How to Use Nema 6 Stepper Motor: Examples, Pinouts, and Specs

Design with Nema 6 Stepper Motor in Cirkit Designer

Design with Nema 6 Stepper Motor in Cirkit DesignerIntroduction

The Nema 6 stepper motor is a high-precision motor designed for applications requiring accurate control of angular position, speed, and torque. With a frame size of 6 inches, it is suitable for heavy-duty tasks and is commonly used in industrial automation, robotics, CNC machinery, and 3D printing. Its ability to divide a full rotation into a large number of steps makes it ideal for applications where precision is critical.

Explore Projects Built with Nema 6 Stepper Motor

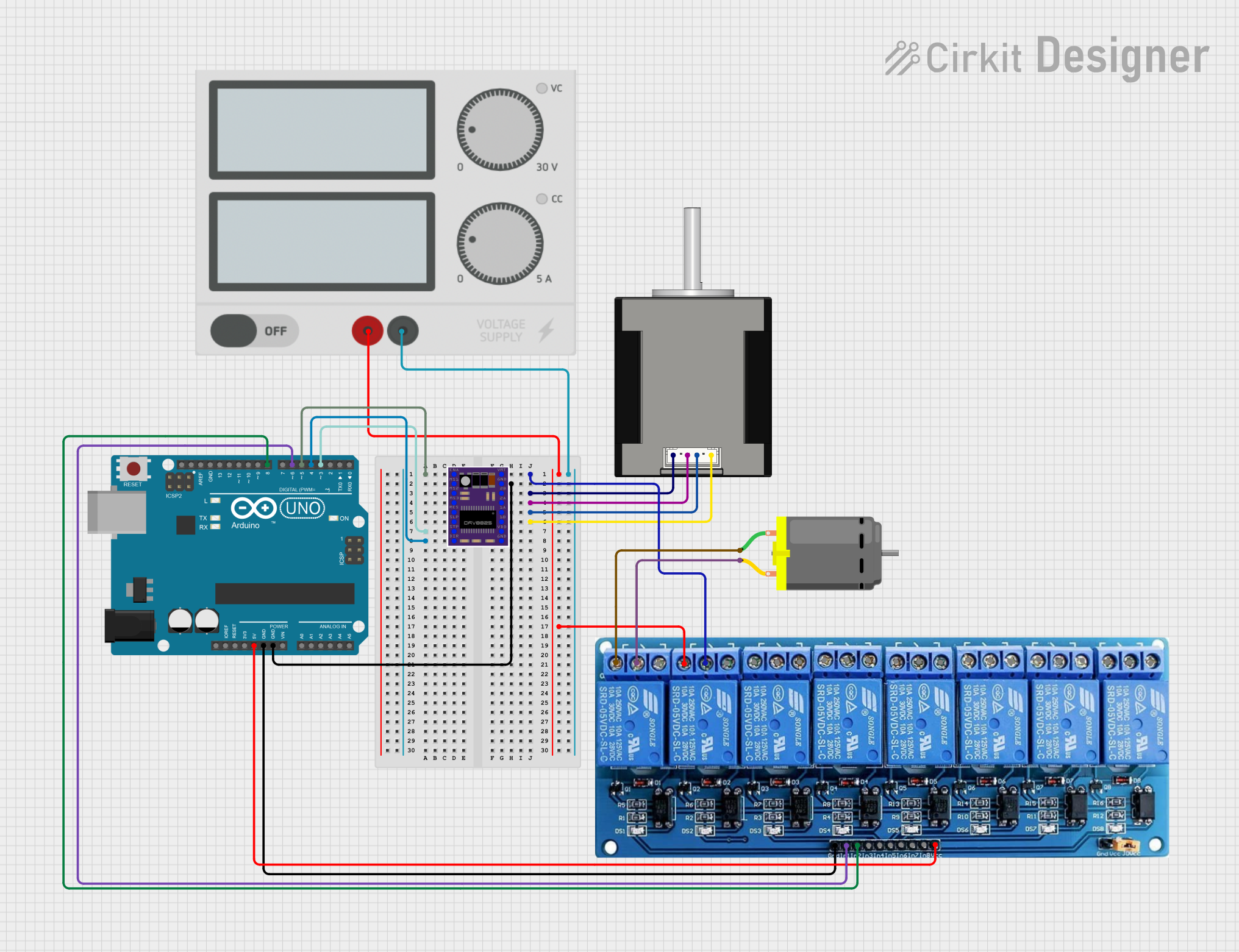

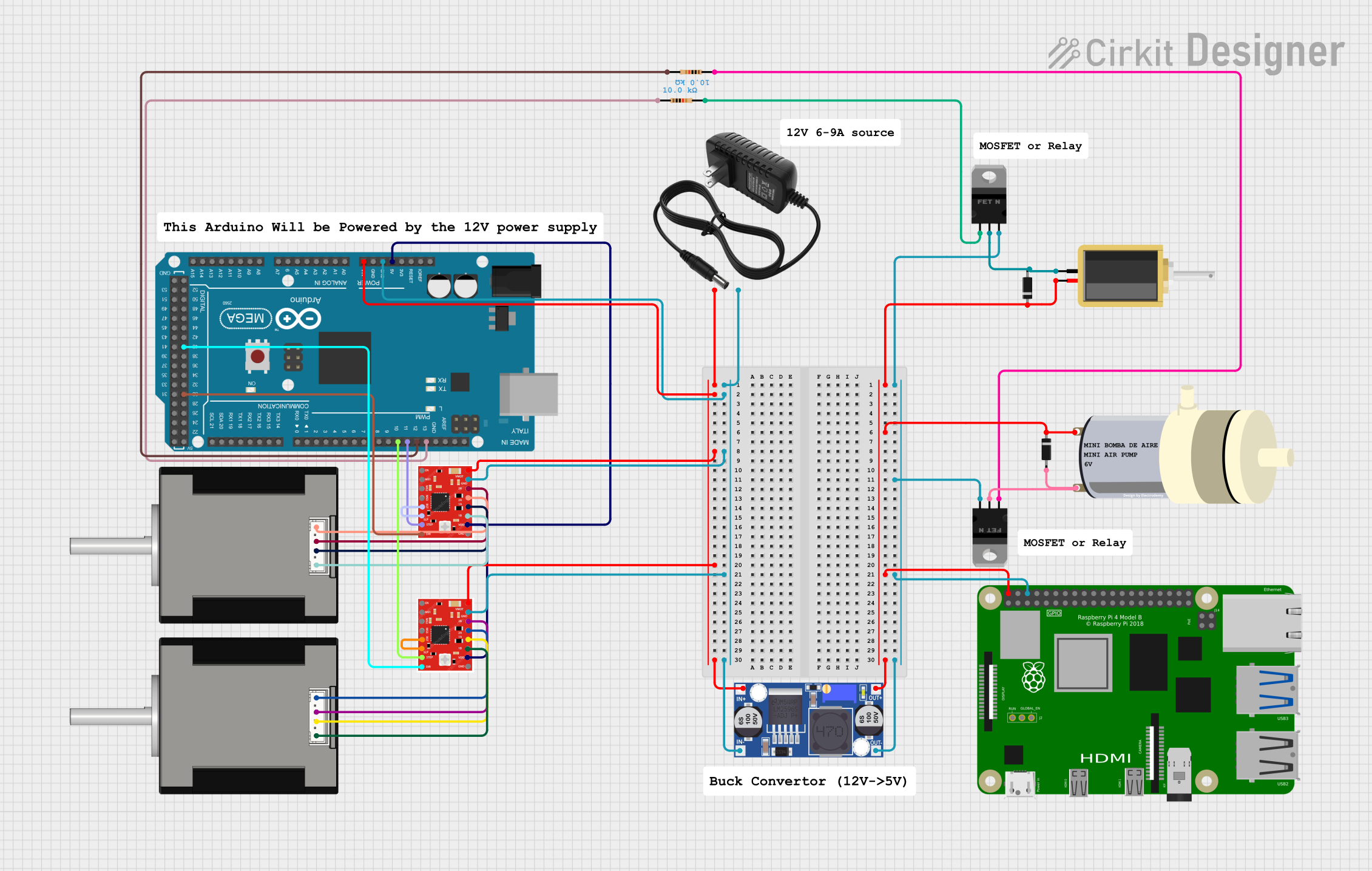

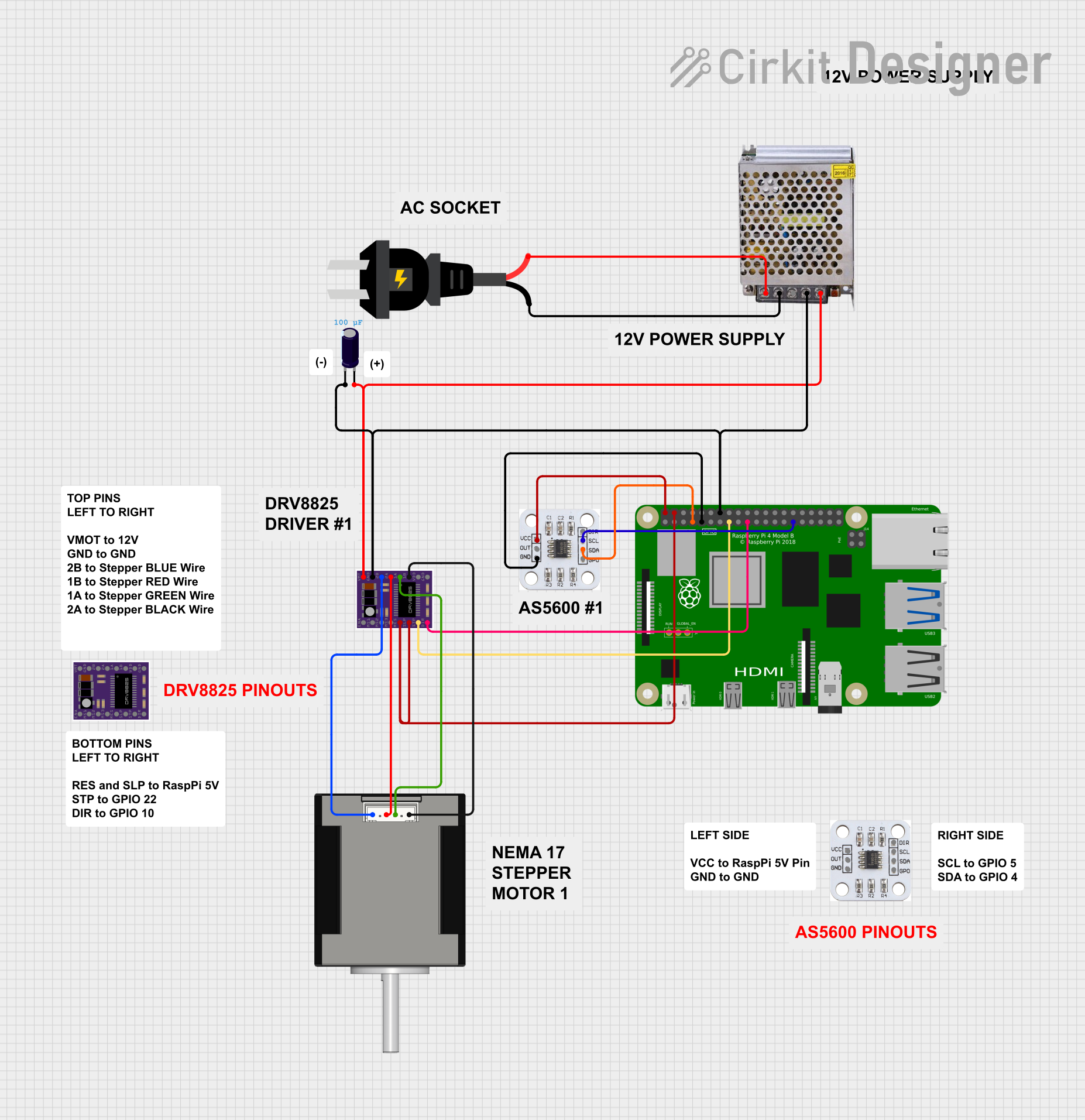

Open Project in Cirkit Designer

Open Project in Cirkit Designer

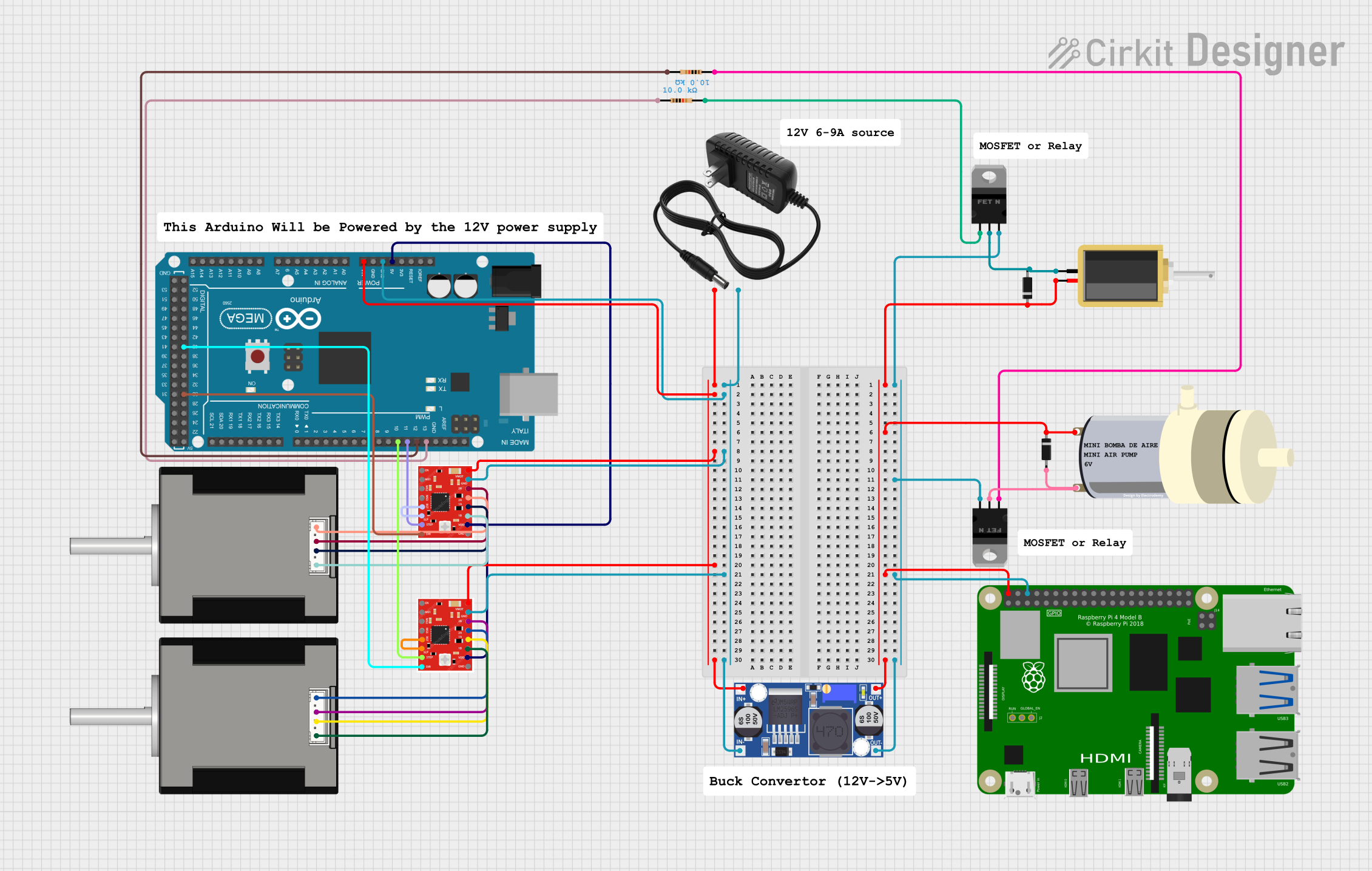

Open Project in Cirkit Designer

Open Project in Cirkit Designer

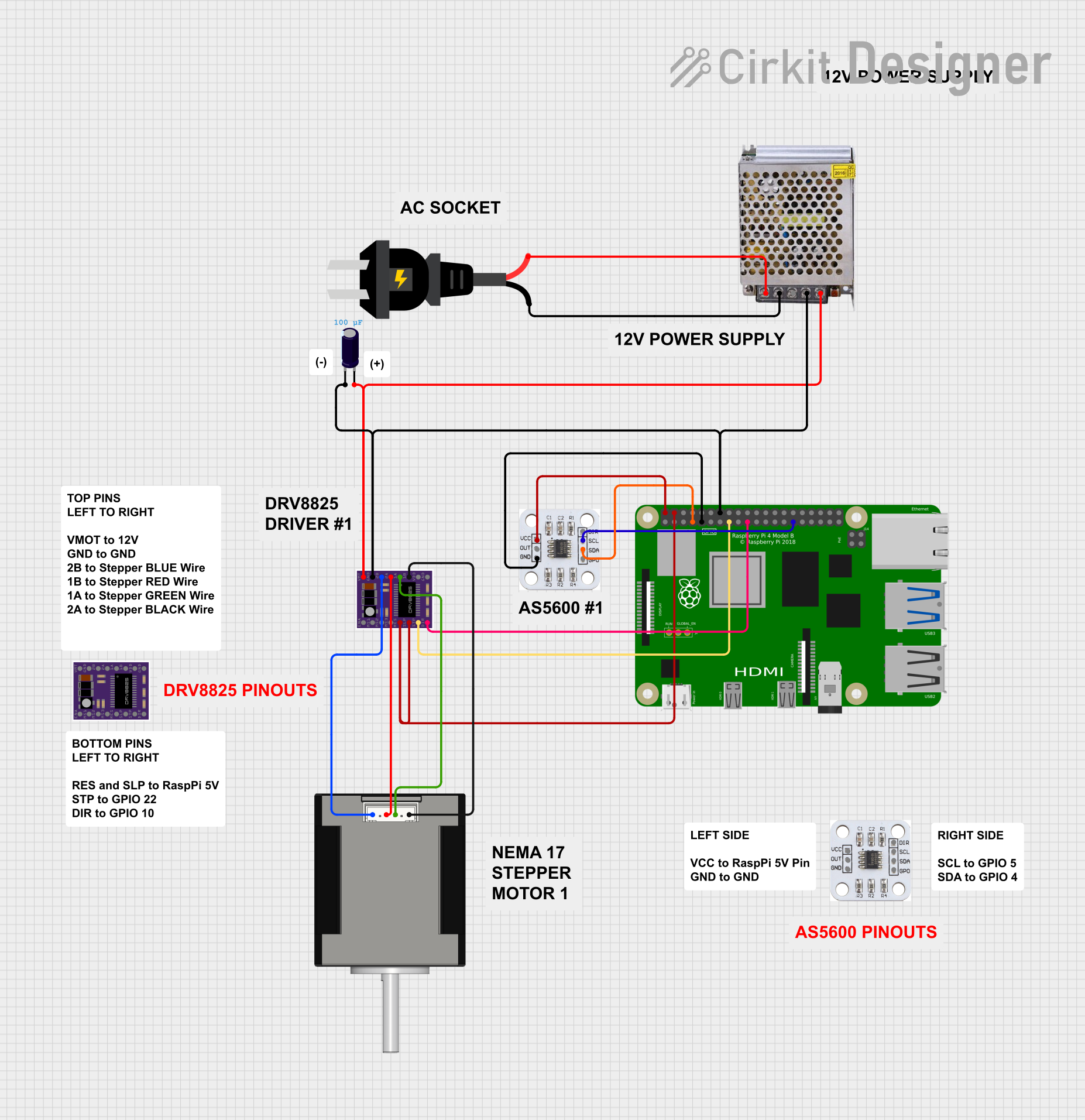

Open Project in Cirkit Designer

Open Project in Cirkit Designer

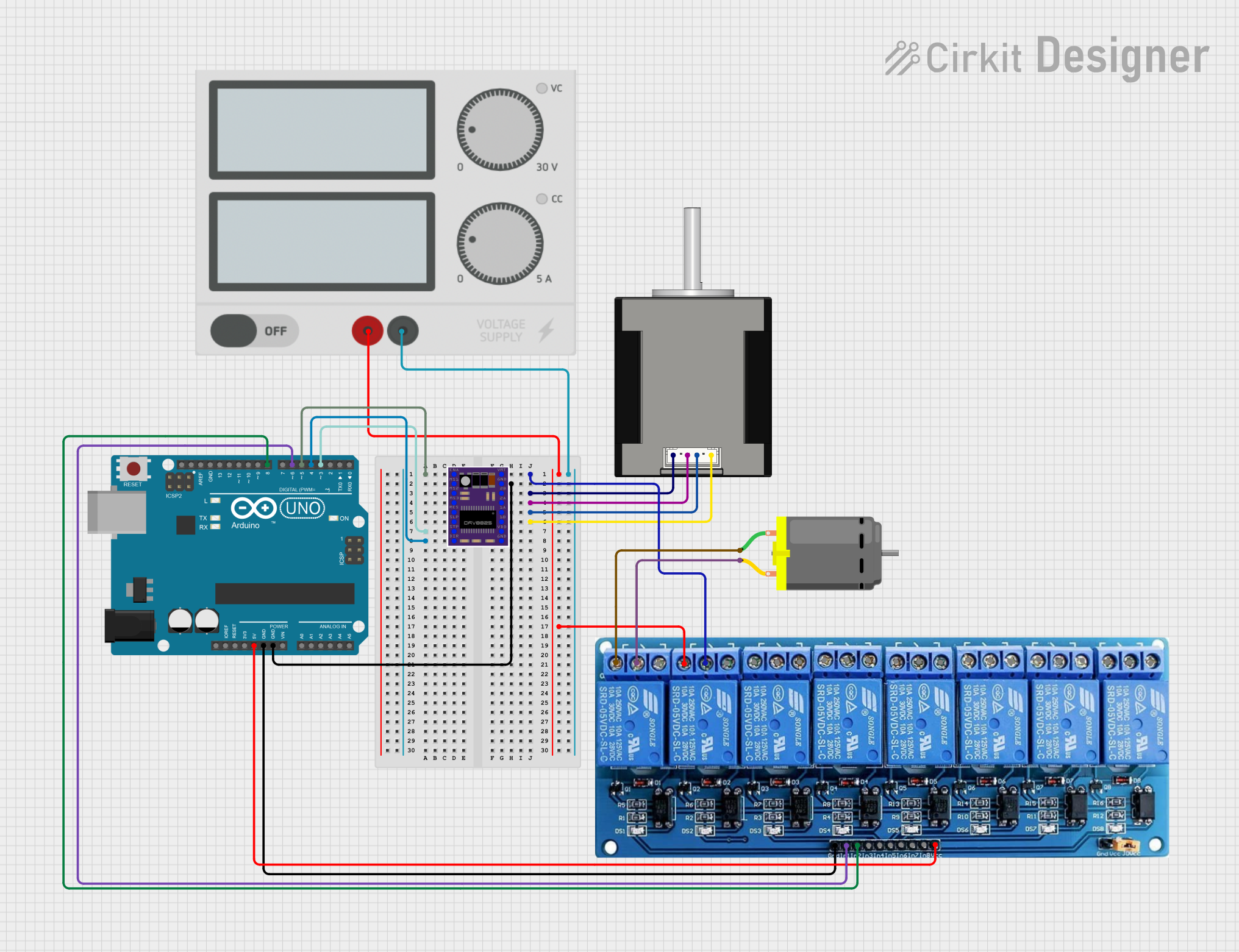

Open Project in Cirkit Designer

Open Project in Cirkit DesignerExplore Projects Built with Nema 6 Stepper Motor

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit DesignerCommon Applications

- CNC machines for precise cutting and engraving

- Robotics for controlled movement and positioning

- 3D printers for accurate layer deposition

- Conveyor systems in industrial automation

- Medical devices requiring precise motion control

Technical Specifications

Below are the key technical details of the Nema 6 stepper motor:

| Parameter | Value |

|---|---|

| Frame Size | 6 inches (152.4 mm) |

| Step Angle | 1.8° (200 steps per revolution) |

| Holding Torque | Up to 12 Nm (varies by model) |

| Rated Voltage | 12V to 48V (model-dependent) |

| Rated Current | 2A to 6A per phase |

| Number of Phases | 2 |

| Shaft Diameter | 12 mm |

| Insulation Resistance | ≥ 100 MΩ |

| Operating Temperature | -20°C to +50°C |

| Weight | Approximately 4.5 kg |

Pin Configuration and Descriptions

The Nema 6 stepper motor typically has four or six wires, depending on whether it is a bipolar or unipolar motor. Below is the pin configuration for a standard 4-wire bipolar stepper motor:

| Wire Color | Function | Description |

|---|---|---|

| Red | Coil A+ | Positive terminal of Coil A |

| Blue | Coil A- | Negative terminal of Coil A |

| Green | Coil B+ | Positive terminal of Coil B |

| Black | Coil B- | Negative terminal of Coil B |

For a 6-wire unipolar motor, two additional wires (commonly yellow and white) are used as center taps for each coil.

Usage Instructions

How to Use the Nema 6 Stepper Motor in a Circuit

- Power Supply: Ensure the power supply matches the motor's rated voltage and current. Use a stepper motor driver to regulate power and control the motor.

- Driver Connection: Connect the motor to a compatible stepper motor driver. For a 4-wire motor, connect the wires to the driver as per the pin configuration.

- Microcontroller Interface: Use a microcontroller (e.g., Arduino UNO) to send control signals to the driver. The driver will interpret these signals to control the motor's steps and direction.

- Programming: Write a program to control the motor's speed, direction, and number of steps. Use libraries like the Arduino

AccelStepperlibrary for easier implementation.

Important Considerations

- Current Limiting: Set the current limit on the driver to prevent overheating and damage to the motor.

- Cooling: Use a heat sink or cooling fan if the motor operates at high currents for extended periods.

- Step Resolution: Adjust the microstepping settings on the driver for smoother motion and higher resolution.

- Wiring: Double-check the wiring to avoid short circuits or incorrect connections.

Example Code for Arduino UNO

Below is an example code to control a Nema 6 stepper motor using an Arduino UNO and a stepper motor driver:

#include <AccelStepper.h>

// Define motor interface type. Use 1 for a driver with STEP and DIR pins.

#define MOTOR_INTERFACE_TYPE 1

// Define pin connections

const int stepPin = 2; // Pin connected to the STEP input on the driver

const int dirPin = 3; // Pin connected to the DIR input on the driver

// Create an instance of the AccelStepper class

AccelStepper stepper(MOTOR_INTERFACE_TYPE, stepPin, dirPin);

void setup() {

// Set the maximum speed and acceleration

stepper.setMaxSpeed(1000); // Maximum speed in steps per second

stepper.setAcceleration(500); // Acceleration in steps per second^2

// Set initial direction

stepper.setSpeed(500); // Speed in steps per second

}

void loop() {

// Move the motor forward 200 steps (1 full revolution for 1.8° step angle)

stepper.moveTo(200);

while (stepper.distanceToGo() != 0) {

stepper.run(); // Run the motor to the target position

}

delay(1000); // Wait for 1 second

// Move the motor backward 200 steps

stepper.moveTo(-200);

while (stepper.distanceToGo() != 0) {

stepper.run(); // Run the motor to the target position

}

delay(1000); // Wait for 1 second

}

Notes:

- Replace

stepPinanddirPinwith the actual pins connected to your driver. - Adjust

setMaxSpeedandsetAccelerationvalues based on your application.

Troubleshooting and FAQs

Common Issues and Solutions

Motor Not Moving:

- Cause: Incorrect wiring or loose connections.

- Solution: Verify the wiring and ensure all connections are secure.

Motor Vibrates but Does Not Rotate:

- Cause: Incorrect step sequence or insufficient current.

- Solution: Check the driver settings and ensure the current limit is properly configured.

Overheating:

- Cause: Excessive current or poor ventilation.

- Solution: Reduce the current limit on the driver and improve cooling.

Skipping Steps:

- Cause: Excessive load or incorrect microstepping settings.

- Solution: Reduce the load or adjust the microstepping settings for smoother operation.

FAQs

Can I run the Nema 6 stepper motor without a driver?

- No, a stepper motor driver is required to control the motor's steps and direction.

What is the advantage of microstepping?

- Microstepping provides smoother motion, reduces noise, and increases positional accuracy.

How do I determine the correct power supply for my motor?

- Check the motor's rated voltage and current, and select a power supply that meets or exceeds these requirements.

Can I use the Nema 6 stepper motor for high-speed applications?

- Stepper motors are not ideal for high-speed applications due to torque drop-off at higher speeds. Use a servo motor for such cases.

By following this documentation, you can effectively integrate the Nema 6 stepper motor into your projects and troubleshoot common issues.