How to Use DVR8825 Stepper Driver: Examples, Pinouts, and Specs

Design with DVR8825 Stepper Driver in Cirkit Designer

Design with DVR8825 Stepper Driver in Cirkit DesignerIntroduction

The DVR8825 is a high-performance microstepping driver designed for controlling stepper motors. It features adjustable current control, enabling smooth motor operation and reduced noise. With support for up to 2.5A per phase and multiple microstepping modes (full, half, quarter, eighth, and sixteenth), the DVR8825 is ideal for applications requiring precise motor control. Common use cases include robotics, 3D printers, CNC machines, and other automation systems.

Explore Projects Built with DVR8825 Stepper Driver

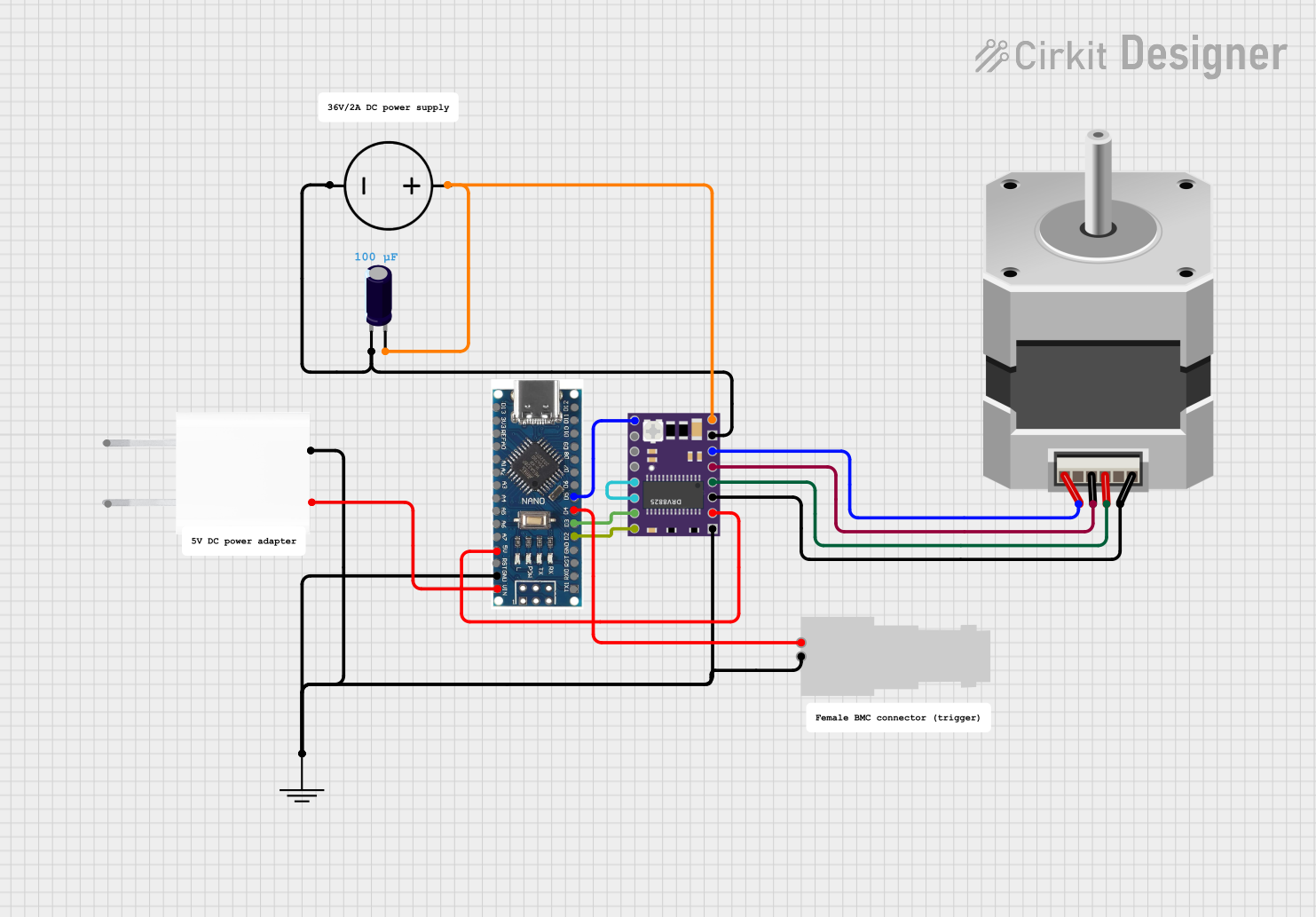

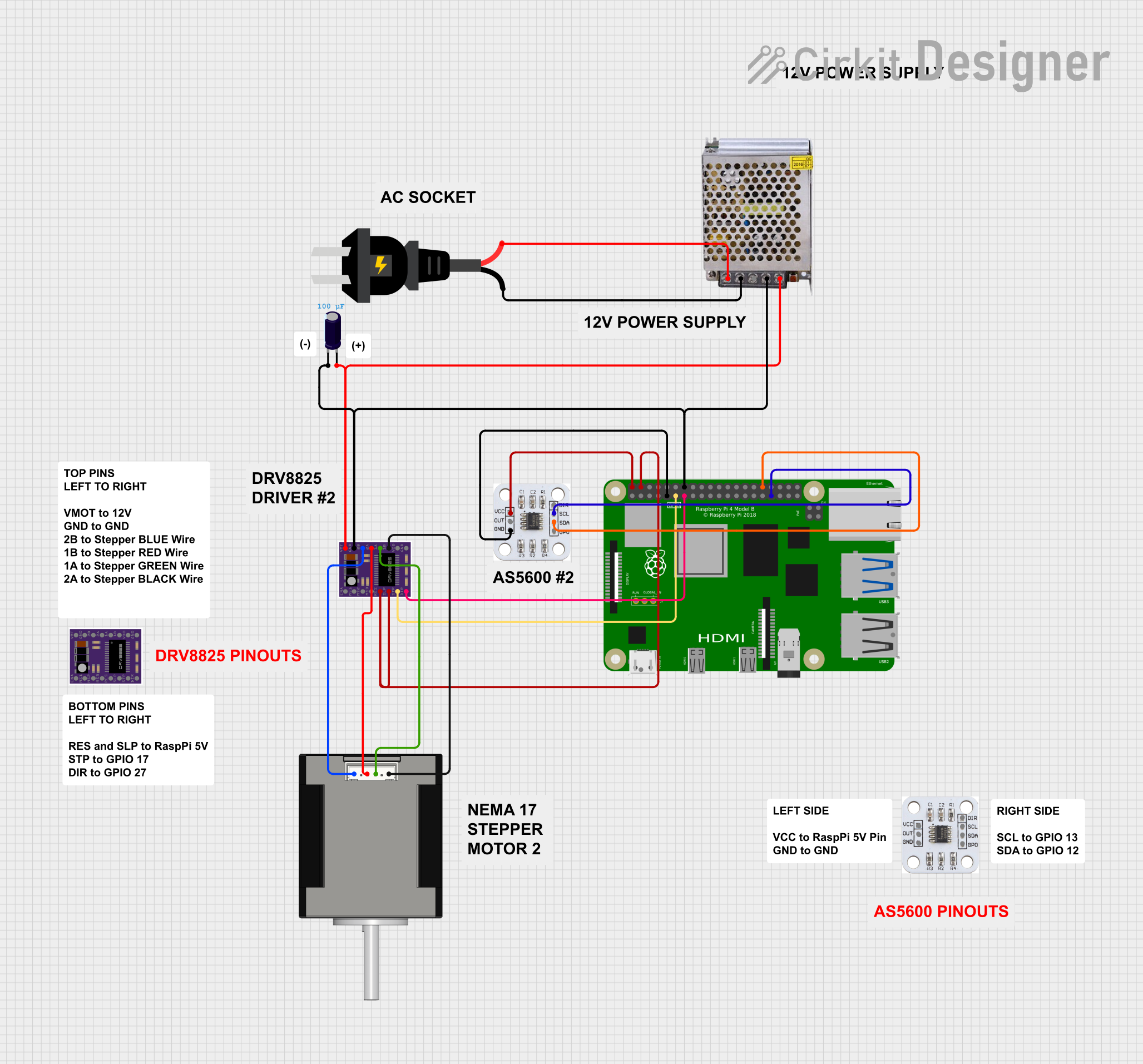

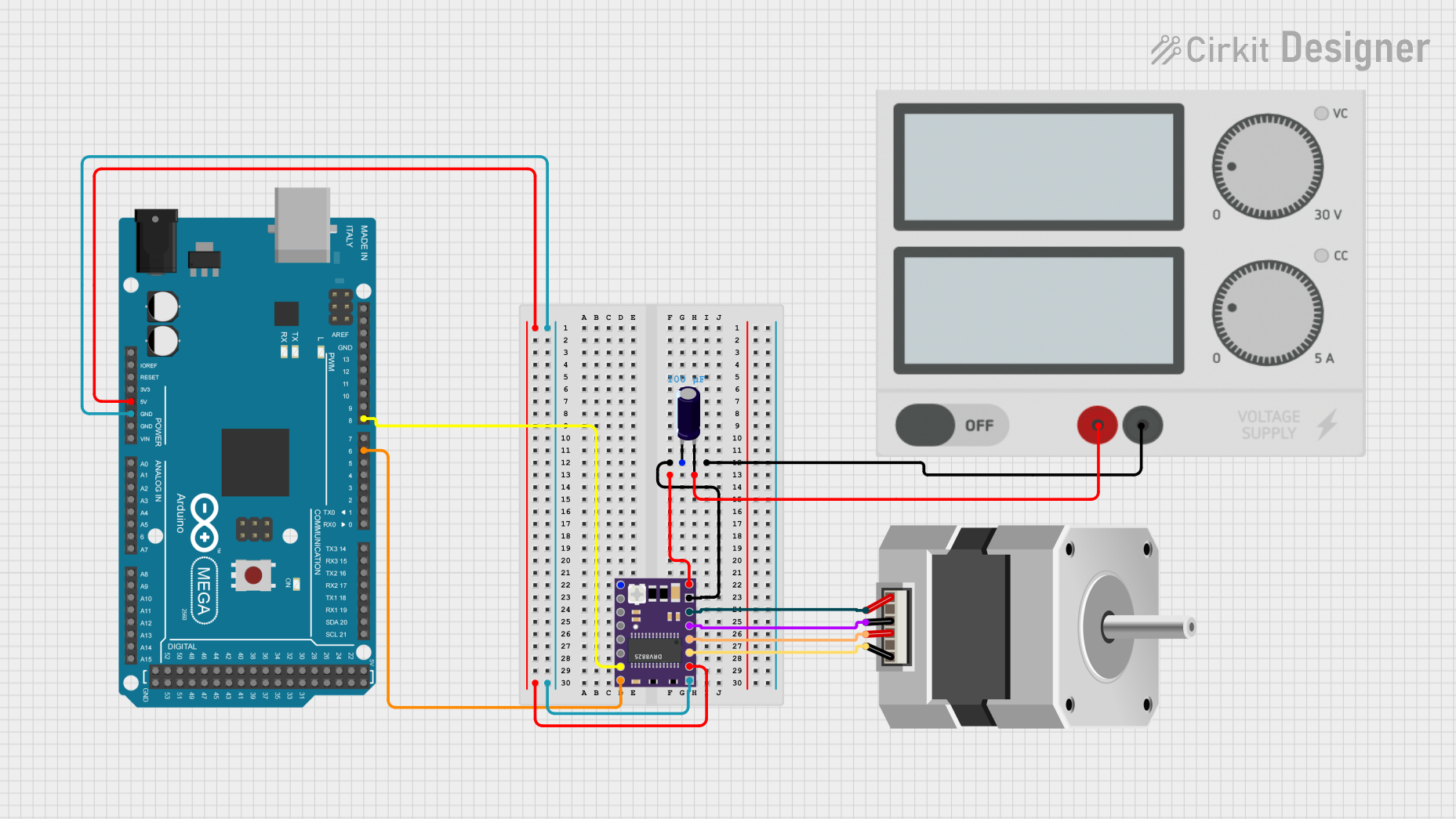

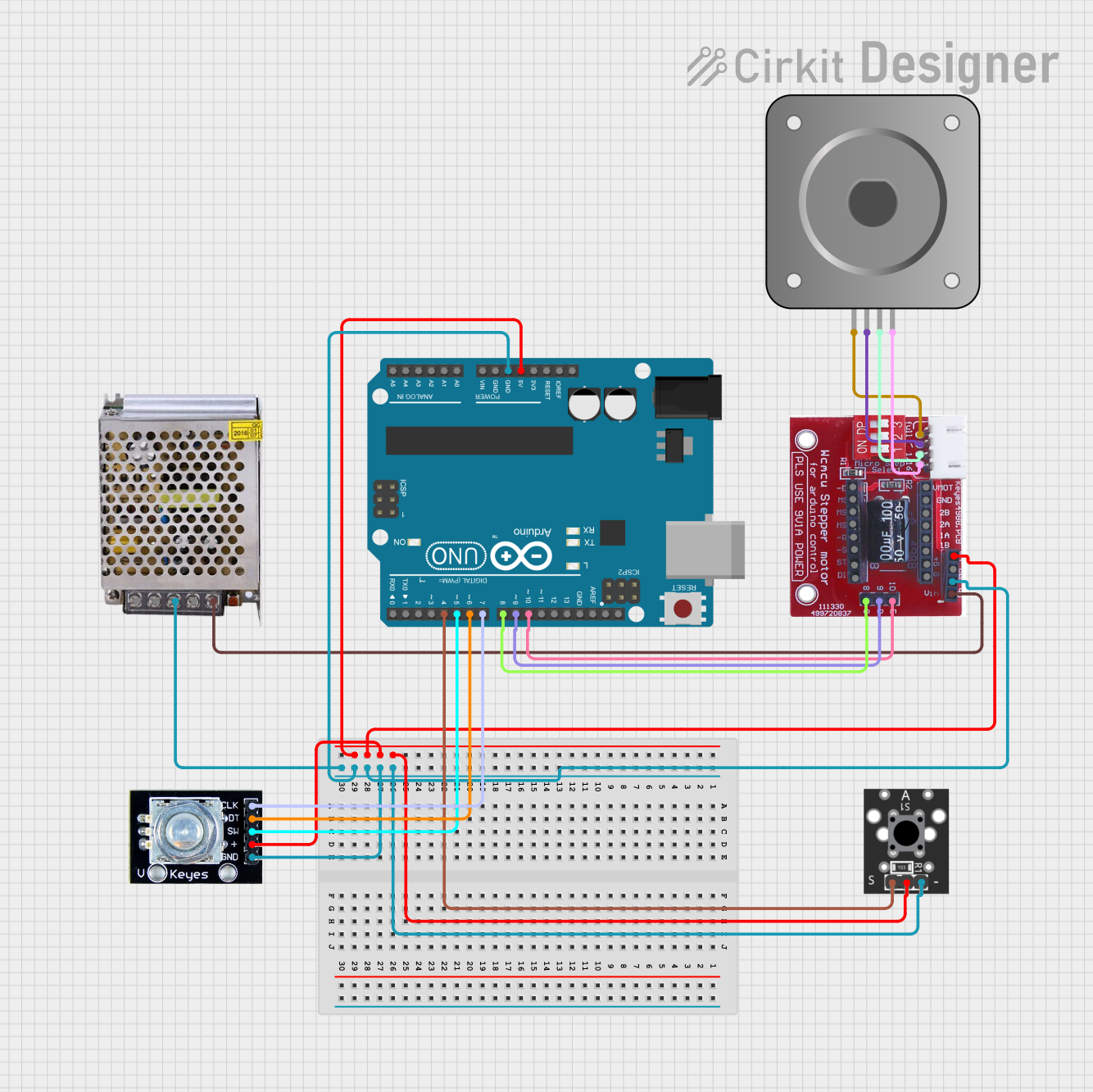

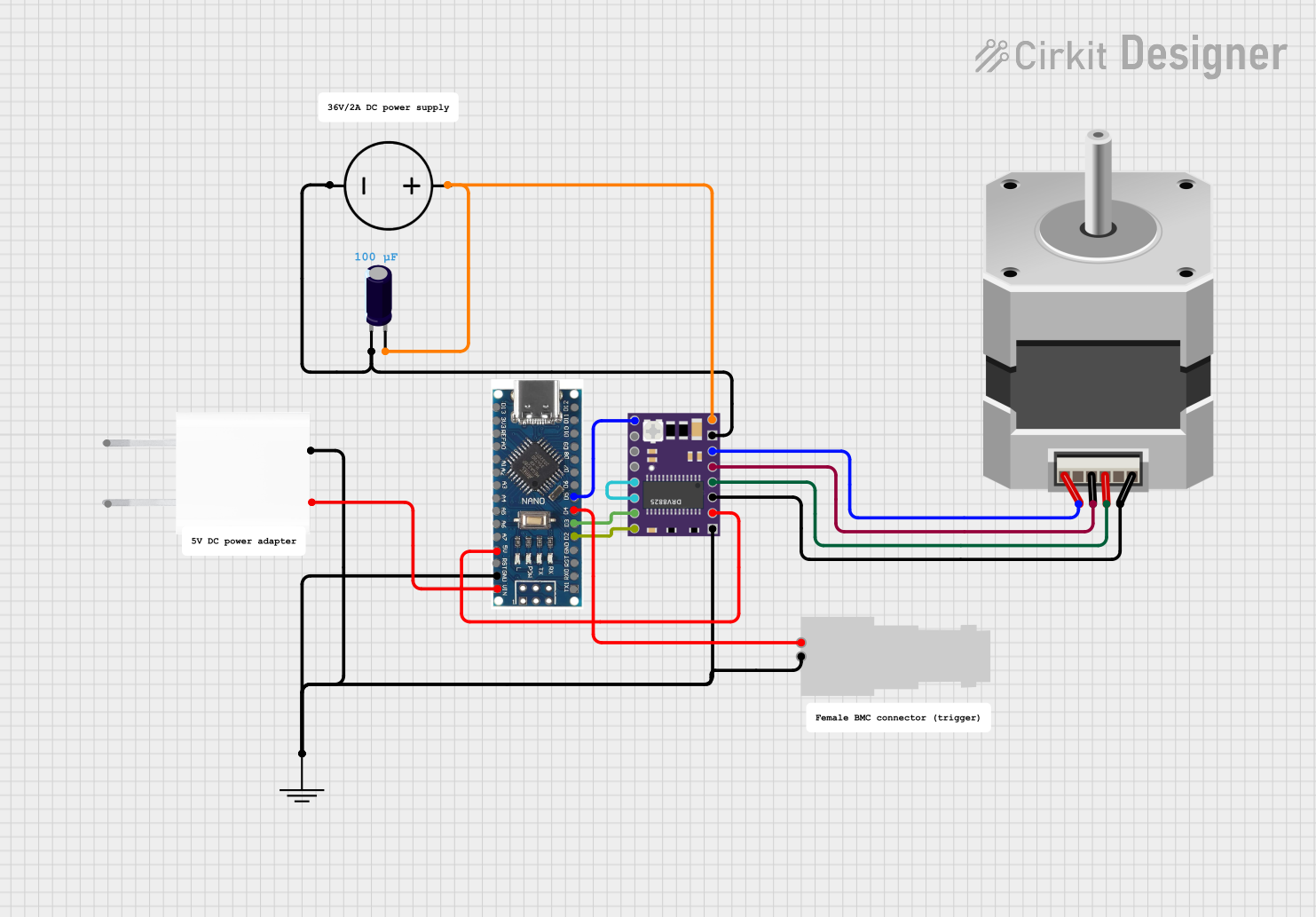

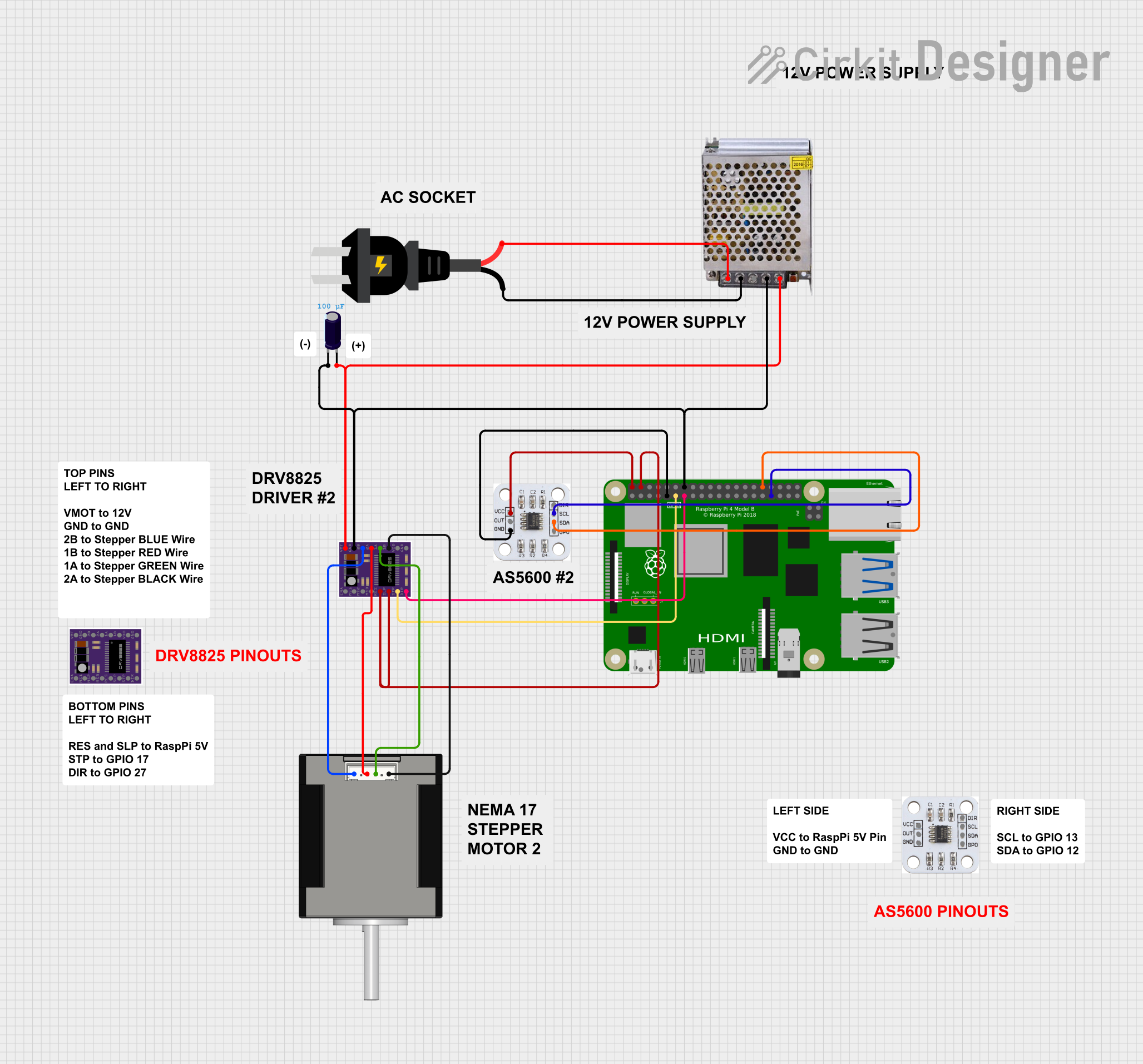

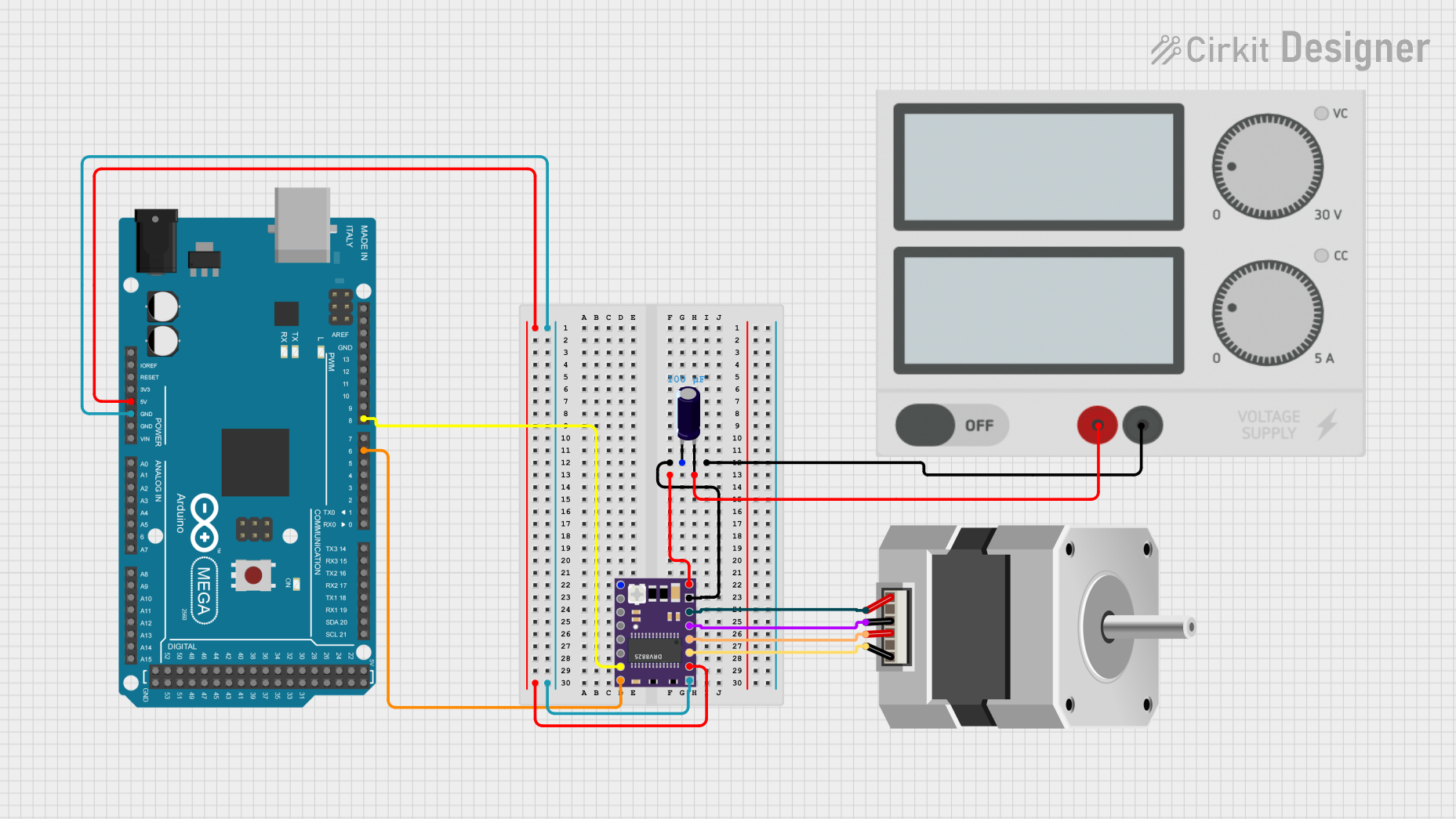

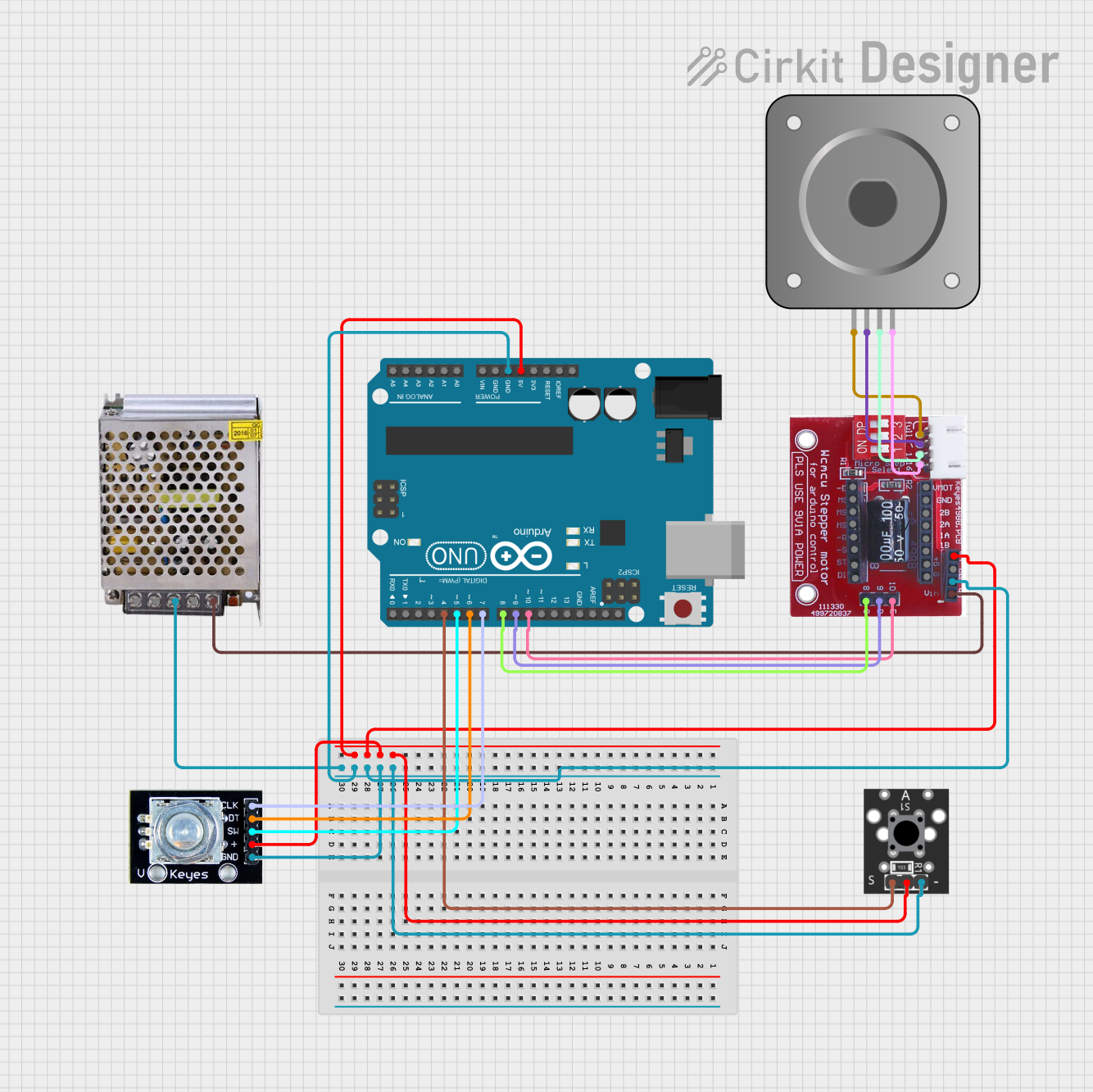

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit DesignerExplore Projects Built with DVR8825 Stepper Driver

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit DesignerTechnical Specifications

Key Technical Details

- Input Voltage Range: 8.2V to 45V

- Maximum Current per Phase: 2.5A (with sufficient cooling)

- Microstepping Modes: Full, 1/2, 1/4, 1/8, 1/16

- Logic Voltage: 3.3V or 5V compatible

- Thermal Shutdown Protection: Yes

- Overcurrent Protection: Yes

- Dimensions: 15mm x 20mm (approx.)

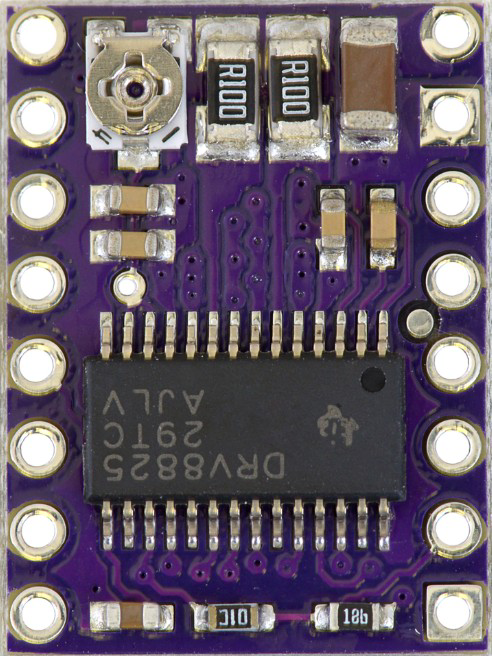

Pin Configuration and Descriptions

The DVR8825 has 16 pins, which are typically arranged as follows:

| Pin Name | Description |

|---|---|

| VMOT | Motor power supply (8.2V to 45V). Connect to the positive terminal of the motor power supply. |

| GND | Ground for motor power supply. Connect to the negative terminal of the motor power supply. |

| B2, B1 | Outputs for connecting to one coil of the stepper motor. |

| A1, A2 | Outputs for connecting to the other coil of the stepper motor. |

| VDD | Logic power supply (3.3V or 5V). |

| GND | Ground for logic power supply. |

| STEP | Step input. A rising edge on this pin advances the motor by one step. |

| DIR | Direction input. High or low signal determines the rotation direction. |

| ENABLE | Enable input. Pull low to enable the driver; pull high to disable it. |

| MS1, MS2, MS3 | Microstepping mode selection pins. Configure these to set the desired microstepping mode. |

| RESET | Reset input. Pull low to reset the driver. |

| SLEEP | Sleep mode input. Pull low to put the driver into low-power sleep mode. |

| FAULT | Fault output. Goes low when a fault condition (e.g., overcurrent) occurs. |

Microstepping Mode Configuration

The microstepping mode is determined by the states of the MS1, MS2, and MS3 pins:

| MS1 | MS2 | MS3 | Microstepping Mode |

|---|---|---|---|

| Low | Low | Low | Full Step |

| High | Low | Low | Half Step |

| Low | High | Low | Quarter Step |

| High | High | Low | Eighth Step |

| High | High | High | Sixteenth Step |

Usage Instructions

How to Use the DVR8825 in a Circuit

- Power Supply: Connect the motor power supply (8.2V to 45V) to the VMOT and GND pins. Add a decoupling capacitor (e.g., 100µF) across these pins to reduce voltage spikes.

- Motor Connection: Connect the stepper motor coils to the A1, A2, B1, and B2 pins. Ensure the correct pairing of the motor wires.

- Logic Power: Connect the VDD pin to the logic voltage (3.3V or 5V) and the GND pin to the logic ground.

- Control Signals: Connect the STEP and DIR pins to your microcontroller or control circuit. Use the ENABLE pin to enable or disable the driver as needed.

- Microstepping Configuration: Set the MS1, MS2, and MS3 pins to configure the desired microstepping mode.

- Current Adjustment: Use the onboard potentiometer to adjust the current limit. Start with a low setting and gradually increase it while monitoring the motor's performance and temperature.

Important Considerations and Best Practices

- Heat Dissipation: The DVR8825 can handle up to 2.5A per phase with adequate cooling. Use a heatsink or active cooling to prevent overheating.

- Current Limiting: Set the current limit to match your stepper motor's rated current to avoid damaging the motor or driver.

- Decoupling Capacitors: Always use a capacitor (e.g., 100µF) across the VMOT and GND pins to protect the driver from voltage spikes.

- Sleep Mode: Use the SLEEP pin to reduce power consumption when the driver is not in use.

- Fault Handling: Monitor the FAULT pin to detect and respond to fault conditions.

Example Code for Arduino UNO

Below is an example of how to control a stepper motor using the DVR8825 and an Arduino UNO:

// Define pin connections

#define STEP_PIN 3 // Connect to the STEP pin of the DVR8825

#define DIR_PIN 4 // Connect to the DIR pin of the DVR8825

void setup() {

pinMode(STEP_PIN, OUTPUT); // Set STEP pin as output

pinMode(DIR_PIN, OUTPUT); // Set DIR pin as output

digitalWrite(DIR_PIN, HIGH); // Set initial direction (HIGH = one direction)

}

void loop() {

// Generate a step pulse

digitalWrite(STEP_PIN, HIGH); // Set STEP pin HIGH

delayMicroseconds(500); // Wait for 500 microseconds

digitalWrite(STEP_PIN, LOW); // Set STEP pin LOW

delayMicroseconds(500); // Wait for 500 microseconds

}

Troubleshooting and FAQs

Common Issues and Solutions

Motor Not Moving:

- Check the power supply connections to VMOT and GND.

- Verify the STEP and DIR signals from the microcontroller.

- Ensure the motor coils are correctly connected to A1, A2, B1, and B2.

Overheating:

- Ensure the current limit is set correctly using the potentiometer.

- Add a heatsink or active cooling to the driver.

Driver Not Enabling:

- Check the ENABLE pin. It should be pulled low to enable the driver.

- Verify the logic power supply (VDD and GND).

Fault Condition (FAULT Pin Low):

- Check for overcurrent or thermal shutdown conditions.

- Reduce the current limit or improve cooling.

Motor Vibrating but Not Rotating:

- Verify the microstepping mode configuration (MS1, MS2, MS3).

- Ensure the motor coils are correctly paired.

FAQs

Can I use the DVR8825 with a 12V power supply? Yes, the DVR8825 supports motor power supplies from 8.2V to 45V, so 12V is within the acceptable range.

How do I set the current limit? Use the onboard potentiometer. Measure the VREF voltage and calculate the current limit using the formula:

Current Limit = VREF × 2(for DVR8825).What happens if I exceed the current limit? The driver will enter overcurrent protection mode, and the FAULT pin will go low. Reduce the current limit or improve cooling to resolve this.

Can I use the DVR8825 with a 3.3V microcontroller? Yes, the DVR8825 is compatible with both 3.3V and 5V logic levels.