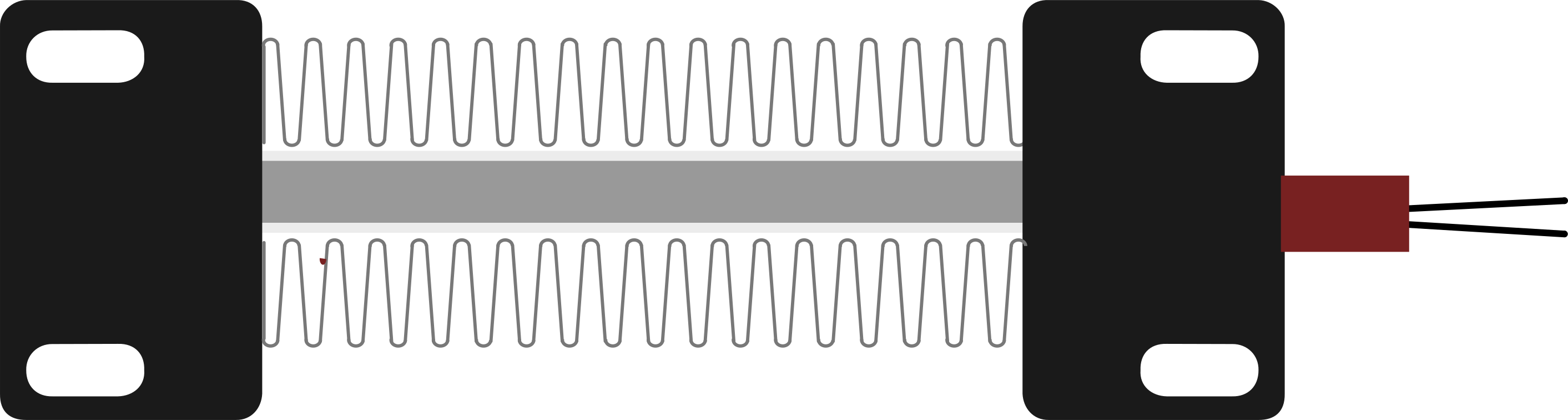

How to Use heater ptc: Examples, Pinouts, and Specs

Design with heater ptc in Cirkit Designer

Design with heater ptc in Cirkit DesignerIntroduction

A PTC (Positive Temperature Coefficient) heater is a type of heating element that increases its electrical resistance as its temperature rises. This unique property allows the heater to self-regulate its temperature, making it a safe and efficient choice for various heating applications. Unlike traditional heating elements, PTC heaters do not require complex external control systems to maintain a consistent temperature, as they naturally limit their current draw when the desired temperature is reached.

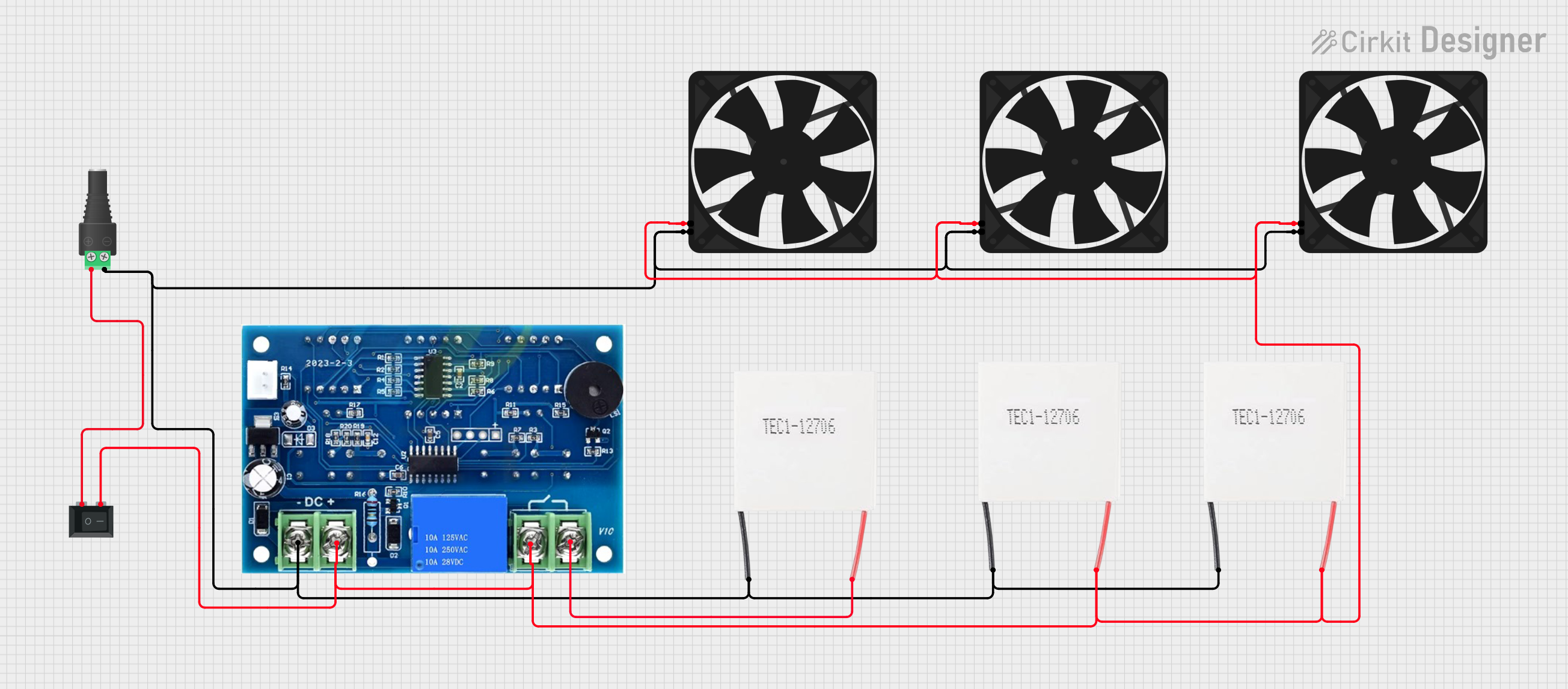

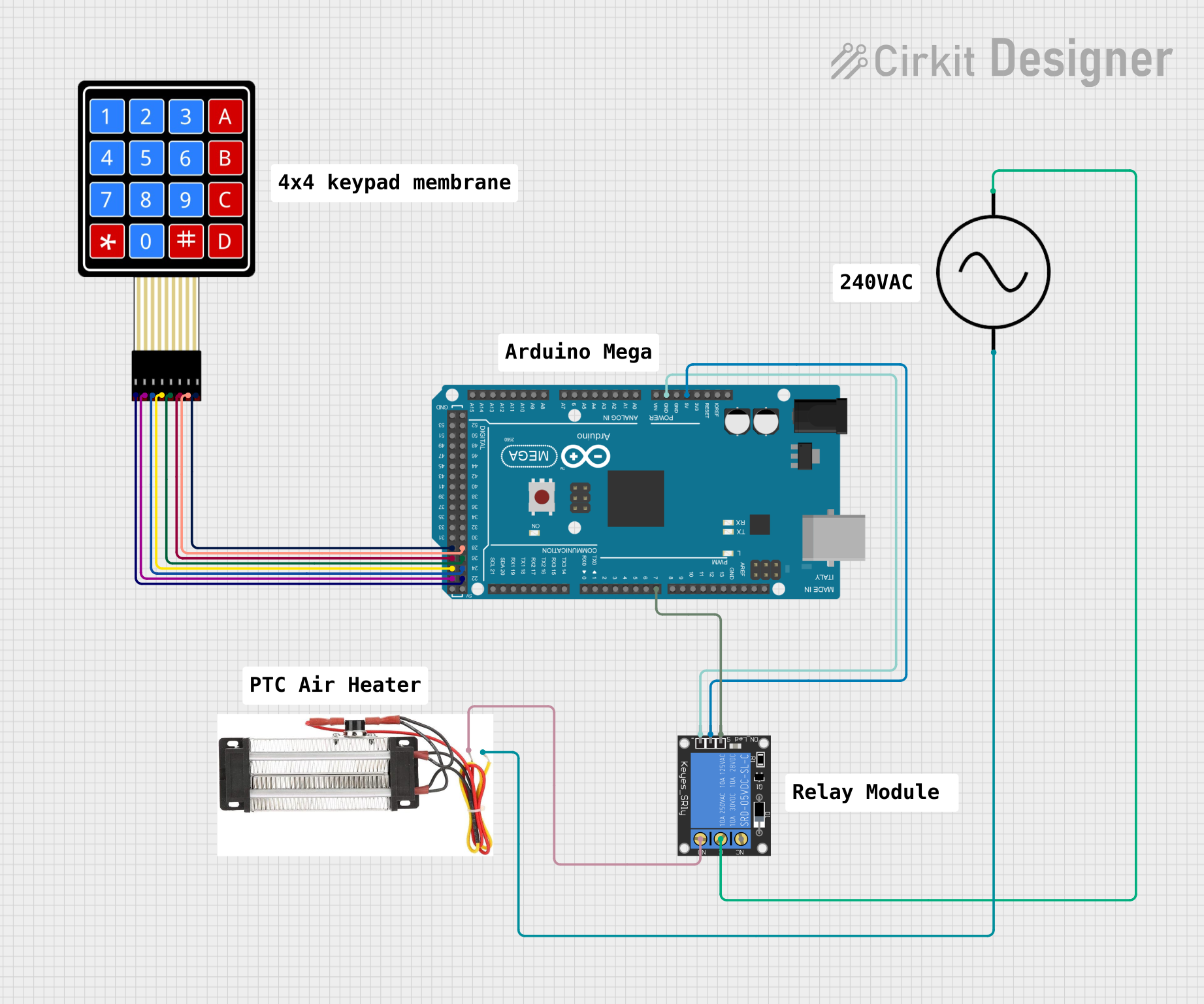

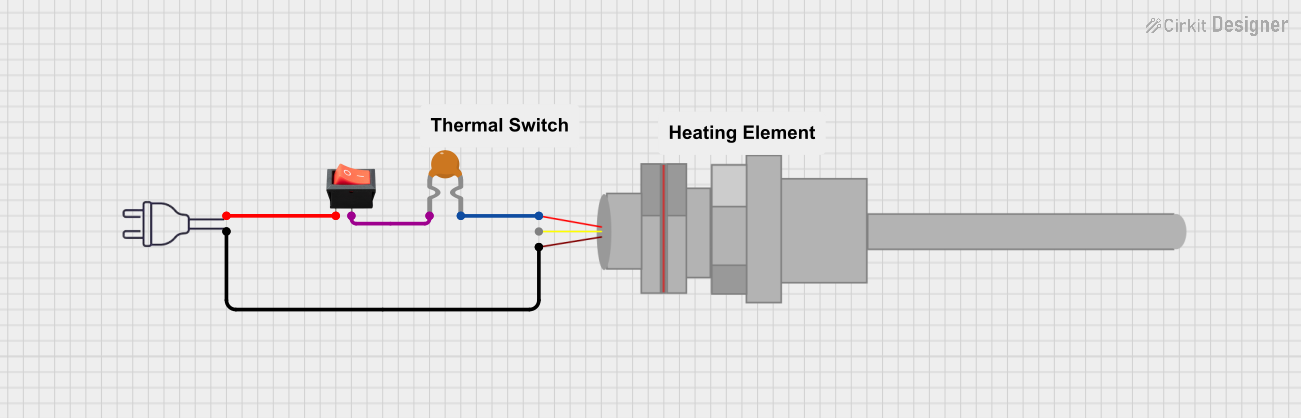

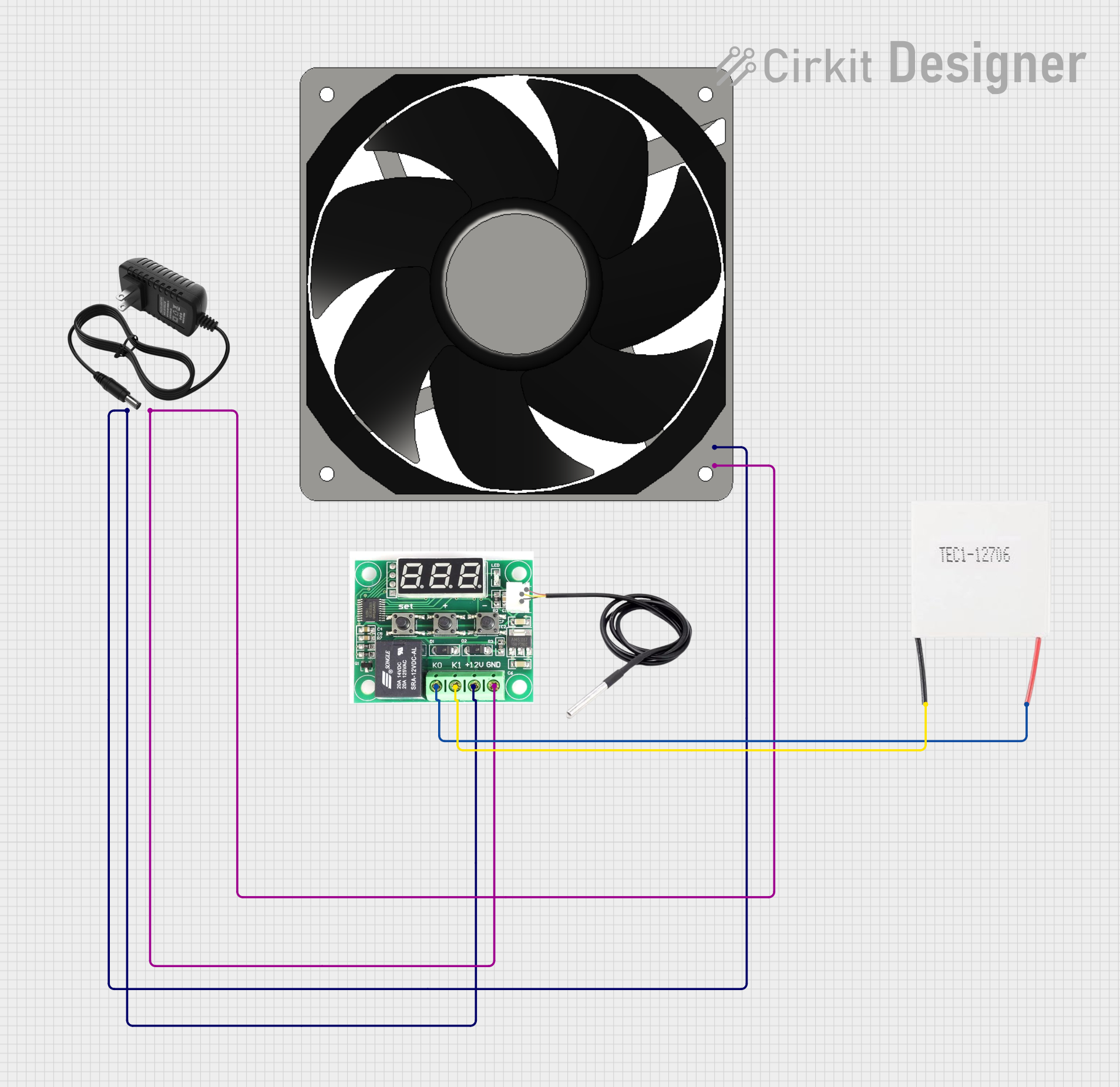

Explore Projects Built with heater ptc

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit DesignerExplore Projects Built with heater ptc

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

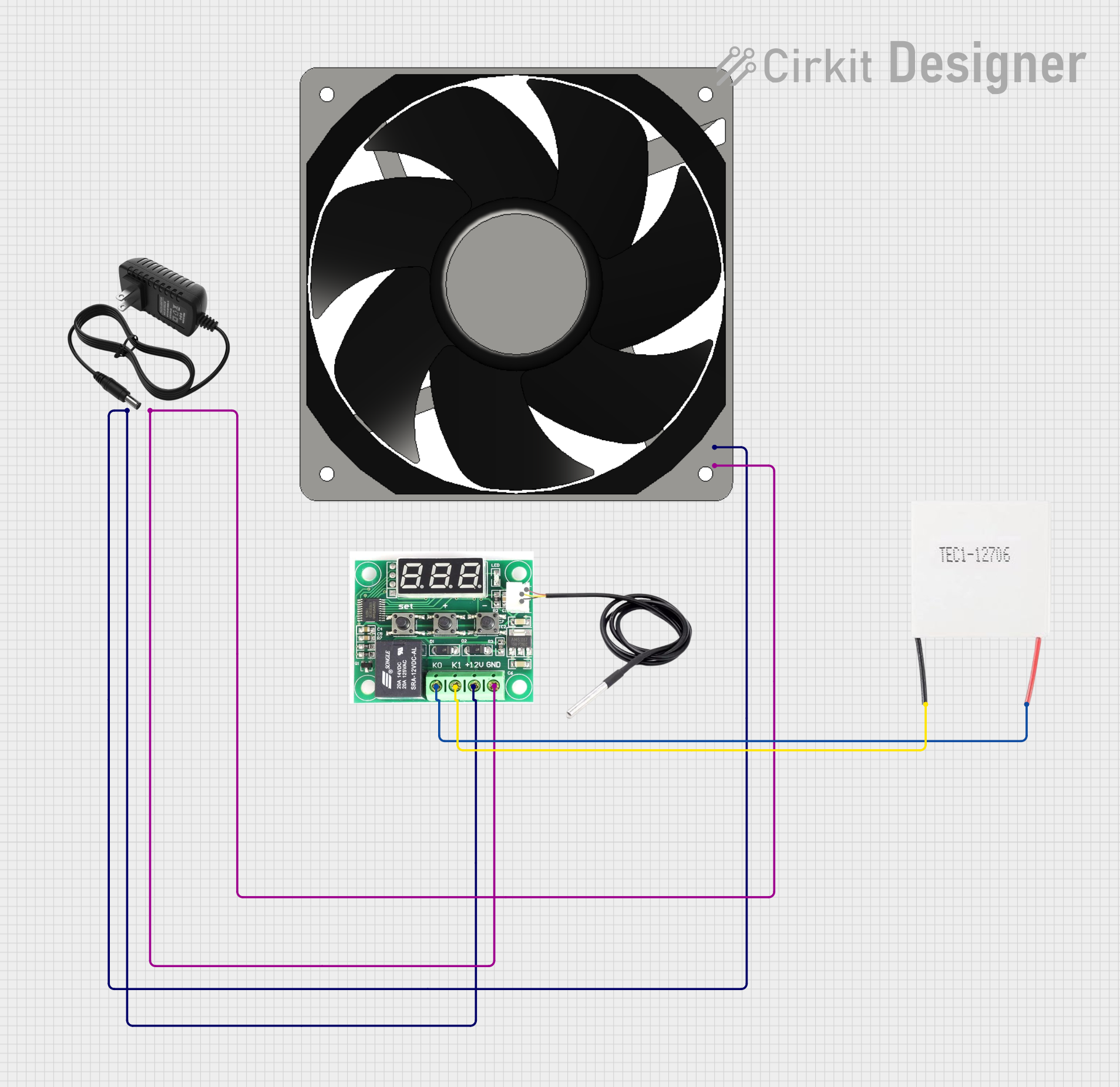

Open Project in Cirkit DesignerCommon Applications and Use Cases

- Space heaters and personal heating devices

- Automotive seat warmers and defoggers

- Industrial equipment requiring temperature regulation

- Medical devices for controlled heating

- Battery warmers in cold environments

- 3D printer bed heating systems

Technical Specifications

Below are the key technical details for a typical PTC heater. Note that specific values may vary depending on the model and manufacturer.

| Parameter | Value |

|---|---|

| Operating Voltage | 12V, 24V, or 110-240V AC/DC |

| Power Rating | 10W to 500W (varies by model) |

| Temperature Range | 60°C to 280°C (self-regulating) |

| Resistance at Room Temp | Typically 10Ω to 1kΩ |

| Heating Time | 10-30 seconds to reach steady state |

| Material | Ceramic (PTC thermistor) |

| Safety Features | Overheat protection (self-regulating) |

Pin Configuration and Descriptions

PTC heaters typically have two terminals for electrical connections. Below is a description of the pin configuration:

| Pin | Description |

|---|---|

| Pin 1 | Positive terminal (connect to power supply +V) |

| Pin 2 | Negative terminal (connect to power supply ground) |

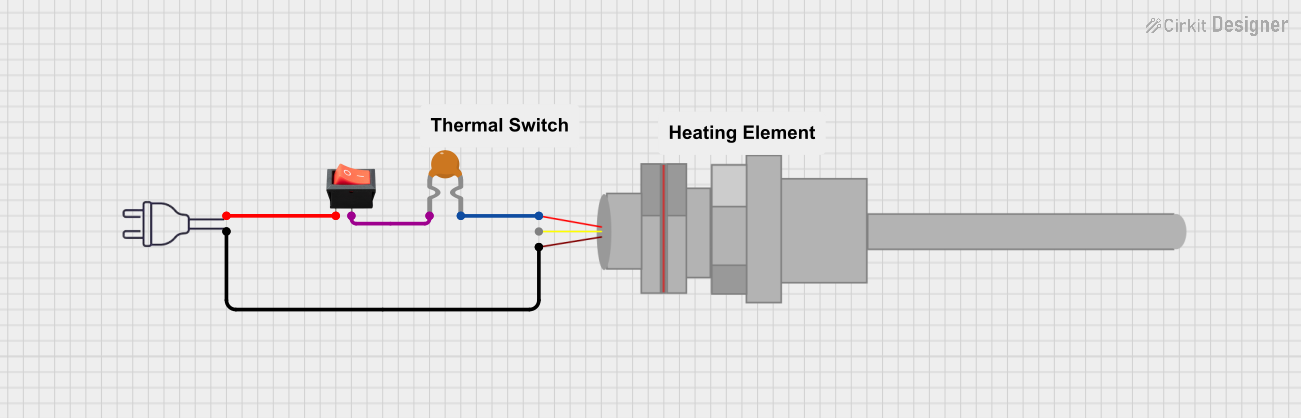

Usage Instructions

How to Use the Component in a Circuit

- Power Supply Selection: Choose a power supply that matches the operating voltage of the PTC heater (e.g., 12V or 24V). Ensure the power supply can provide sufficient current for the heater's power rating.

- Wiring: Connect the positive terminal of the PTC heater to the positive output of the power supply and the negative terminal to the ground.

- Mounting: Secure the PTC heater to the surface or enclosure where heat is required. Use thermal adhesive or mounting brackets as needed.

- Testing: Power on the circuit and verify that the PTC heater begins to warm up. The heater will self-regulate its temperature once it reaches the designed operating range.

Important Considerations and Best Practices

- Avoid Overvoltage: Do not exceed the rated voltage of the PTC heater, as this may damage the component or reduce its lifespan.

- Ensure Proper Ventilation: Allow adequate airflow around the heater to prevent overheating of surrounding components.

- Thermal Insulation: Use thermal insulation to direct heat to the desired area and improve efficiency.

- Avoid Short Circuits: Ensure proper insulation of the terminals to prevent accidental short circuits.

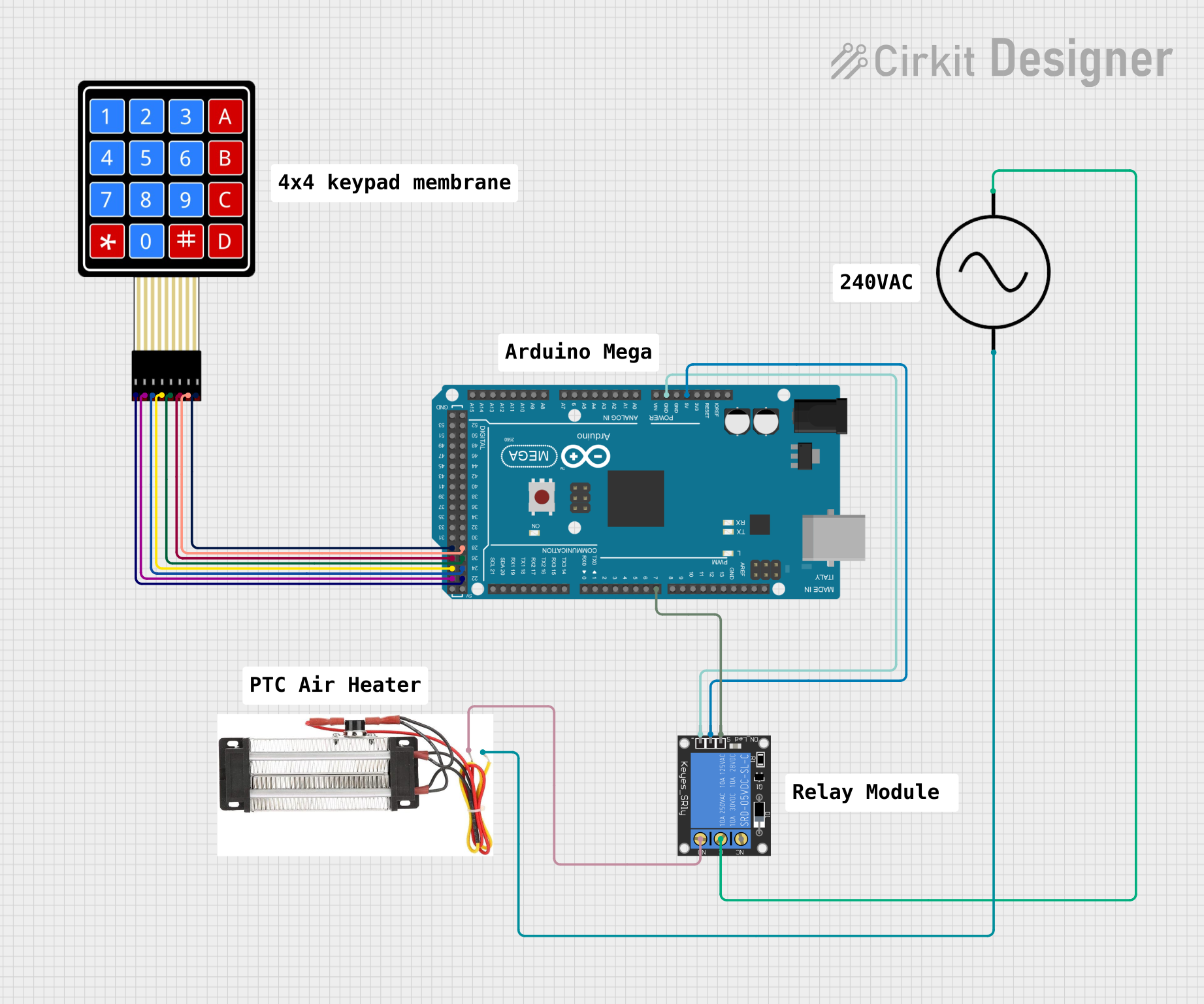

- Arduino Integration: If using the PTC heater with an Arduino, use a relay or MOSFET to control the heater, as the Arduino cannot directly supply the required current.

Example Arduino Code

Below is an example of how to control a 12V PTC heater using an Arduino UNO and a relay module:

// Define the relay control pin

const int relayPin = 7;

void setup() {

// Set the relay pin as an output

pinMode(relayPin, OUTPUT);

// Turn off the relay initially

digitalWrite(relayPin, LOW);

}

void loop() {

// Turn on the PTC heater by activating the relay

digitalWrite(relayPin, HIGH);

delay(10000); // Keep the heater on for 10 seconds

// Turn off the PTC heater

digitalWrite(relayPin, LOW);

delay(10000); // Keep the heater off for 10 seconds

}

Note: Use an external power supply to power the PTC heater. The relay module should be connected to the Arduino and the external power supply to control the heater safely.

Troubleshooting and FAQs

Common Issues and Solutions

PTC Heater Not Heating Up

- Cause: Insufficient power supply or incorrect wiring.

- Solution: Verify the power supply voltage and current rating. Check the wiring for loose connections.

PTC Heater Overheating

- Cause: Poor ventilation or incorrect voltage.

- Solution: Ensure proper airflow around the heater and verify that the supply voltage matches the heater's rating.

Heater Turns Off Too Quickly

- Cause: Ambient temperature too high or heater is reaching its self-regulation point.

- Solution: Check the operating environment and ensure the heater is suitable for the application.

Arduino Not Controlling the Heater

- Cause: Incorrect relay wiring or code issues.

- Solution: Verify the relay connections and ensure the Arduino code matches the pin configuration.

FAQs

Q: Can I use a PTC heater with a battery?

- A: Yes, as long as the battery voltage matches the heater's operating voltage and can supply sufficient current.

Q: Is a PTC heater safe to use without a thermostat?

- A: Yes, PTC heaters are self-regulating and do not require an external thermostat for basic operation.

Q: Can I use a PTC heater for liquid heating?

- A: Some PTC heaters are designed for liquid heating, but ensure the heater is rated for such applications and properly insulated.

Q: How long does a PTC heater last?

- A: PTC heaters are highly durable and can last for thousands of hours if used within their specified ratings.

This concludes the documentation for the PTC heater. For further assistance, consult the manufacturer's datasheet or technical support.