How to Use Flex Sensor: Examples, Pinouts, and Specs

Design with Flex Sensor in Cirkit Designer

Design with Flex Sensor in Cirkit DesignerIntroduction

The Flex Sensor (Manufacturer Part ID: 1070) by Spectra Symbol is a variable resistor that alters its resistance based on the degree of bending or flexing. This unique property makes it an essential component in motion detection and position sensing applications. The sensor is lightweight, thin, and highly reliable, making it suitable for integration into a wide range of projects.

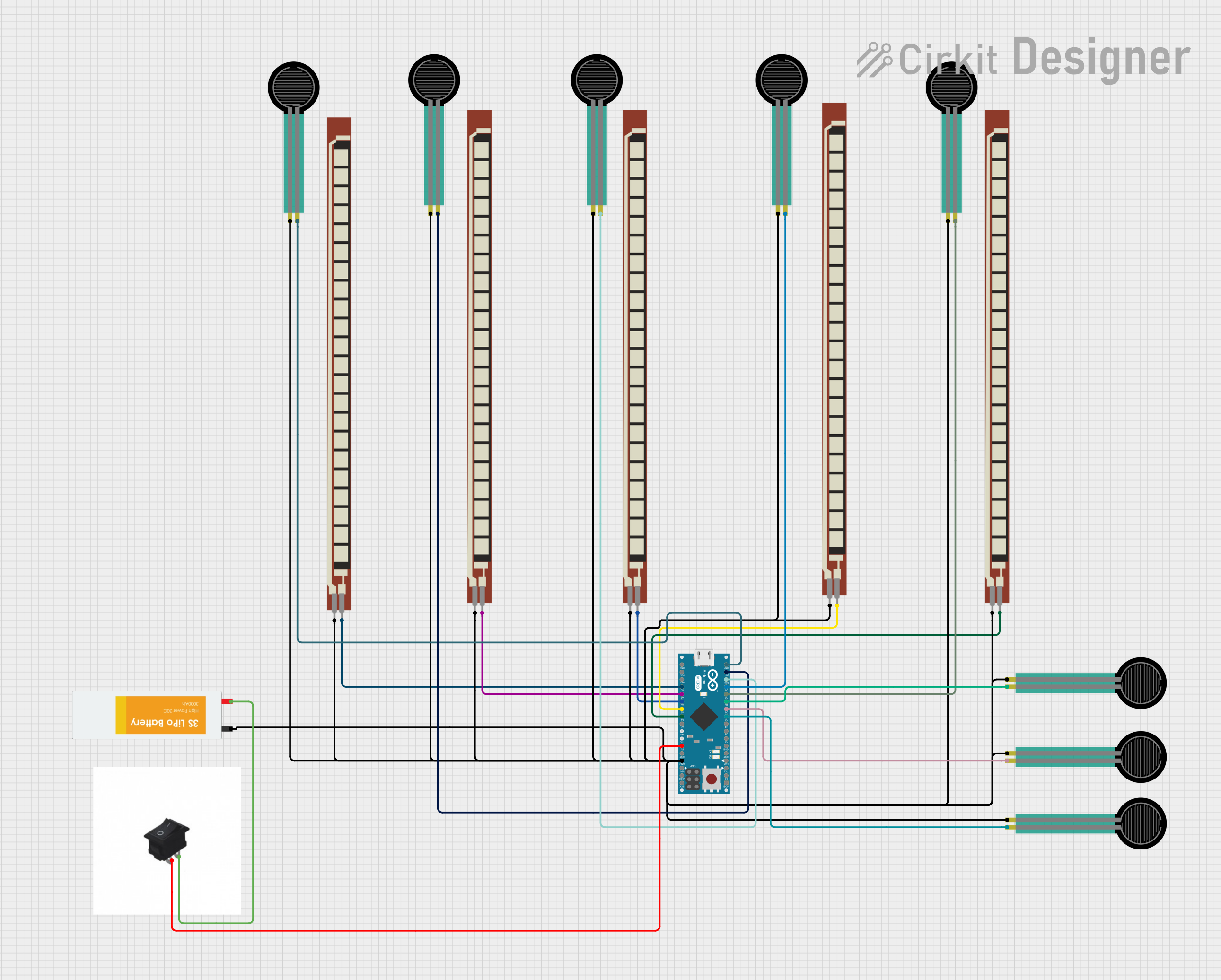

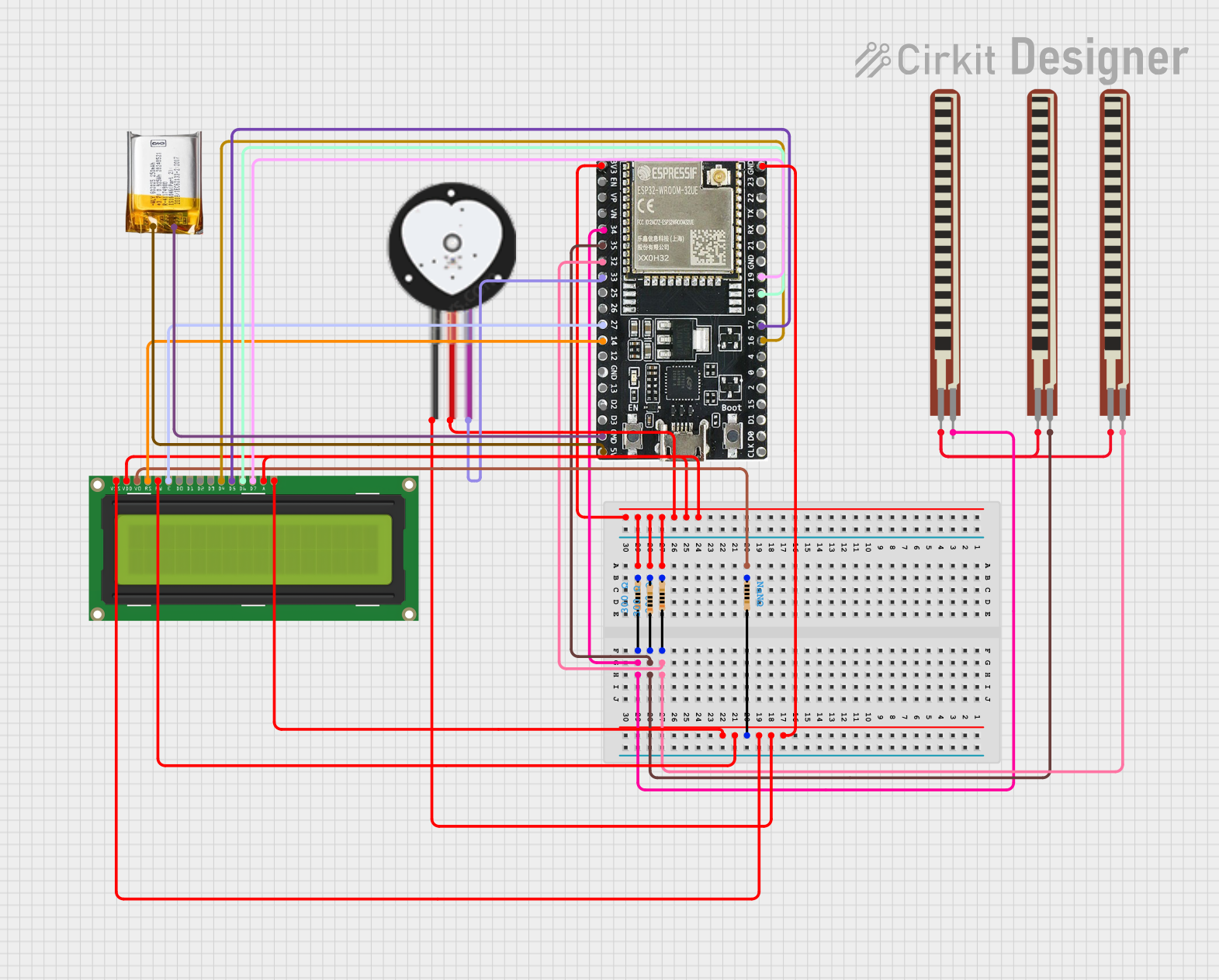

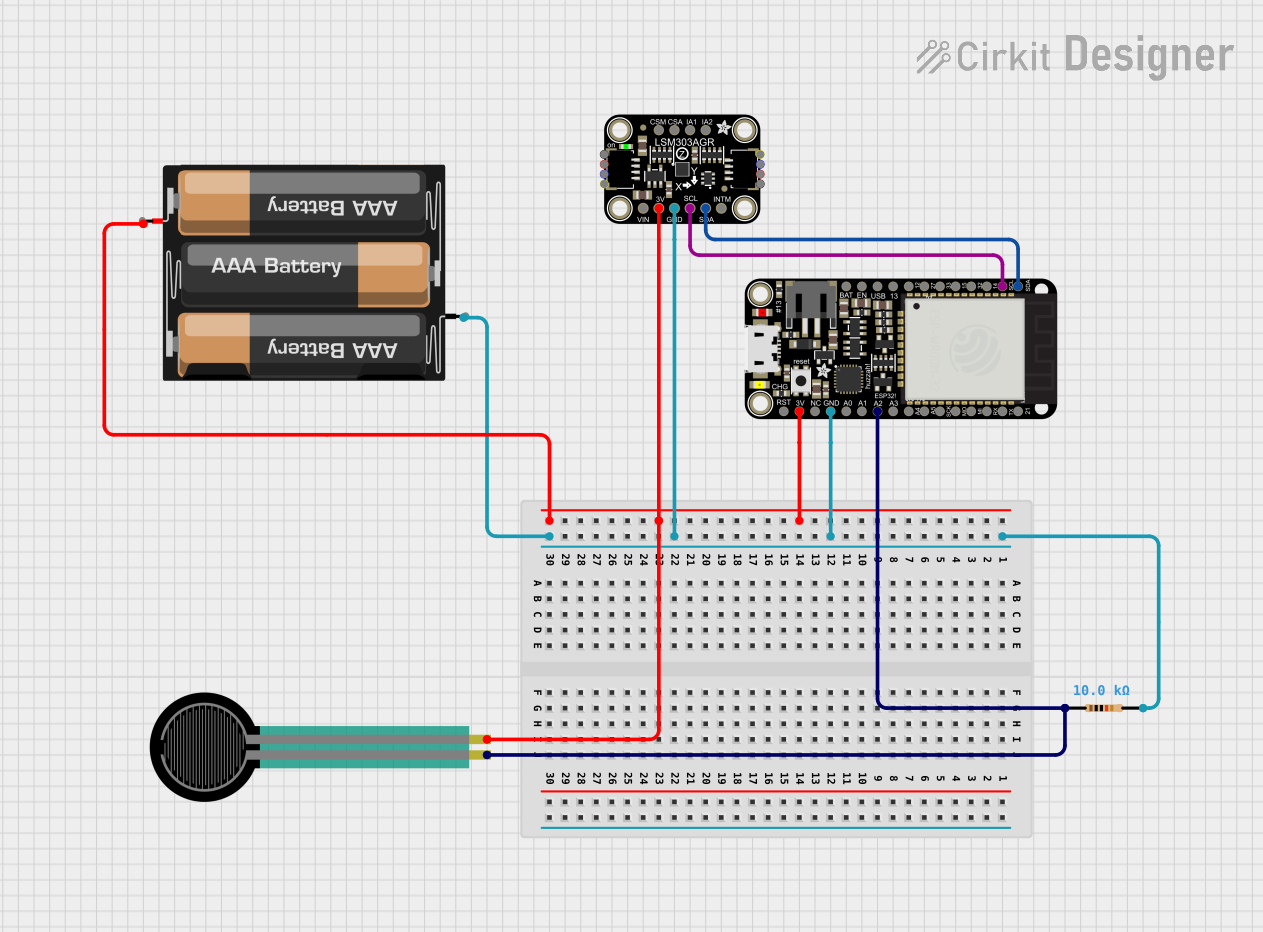

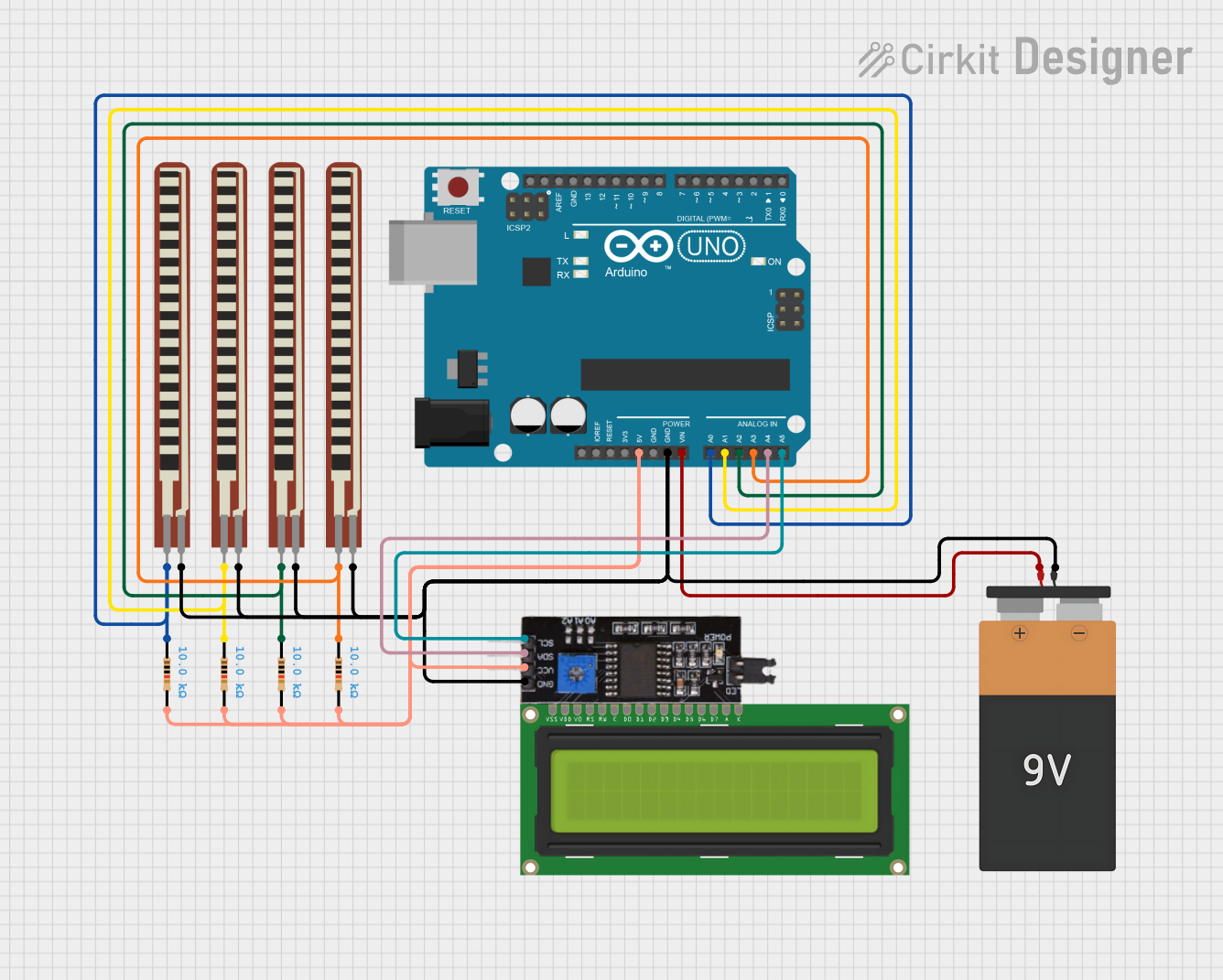

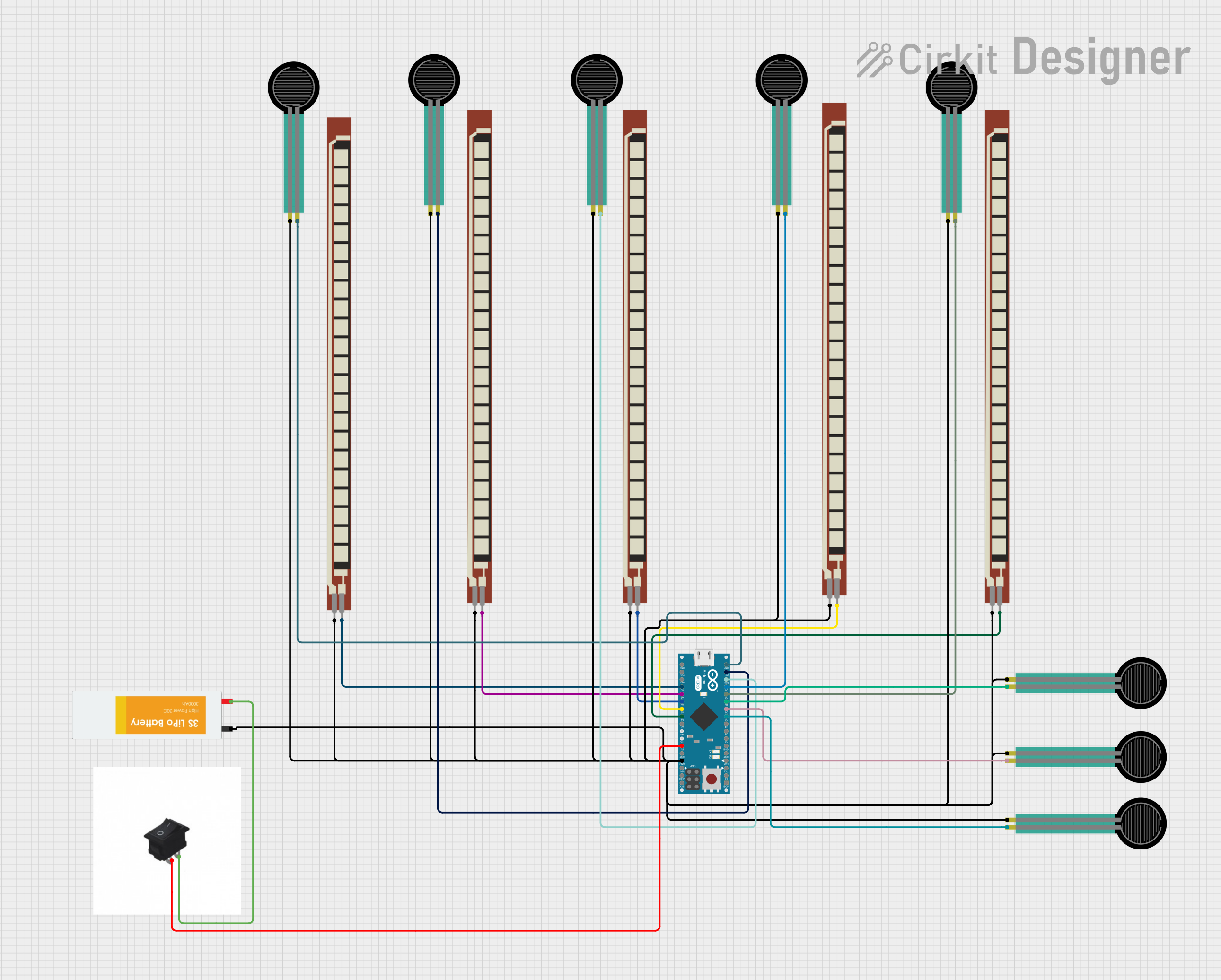

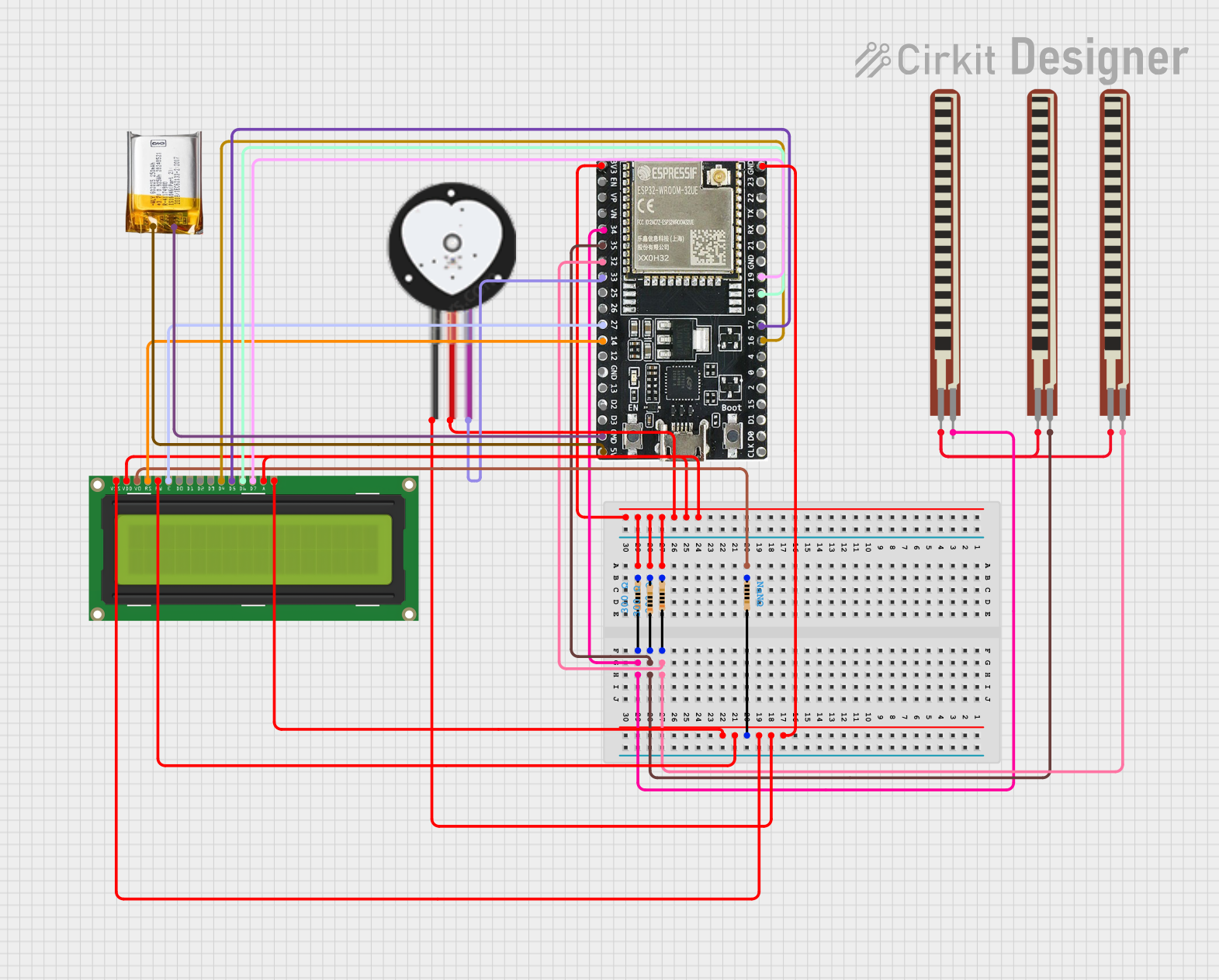

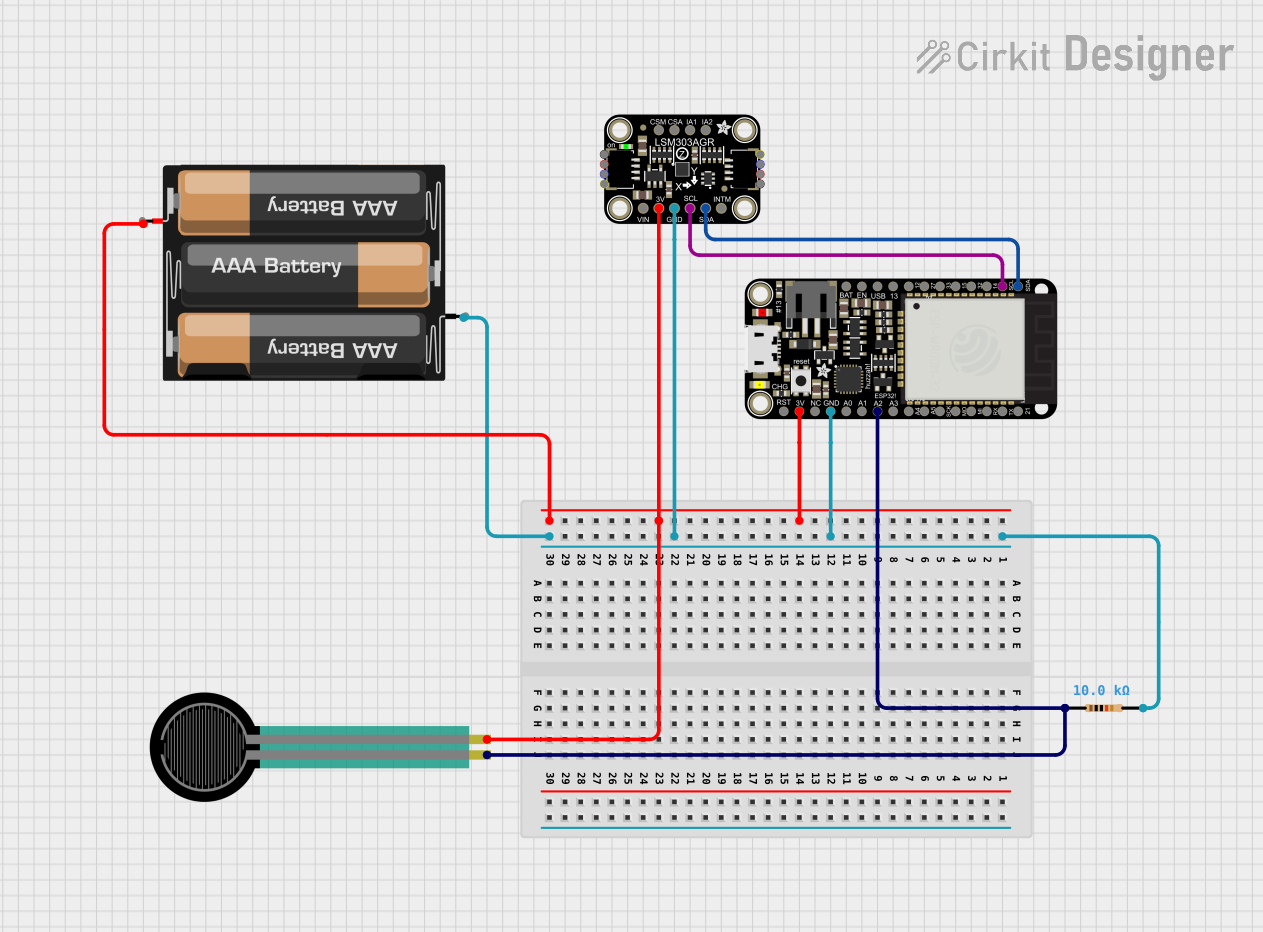

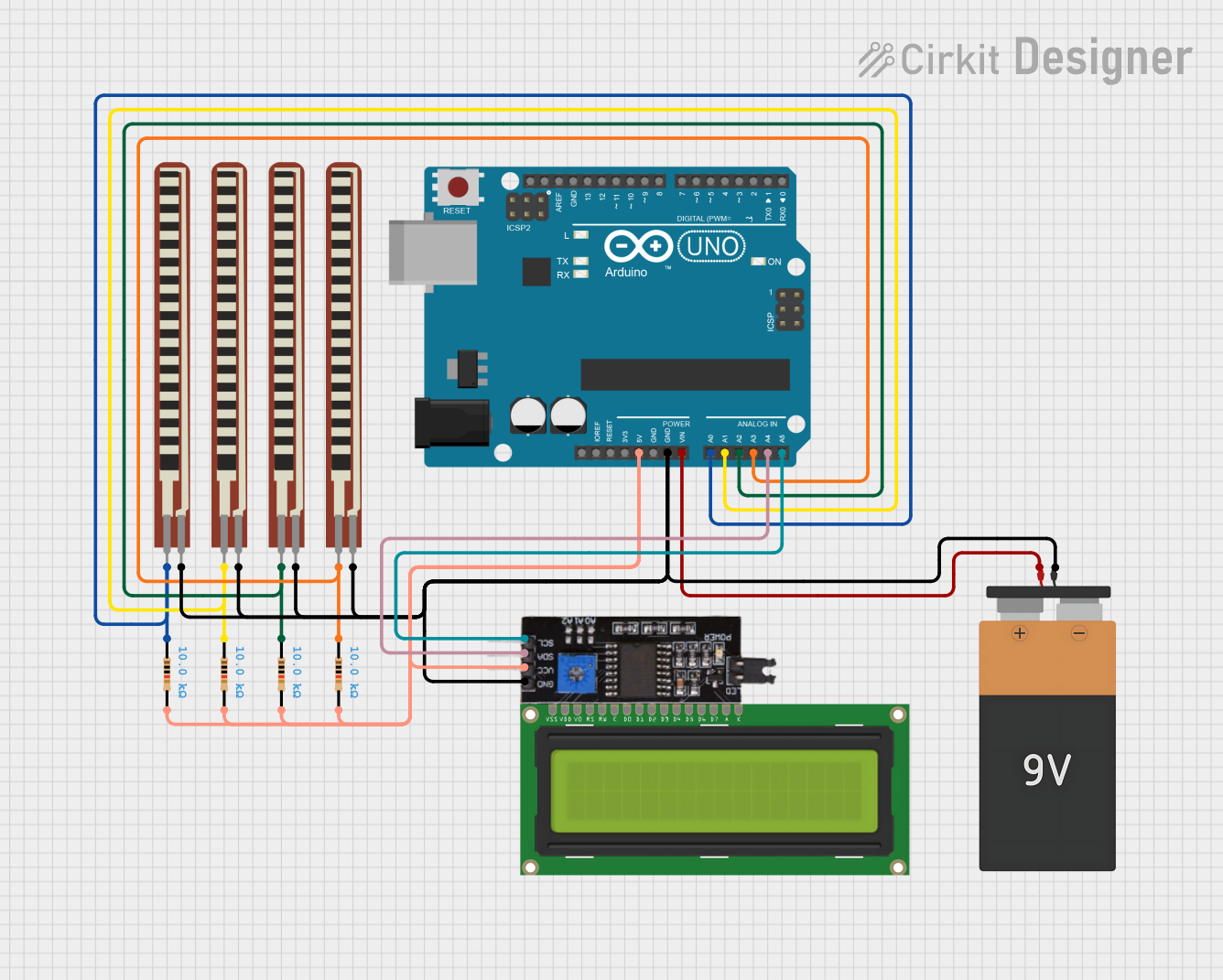

Explore Projects Built with Flex Sensor

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit DesignerExplore Projects Built with Flex Sensor

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit DesignerCommon Applications

- Robotics: Detecting joint movement or angular displacement.

- Gaming Controllers: Measuring finger or hand movements for interactive gaming.

- Wearable Technology: Monitoring body posture or gestures.

- Medical Devices: Tracking rehabilitation exercises or hand movements.

- Automotive Systems: Detecting steering wheel or seat adjustments.

Technical Specifications

Below are the key technical details of the Flex Sensor (Part ID: 1070):

| Parameter | Value |

|---|---|

| Manufacturer | Spectra Symbol |

| Part ID | 1070 |

| Resistance (Flat State) | 10 kΩ ± 30% |

| Resistance (Bent State) | Up to ~40 kΩ (depending on bend) |

| Bend Angle Range | 0° to ~90° |

| Power Rating | 0.5 W (continuous) |

| Operating Voltage | 0-5 V |

| Operating Temperature | -35°C to +80°C |

| Length | 2.2 inches (55.88 mm) |

| Thickness | 0.43 mm |

Pin Configuration and Descriptions

The Flex Sensor has two terminals, as it functions as a variable resistor. Below is the pin configuration:

| Pin | Description |

|---|---|

| Pin 1 | One end of the resistive element (connect to VCC) |

| Pin 2 | Other end of the resistive element (connect to GND) |

Usage Instructions

How to Use the Flex Sensor in a Circuit

Basic Circuit Setup:

- The Flex Sensor is typically used in a voltage divider circuit.

- Connect one terminal of the sensor to a fixed resistor (e.g., 10 kΩ) and the other terminal to the ground (GND).

- The junction between the fixed resistor and the Flex Sensor is connected to an analog input pin of a microcontroller (e.g., Arduino UNO).

Reading the Sensor Output:

- As the sensor bends, its resistance increases, causing a change in the voltage at the analog input pin.

- This voltage can be read and processed to determine the degree of bending.

Important Considerations and Best Practices

- Avoid Over-Bending: Do not bend the sensor beyond its specified range (~90°) to prevent damage.

- Mounting: Secure the sensor carefully to avoid stress on the terminals.

- Debouncing: If the sensor is used in dynamic applications, consider implementing software debouncing to filter noise.

- Calibration: Calibrate the sensor for your specific application to map resistance values to meaningful angles or positions.

Example: Using the Flex Sensor with Arduino UNO

Below is an example code snippet to read the Flex Sensor's output using an Arduino UNO:

// Flex Sensor Example with Arduino UNO

// Reads the sensor value and prints the corresponding voltage to the Serial Monitor

const int flexSensorPin = A0; // Analog pin connected to the Flex Sensor

const int vcc = 5; // Supply voltage (5V)

void setup() {

Serial.begin(9600); // Initialize Serial communication at 9600 baud

pinMode(flexSensorPin, INPUT); // Set the sensor pin as input

}

void loop() {

int sensorValue = analogRead(flexSensorPin); // Read the analog value

float voltage = (sensorValue / 1023.0) * vcc; // Convert to voltage

// Print the sensor value and voltage to the Serial Monitor

Serial.print("Sensor Value: ");

Serial.print(sensorValue);

Serial.print(" | Voltage: ");

Serial.println(voltage);

delay(500); // Wait for 500ms before the next reading

}

Notes:

- Replace the fixed resistor in the voltage divider circuit with a value close to the sensor's flat resistance (10 kΩ) for optimal performance.

- Use the

map()function in Arduino to convert the sensor readings into meaningful units (e.g., degrees of bending).

Troubleshooting and FAQs

Common Issues and Solutions

No Change in Sensor Output:

- Cause: Loose connections or damaged sensor.

- Solution: Check all connections and ensure the sensor is not physically damaged.

Inconsistent Readings:

- Cause: Electrical noise or improper mounting.

- Solution: Use a capacitor (e.g., 0.1 µF) across the sensor terminals to filter noise. Ensure the sensor is securely mounted.

Sensor Not Responding to Bends:

- Cause: Exceeding the sensor's bend angle or using an incorrect resistor value in the voltage divider.

- Solution: Ensure the bend angle is within the specified range and use a resistor value close to 10 kΩ.

FAQs

Q1: Can the Flex Sensor detect the direction of bending?

A1: No, the Flex Sensor only measures the degree of bending, not the direction. For directional sensing, additional sensors or configurations are required.

Q2: How do I extend the lifespan of the Flex Sensor?

A2: Avoid over-bending, handle the sensor carefully, and ensure proper mounting to reduce mechanical stress.

Q3: Can I use the Flex Sensor with a 3.3V microcontroller?

A3: Yes, the sensor can operate at 3.3V. However, ensure the voltage divider circuit is adjusted accordingly for accurate readings.

Q4: Is the Flex Sensor waterproof?

A4: No, the Flex Sensor is not waterproof. If used in environments with moisture, consider adding a protective covering.

By following this documentation, you can effectively integrate the Flex Sensor into your projects and troubleshoot common issues with ease.