How to Use Pololu S18V20F12 12V Step Up/Step Down: Examples, Pinouts, and Specs

Design with Pololu S18V20F12 12V Step Up/Step Down in Cirkit Designer

Design with Pololu S18V20F12 12V Step Up/Step Down in Cirkit DesignerIntroduction

The Pololu S18V20F12 is a highly versatile DC-DC converter designed to provide a stable 12V output from a wide range of input voltages. This step-up/step-down regulator is ideal for applications where the input voltage may vary above or below the desired output voltage. Its compact design and high efficiency make it suitable for powering a variety of electronic devices, including sensors, microcontrollers, and small motors.

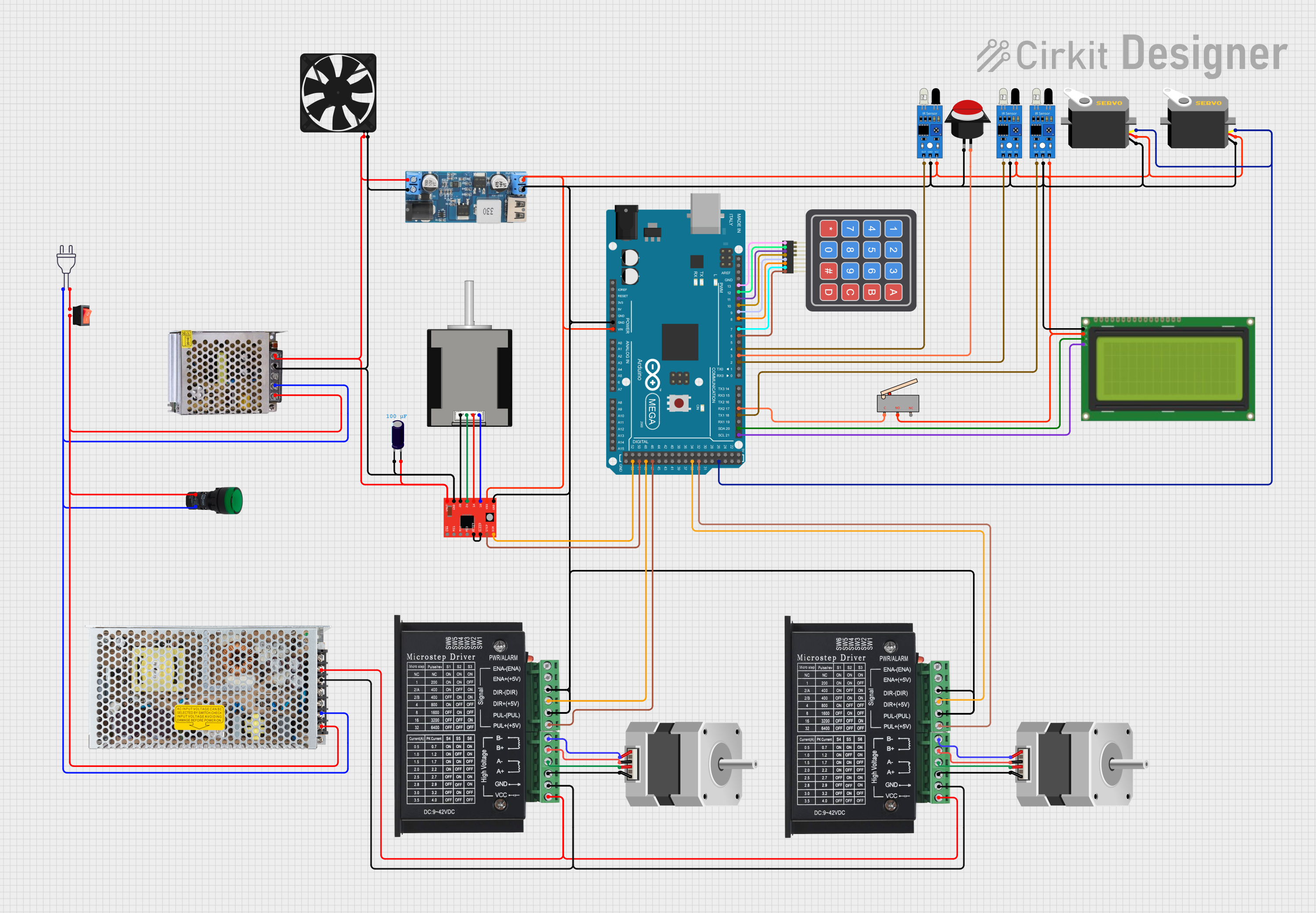

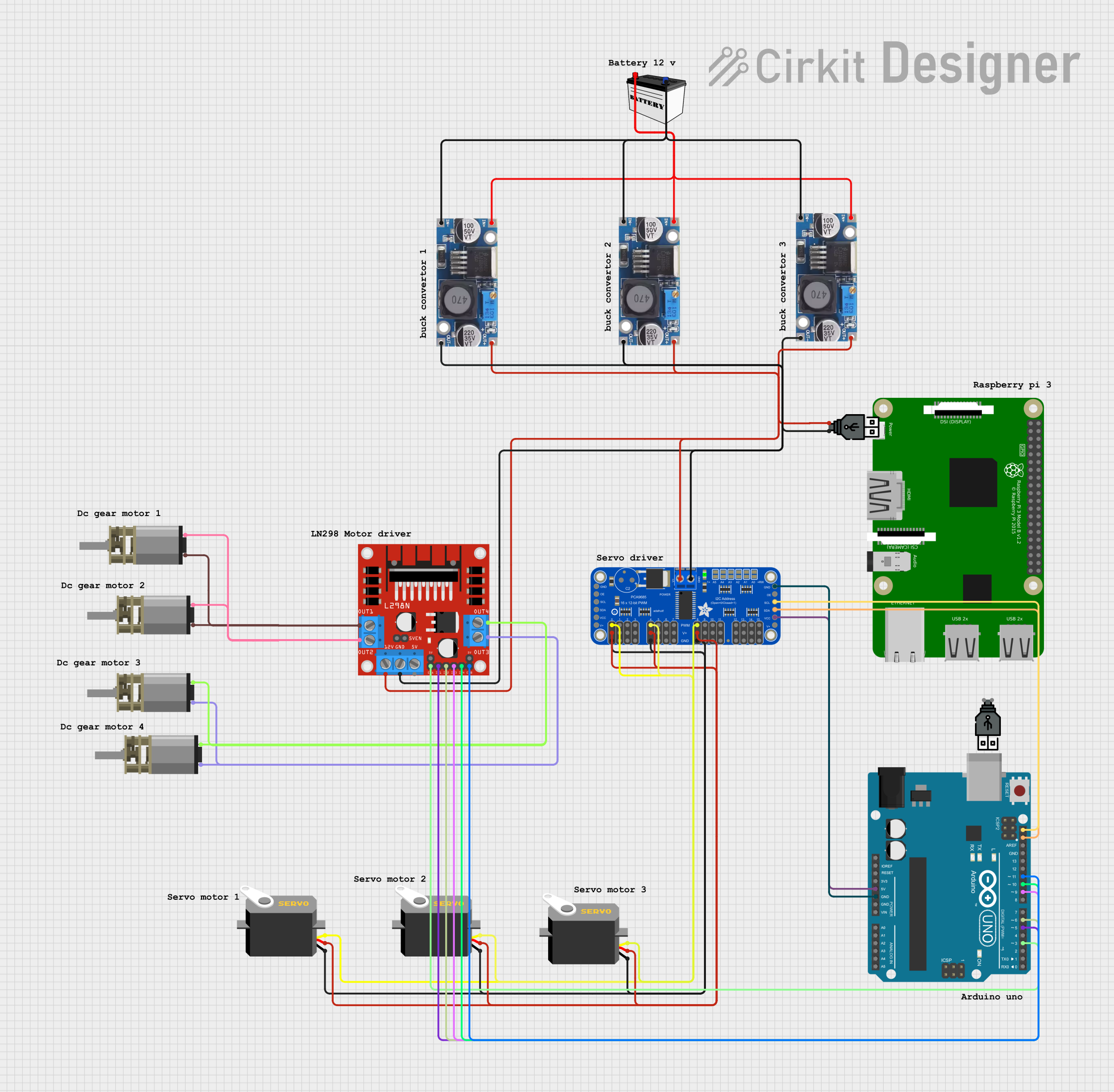

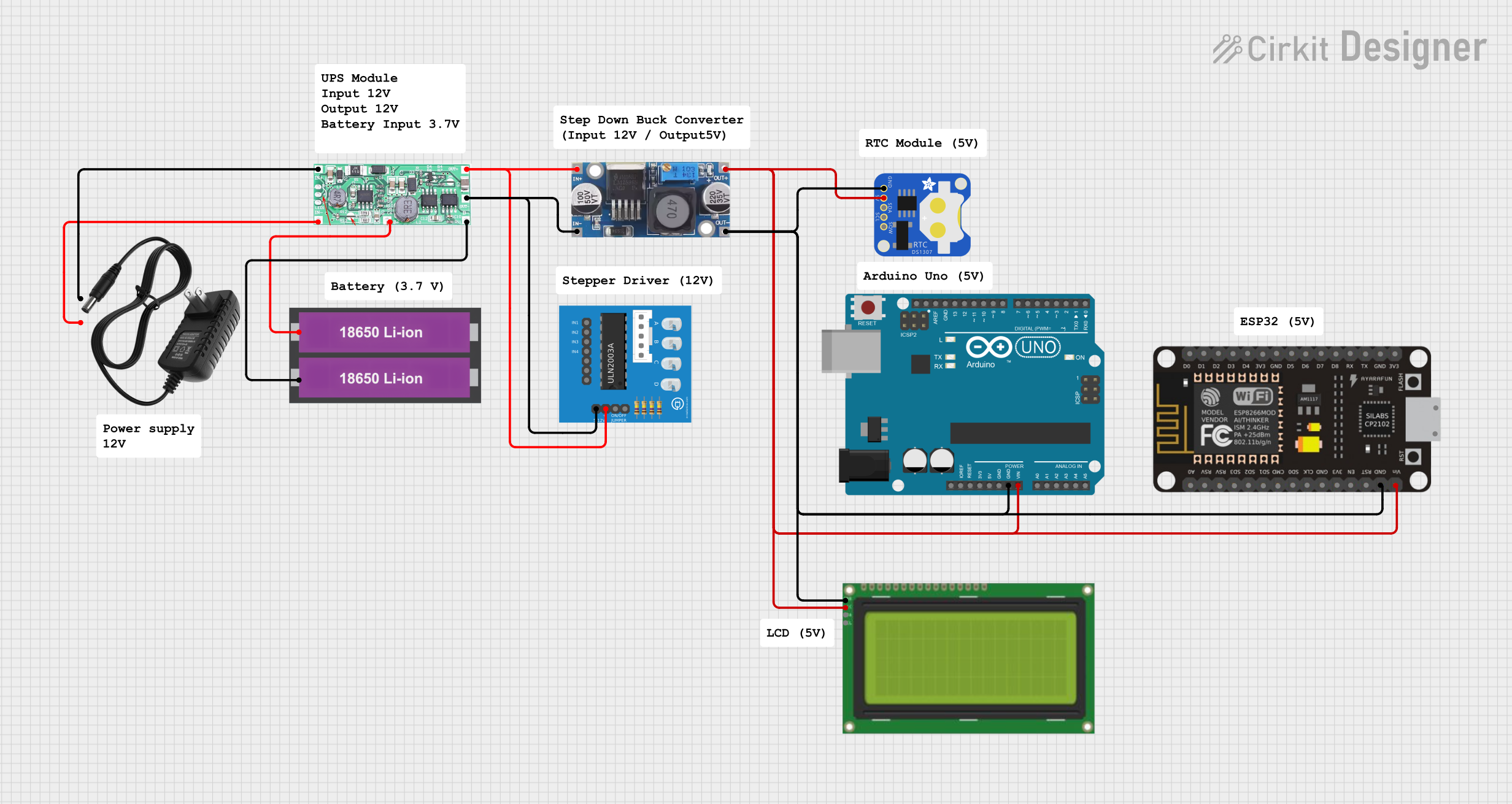

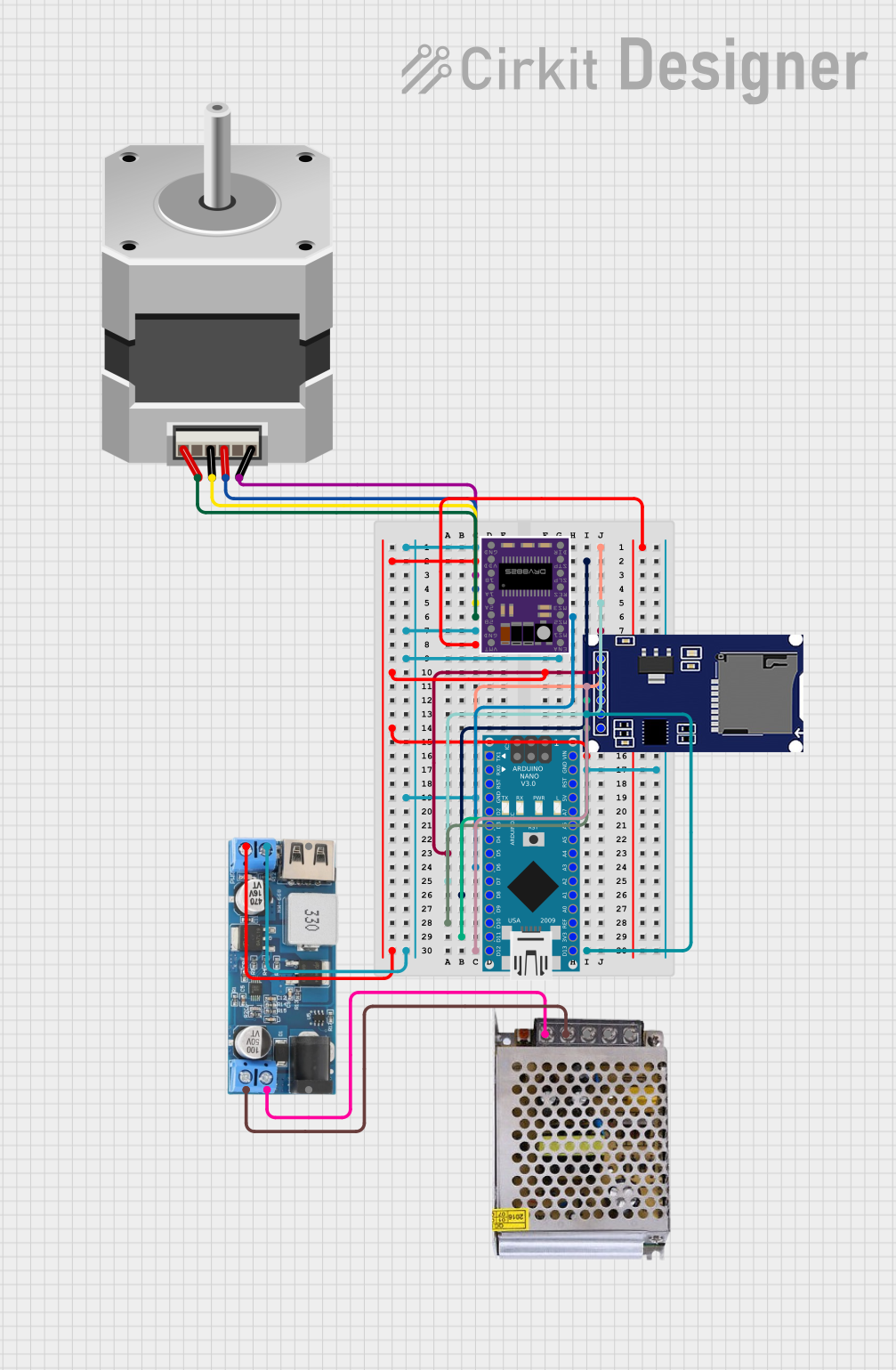

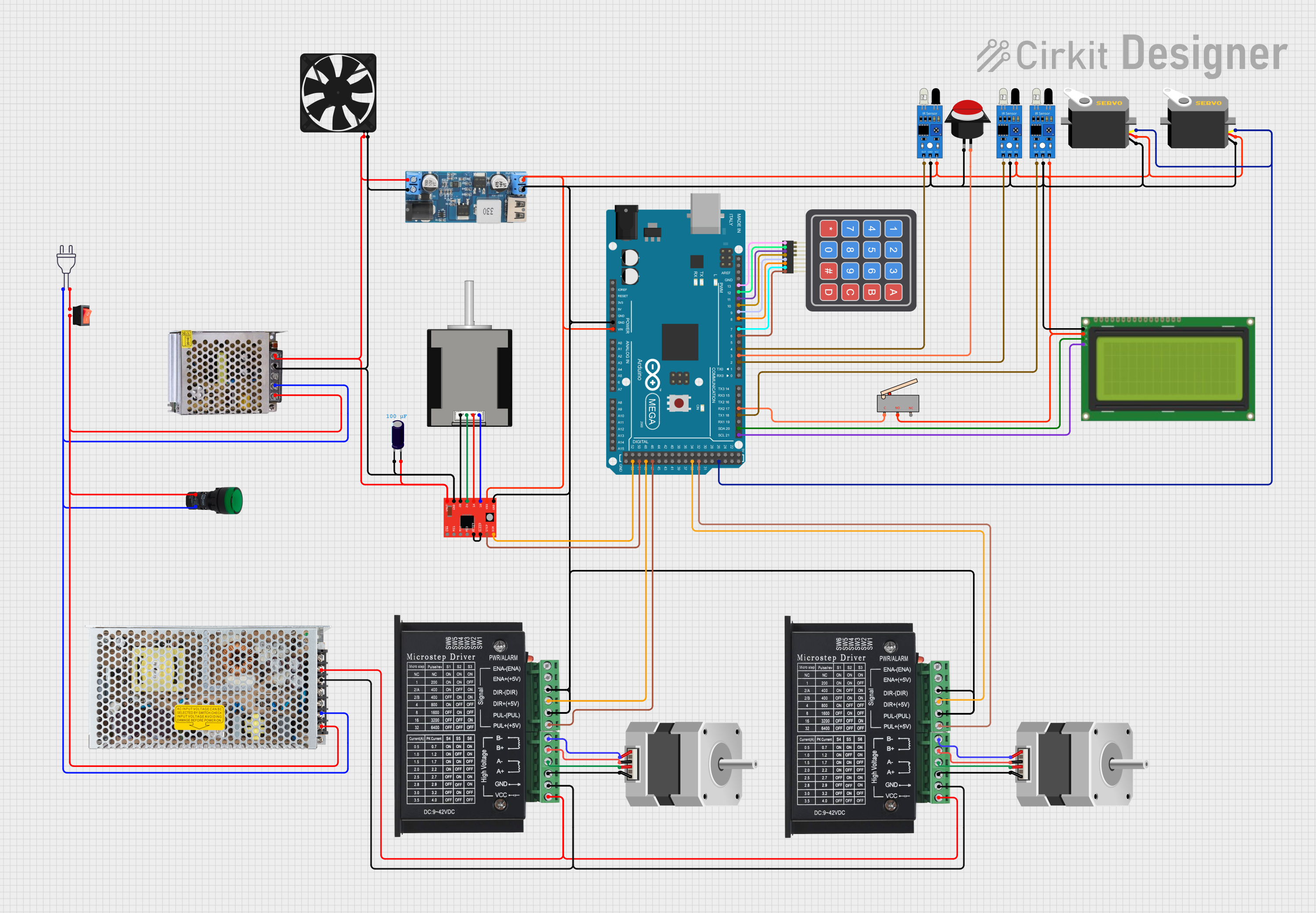

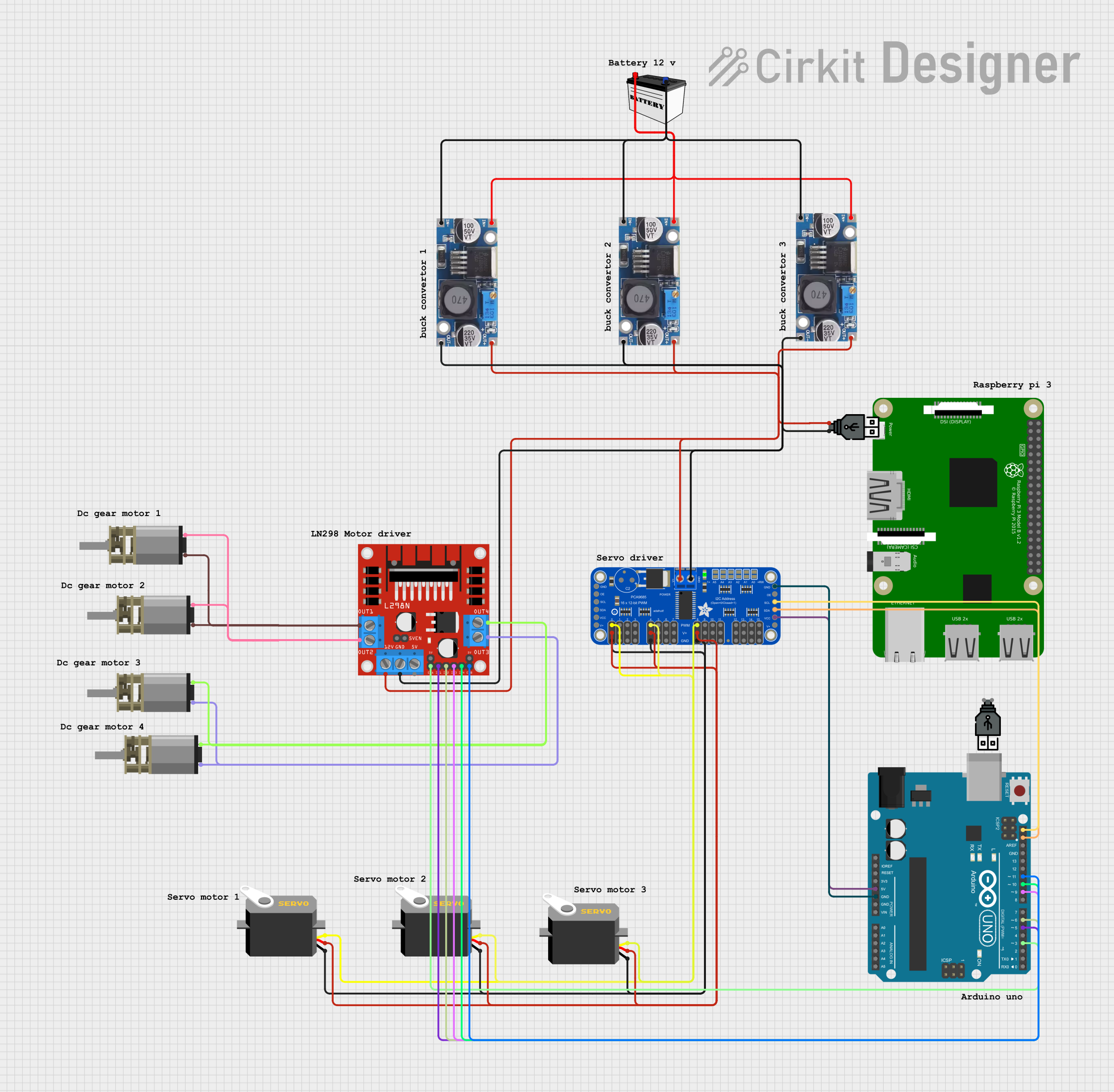

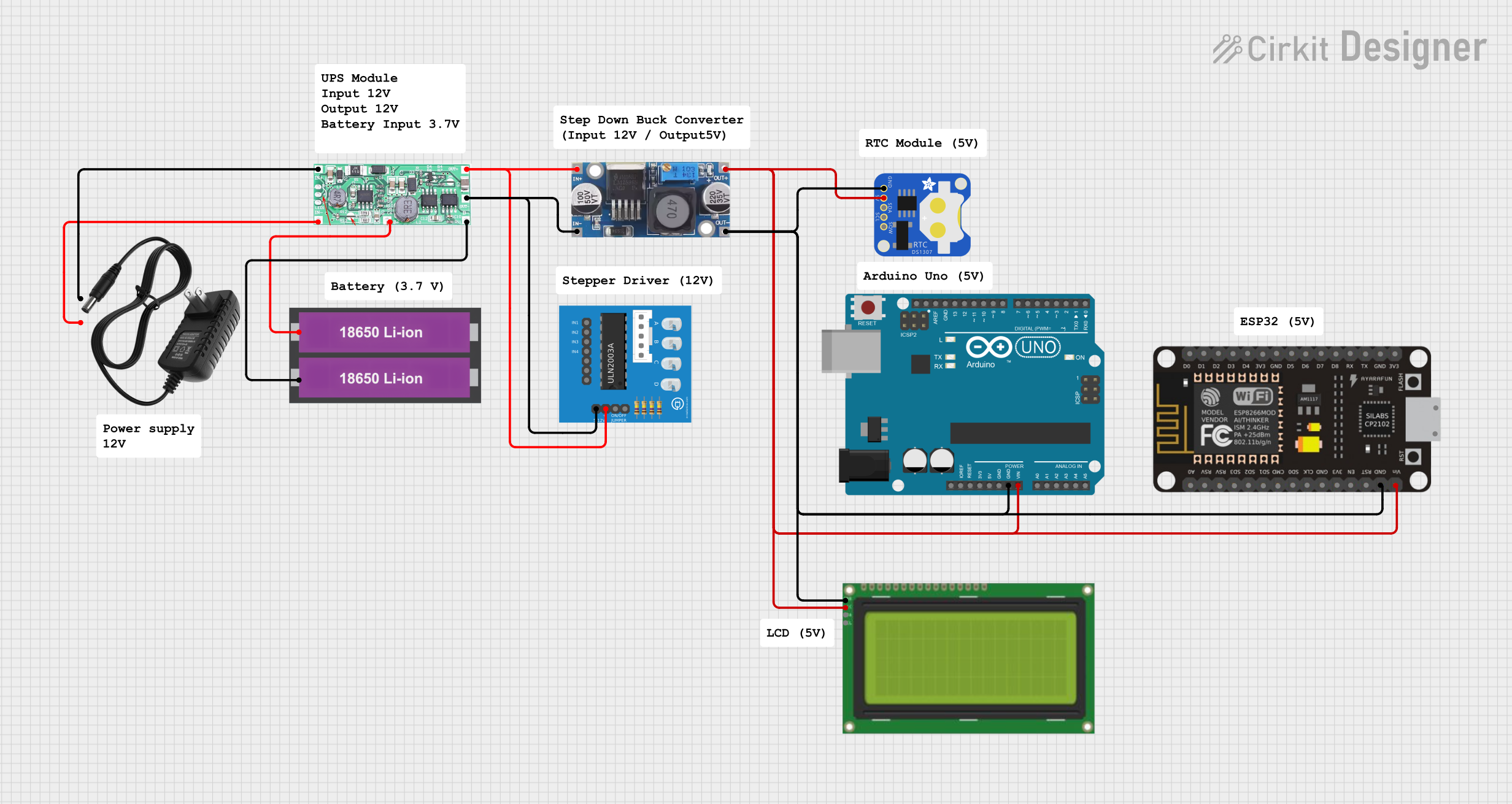

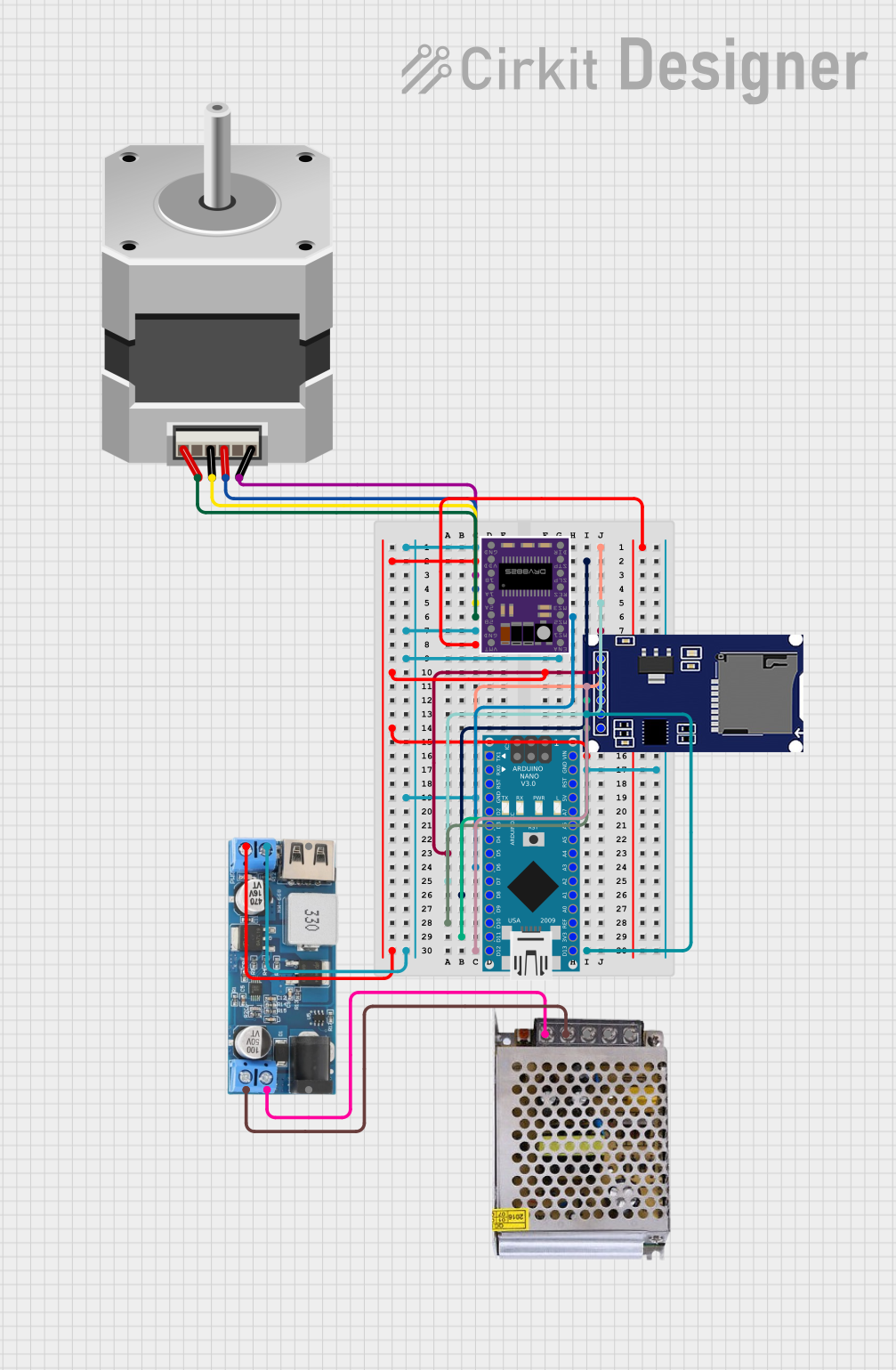

Explore Projects Built with Pololu S18V20F12 12V Step Up/Step Down

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit DesignerExplore Projects Built with Pololu S18V20F12 12V Step Up/Step Down

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit DesignerCommon Applications and Use Cases

- Powering 12V devices from batteries with varying voltage levels (e.g., LiPo, NiMH).

- Stabilizing voltage in automotive or solar-powered systems.

- Supplying power to microcontrollers, sensors, and communication modules.

- Robotics and portable electronics requiring a reliable 12V source.

Technical Specifications

The following table outlines the key technical details of the Pololu S18V20F12:

| Parameter | Value |

|---|---|

| Output Voltage | 12V (fixed) |

| Input Voltage Range | 2.8V to 32V |

| Maximum Output Current | 2A (continuous, depending on input voltage) |

| Efficiency | Up to 90% |

| Switching Frequency | ~400 kHz |

| Dimensions | 24.9 mm × 25.4 mm × 3.8 mm |

| Weight | 3.5 g |

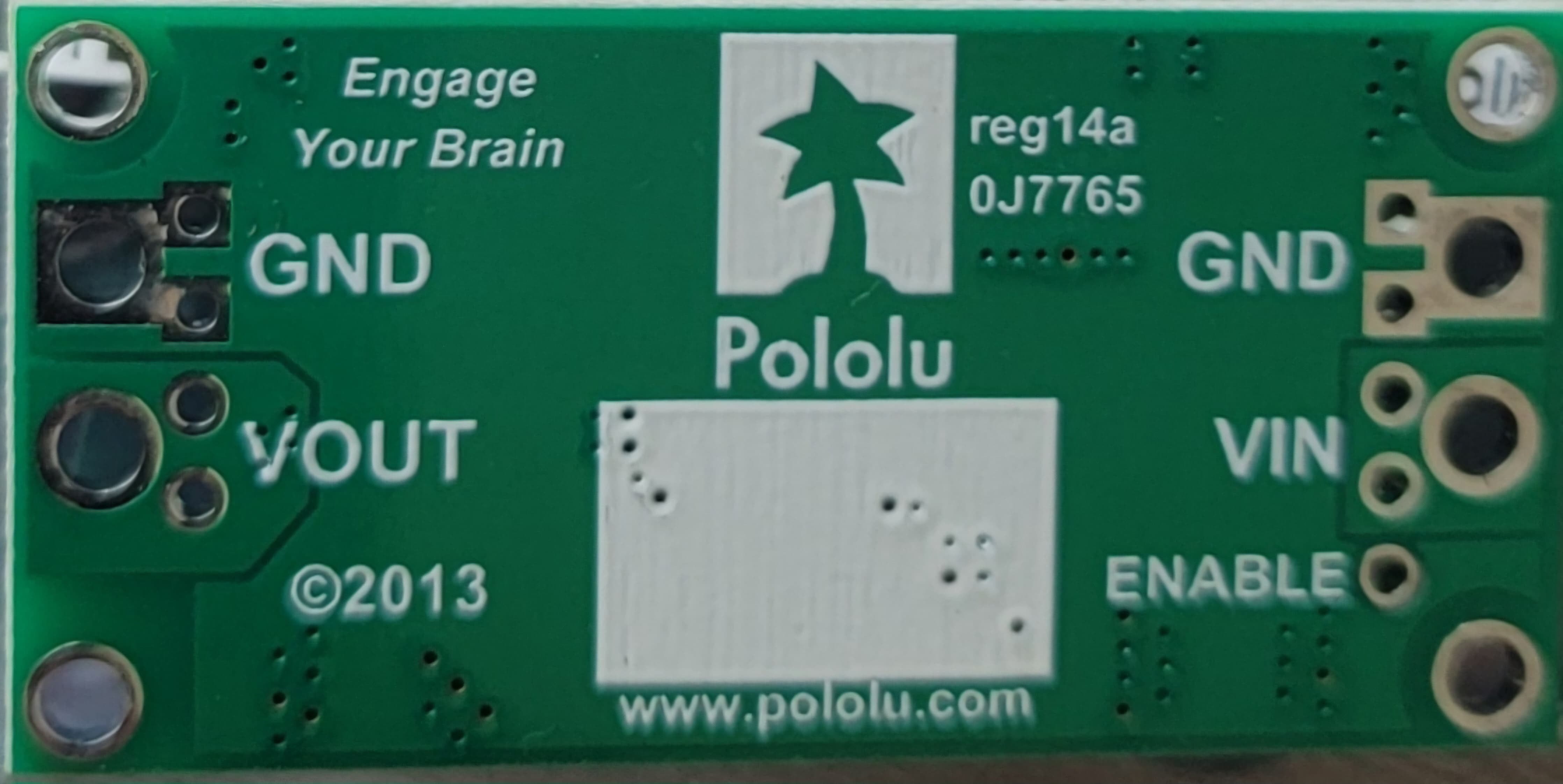

Pin Configuration and Descriptions

The Pololu S18V20F12 has six pins for easy integration into circuits. The table below describes each pin:

| Pin Name | Description |

|---|---|

| VIN | Input voltage pin (2.8V to 32V). Connect to the positive terminal of the power source. |

| GND | Ground pin. Connect to the negative terminal of the power source. |

| VOUT | Regulated 12V output pin. Connect to the load requiring 12V. |

| SHDN | Shutdown pin. Drive low (0V) to disable the regulator; leave floating or high to enable. |

| PG | Power good indicator. Outputs high when the output voltage is in regulation. |

| FB | Feedback pin. Used for advanced configurations (leave unconnected for default). |

Usage Instructions

How to Use the Component in a Circuit

Connect the Input Voltage:

- Connect the VIN pin to the positive terminal of your power source (e.g., battery or power supply).

- Connect the GND pin to the negative terminal of your power source.

Connect the Output Voltage:

- Connect the VOUT pin to the positive terminal of your load (e.g., a 12V device).

- Ensure the load's ground is connected to the GND pin.

Optional Connections:

- Use the SHDN pin to enable or disable the regulator. Leave it floating or connect it to VIN to enable the regulator. Pull it to GND to disable it.

- The PG pin can be used to monitor the output voltage status. It outputs a high signal when the output is stable.

- The FB pin is for advanced users who need to adjust the feedback loop. For standard operation, leave it unconnected.

Power On:

- Once all connections are secure, power on the input source. The regulator will provide a stable 12V output.

Important Considerations and Best Practices

- Input Voltage Range: Ensure the input voltage stays within the 2.8V to 32V range to avoid damaging the regulator.

- Heat Dissipation: At high currents, the regulator may generate heat. Consider adding a heatsink or improving airflow if the regulator becomes too warm.

- Current Limitations: The maximum output current depends on the input voltage. For example, at lower input voltages, the regulator may not provide the full 2A output.

- Capacitors: Add input and output capacitors close to the regulator to improve stability and reduce noise. A 10 µF capacitor is recommended on both VIN and VOUT.

Example: Using with an Arduino UNO

The Pololu S18V20F12 can be used to power an Arduino UNO from a battery. Below is an example circuit and code:

Circuit Connections

- Connect the VIN pin to the positive terminal of a 9V battery.

- Connect the GND pin to the negative terminal of the battery.

- Connect the VOUT pin to the Arduino UNO's VIN pin.

- Connect the GND pin to the Arduino UNO's GND pin.

Arduino Code Example

// Example code to blink an LED connected to pin 13 on the Arduino UNO

// Ensure the Pololu S18V20F12 is providing a stable 12V to the Arduino's VIN pin

void setup() {

pinMode(13, OUTPUT); // Set pin 13 as an output

}

void loop() {

digitalWrite(13, HIGH); // Turn the LED on

delay(1000); // Wait for 1 second

digitalWrite(13, LOW); // Turn the LED off

delay(1000); // Wait for 1 second

}

Troubleshooting and FAQs

Common Issues and Solutions

No Output Voltage:

- Check the input voltage. Ensure it is within the 2.8V to 32V range.

- Verify that the SHDN pin is not pulled low. Leave it floating or connect it to VIN.

Output Voltage is Unstable:

- Add capacitors (e.g., 10 µF) close to the VIN and VOUT pins to improve stability.

- Ensure the input power source can supply sufficient current.

Regulator Overheating:

- Reduce the load current if possible.

- Improve cooling by adding a heatsink or increasing airflow around the regulator.

PG Pin Not High:

- Check the load and ensure it is not drawing more current than the regulator can provide.

- Verify that the input voltage is stable and within range.

FAQs

Q: Can I adjust the output voltage?

A: No, the Pololu S18V20F12 provides a fixed 12V output. For adjustable output, consider other Pololu regulators.

Q: What happens if the input voltage exceeds 32V?

A: Exceeding 32V can damage the regulator. Use a voltage clamp or protection circuit to prevent overvoltage.

Q: Can I use this regulator with a solar panel?

A: Yes, as long as the solar panel's output voltage stays within the 2.8V to 32V range and provides sufficient current.

Q: Is reverse polarity protection included?

A: No, the regulator does not have built-in reverse polarity protection. Use a diode or other protection circuit to prevent damage.