How to Use Resettable Fuse PTC: Examples, Pinouts, and Specs

Design with Resettable Fuse PTC in Cirkit Designer

Design with Resettable Fuse PTC in Cirkit DesignerIntroduction

A Resettable Fuse PTC (Positive Temperature Coefficient) is a protective electronic component designed to limit the flow of excessive current in a circuit. Unlike traditional fuses, which must be replaced after a single use, a PTC fuse automatically resets after the overcurrent condition has been cleared and the unit cools down. This makes them ideal for a wide range of applications where overcurrent protection is necessary but manual resetting or replacement of fuses is impractical or undesirable.

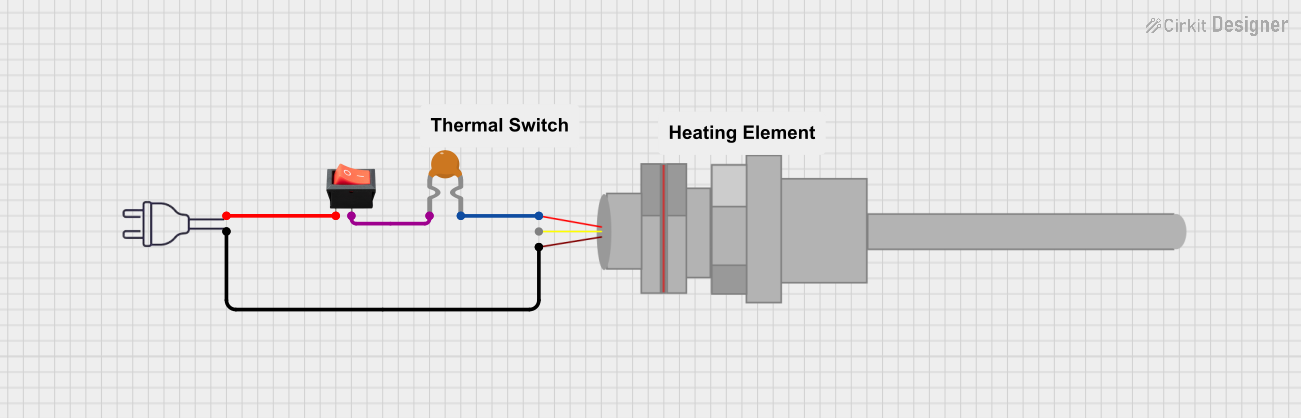

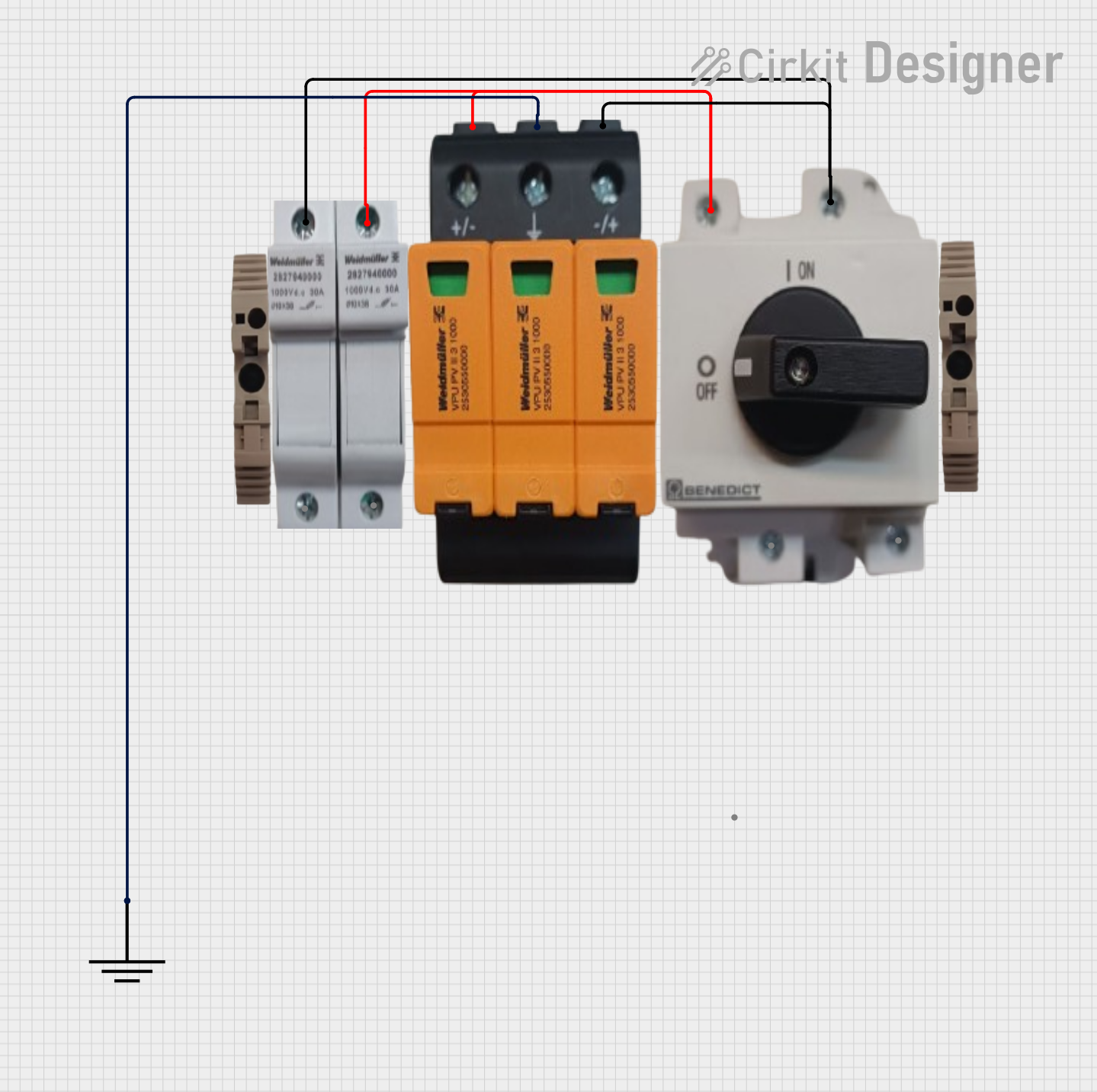

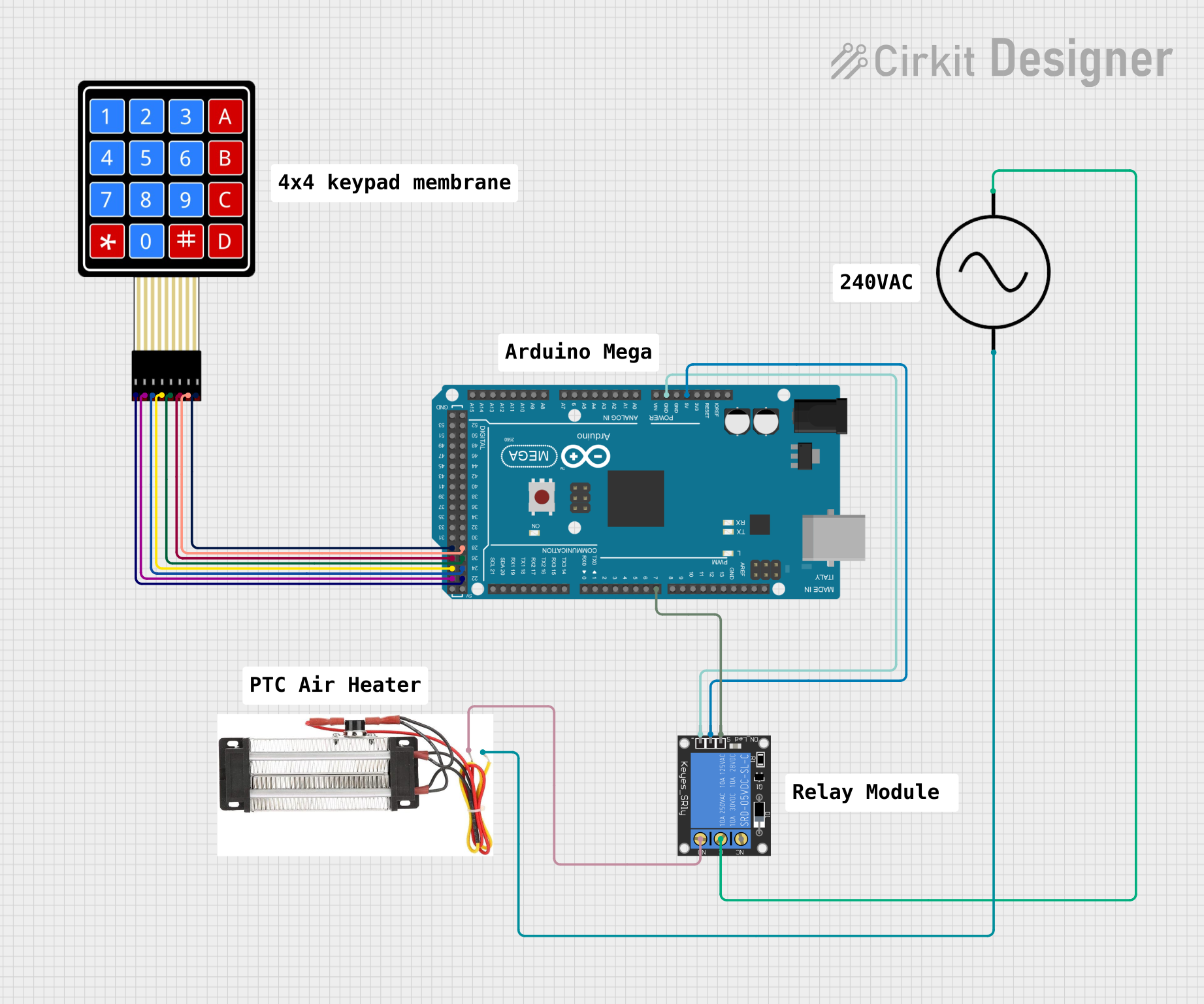

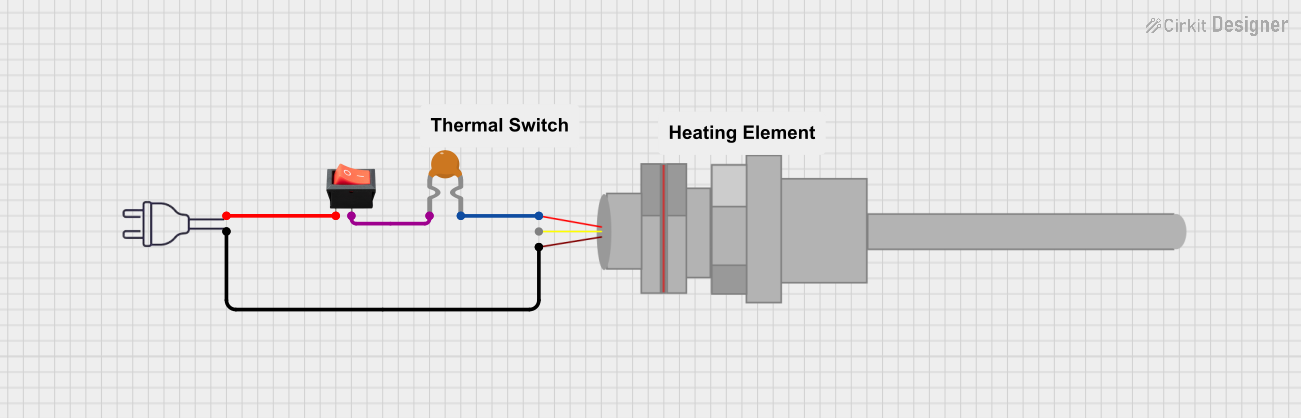

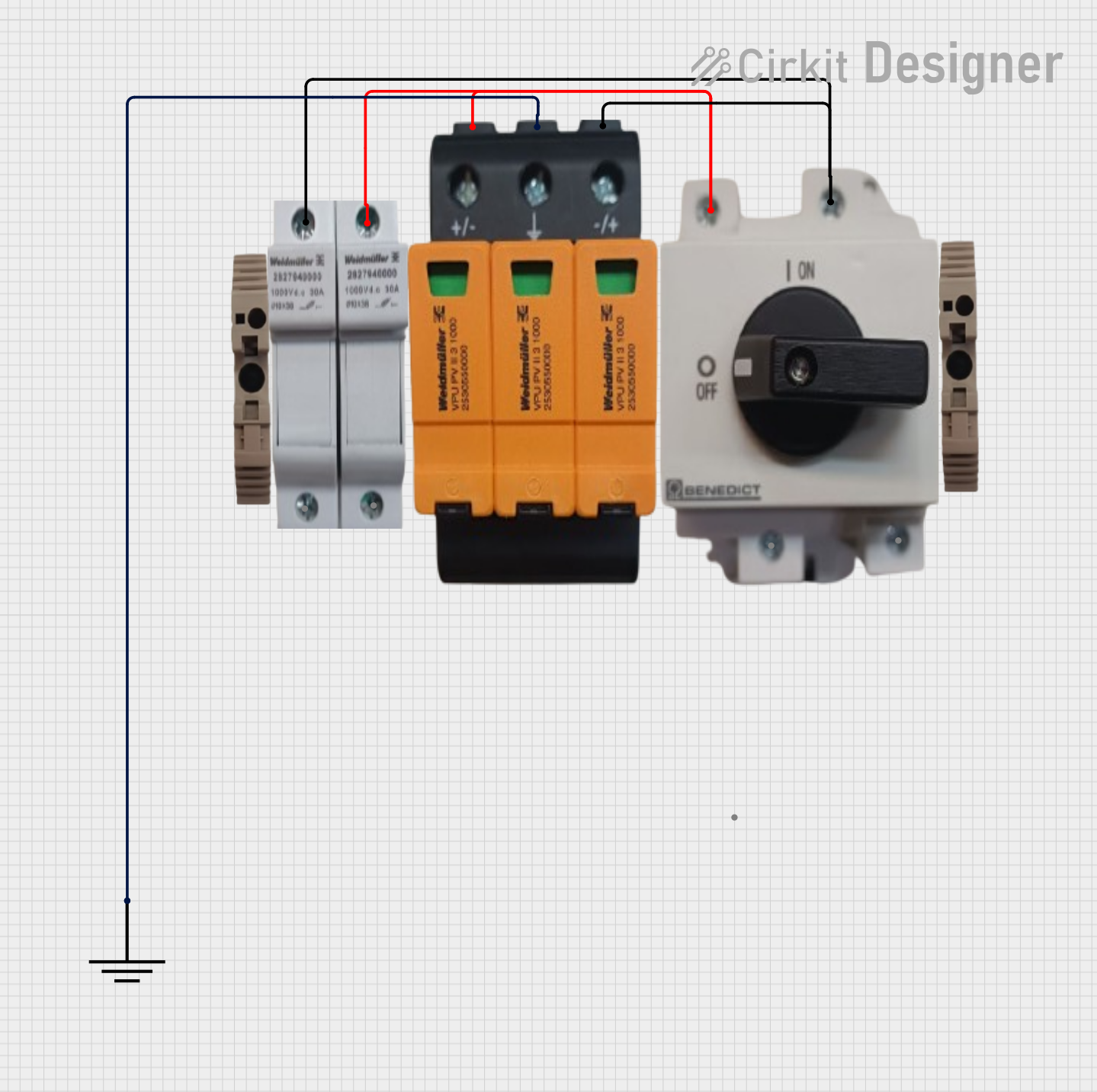

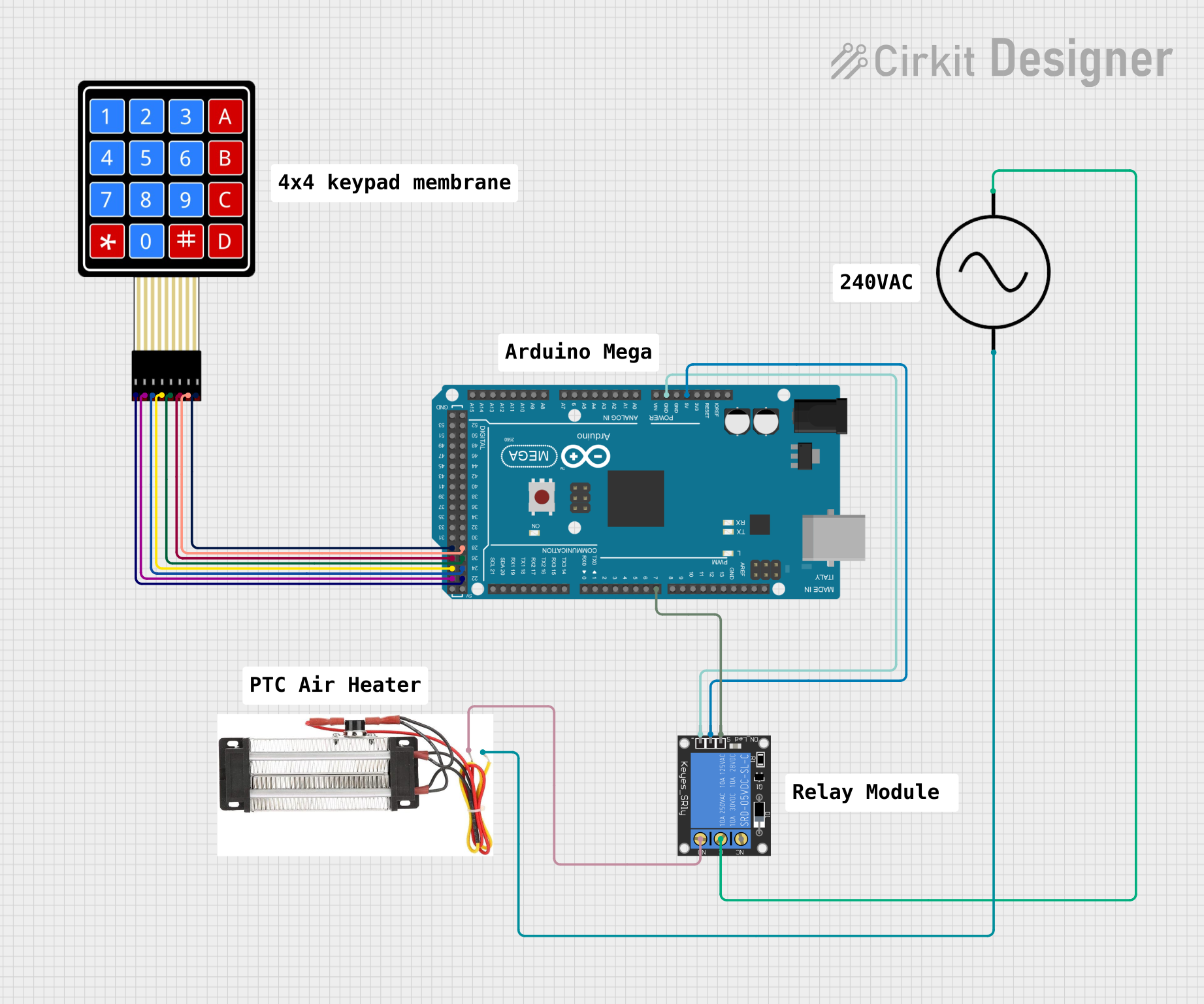

Explore Projects Built with Resettable Fuse PTC

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit DesignerExplore Projects Built with Resettable Fuse PTC

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit DesignerCommon Applications and Use Cases

- Overcurrent protection in consumer electronics (e.g., smartphones, laptops)

- Protection for battery packs and chargers

- Automotive electronics

- Power supplies

- Medical devices

Technical Specifications

Key Technical Details

- Voltage Rating: The maximum voltage the PTC can withstand without damage.

- Current Rating: The nominal operating current before the PTC trips.

- Trip Current: The current at which the PTC will trip and increase its resistance.

- Maximum Interrupt Current: The maximum fault current the PTC can withstand without damage.

- Time to Trip: The time it takes for the PTC to trip at a specified multiple of its rated current.

- Resistance: The initial resistance of the PTC before tripping and the resistance after tripping.

Pin Configuration and Descriptions

| Pin Number | Description |

|---|---|

| 1 | Current Input |

| 2 | Current Output |

Note: The PTC is a two-terminal device, with the current flowing from pin 1 to pin 2.

Usage Instructions

How to Use the Component in a Circuit

- Identify the Correct PTC: Select a PTC with a voltage rating above the maximum circuit voltage and a current rating that matches the normal operating current of the circuit.

- Circuit Placement: Place the PTC in series with the load that needs protection.

- Soldering: Solder the PTC to the PCB with care to avoid excessive heat, which could trip the PTC prematurely.

Important Considerations and Best Practices

- Selecting PTC: Ensure the trip current of the PTC is above the normal operating current but below the current that could damage the circuit.

- Thermal Considerations: Be aware of the thermal environment as PTCs can trip due to ambient temperature increases.

- Recovery Time: After tripping, allow time for the PTC to cool down and reset before resuming normal operation.

- Testing: Test the PTC in the actual circuit to ensure it trips at the appropriate current levels.

Troubleshooting and FAQs

Common Issues Users Might Face

- PTC Does Not Reset: If the PTC does not reset after tripping, check if the overcurrent condition still exists or if the ambient temperature is too high.

- Nuisance Tripping: If the PTC trips during normal operation, it may be incorrectly specified. Check the trip current and ambient temperature conditions.

Solutions and Tips for Troubleshooting

- Persistent Overcurrent: Investigate the circuit for faults or short circuits that may cause continuous overcurrent conditions.

- Ambient Temperature: Ensure the PTC is operating within its specified temperature range.

- Proper Sizing: Verify that the PTC is correctly sized for both the operating current and the maximum fault current of the circuit.

FAQs

Q: Can a PTC be used multiple times? A: Yes, a PTC is designed to reset itself after cooling down, allowing for multiple uses.

Q: How quickly does a PTC reset? A: The reset time can vary based on the PTC's design and the severity of the overcurrent condition. It can range from a few seconds to several minutes.

Q: Is a PTC the same as a thermistor? A: While both PTCs and thermistors have temperature-dependent resistance, a PTC is specifically designed to protect against overcurrent, while thermistors are generally used for temperature sensing.

Q: Can I use a PTC with an Arduino UNO? A: Yes, a PTC can be used in circuits involving an Arduino UNO for overcurrent protection.

Example Code for Arduino UNO

// Example code to demonstrate the use of a PTC with an Arduino UNO

// This code does not directly interact with the PTC but shows a typical setup.

void setup() {

pinMode(LED_BUILTIN, OUTPUT); // Set the built-in LED as an output

}

void loop() {

digitalWrite(LED_BUILTIN, HIGH); // Turn on the LED

delay(1000); // Wait for 1 second

digitalWrite(LED_BUILTIN, LOW); // Turn off the LED

delay(1000); // Wait for 1 second

}

// Note: The PTC would be placed in series with the LED or other components

// to protect against overcurrent. The code itself does not control the PTC.

Remember to keep the PTC's specifications in mind when designing circuits with the Arduino UNO to ensure proper protection.