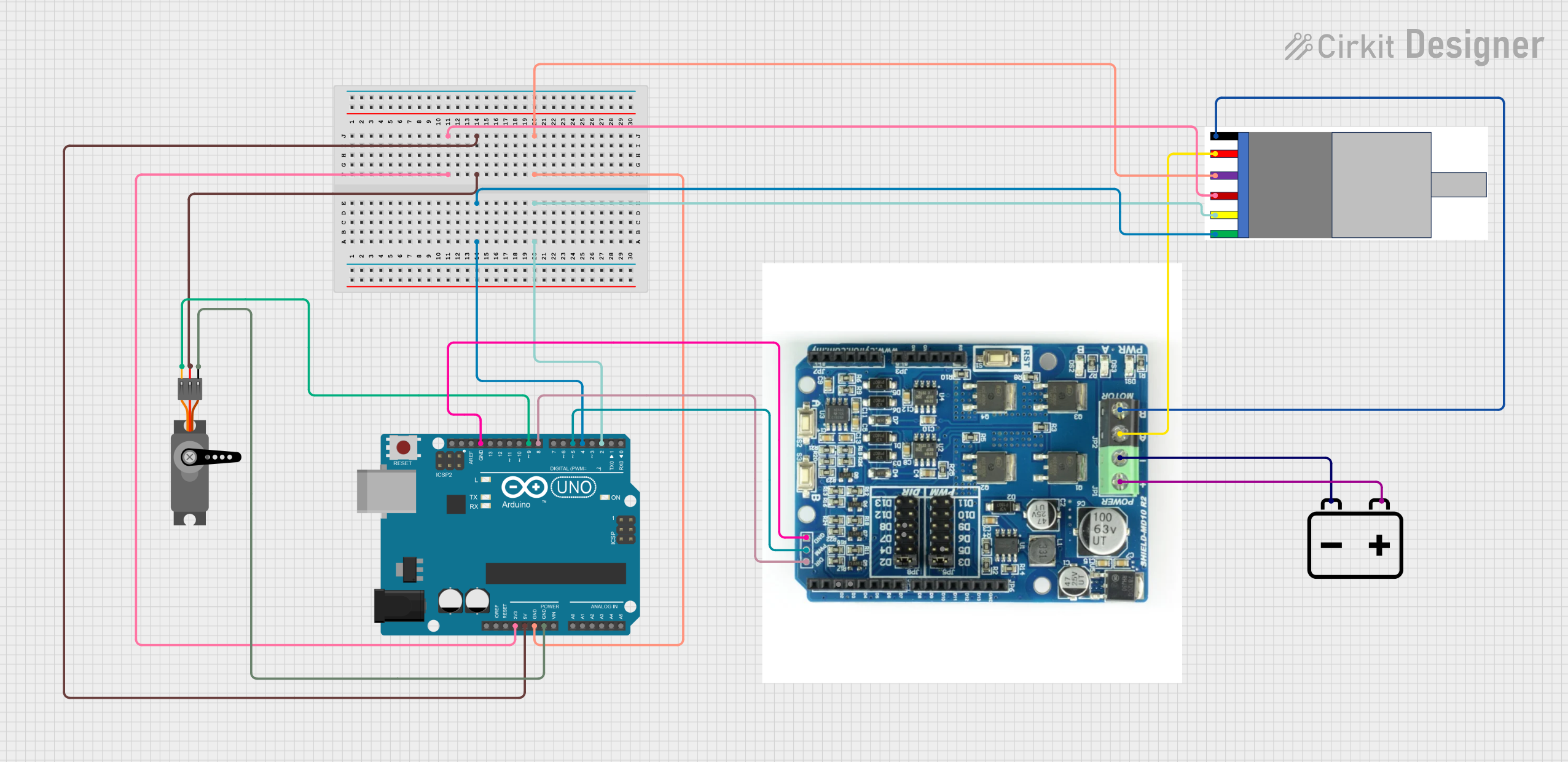

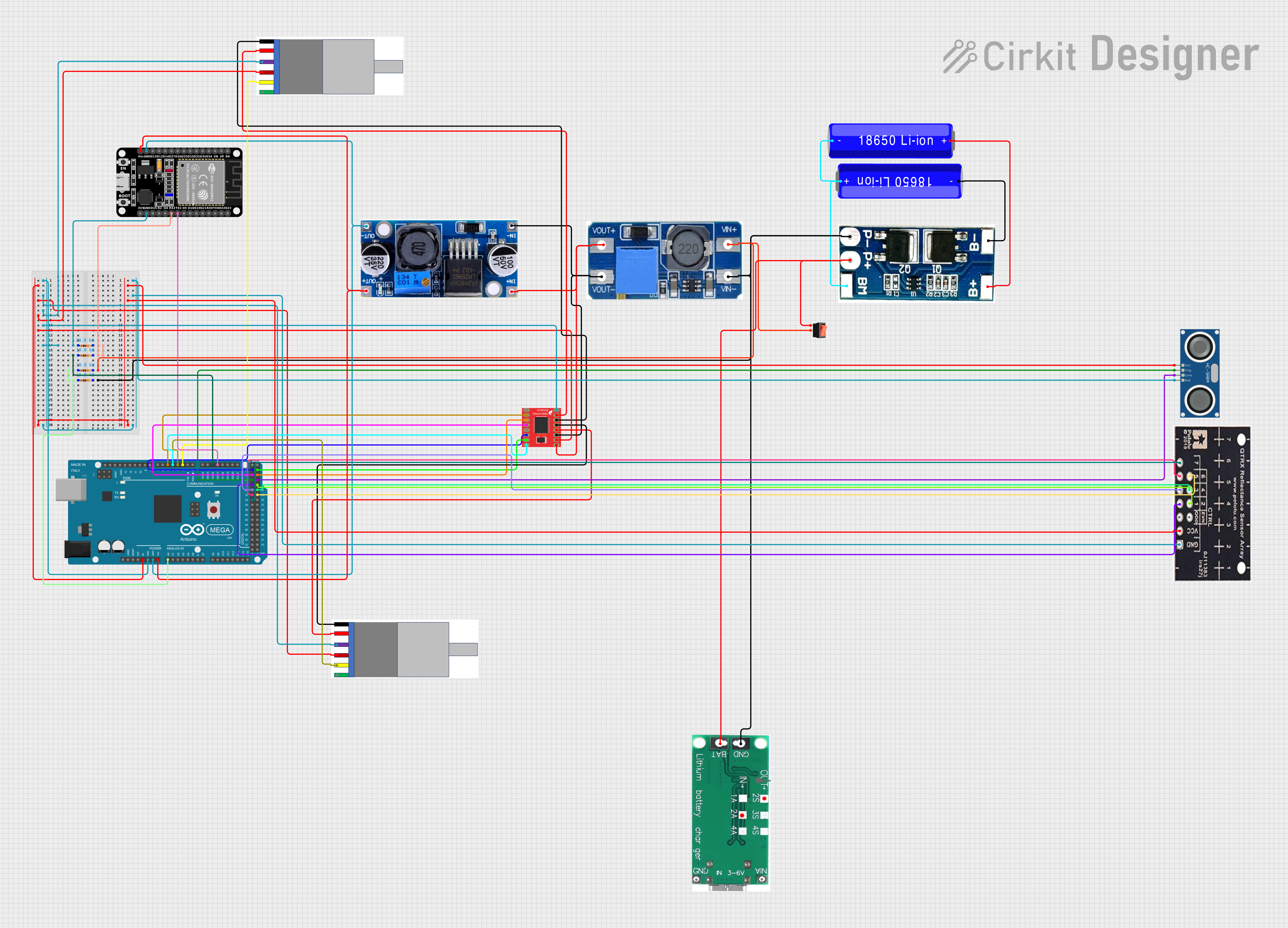

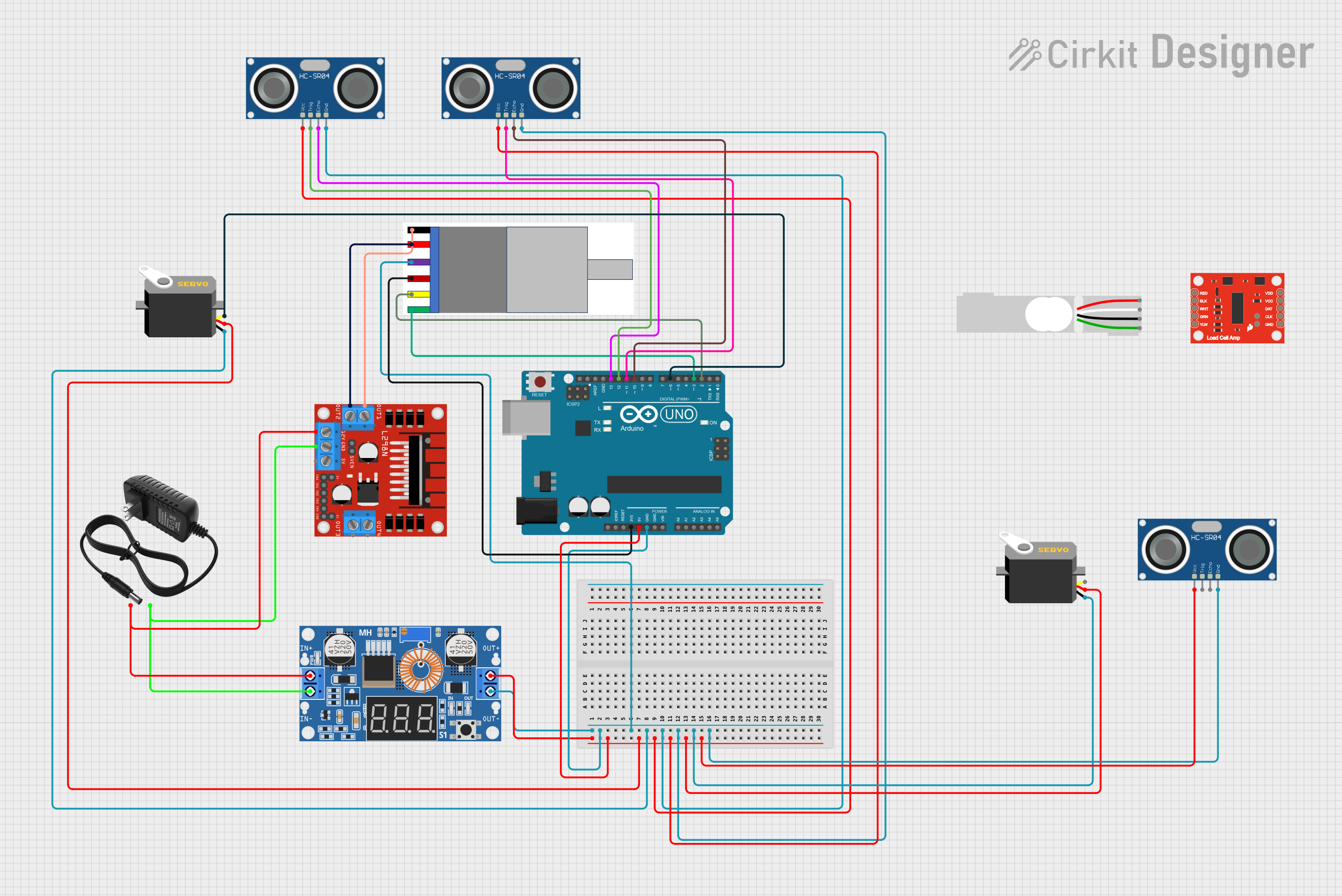

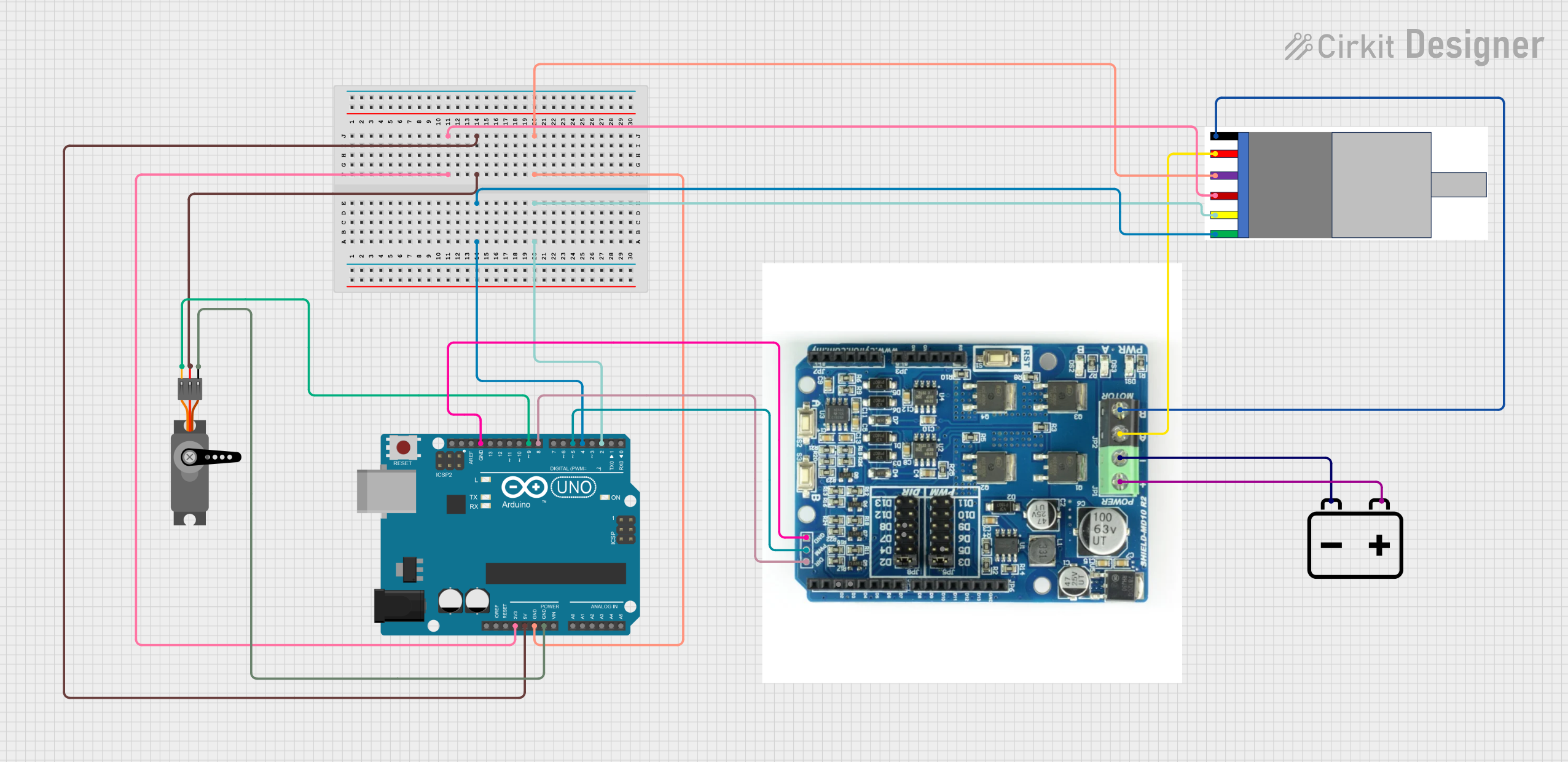

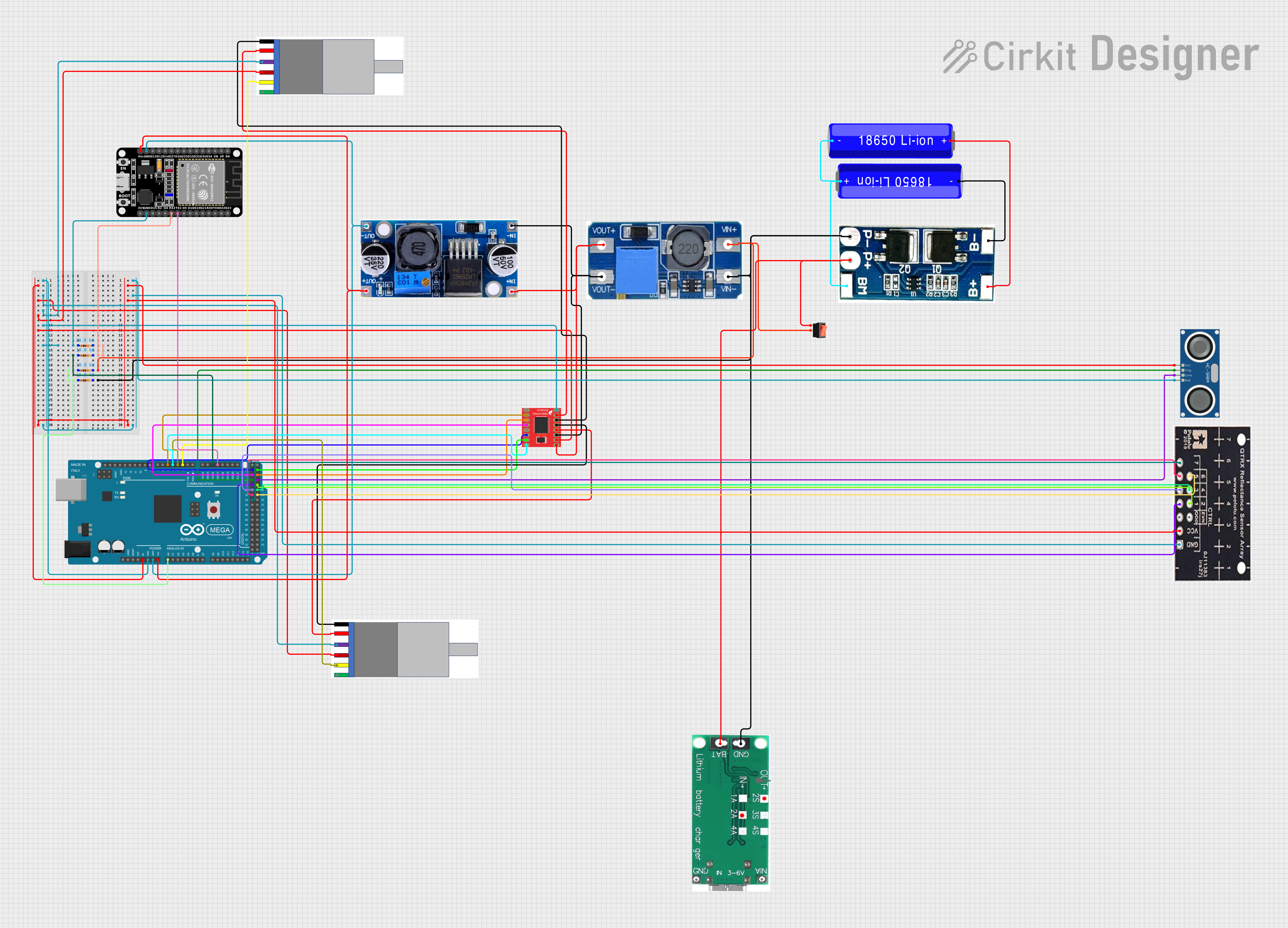

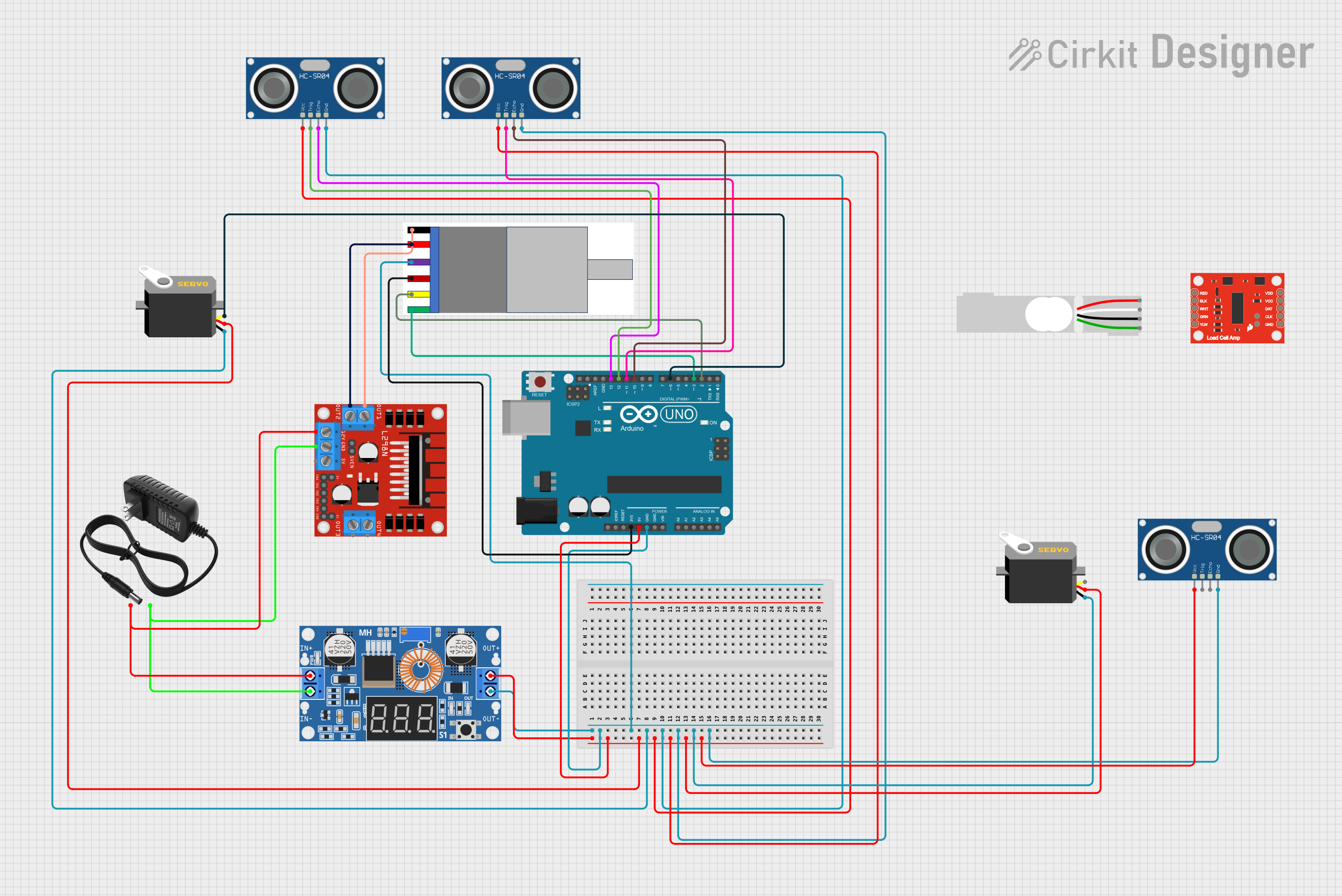

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit DesignerExplore Projects Built with Gear Motor with integrated Encoder

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit DesignerTechnical Specifications

General Specifications

- Rated Voltage: 12V DC

- Gear Ratio: 50:1

- No-Load Speed: 100 RPM

- Rated Torque: 2.5 kg·cm

- Encoder Type: Quadrature Encoder

- Encoder Resolution: 300 pulses per revolution (PPR)

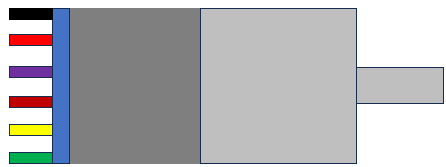

Pin Configuration and Descriptions

| Pin Number | Description | Notes |

|---|---|---|

| 1 | Motor Power (+) | Connect to positive voltage |

| 2 | Motor Power (-) | Connect to ground |

| 3 | Encoder Vcc | Typically 3.3V or 5V |

| 4 | Encoder GND | Ground for the encoder circuit |

| 5 | Encoder Channel A | Outputs pulses for direction A |

| 6 | Encoder Channel B | Outputs pulses for direction B |

Usage Instructions

Connecting the Motor

- Connect the motor power pins to your power supply, ensuring that the voltage matches the rated voltage of the motor.

- Use a motor driver compatible with the motor's current requirements to control the motor's direction and speed.

Interfacing with the Encoder

- Connect the encoder Vcc and GND pins to a power source that matches the encoder's voltage requirements.

- Connect the encoder output channels (A and B) to the digital input pins on your microcontroller or interface board.

Best Practices

- Always ensure that the power supply does not exceed the rated voltage of the motor.

- Use a motor driver with overcurrent protection to prevent damage to the motor.

- When connecting the encoder to a microcontroller, use pull-up resistors if required by the microcontroller's input circuitry.

- Implement proper debouncing in software to ensure accurate reading of encoder signals.

Example Code for Arduino UNO

// Define motor control and encoder pins

const int motorPin1 = 3; // Motor control pin 1

const int motorPin2 = 4; // Motor control pin 2

const int encoderPinA = 2; // Encoder channel A

const int encoderPinB = 3; // Encoder channel B

// Variables to hold encoder count

volatile long encoderCount = 0;

// Interrupt service routine for encoder channel A

void encoderA_ISR() {

// Determine direction based on channel B state

if (digitalRead(encoderPinB) == HIGH) {

encoderCount++;

} else {

encoderCount--;

}

}

void setup() {

// Set motor control pins as outputs

pinMode(motorPin1, OUTPUT);

pinMode(motorPin2, OUTPUT);

// Set encoder pins as inputs

pinMode(encoderPinA, INPUT);

pinMode(encoderPinB, INPUT);

// Attach interrupt for encoder channel A

attachInterrupt(digitalPinToInterrupt(encoderPinA), encoderA_ISR, RISING);

}

void loop() {

// Example: Drive motor forward

digitalWrite(motorPin1, HIGH);

digitalWrite(motorPin2, LOW);

// Implement motor control logic and use encoderCount as needed

// ...

}

Troubleshooting and FAQs

Common Issues

- Motor does not turn: Check power supply connections and ensure the voltage is correct. Verify that the motor driver is functioning properly.

- Encoder not providing output: Ensure that the encoder Vcc and GND are correctly connected and that the power supply voltage matches the encoder's requirements.

- Inaccurate encoder readings: Confirm that the encoder pins are connected to the correct microcontroller pins. Check for proper debouncing in the software.

FAQs

Q: Can I use a different voltage supply for the motor? A: It is essential to use a power supply that matches the rated voltage of the motor to prevent damage.

Q: How can I reverse the motor direction? A: To reverse the motor direction, reverse the polarity of the motor power connections, either manually or using a motor driver.

Q: What is the purpose of the encoder? A: The encoder provides feedback on the motor shaft's position, speed, or direction, which is essential for precise control in closed-loop systems.

Q: How do I interpret the encoder signals? A: The encoder outputs two square wave signals (A and B) that are 90 degrees out of phase. By counting these pulses and observing the phase relationship, you can determine the position and direction of the motor shaft.

Remember to always follow safety guidelines when working with electronic components and consult the manufacturer's datasheet for specific details about the gear motor with integrated encoder by Naroote.