How to Use Servo: Examples, Pinouts, and Specs

Design with Servo in Cirkit Designer

Design with Servo in Cirkit DesignerIntroduction

A servo is a rotary actuator that allows for precise control of angular position, velocity, and acceleration. It consists of a motor coupled to a sensor for position feedback, along with a control circuit. Servos are widely used in robotics, automation, remote-controlled vehicles, and other applications requiring precise movement and positioning.

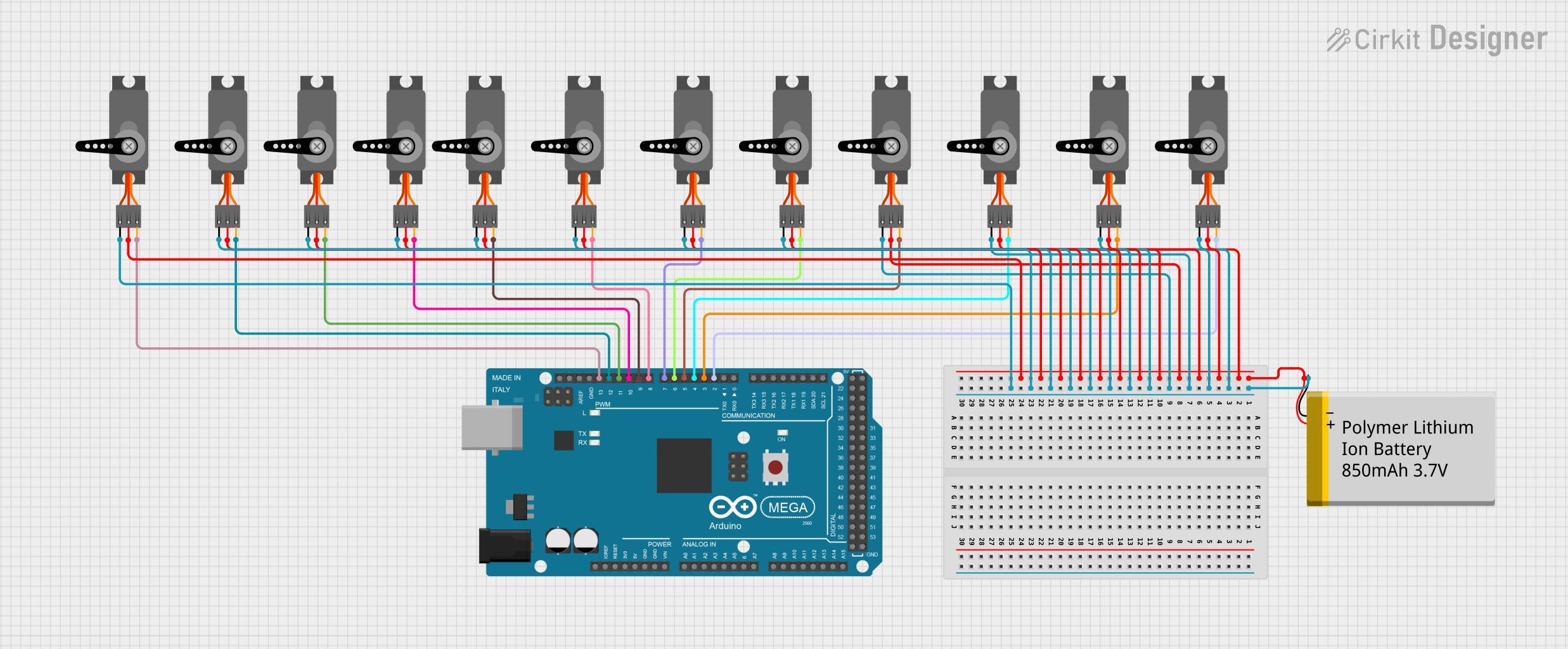

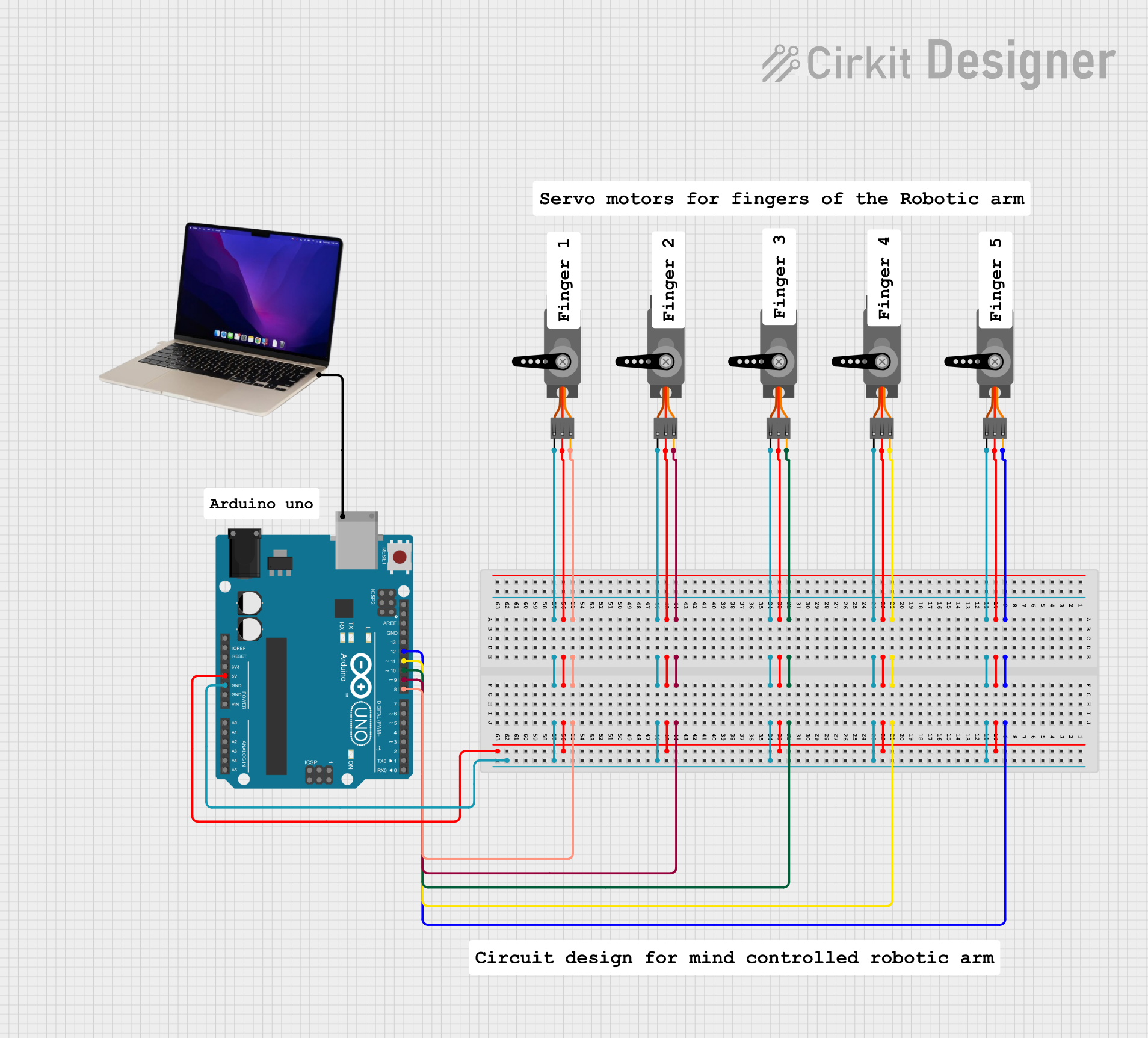

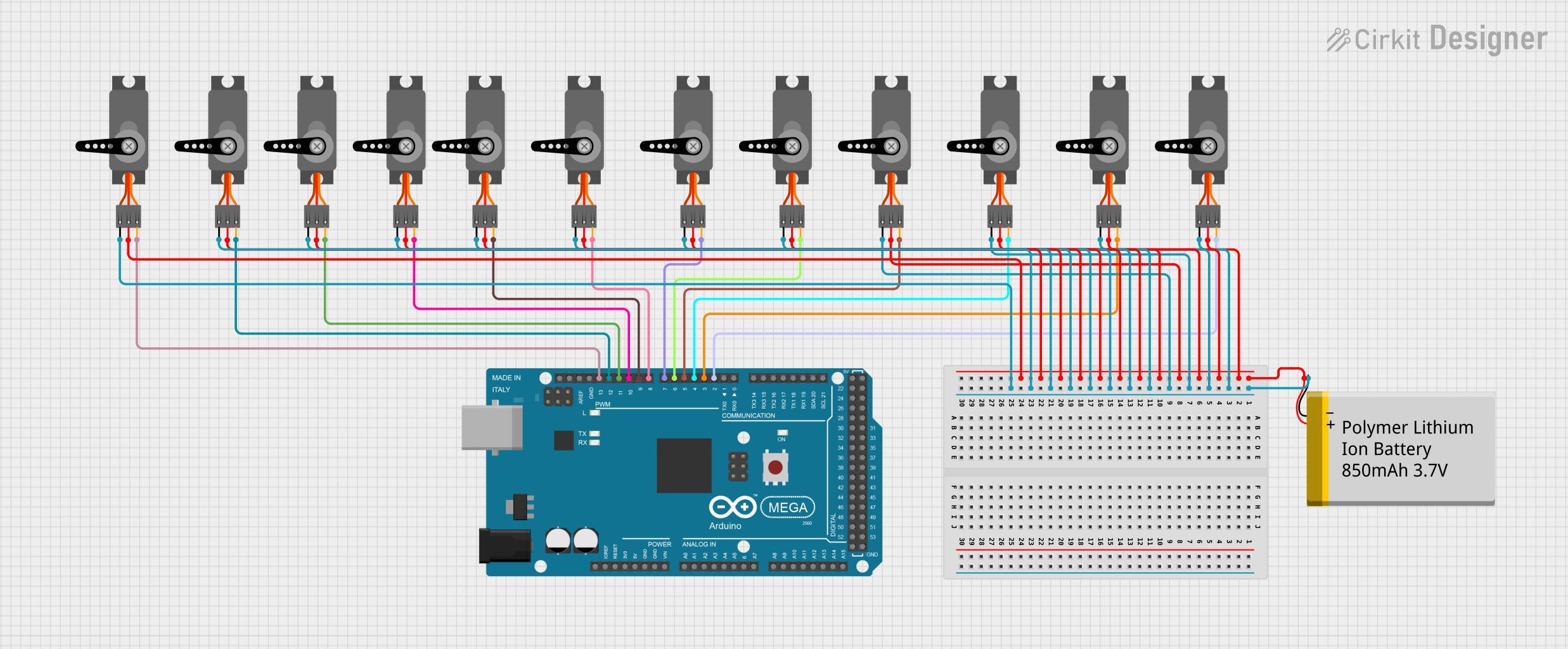

Explore Projects Built with Servo

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit DesignerExplore Projects Built with Servo

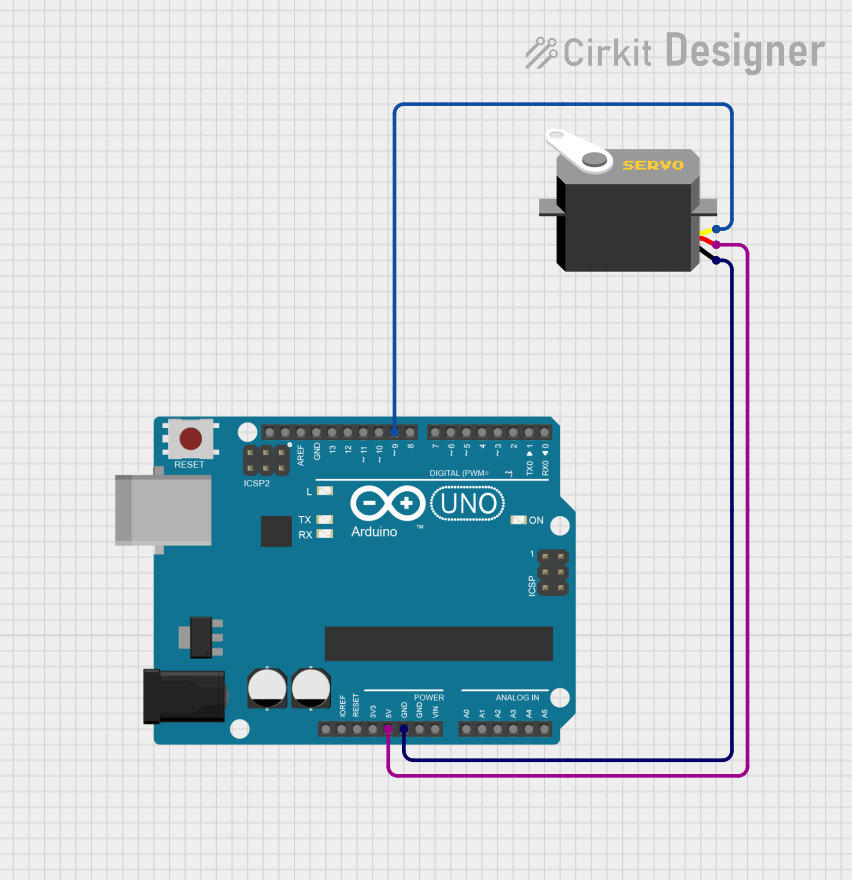

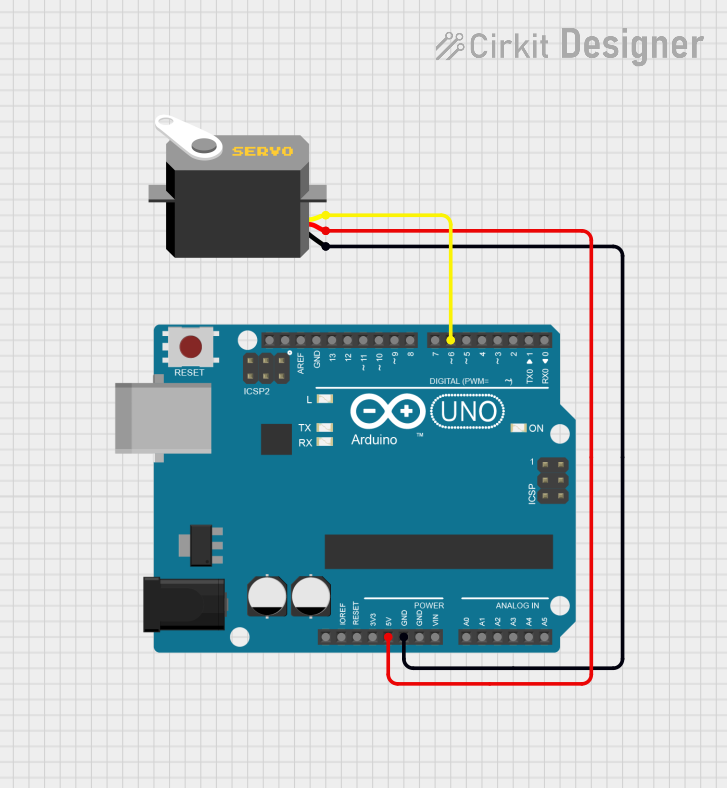

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit DesignerCommon Applications:

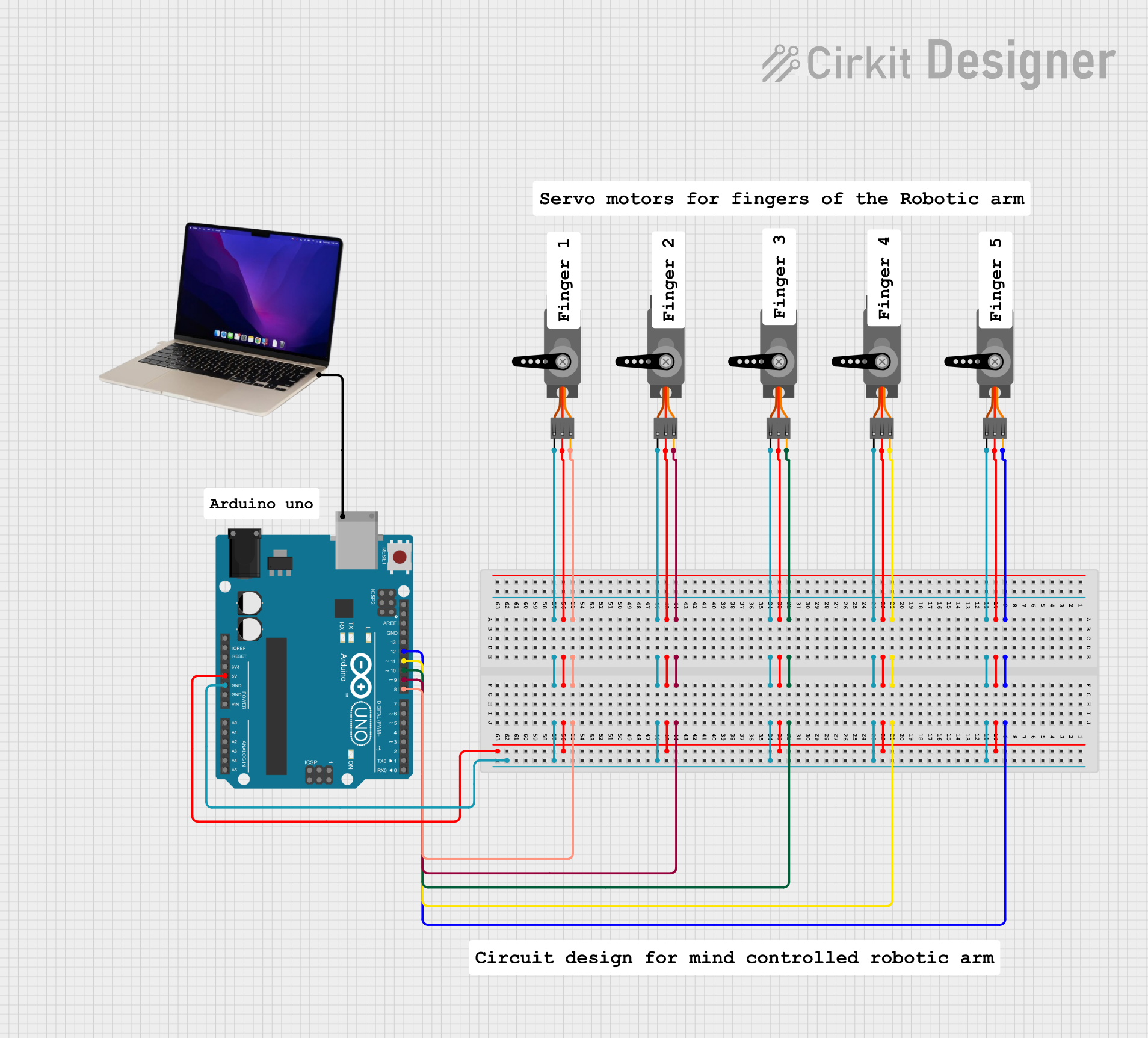

- Robotics: For controlling robotic arms, grippers, and joints.

- Remote-controlled vehicles: Steering mechanisms and throttle control.

- Automation: Conveyor belts, sorting systems, and other industrial machinery.

- Hobby projects: Model airplanes, boats, and cars.

- Camera gimbals: For stabilizing and positioning cameras.

Technical Specifications

Below are the general technical specifications for a standard hobby servo. Note that specifications may vary depending on the specific model and manufacturer.

Key Technical Details:

- Operating Voltage: 4.8V to 6V (typical range)

- Torque: 1.5 kg-cm to 20 kg-cm (varies by model)

- Speed: 0.1 to 0.2 seconds per 60° (at 6V)

- Control Signal: Pulse Width Modulation (PWM)

- Angle Range: 0° to 180° (standard), some models support 360° continuous rotation

- Connector Type: 3-pin (Signal, VCC, GND)

Pin Configuration:

The servo typically has a 3-pin connector with the following pinout:

| Pin Number | Name | Description |

|---|---|---|

| 1 | Signal | Receives PWM signal for position control |

| 2 | VCC | Power supply (4.8V to 6V) |

| 3 | GND | Ground connection |

Usage Instructions

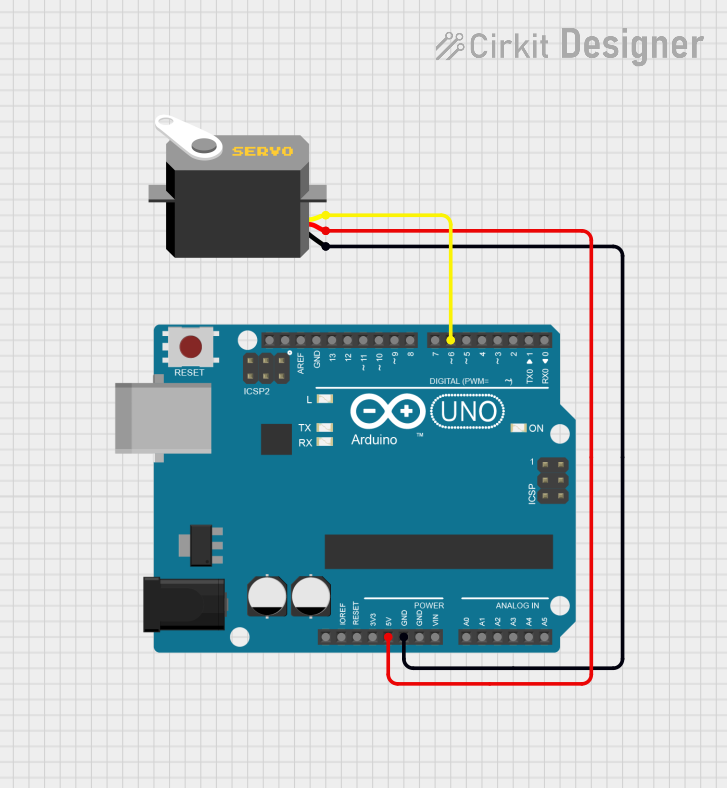

How to Use a Servo in a Circuit:

- Power the Servo: Connect the VCC pin to a 5V or 6V power source and the GND pin to the ground of your circuit.

- Control Signal: Connect the Signal pin to a microcontroller (e.g., Arduino) or a PWM signal generator.

- PWM Signal: Send a PWM signal to the Signal pin to control the servo's position. The pulse width determines the angle:

- A pulse width of ~1ms corresponds to 0°.

- A pulse width of ~1.5ms corresponds to 90° (center position).

- A pulse width of ~2ms corresponds to 180°.

Important Considerations:

- Power Supply: Use a separate power supply for the servo if it draws significant current, as it may cause voltage drops in your circuit.

- Signal Stability: Ensure the PWM signal is stable to avoid jittery movements.

- Avoid Overloading: Do not exceed the torque rating of the servo to prevent damage.

- Continuous Rotation Servos: For these models, the PWM signal controls speed and direction instead of position.

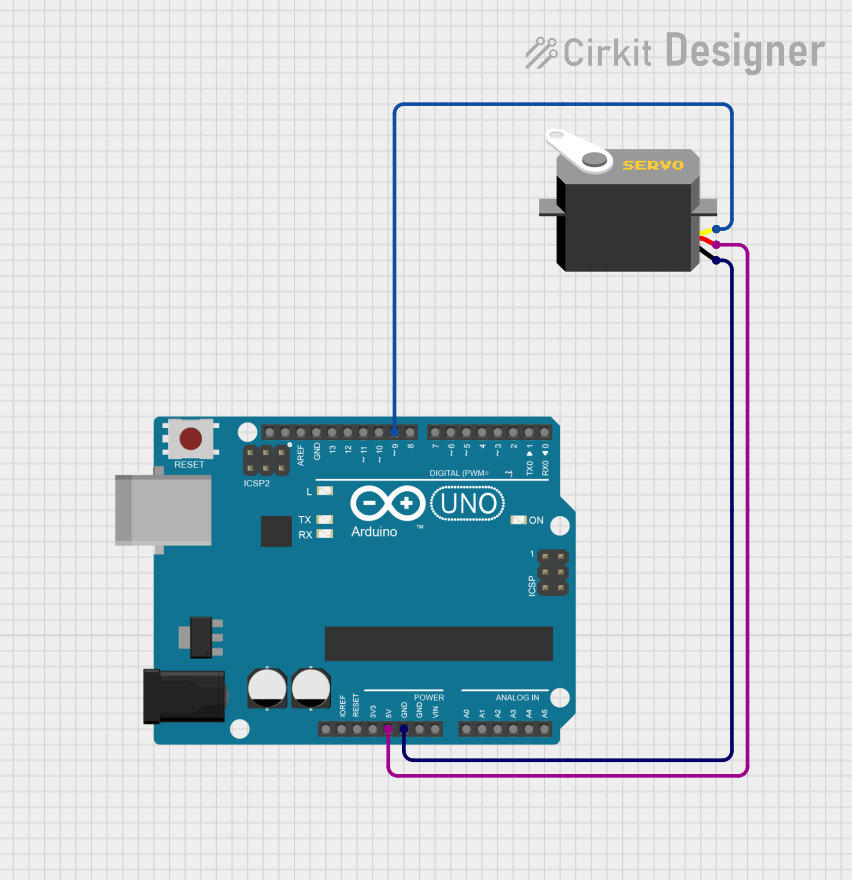

Example: Connecting a Servo to an Arduino UNO

Below is an example of how to control a servo using an Arduino UNO:

#include <Servo.h> // Include the Servo library

Servo myServo; // Create a Servo object

void setup() {

myServo.attach(9); // Attach the servo to pin 9 on the Arduino

}

void loop() {

myServo.write(0); // Move the servo to 0 degrees

delay(1000); // Wait for 1 second

myServo.write(90); // Move the servo to 90 degrees

delay(1000); // Wait for 1 second

myServo.write(180); // Move the servo to 180 degrees

delay(1000); // Wait for 1 second

}

Notes:

- Ensure the servo is connected to a suitable power source.

- Use a capacitor across the power supply to reduce noise and voltage fluctuations.

Troubleshooting and FAQs

Common Issues and Solutions:

Servo Not Moving:

- Cause: Incorrect wiring or insufficient power supply.

- Solution: Double-check the connections and ensure the power supply meets the servo's requirements.

Jittery Movements:

- Cause: Unstable PWM signal or electrical noise.

- Solution: Use a decoupling capacitor across the power supply and ensure the PWM signal is stable.

Overheating:

- Cause: Overloading the servo or running it continuously at high torque.

- Solution: Reduce the load on the servo or use a higher-torque model.

Limited Range of Motion:

- Cause: Mechanical obstruction or incorrect PWM signal.

- Solution: Check for physical obstructions and verify the PWM signal's pulse width.

FAQs:

Q: Can I control multiple servos with one Arduino?

A: Yes, you can control multiple servos using the Servo library. However, ensure the power supply can handle the combined current draw.Q: What happens if I exceed the torque rating?

A: Exceeding the torque rating can damage the servo's gears or motor. Always use a servo with a torque rating higher than your application's requirements.Q: Can I use a servo with a 3.3V microcontroller?

A: Yes, but you may need a level shifter to ensure the PWM signal is compatible with the servo's input requirements.Q: How do I know if my servo is a continuous rotation model?

A: Continuous rotation servos are typically labeled as such. Additionally, they will not stop at specific angles but instead vary speed and direction based on the PWM signal.

By following this documentation, you can effectively integrate and troubleshoot a servo in your projects!