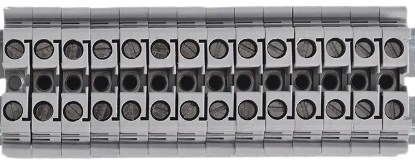

How to Use DIN RAIL TBLOCK: Examples, Pinouts, and Specs

Design with DIN RAIL TBLOCK in Cirkit Designer

Design with DIN RAIL TBLOCK in Cirkit DesignerIntroduction

The DIN RAIL TBLOCK is a terminal block designed for mounting on standard DIN rails. It is widely used for connecting and organizing electrical wires in industrial, commercial, and residential applications. This component provides a secure and efficient way to manage wiring in control panels, distribution boards, and other electrical systems. Its modular design allows for easy installation and maintenance, making it a popular choice for professionals and hobbyists alike.

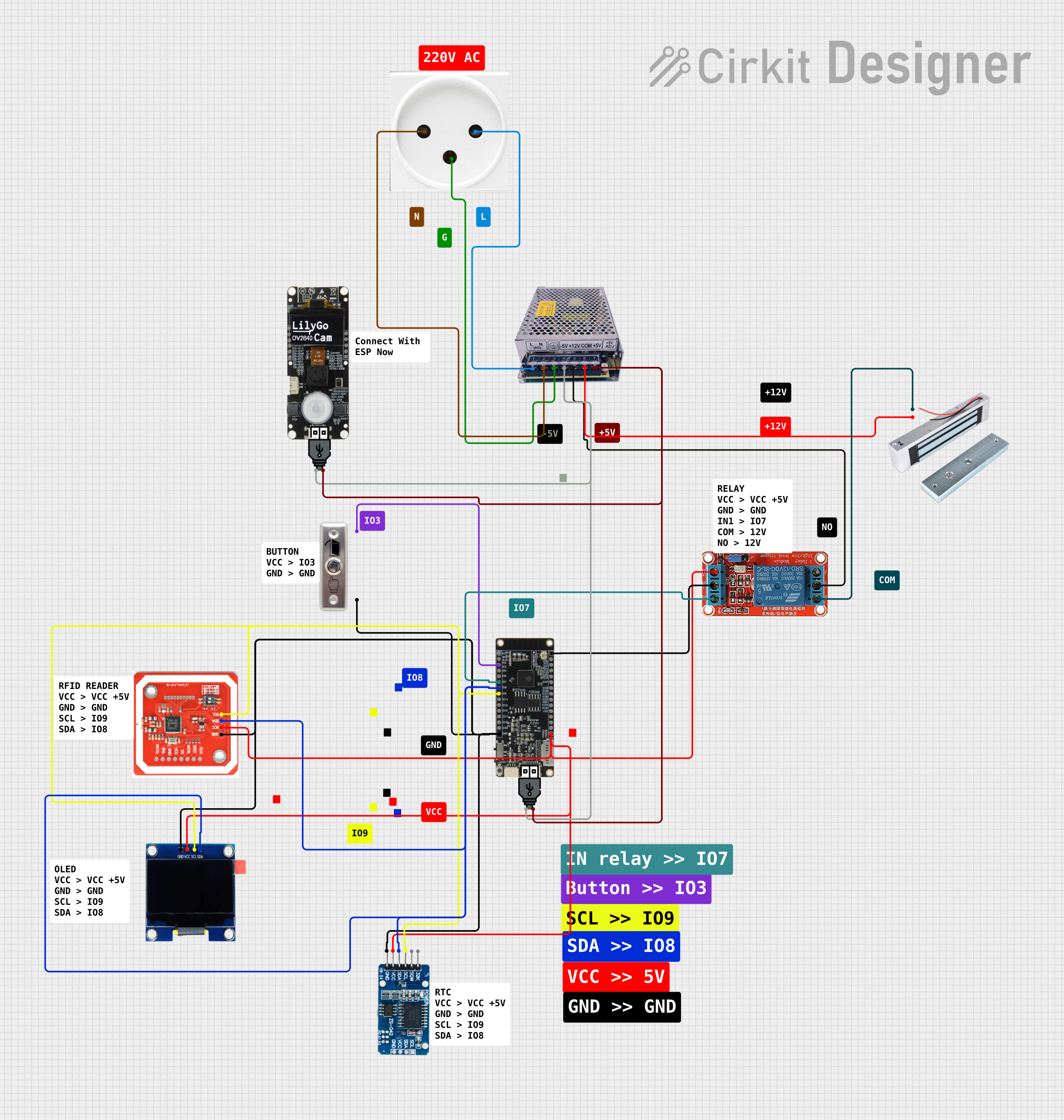

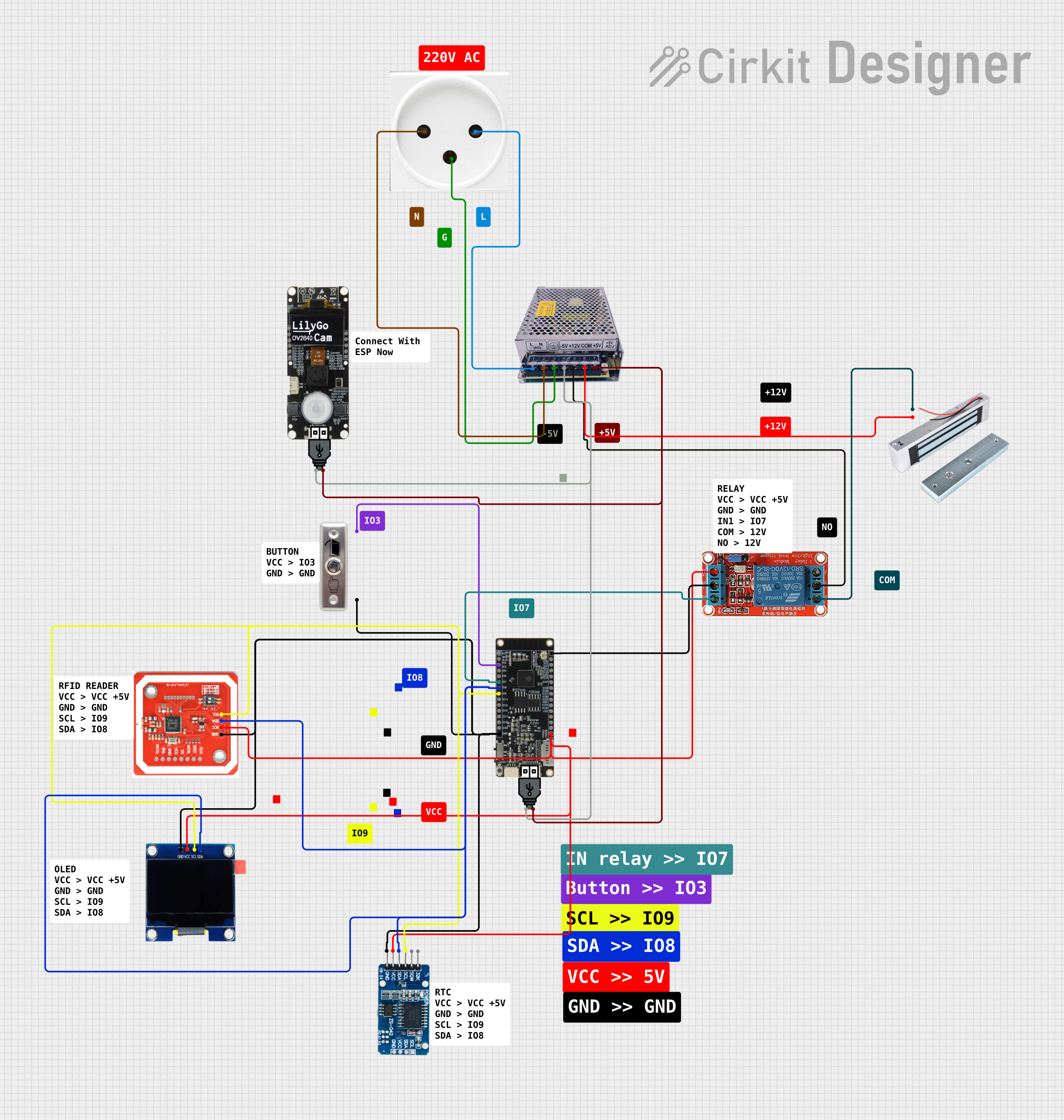

Explore Projects Built with DIN RAIL TBLOCK

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit DesignerExplore Projects Built with DIN RAIL TBLOCK

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit DesignerCommon Applications and Use Cases

- Industrial control panels

- Power distribution systems

- Automation systems

- Signal and data wiring organization

- Electrical testing and prototyping setups

Technical Specifications

The following table outlines the key technical specifications of the DIN RAIL TBLOCK:

| Parameter | Value |

|---|---|

| Manufacturer | DIN RAIL TBLOCK |

| Manufacturer Part ID | DIN RAIL TBLOCK |

| Mounting Type | DIN Rail (35mm standard) |

| Voltage Rating | Up to 600V |

| Current Rating | Up to 30A |

| Wire Size Compatibility | 22 AWG to 10 AWG |

| Material | Flame-retardant thermoplastic |

| Operating Temperature | -40°C to +105°C |

| Connection Type | Screw or spring clamp terminals |

| Dimensions (L x W x H) | Varies by model (e.g., 42 x 6 x 45 mm) |

Pin Configuration and Descriptions

The DIN RAIL TBLOCK does not have traditional pins but instead features terminal slots for wire connections. Below is a description of the terminal layout:

| Terminal | Description |

|---|---|

| Terminal 1 | Input wire connection (positive or signal) |

| Terminal 2 | Output wire connection (positive or signal) |

| Terminal 3 | Ground or neutral wire connection |

Usage Instructions

How to Use the Component in a Circuit

Mounting the Terminal Block:

- Secure the DIN RAIL TBLOCK onto a 35mm DIN rail by snapping it into place. Ensure it is firmly attached to prevent movement during operation.

Connecting Wires:

- Strip the insulation from the wire ends (approximately 6-8mm).

- Insert the stripped wire into the appropriate terminal slot (e.g., Terminal 1 for input, Terminal 2 for output).

- Tighten the screw or engage the spring clamp to secure the wire. Avoid overtightening to prevent damage to the wire or terminal.

Testing the Connections:

- Use a multimeter to verify continuity and ensure proper connections.

- Check for any loose wires or improper connections before powering the circuit.

Powering the Circuit:

- Once all connections are verified, power the circuit and monitor for proper operation.

Important Considerations and Best Practices

- Wire Compatibility: Ensure the wire gauge is within the supported range (22 AWG to 10 AWG).

- Tightening Torque: Follow the manufacturer's recommended torque specifications to avoid damaging the terminal or wire.

- Environmental Conditions: Use the terminal block within the specified operating temperature range (-40°C to +105°C).

- Labeling: Use wire markers or labels to identify connections for easier troubleshooting and maintenance.

- Safety: Always disconnect power before making or modifying connections.

Example: Connecting to an Arduino UNO

The DIN RAIL TBLOCK can be used to organize and secure connections between an Arduino UNO and external components. Below is an example of wiring an LED to an Arduino through the terminal block:

Circuit Diagram

- Terminal 1: Connects to Arduino digital pin (e.g., D13).

- Terminal 2: Connects to the positive leg of the LED.

- Terminal 3: Connects to the ground (GND) of the Arduino.

Arduino Code Example

// Simple LED Blink Example

// This code blinks an LED connected via the DIN RAIL TBLOCK

const int ledPin = 13; // Pin connected to Terminal 1 of the DIN RAIL TBLOCK

void setup() {

pinMode(ledPin, OUTPUT); // Set the pin as an output

}

void loop() {

digitalWrite(ledPin, HIGH); // Turn the LED on

delay(1000); // Wait for 1 second

digitalWrite(ledPin, LOW); // Turn the LED off

delay(1000); // Wait for 1 second

}

Troubleshooting and FAQs

Common Issues Users Might Face

Loose Connections:

- Symptom: Intermittent or no power to connected components.

- Solution: Check and tighten all terminal screws or clamps. Ensure wires are properly stripped and inserted.

Overheating:

- Symptom: Terminal block becomes hot during operation.

- Solution: Verify that the current does not exceed the 30A rating. Use appropriate wire gauge for the load.

Wire Slippage:

- Symptom: Wires slip out of the terminal slots.

- Solution: Ensure the wire is stripped to the correct length and the terminal is securely tightened.

Corrosion or Damage:

- Symptom: Poor electrical contact or visible damage to the terminal block.

- Solution: Replace the terminal block if corrosion or damage is observed. Use components rated for the environmental conditions.

FAQs

Q1: Can the DIN RAIL TBLOCK handle both AC and DC currents?

A1: Yes, the terminal block is designed to handle both AC and DC currents, provided the voltage and current ratings are not exceeded.

Q2: How many terminal blocks can be mounted on a single DIN rail?

A2: The number depends on the length of the DIN rail and the dimensions of the terminal blocks. Ensure adequate spacing for safe operation.

Q3: Can I use the DIN RAIL TBLOCK for high-frequency signals?

A3: Yes, but ensure the terminal block's material and design are suitable for the specific frequency range to minimize signal loss.

Q4: Is the terminal block reusable?

A4: Yes, the terminal block can be reused, but inspect it for wear or damage before reinstallation.