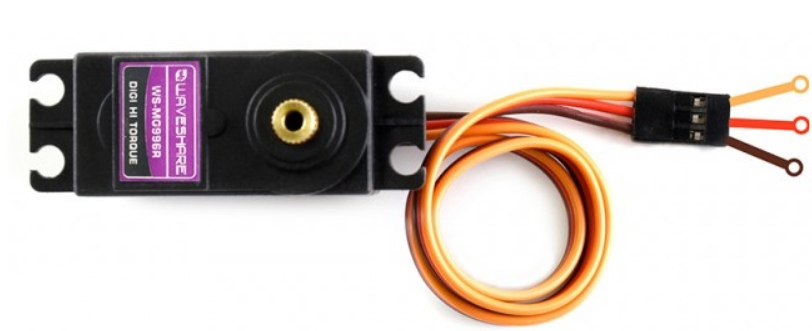

How to Use MG996R: Examples, Pinouts, and Specs

Design with MG996R in Cirkit Designer

Design with MG996R in Cirkit DesignerIntroduction

The MG996R is a robust high-torque digital servo motor widely used in the field of radio-controlled (RC) models, robotics, and automation. With its metal gears, the servo is designed for durability and can handle a substantial load, making it an ideal choice for applications requiring precise motion control and reliability. It is capable of rotating up to 180 degrees, offering a wide range of motion for various mechanical setups.

Explore Projects Built with MG996R

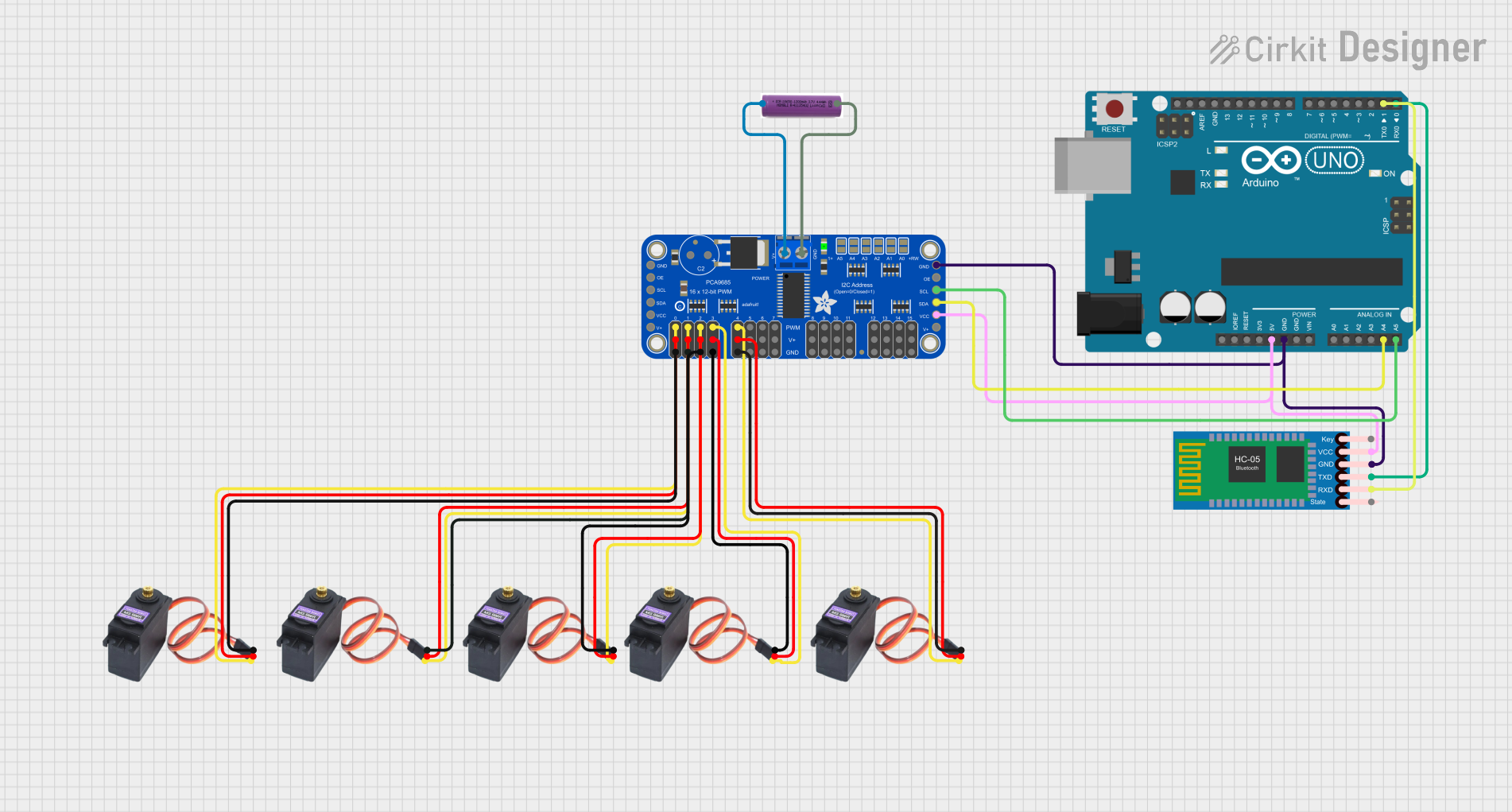

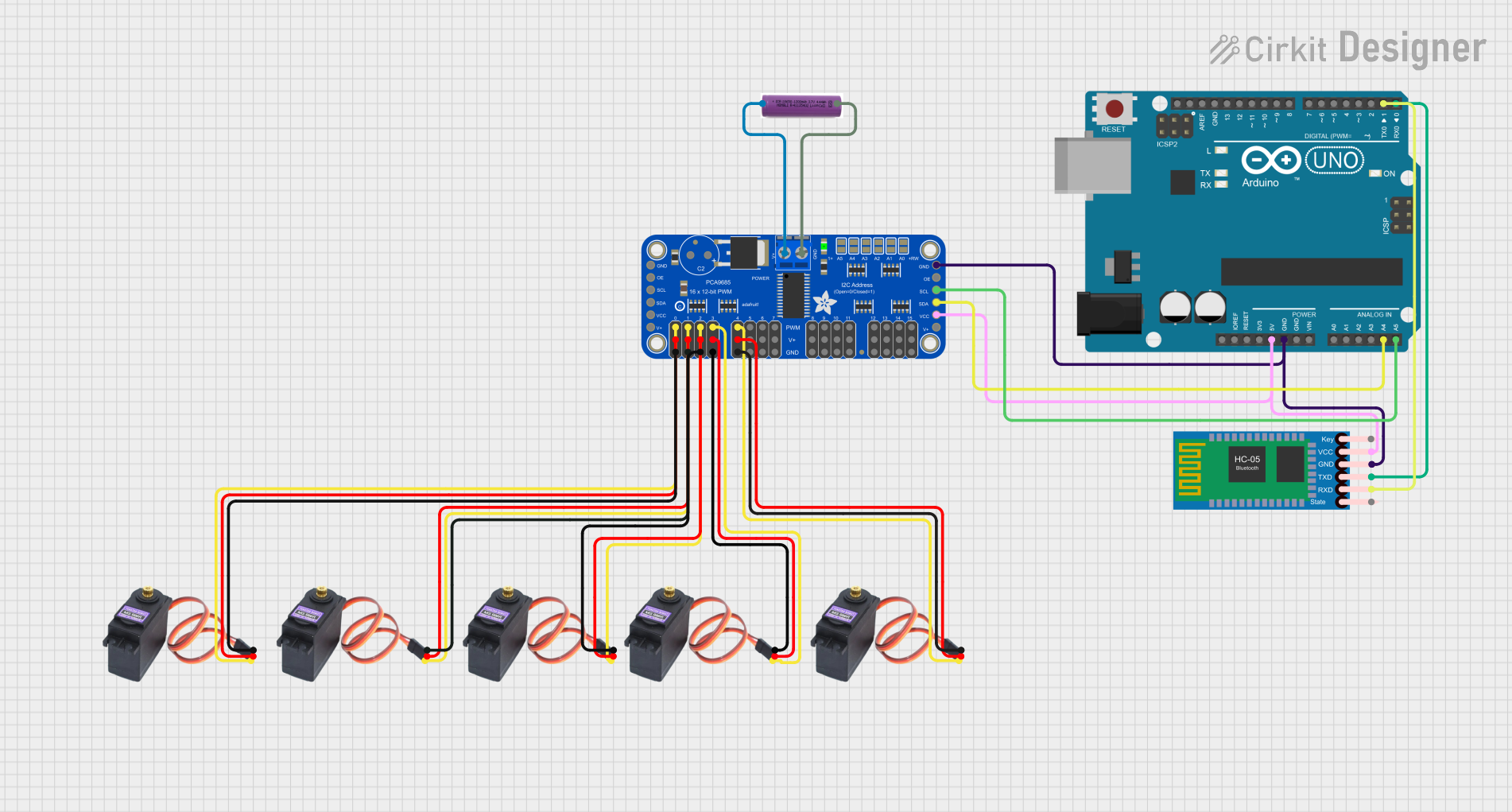

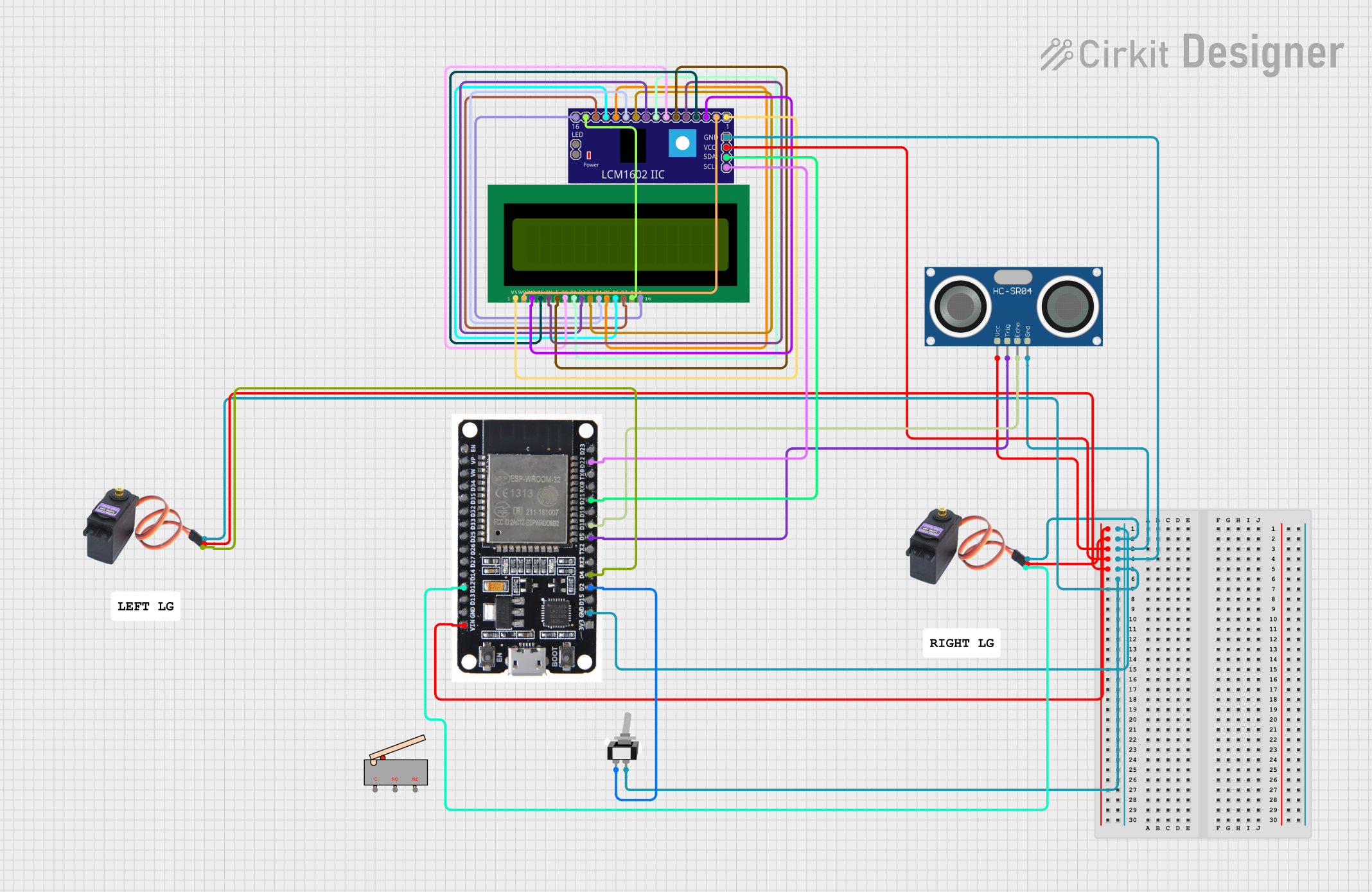

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit DesignerExplore Projects Built with MG996R

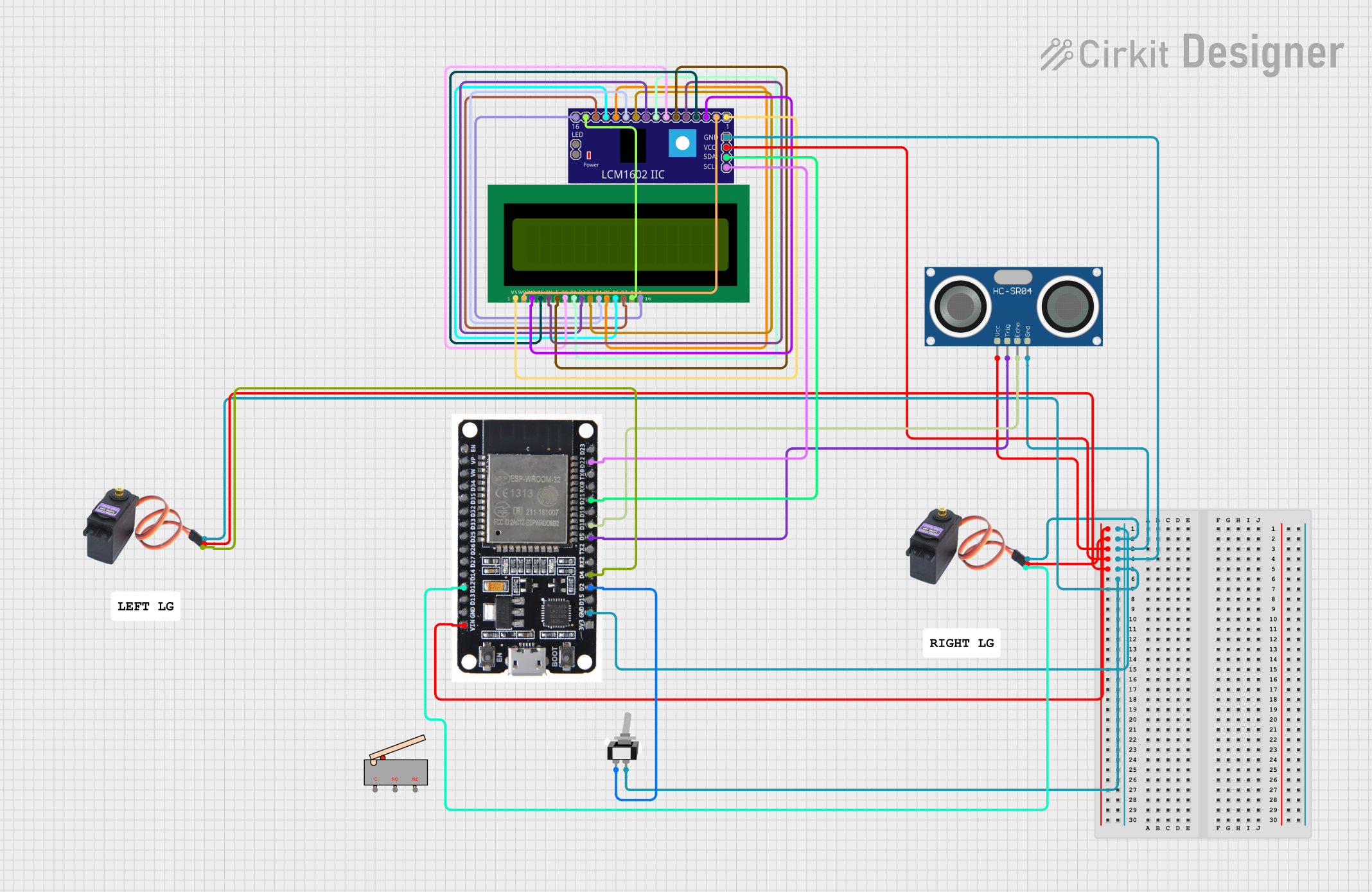

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit DesignerCommon Applications and Use Cases

- Steering and throttle control for RC cars, boats, and airplanes

- Actuators for robotic arms and legs

- Pan and tilt mechanisms for cameras and sensors

- Animatronics and custom hobby projects

Technical Specifications

Key Technical Details

- Operating Voltage: 4.8V to 7.2V

- Stall Torque: 9.4 kg-cm (4.8V), 11 kg-cm (6V)

- Operating Speed: 0.17 sec/60° (4.8V), 0.14 sec/60° (6V)

- Temperature Range: -30°C to +60°C

- Weight: 55g

- Dimensions: 40.7 x 19.7 x 42.9 mm

Pin Configuration and Descriptions

| Pin Number | Signal | Description |

|---|---|---|

| 1 | Ground (GND) | Connect to the ground of the power supply |

| 2 | Power (VCC) | Connect to the positive of the power supply |

| 3 | Signal (PWM) | Connect to the PWM signal output from a controller |

Usage Instructions

How to Use the Component in a Circuit

- Power Supply: Connect the power pin (VCC) to a suitable power supply within the operating voltage range. Ensure the ground pin (GND) is connected to the common ground of the system.

- Signal Connection: Connect the signal pin (PWM) to a PWM-capable output on a microcontroller, such as an Arduino UNO.

- Mounting: Secure the servo motor to your project using the mounting holes provided on the servo casing.

Important Considerations and Best Practices

- Power Requirements: Always use a regulated power supply to prevent damage due to voltage spikes.

- Current Draw: Be aware of the current draw, especially under load, to ensure the power supply can handle the servo's requirements.

- Signal Pulse Width: The typical pulse width for controlling the MG996R ranges from 1ms to 2ms, corresponding to 0° and 180°, respectively.

- Avoid Stalling: Prevent the servo from stalling at its endpoints, as this can lead to overheating and damage.

Example Code for Arduino UNO

#include <Servo.h>

Servo myservo; // Create servo object to control the MG996R

void setup() {

myservo.attach(9); // Attaches the servo on pin 9 to the servo object

}

void loop() {

myservo.write(0); // Turn servo to 0 degrees

delay(1000); // Wait 1 second

myservo.write(90); // Turn servo to 90 degrees (middle position)

delay(1000); // Wait 1 second

myservo.write(180); // Turn servo to 180 degrees

delay(1000); // Wait 1 second

}

Troubleshooting and FAQs

Common Issues Users Might Face

- Servo not responding: Ensure all connections are secure and the power supply is within the specified voltage range.

- Erratic Movements: Check for any signal interference or inconsistencies in the PWM signal from the controller.

- Overheating: If the servo is overheating, reduce the load or duty cycle to prevent damage.

Solutions and Tips for Troubleshooting

- Power Supply Issues: Use a multimeter to verify the voltage and current supplied to the servo.

- Signal Integrity: Use an oscilloscope to check the PWM signal's quality and ensure it matches the expected pulse width.

- Mechanical Binding: Ensure that the servo is not mechanically obstructed or overloaded.

FAQs

Q: Can I control the MG996R with a standard RC transmitter and receiver? A: Yes, the MG996R can be controlled using standard RC equipment by connecting it to the receiver's appropriate channel.

Q: What is the maximum angle the MG996R can rotate? A: The MG996R can rotate up to 180 degrees, but the actual range may vary slightly depending on the controller and signal calibration.

Q: How do I calibrate the servo for precise movements? A: Calibration involves adjusting the PWM signal's pulse width to match the servo's endpoints accurately. This can be done through trial and error or by using a servo tester.

Q: Can the MG996R be used continuously for long periods? A: While the MG996R is durable, it is not designed for continuous rotation or prolonged use without rest. Overuse can lead to overheating and wear out the gears faster.