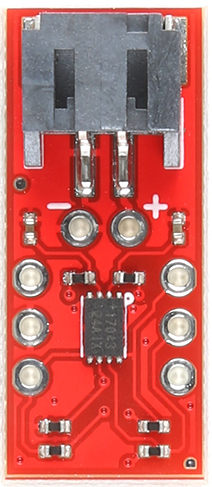

How to Use LiPo Fuel Gauge (MAX1704X): Examples, Pinouts, and Specs

Design with LiPo Fuel Gauge (MAX1704X) in Cirkit Designer

Design with LiPo Fuel Gauge (MAX1704X) in Cirkit DesignerIntroduction

The LiPo Fuel Gauge (MAX1704X), manufactured by SparkFun (Part ID: TOL-20680), is a highly accurate battery fuel gauge designed specifically for lithium polymer (LiPo) batteries. It provides real-time voltage and state-of-charge (SOC) measurements, enabling efficient power management in portable devices. The MAX1704X uses advanced algorithms to estimate the remaining battery capacity without requiring a current-sense resistor or battery characterization.

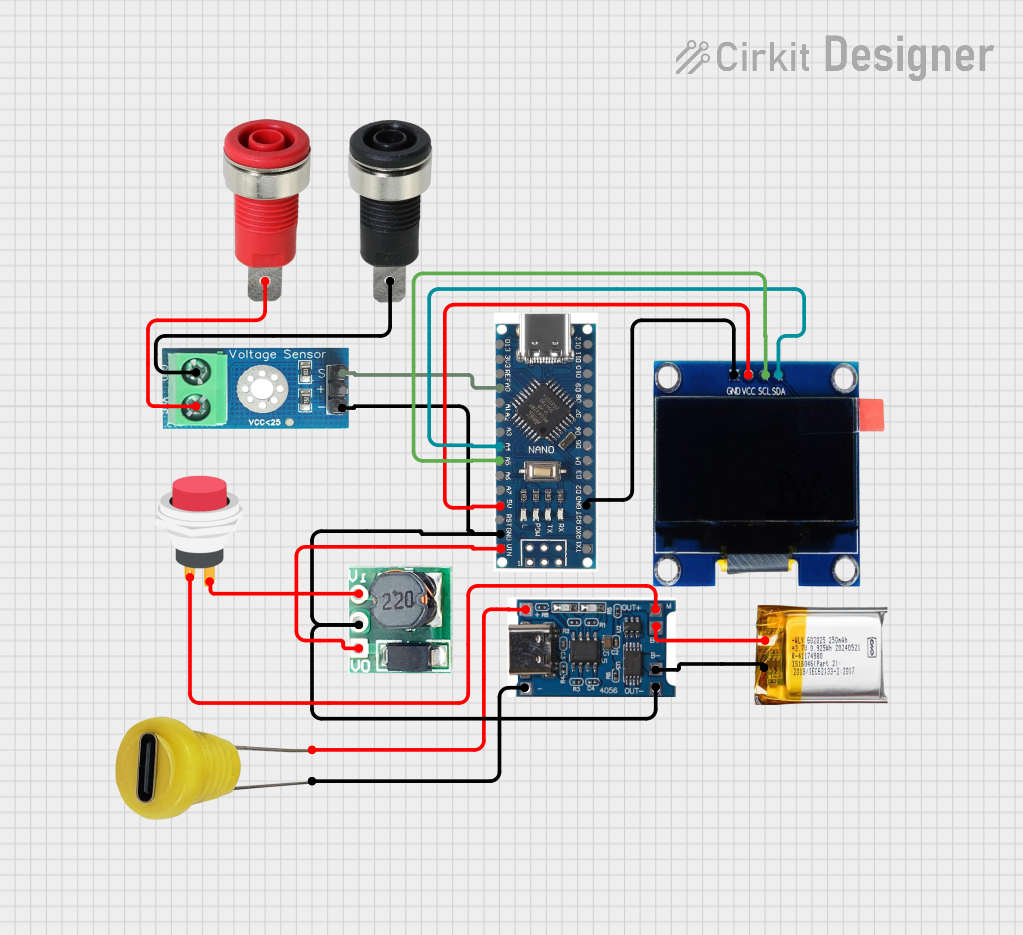

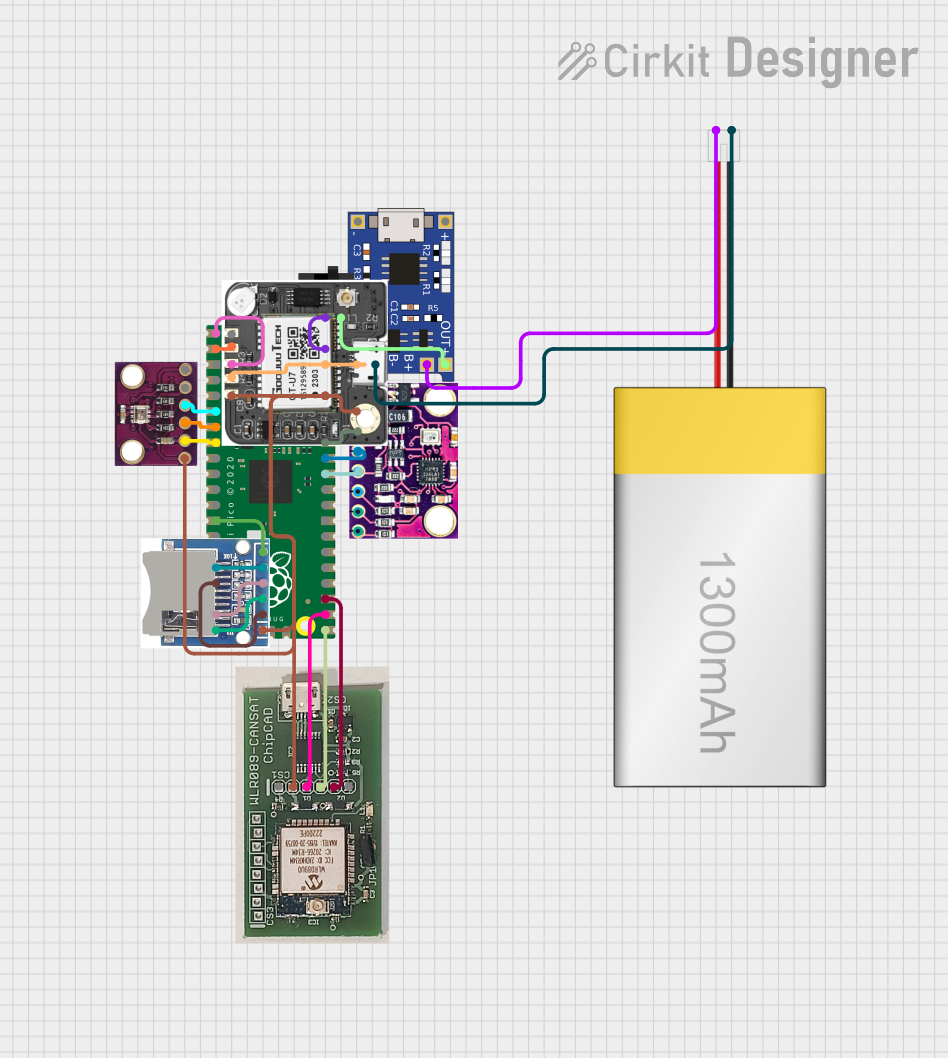

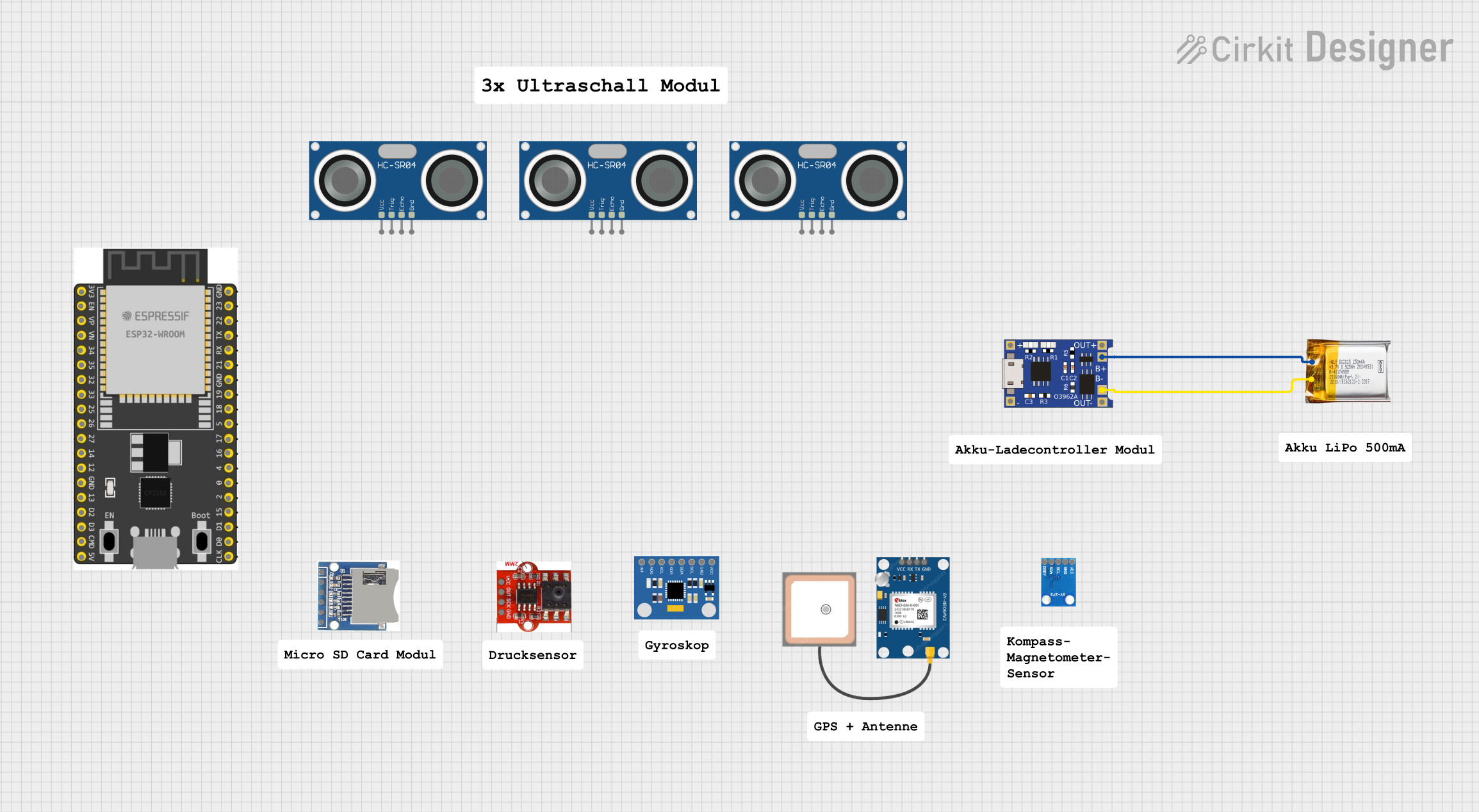

Explore Projects Built with LiPo Fuel Gauge (MAX1704X)

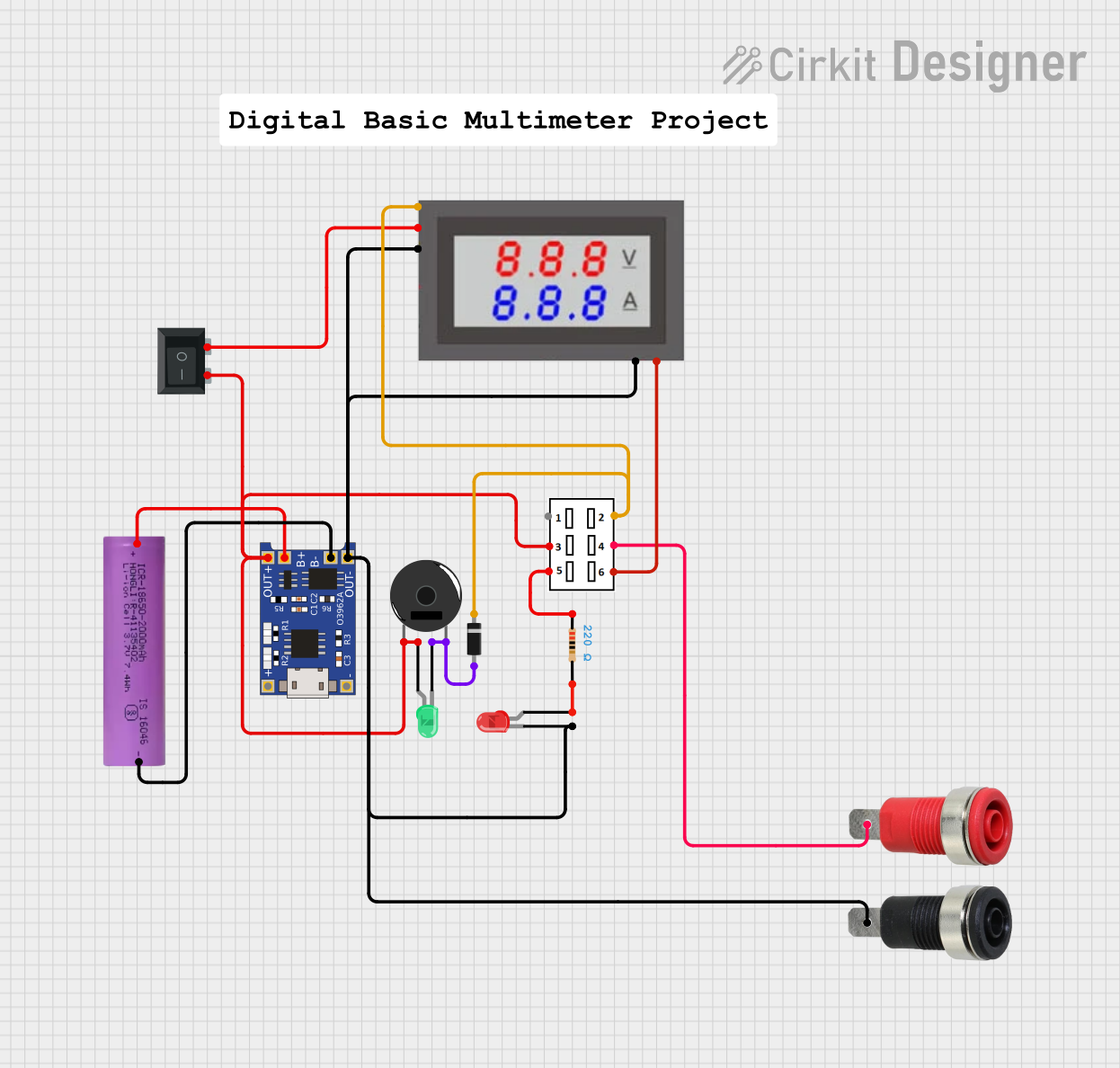

Open Project in Cirkit Designer

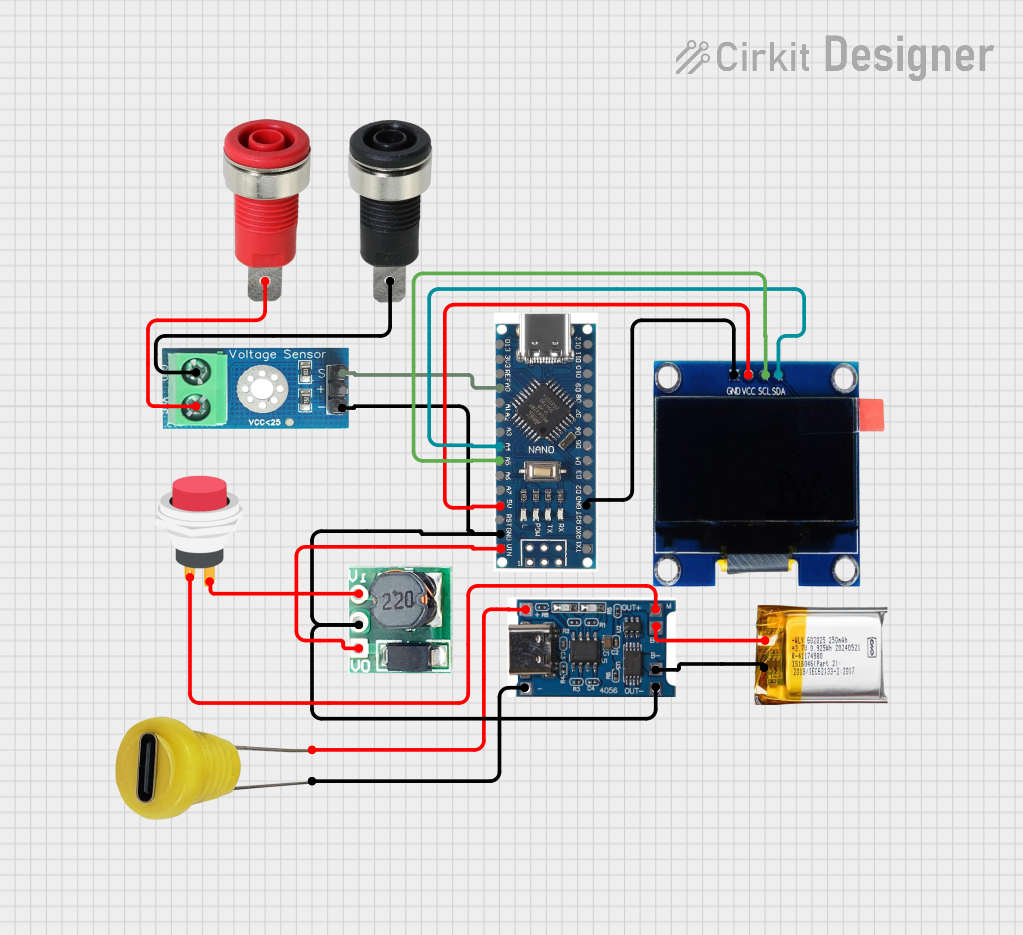

Open Project in Cirkit Designer

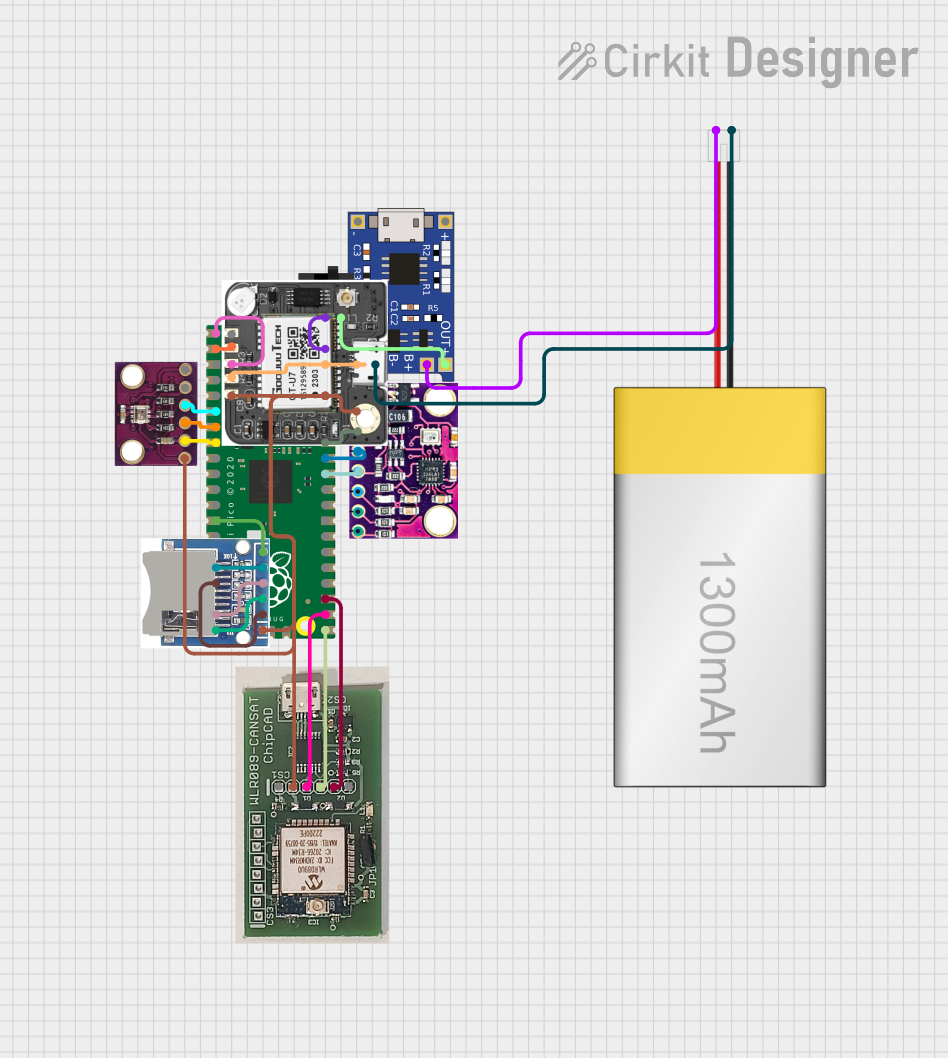

Open Project in Cirkit Designer

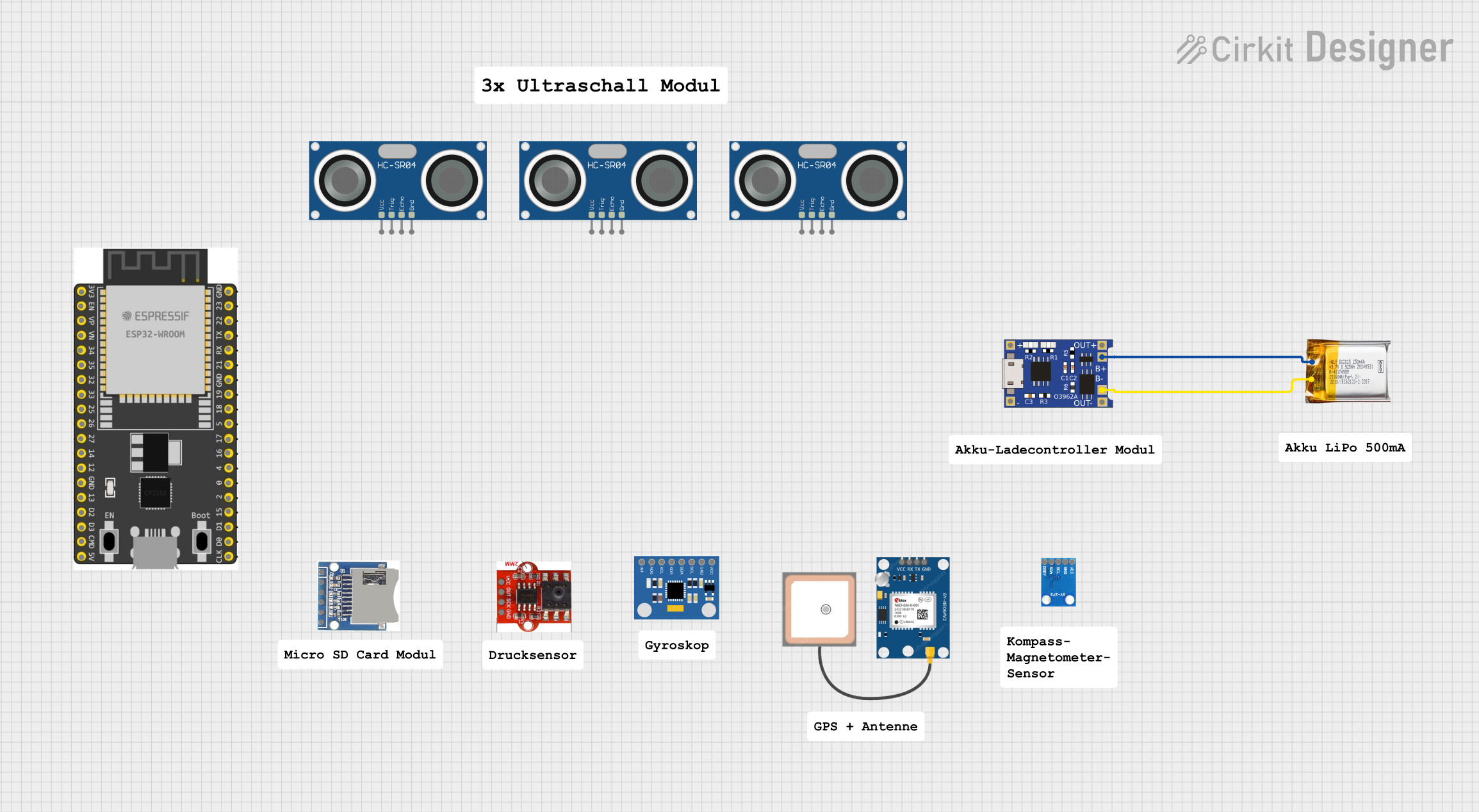

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit DesignerExplore Projects Built with LiPo Fuel Gauge (MAX1704X)

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit DesignerCommon Applications and Use Cases

- Portable electronics (e.g., smartphones, tablets, and wearables)

- Battery-powered IoT devices

- Robotics and drones

- Power banks and backup power systems

- Any application requiring precise battery monitoring

Technical Specifications

The MAX1704X is a low-power, high-accuracy fuel gauge IC with the following key specifications:

| Parameter | Value |

|---|---|

| Operating Voltage Range | 2.5V to 4.5V |

| Battery Type Supported | Single-cell LiPo |

| State-of-Charge Accuracy | ±1% |

| Communication Interface | I²C (up to 400kHz) |

| Quiescent Current | 50µA (typical) |

| Operating Temperature Range | -40°C to +85°C |

| Package Type | 8-pin µMAX or 10-pin TDFN |

Pin Configuration and Descriptions

The MAX1704X has the following pinout:

8-Pin µMAX Package

| Pin Number | Pin Name | Description |

|---|---|---|

| 1 | VDD | Power supply input (2.5V to 4.5V) |

| 2 | SCL | I²C clock input |

| 3 | SDA | I²C data input/output |

| 4 | GND | Ground |

| 5 | THRM | Optional thermistor input for temperature monitoring |

| 6 | ALRT | Alert output for low SOC or other events |

| 7 | RST | Reset input (active low) |

| 8 | VSS | Ground (internally connected to GND) |

10-Pin TDFN Package

| Pin Number | Pin Name | Description |

|---|---|---|

| 1 | VDD | Power supply input (2.5V to 4.5V) |

| 2 | SCL | I²C clock input |

| 3 | SDA | I²C data input/output |

| 4 | GND | Ground |

| 5 | THRM | Optional thermistor input for temperature monitoring |

| 6 | ALRT | Alert output for low SOC or other events |

| 7 | RST | Reset input (active low) |

| 8 | VSS | Ground (internally connected to GND) |

| 9 | NC | No connection |

| 10 | NC | No connection |

Usage Instructions

How to Use the MAX1704X in a Circuit

- Power Supply: Connect the VDD pin to a 2.5V to 4.5V power source. Ensure the GND and VSS pins are connected to the circuit ground.

- I²C Communication: Connect the SCL and SDA pins to the corresponding I²C lines of your microcontroller. Use pull-up resistors (typically 4.7kΩ) on both lines.

- Battery Connection: Connect the LiPo battery's positive terminal to the VDD pin and the negative terminal to GND.

- Optional Thermistor: If temperature monitoring is required, connect a 10kΩ thermistor to the THRM pin.

- Alert Pin: The ALRT pin can be connected to a microcontroller GPIO pin to monitor low SOC or other alerts.

- Reset Pin: The RST pin can be used to reset the IC. Pull it low momentarily to reset.

Important Considerations and Best Practices

- Ensure the battery voltage is within the operating range (2.5V to 4.5V) to avoid damage to the IC.

- Use proper decoupling capacitors (e.g., 0.1µF and 1µF) near the VDD pin to stabilize the power supply.

- Keep the I²C lines as short as possible to minimize noise and ensure reliable communication.

- If using the ALRT pin, configure the microcontroller to handle interrupts for efficient monitoring.

- Avoid connecting multiple batteries in series or parallel directly to the MAX1704X, as it is designed for single-cell LiPo batteries.

Example Code for Arduino UNO

The following example demonstrates how to interface the MAX1704X with an Arduino UNO to read the battery voltage and SOC:

#include <Wire.h> // Include the Wire library for I²C communication

#define MAX1704X_ADDRESS 0x36 // Default I²C address of MAX1704X

void setup() {

Wire.begin(); // Initialize I²C communication

Serial.begin(9600); // Start serial communication for debugging

// Optional: Reset the MAX1704X

Wire.beginTransmission(MAX1704X_ADDRESS);

Wire.write(0xFE); // Send reset command

Wire.endTransmission();

}

void loop() {

float voltage = readVoltage();

float soc = readSOC();

Serial.print("Voltage: ");

Serial.print(voltage);

Serial.println(" V");

Serial.print("State of Charge: ");

Serial.print(soc);

Serial.println(" %");

delay(1000); // Wait for 1 second before the next reading

}

float readVoltage() {

Wire.beginTransmission(MAX1704X_ADDRESS);

Wire.write(0x02); // Voltage register

Wire.endTransmission(false);

Wire.requestFrom(MAX1704X_ADDRESS, 2);

uint16_t rawVoltage = (Wire.read() << 8) | Wire.read();

return rawVoltage * 0.00125; // Convert to volts

}

float readSOC() {

Wire.beginTransmission(MAX1704X_ADDRESS);

Wire.write(0x04); // SOC register

Wire.endTransmission(false);

Wire.requestFrom(MAX1704X_ADDRESS, 2);

uint16_t rawSOC = (Wire.read() << 8) | Wire.read();

return rawSOC * 0.00390625; // Convert to percentage

}

Troubleshooting and FAQs

Common Issues and Solutions

No I²C Communication:

- Ensure the SCL and SDA lines are connected correctly and have pull-up resistors.

- Verify the MAX1704X's I²C address (default is 0x36) and update the code if necessary.

- Check for loose connections or damaged wires.

Incorrect Voltage or SOC Readings:

- Ensure the battery voltage is within the operating range (2.5V to 4.5V).

- Verify that the battery is properly connected to the VDD and GND pins.

- Check for noise or instability in the power supply.

ALRT Pin Not Triggering:

- Confirm that the alert thresholds are configured correctly in the MAX1704X registers.

- Ensure the microcontroller GPIO pin connected to ALRT is configured as an input.

FAQs

Q: Can the MAX1704X be used with batteries other than LiPo?

A: No, the MAX1704X is specifically designed for single-cell LiPo batteries and may not provide accurate readings for other battery chemistries.

Q: What is the typical accuracy of the SOC measurement?

A: The MAX1704X provides a state-of-charge accuracy of ±1% under typical conditions.

Q: Can I use the MAX1704X with a 2-cell LiPo battery?

A: No, the MAX1704X is designed for single-cell LiPo batteries only. For multi-cell configurations, consider using a different fuel gauge IC.

Q: How do I reset the MAX1704X?

A: You can reset the MAX1704X by pulling the RST pin low momentarily or by sending a reset command (0xFE) via I²C.