How to Use Basler a2A1920-51gcPro: Examples, Pinouts, and Specs

Design with Basler a2A1920-51gcPro in Cirkit Designer

Design with Basler a2A1920-51gcPro in Cirkit DesignerIntroduction

The Basler a2A1920-51gcPro is a high-performance industrial camera designed for demanding machine vision applications. Manufactured by Basler, this camera offers exceptional image quality and reliability, making it a popular choice for automation, quality inspection, and object recognition tasks. With its 1920x1200 pixel resolution, global shutter technology, and GigE interface, the a2A1920-51gcPro is capable of capturing fast-moving objects with precision and transferring data at high speeds.

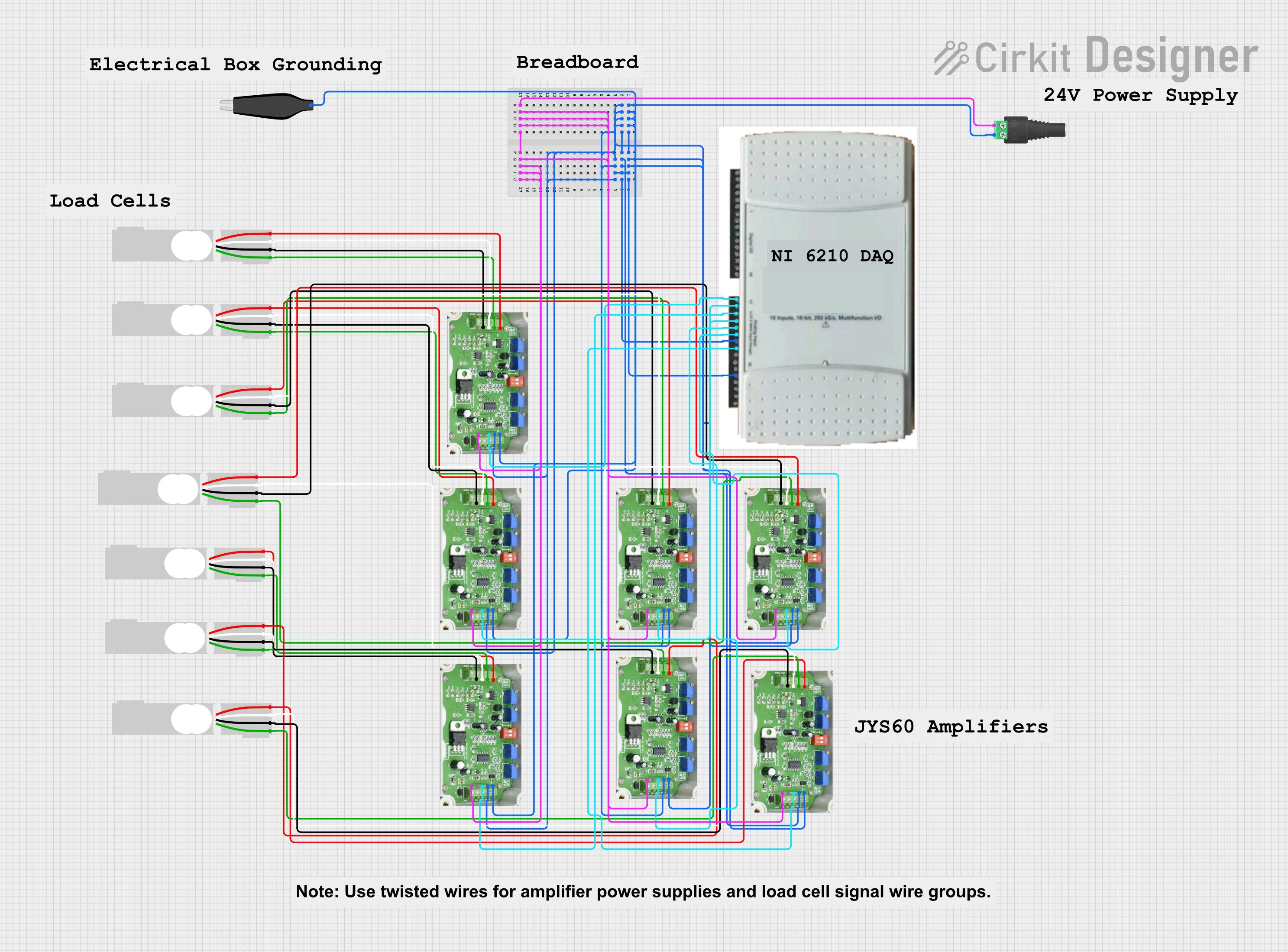

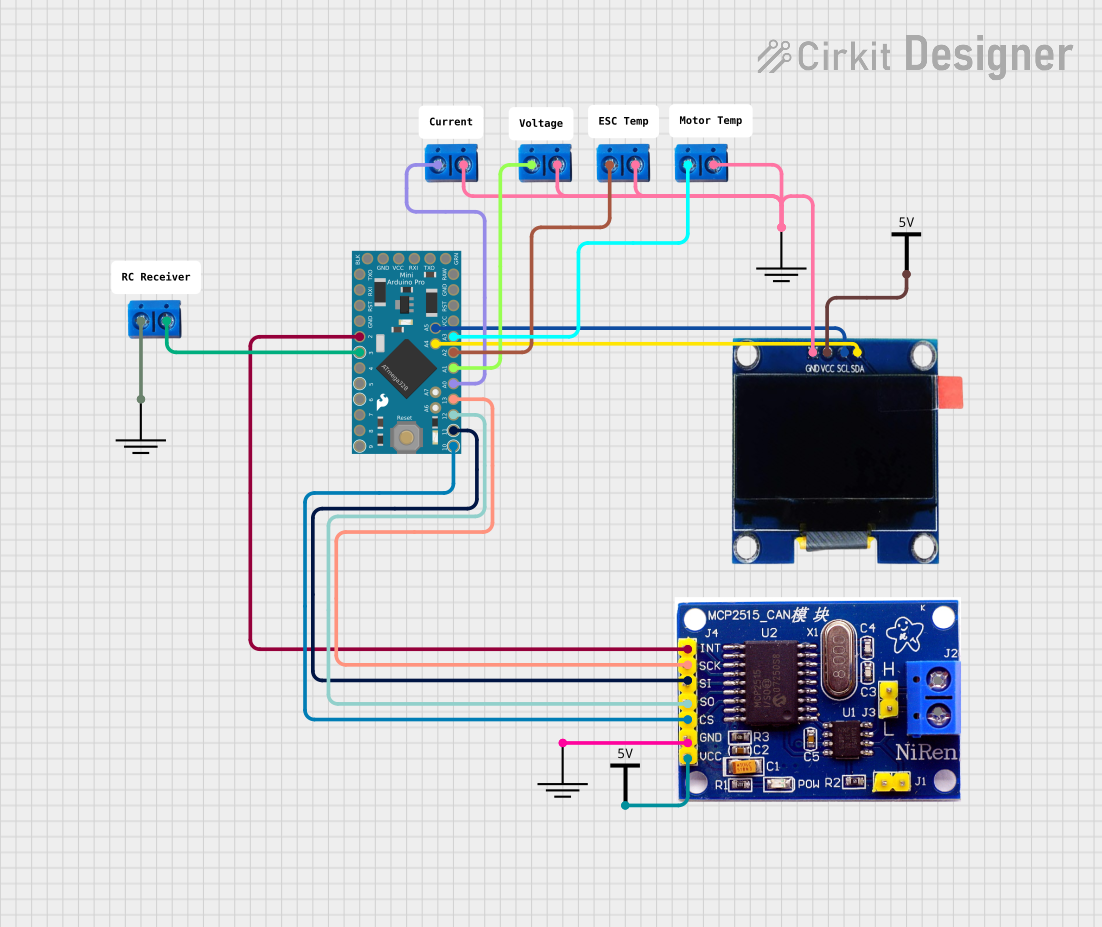

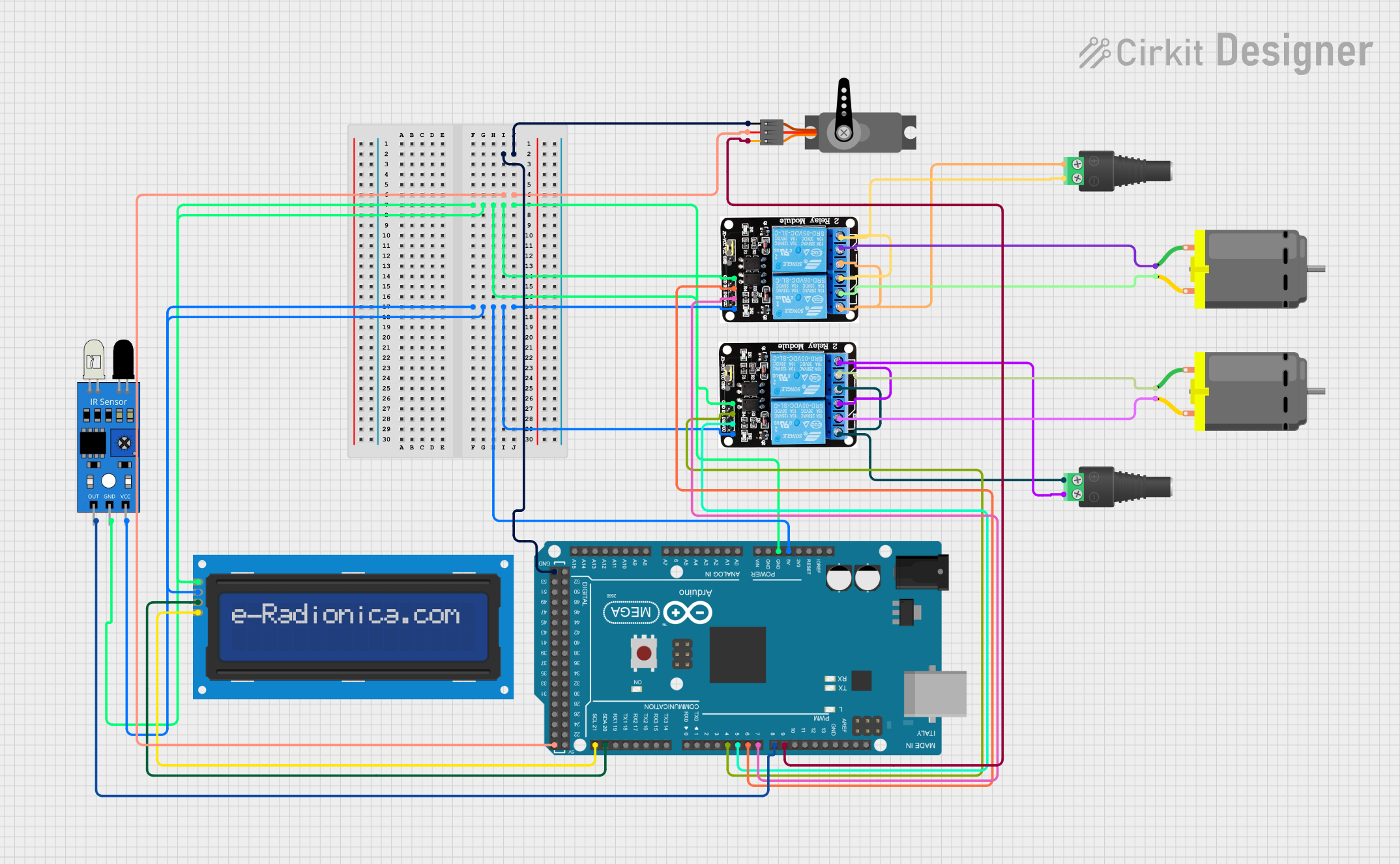

Explore Projects Built with Basler a2A1920-51gcPro

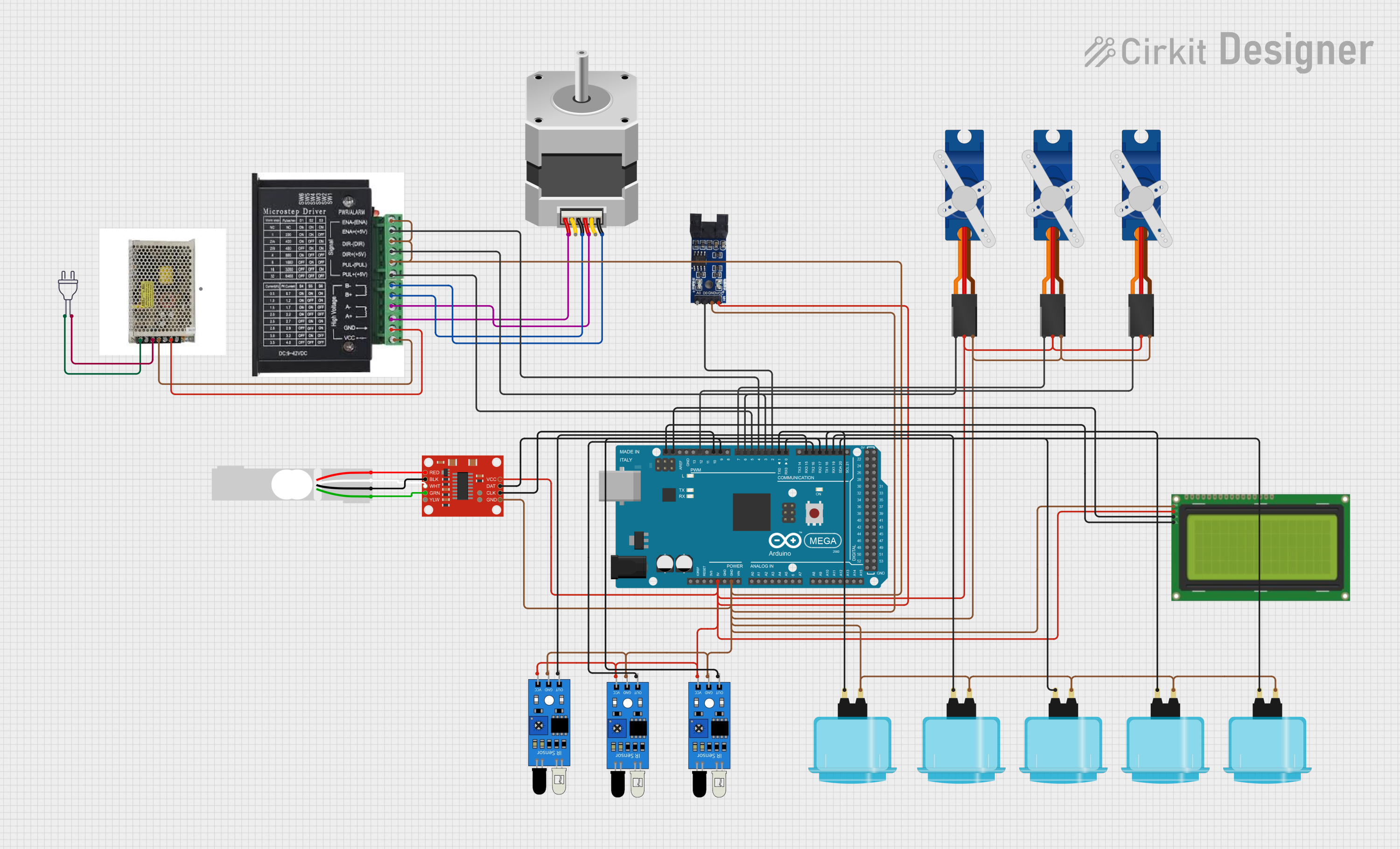

Open Project in Cirkit Designer

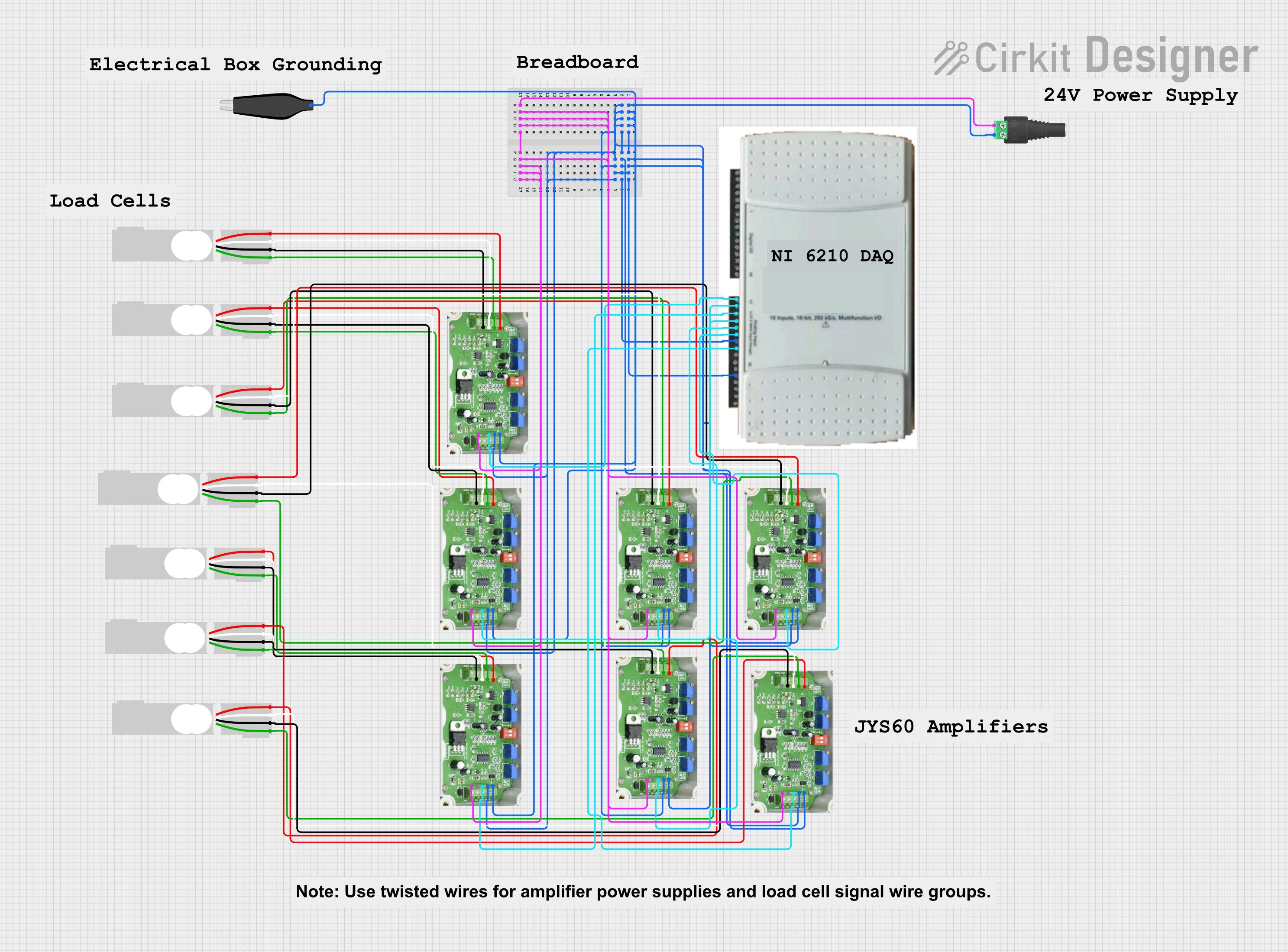

Open Project in Cirkit Designer

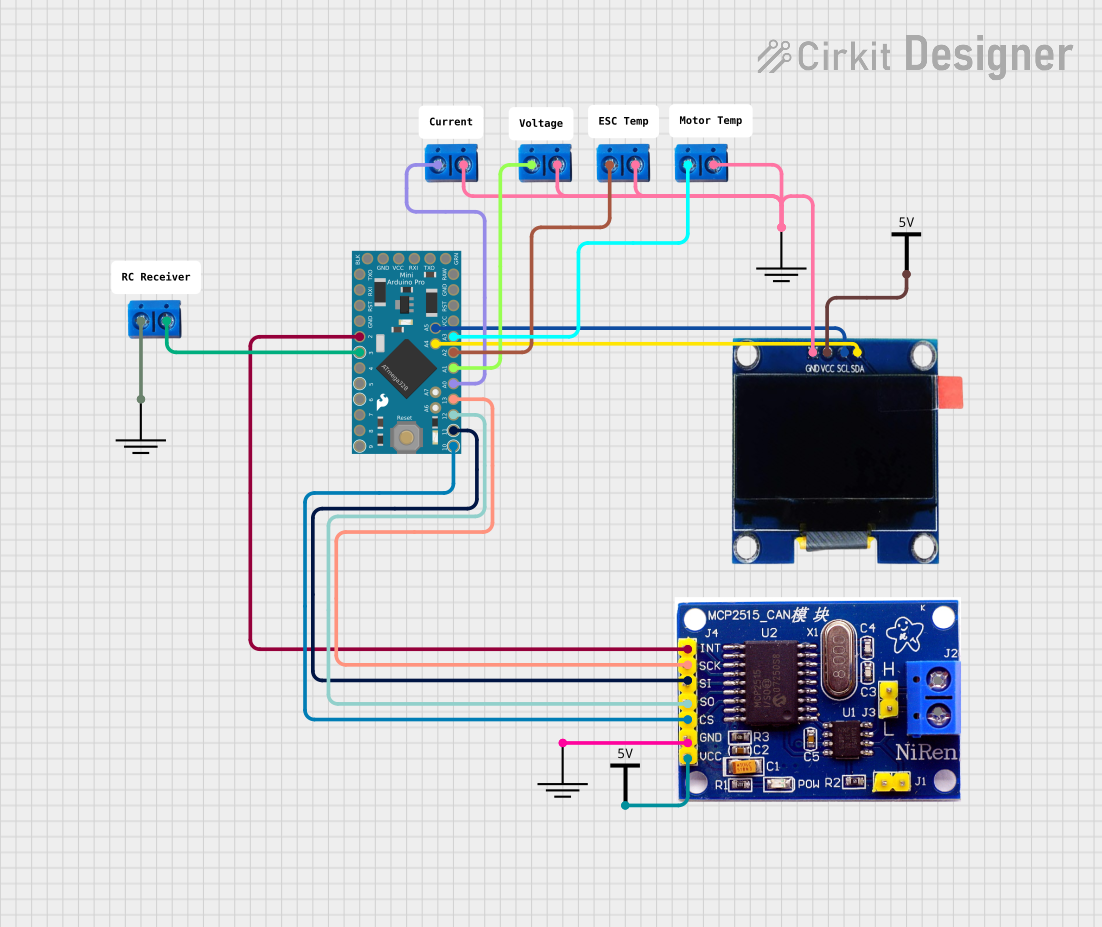

Open Project in Cirkit Designer

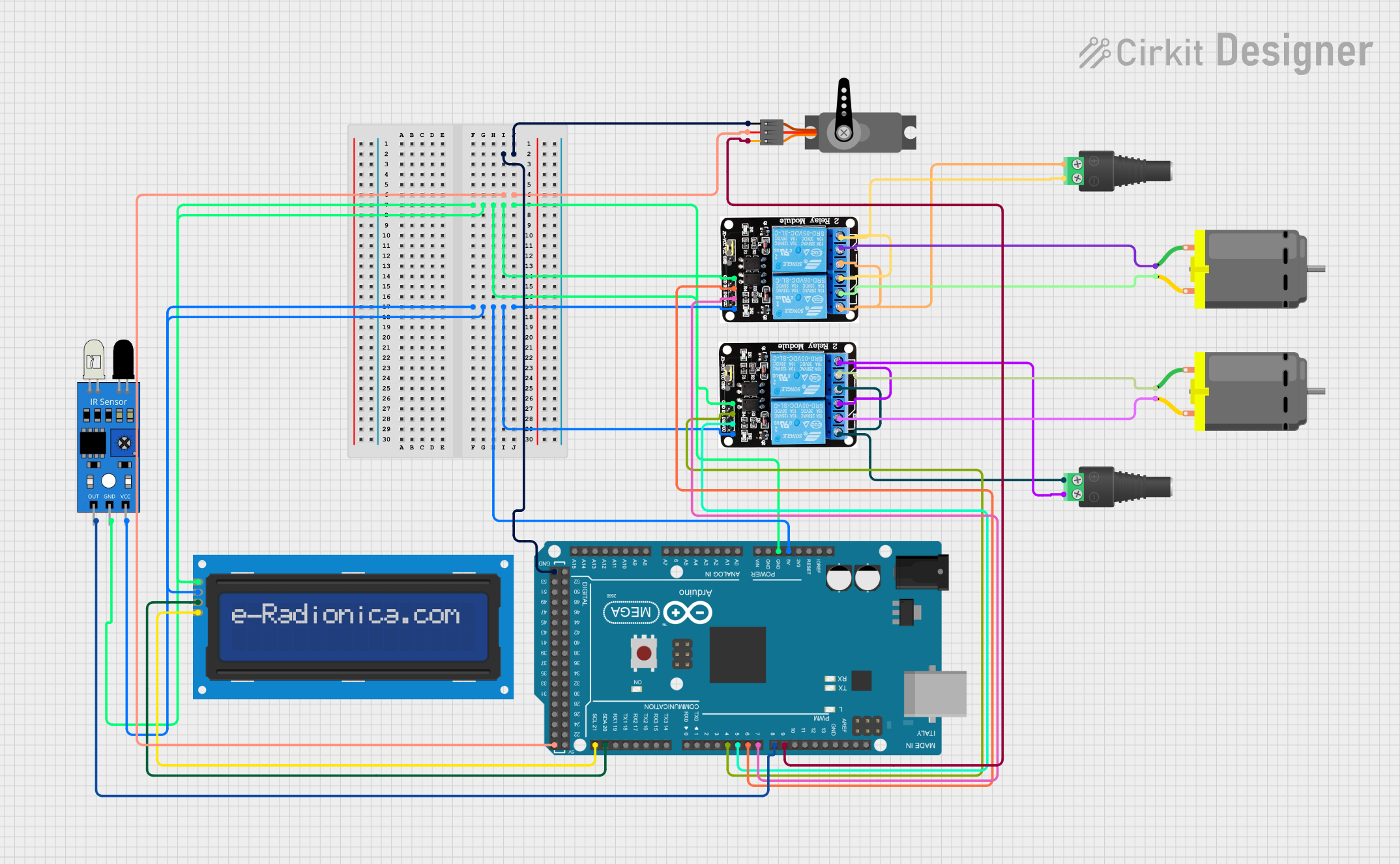

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit DesignerExplore Projects Built with Basler a2A1920-51gcPro

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit DesignerCommon Applications and Use Cases

- Quality Inspection: Detecting defects or irregularities in manufacturing processes.

- Object Recognition: Identifying and classifying objects in industrial automation systems.

- Robotics: Enabling vision-guided robotic systems for precise operations.

- Medical Imaging: Supporting diagnostic equipment with high-resolution imaging.

- Traffic Monitoring: Capturing high-speed vehicles for traffic enforcement or analysis.

Technical Specifications

The following table outlines the key technical details of the Basler a2A1920-51gcPro:

| Specification | Details |

|---|---|

| Resolution | 1920 x 1200 pixels (2.3 MP) |

| Sensor Type | CMOS with global shutter |

| Frame Rate | Up to 51 frames per second (fps) |

| Pixel Size | 5.86 µm x 5.86 µm |

| Interface | Gigabit Ethernet (GigE) |

| Lens Mount | C-mount |

| Power Supply | Power over Ethernet (PoE) or external 12-24V DC |

| Operating Temperature | -20°C to 65°C |

| Dimensions | 29 mm x 29 mm x 42 mm |

| Weight | Approx. 90 g |

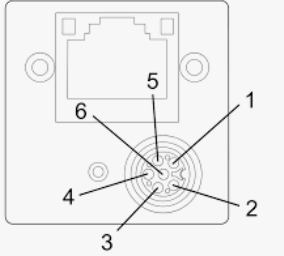

Pin Configuration and Descriptions

The Basler a2A1920-51gcPro uses a standard GigE interface for data transfer and power. Below is the pin configuration for the I/O connector:

| Pin Number | Signal Name | Description |

|---|---|---|

| 1 | Power Input (VCC) | External power supply input (12-24V DC) |

| 2 | Ground (GND) | Ground connection |

| 3 | Trigger Input | External trigger signal for image capture |

| 4 | Strobe Output | Output signal for synchronizing external devices (e.g., flash) |

| 5 | GPIO1 | General-purpose input/output pin |

| 6 | GPIO2 | General-purpose input/output pin |

Usage Instructions

How to Use the Component in a Circuit

- Power Supply: Connect the camera to a Power over Ethernet (PoE) switch or provide an external 12-24V DC power supply to the power input pin.

- Data Connection: Use a Cat5e or Cat6 Ethernet cable to connect the camera to a computer or network switch.

- Lens Installation: Attach a compatible C-mount lens to the camera. Ensure the lens is securely fastened.

- Trigger and GPIO: If required, connect external devices (e.g., triggers, strobes) to the I/O connector using the pin configuration table above.

- Software Setup: Install Basler's pylon Camera Software Suite on your computer. This software provides tools for camera configuration, image acquisition, and development.

Important Considerations and Best Practices

- Lens Selection: Choose a lens with appropriate focal length and aperture for your application.

- Cable Length: For GigE connections, ensure the Ethernet cable length does not exceed 100 meters.

- Heat Management: Operate the camera within the specified temperature range (-20°C to 65°C) to avoid overheating.

- Trigger Configuration: Use the pylon software to configure trigger modes and GPIO functionality as needed.

- Firmware Updates: Regularly check for firmware updates on the Basler website to ensure optimal performance.

Example Code for Arduino UNO Integration

While the Basler a2A1920-51gcPro is typically used with PCs, it can also interface with microcontrollers like the Arduino UNO for basic trigger control. Below is an example of how to send a trigger signal to the camera:

// Example: Sending a trigger signal to the Basler a2A1920-51gcPro

// Connect Arduino pin 7 to the camera's Trigger Input pin (Pin 3 on I/O connector)

const int triggerPin = 7; // Define the Arduino pin connected to the camera trigger

void setup() {

pinMode(triggerPin, OUTPUT); // Set the trigger pin as an output

digitalWrite(triggerPin, LOW); // Initialize the trigger pin to LOW

}

void loop() {

// Send a HIGH pulse to trigger the camera

digitalWrite(triggerPin, HIGH);

delay(10); // Keep the signal HIGH for 10 milliseconds

digitalWrite(triggerPin, LOW);

// Wait for 1 second before sending the next trigger

delay(1000);

}

Note: Ensure the trigger voltage levels are compatible with the camera's input specifications.

Troubleshooting and FAQs

Common Issues and Solutions

No Image Output:

- Cause: Incorrect network configuration or cable connection.

- Solution: Verify the Ethernet cable connection and ensure the camera is detected in the pylon software.

Camera Overheating:

- Cause: Operating in a high-temperature environment.

- Solution: Use the camera within the specified temperature range and ensure proper ventilation.

Trigger Not Working:

- Cause: Incorrect trigger signal or configuration.

- Solution: Check the trigger voltage levels and configure the trigger mode in the pylon software.

Low Frame Rate:

- Cause: Network bandwidth limitations or incorrect settings.

- Solution: Use a dedicated GigE network and optimize camera settings in the pylon software.

FAQs

Q: Can the camera be powered solely via PoE?

- A: Yes, the camera supports Power over Ethernet (PoE) for both power and data transfer.

Q: What is the maximum cable length for GigE?

- A: The maximum cable length is 100 meters when using Cat5e or Cat6 Ethernet cables.

Q: Is the camera compatible with third-party software?

- A: Yes, the camera supports third-party software via the GenICam standard.

Q: Can the camera capture color images?

- A: Yes, the a2A1920-51gcPro is available in both monochrome and color variants.

This concludes the documentation for the Basler a2A1920-51gcPro. For further assistance, refer to the official Basler user manual or contact their technical support.