How to Use Motor Driver - N-Mos PWM Trigger : Examples, Pinouts, and Specs

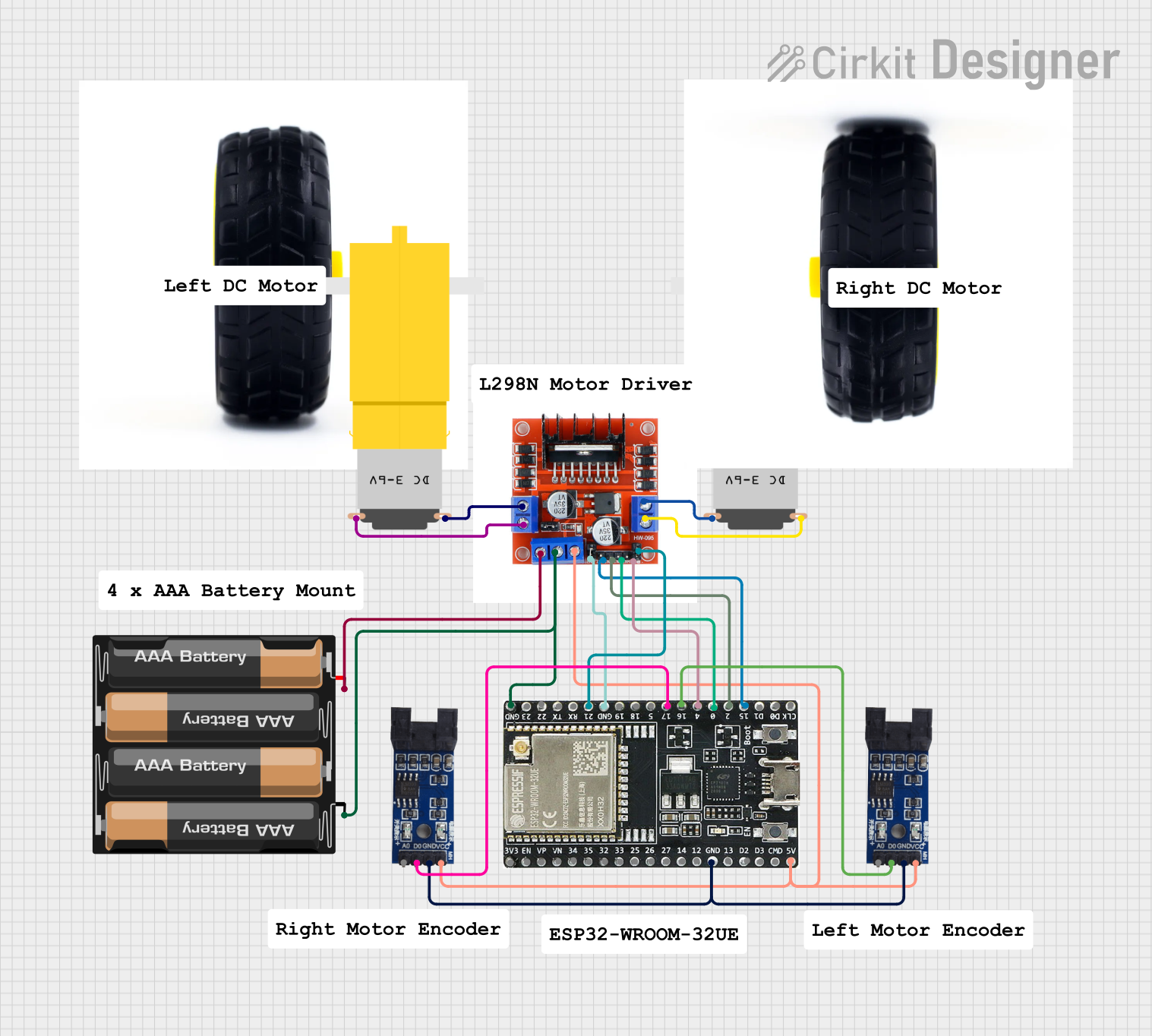

Design with Motor Driver - N-Mos PWM Trigger in Cirkit Designer

Design with Motor Driver - N-Mos PWM Trigger in Cirkit DesignerIntroduction

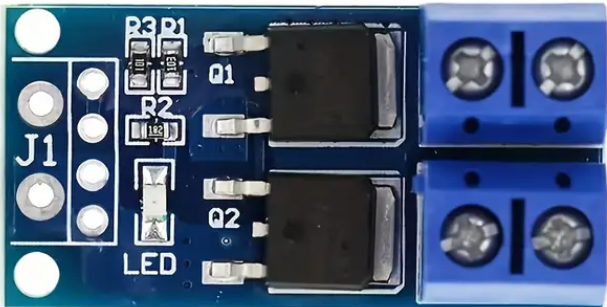

The Motor Driver - N-Mos PWM Trigger is an electronic component designed to control the speed and direction of a motor using an N-channel MOSFET and Pulse Width Modulation (PWM) signals. This driver is commonly used in robotics, automotive applications, and various DIY projects where precise motor control is required.

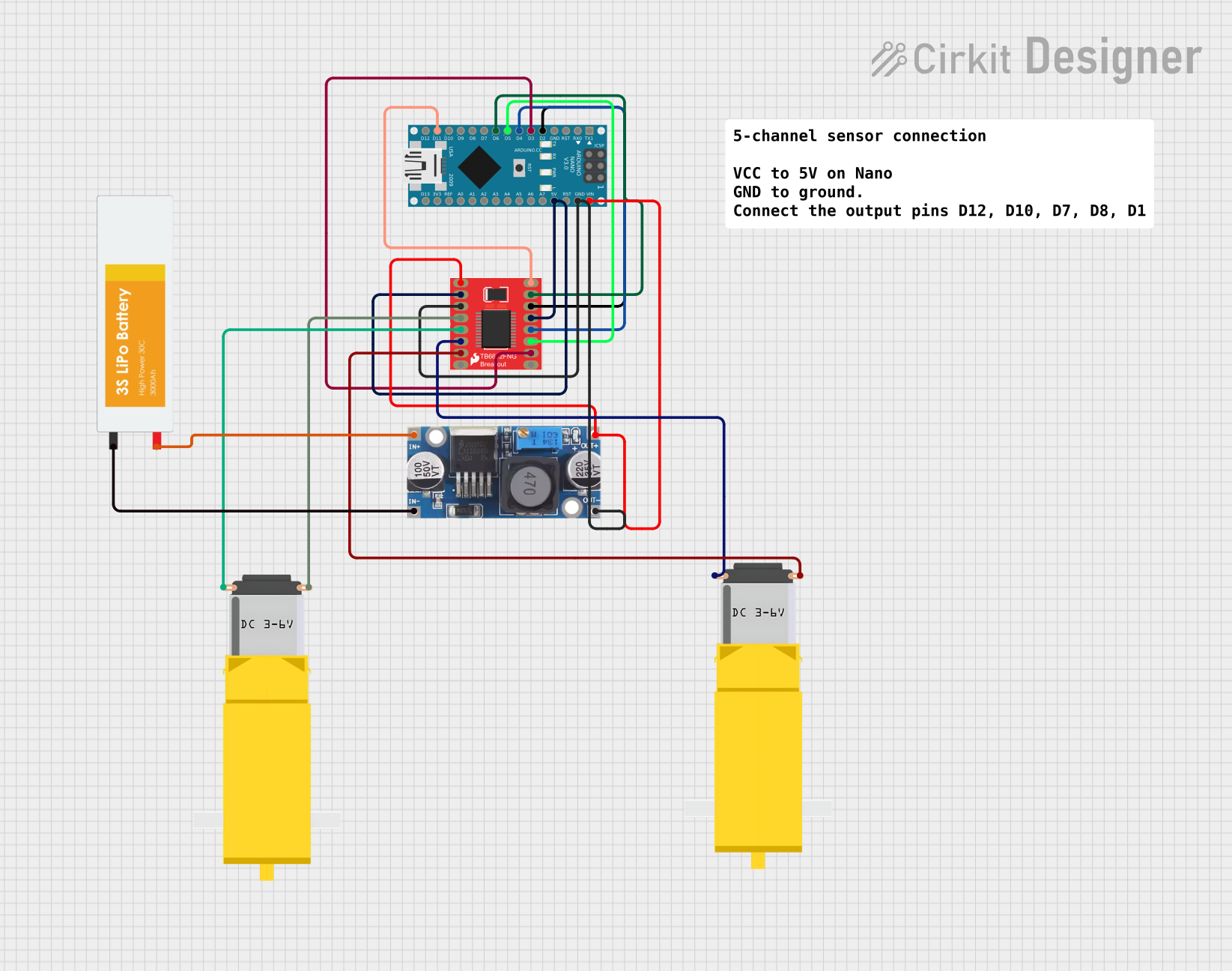

Explore Projects Built with Motor Driver - N-Mos PWM Trigger

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

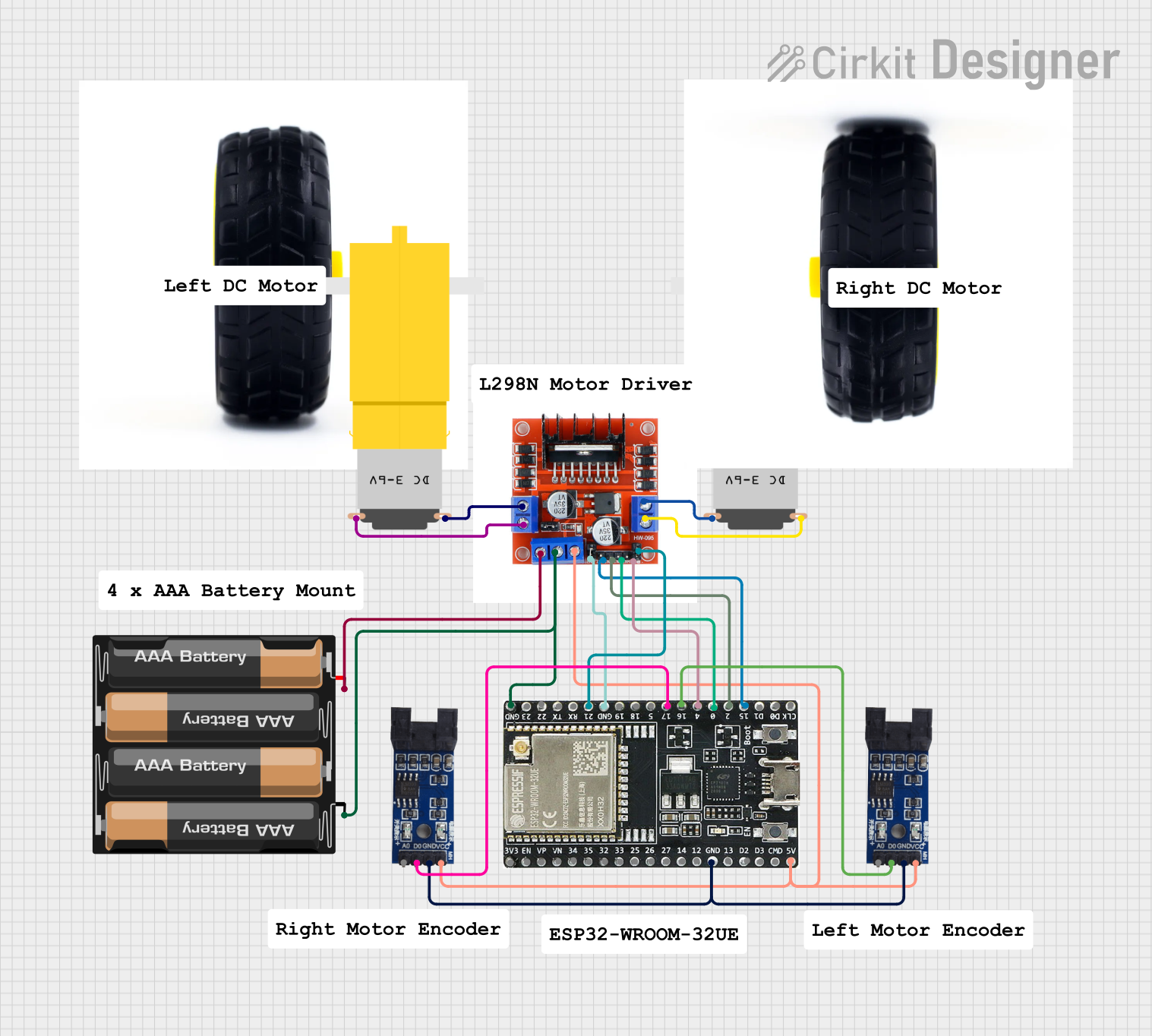

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit DesignerExplore Projects Built with Motor Driver - N-Mos PWM Trigger

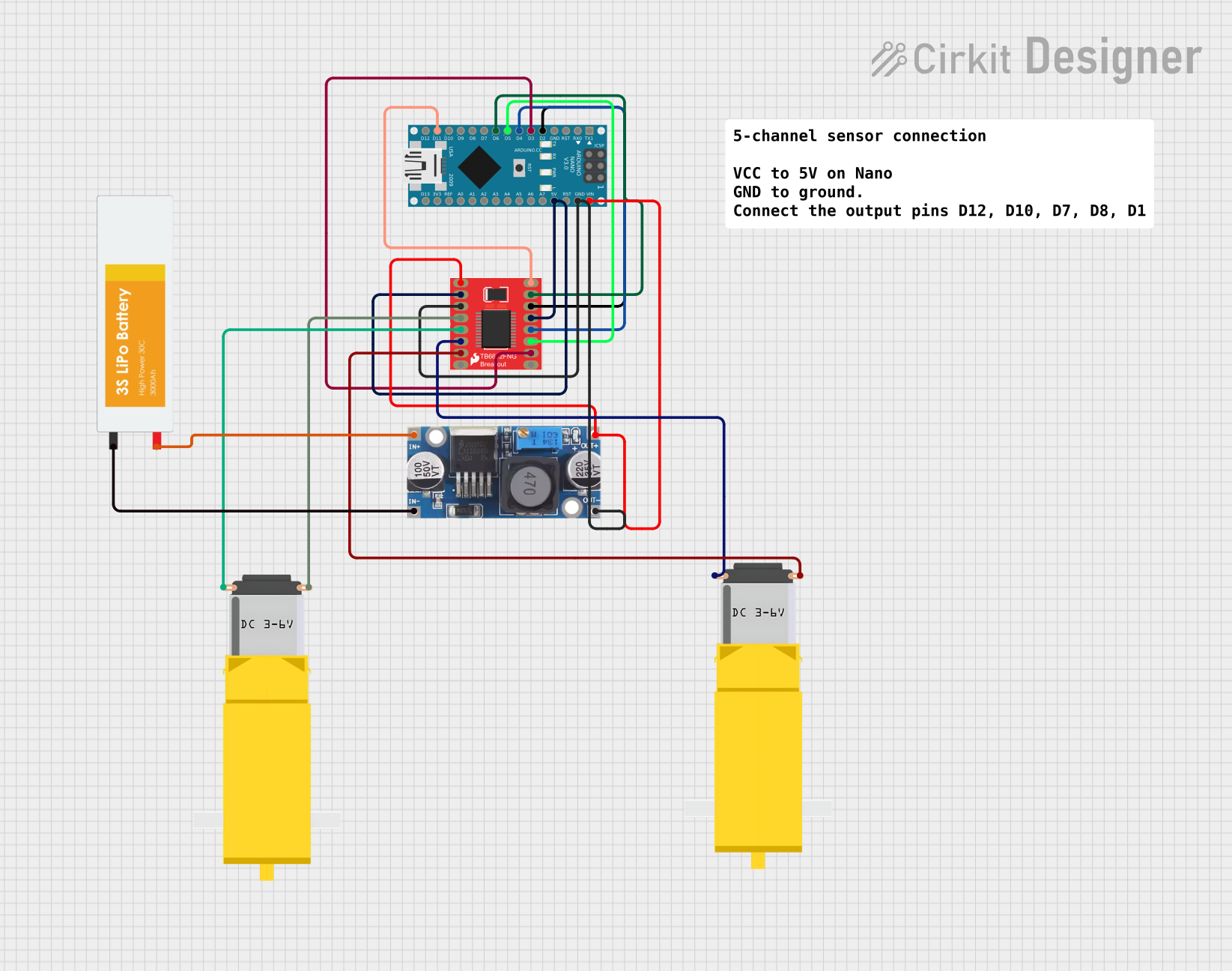

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit DesignerCommon Applications and Use Cases

- Robotics: Controlling the movement of robotic arms or wheels.

- Automotive: Adjusting fan speeds or fuel pump control.

- DIY Projects: Custom-built RC cars, drones, or automated machinery.

Technical Specifications

Key Technical Details

- Operating Voltage: Typically ranges from 5V to 30V.

- Continuous Current Rating: Up to 10A without a heatsink.

- PWM Frequency Range: 1kHz to 20kHz recommended.

- Logic Level Input: Compatible with 3.3V and 5V logic levels.

Pin Configuration and Descriptions

| Pin Number | Pin Name | Description |

|---|---|---|

| 1 | V+ | Motor power supply input (5V to 30V) |

| 2 | GND | Ground connection |

| 3 | PWM | PWM signal input for speed control |

| 4 | DIR | Direction control input (Logic High or Low) |

| 5 | OUT+ | Motor output positive |

| 6 | OUT- | Motor output negative |

Usage Instructions

How to Use the Component in a Circuit

- Power Supply Connection: Connect the motor power supply to the V+ and GND pins, ensuring that the voltage is within the specified operating range.

- Motor Connection: Attach the motor leads to the OUT+ and OUT- pins.

- Control Signal Connection: Connect the PWM signal to the PWM pin for speed control. The duty cycle of the PWM signal will determine the motor speed.

- Direction Control: Apply a logic high or low signal to the DIR pin to set the motor's rotation direction.

Important Considerations and Best Practices

- Heat Dissipation: Ensure adequate cooling if the motor driver is expected to handle currents near the maximum rating.

- PWM Signal: Use a microcontroller to generate the PWM signal with the appropriate frequency and duty cycle.

- Protective Diodes: Include flyback diodes across the motor terminals to protect the driver from voltage spikes.

- Isolation: Consider using optoisolators to separate the control circuit from the power circuit for added safety.

Example Code for Arduino UNO

// Define the pins connected to the motor driver

const int pwmPin = 3; // PWM input for speed control

const int dirPin = 4; // Direction control input

void setup() {

// Set the motor driver pins as outputs

pinMode(pwmPin, OUTPUT);

pinMode(dirPin, OUTPUT);

}

void loop() {

// Set motor direction to forward

digitalWrite(dirPin, HIGH);

// Ramp up the motor speed

for (int speed = 0; speed <= 255; speed++) {

analogWrite(pwmPin, speed);

delay(10);

}

// Ramp down the motor speed

for (int speed = 255; speed >= 0; speed--) {

analogWrite(pwmPin, speed);

delay(10);

}

// Change motor direction to reverse

digitalWrite(dirPin, LOW);

// Repeat the ramp up and ramp down process

// ... (same as above)

}

Troubleshooting and FAQs

Common Issues

- Motor not spinning: Check power supply connections and ensure the PWM signal is being sent.

- Overheating: If the driver is too hot, reduce the load or improve heat dissipation.

- Inconsistent speed control: Verify the PWM frequency and duty cycle are within specifications.

Solutions and Tips for Troubleshooting

- Power Supply: Confirm that the voltage and current ratings are within the limits of the motor driver.

- Signal Integrity: Use an oscilloscope to check the PWM and direction signals for proper levels and noise.

- Connections: Ensure all connections are secure and free from shorts or opens.

FAQs

Q: Can I control two motors with this driver? A: No, this driver is designed for single motor control. Use separate drivers for each motor.

Q: What is the maximum PWM frequency I can use? A: While the driver can handle a range of frequencies, it is recommended to stay within 1kHz to 20kHz for optimal performance.

Q: How do I reverse the motor direction? A: Apply a logic high or low to the DIR pin to reverse the motor's direction. The actual logic level for forward or reverse may depend on the motor driver's design.

Remember to always consult the datasheet of the specific motor driver model you are using for the most accurate and detailed information.