How to Use Magnum CUT 55: Examples, Pinouts, and Specs

Design with Magnum CUT 55 in Cirkit Designer

Design with Magnum CUT 55 in Cirkit DesignerIntroduction

The Magnum CUT 55 is a compact and efficient plasma cutting machine designed for precision cutting of various metals, including steel, stainless steel, aluminum, and copper. Manufactured by Magnum, this device is ideal for both professional workshops and DIY enthusiasts. Its lightweight design, adjustable output, and high cutting capacity make it a versatile tool for a wide range of applications.

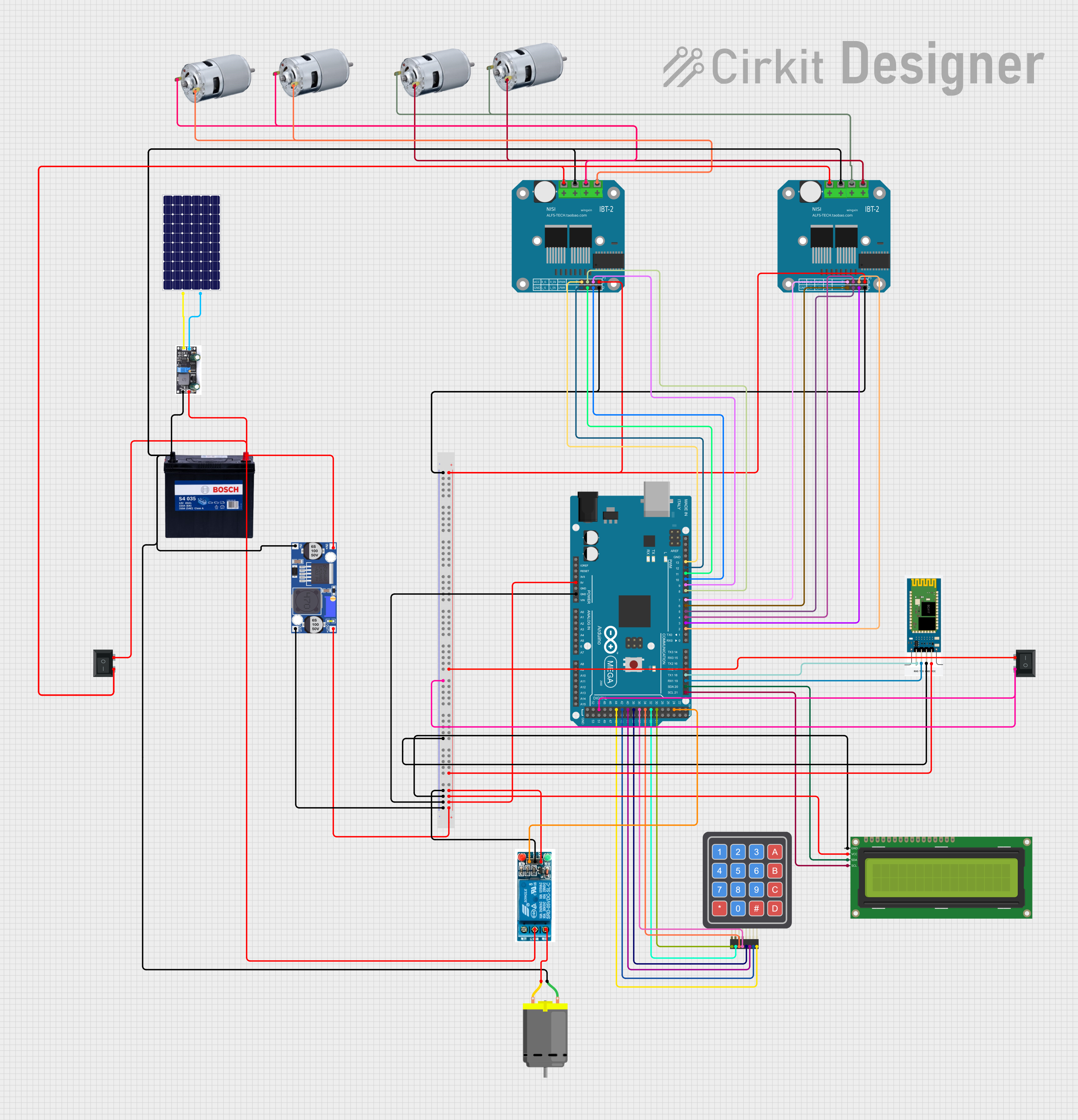

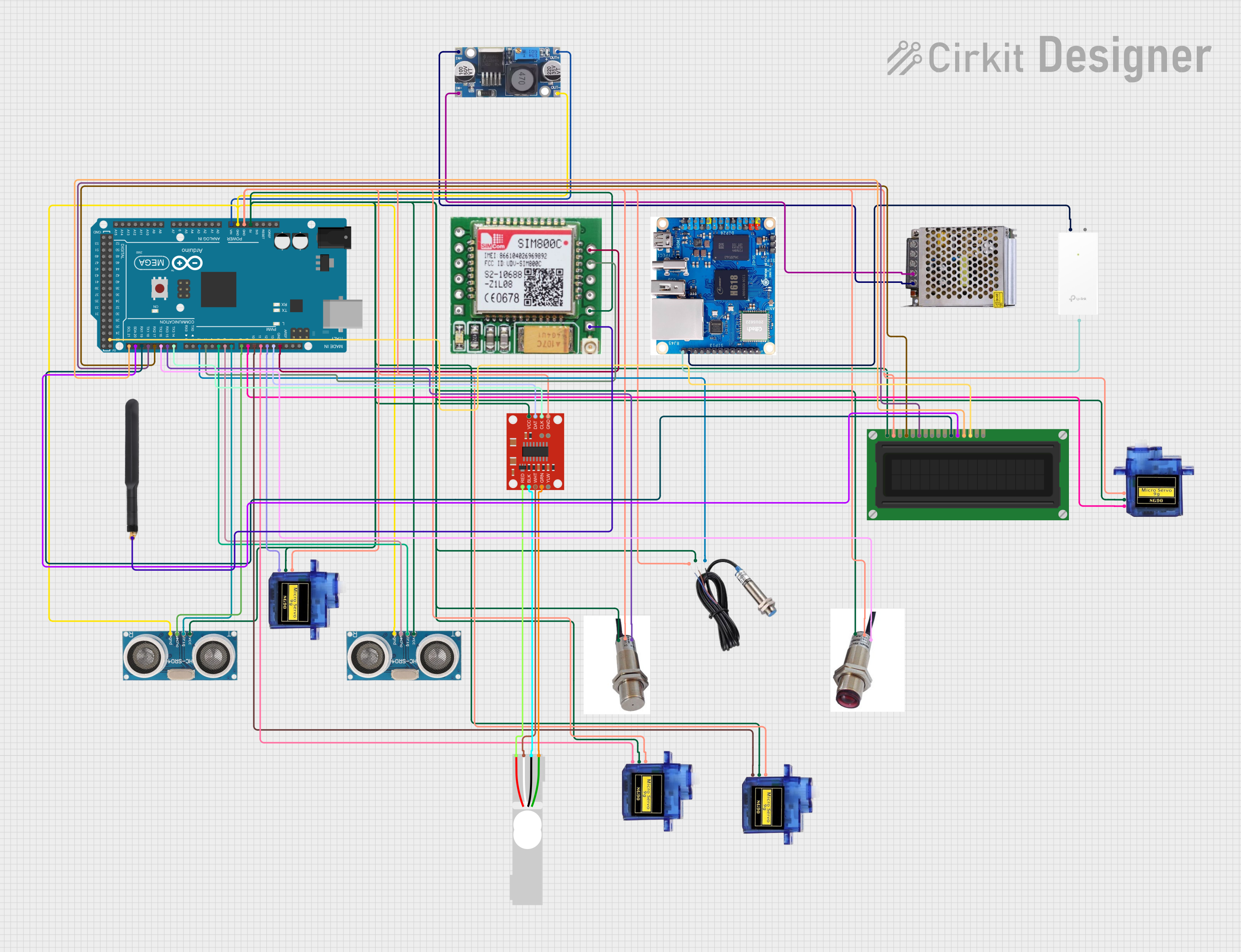

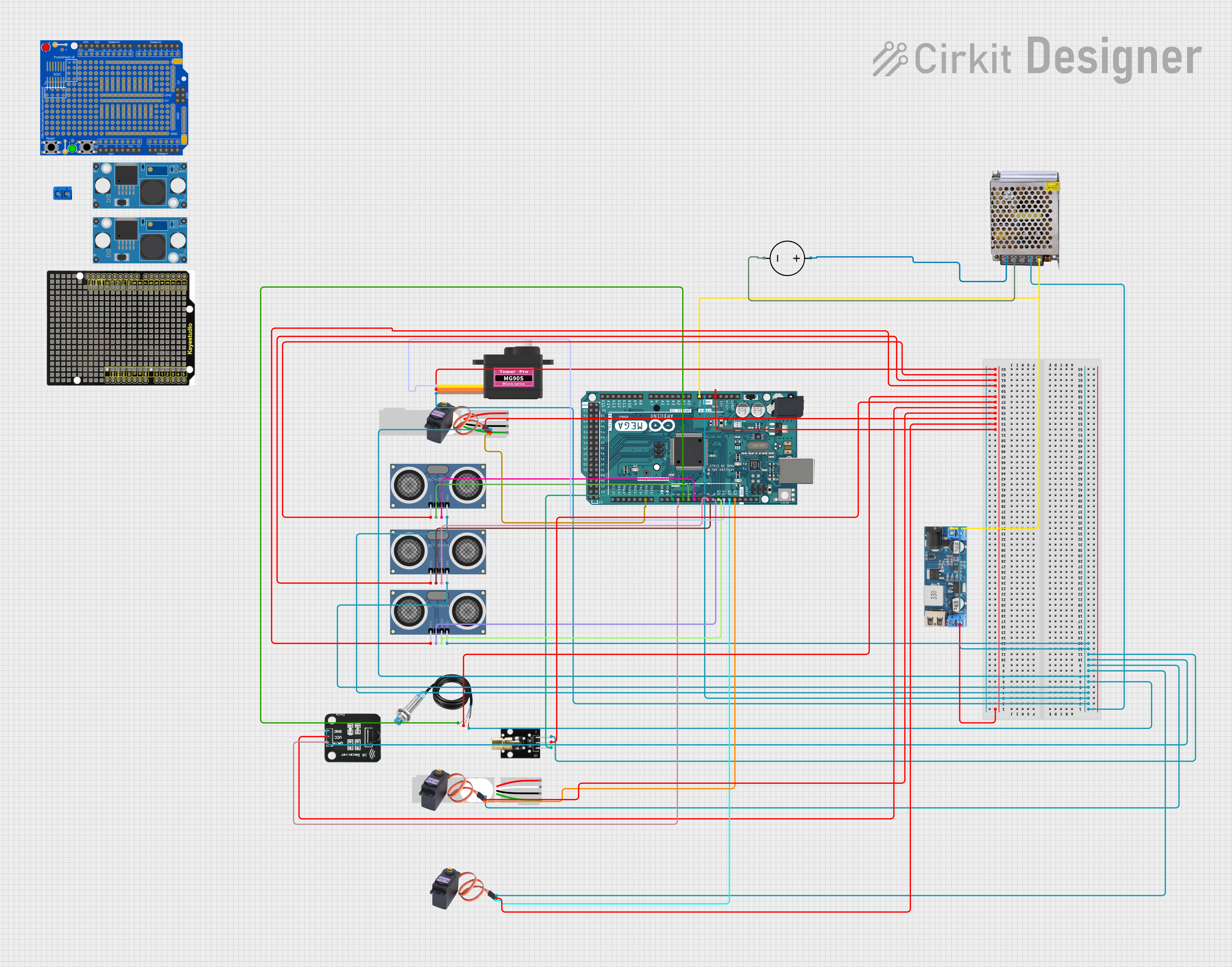

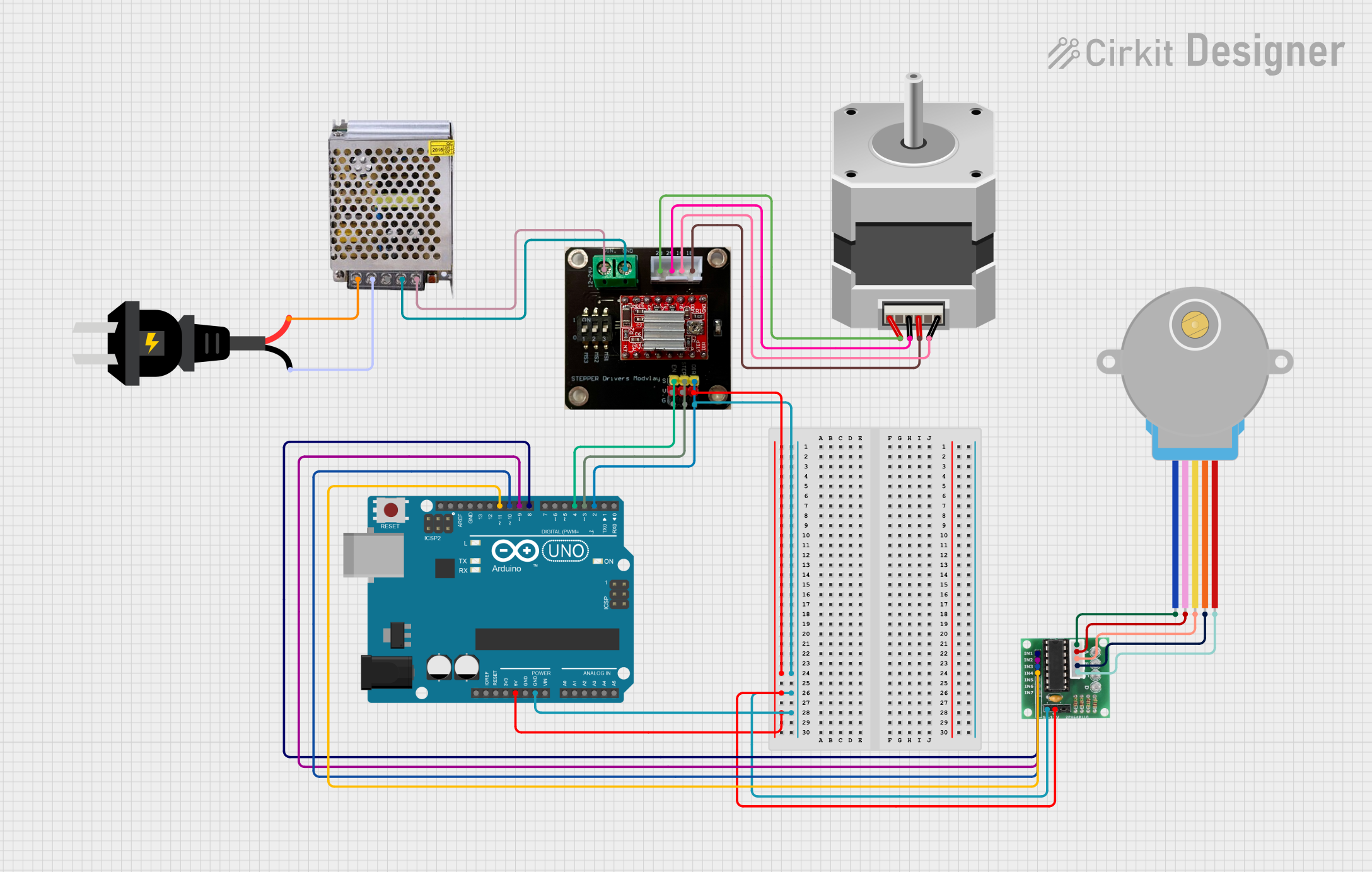

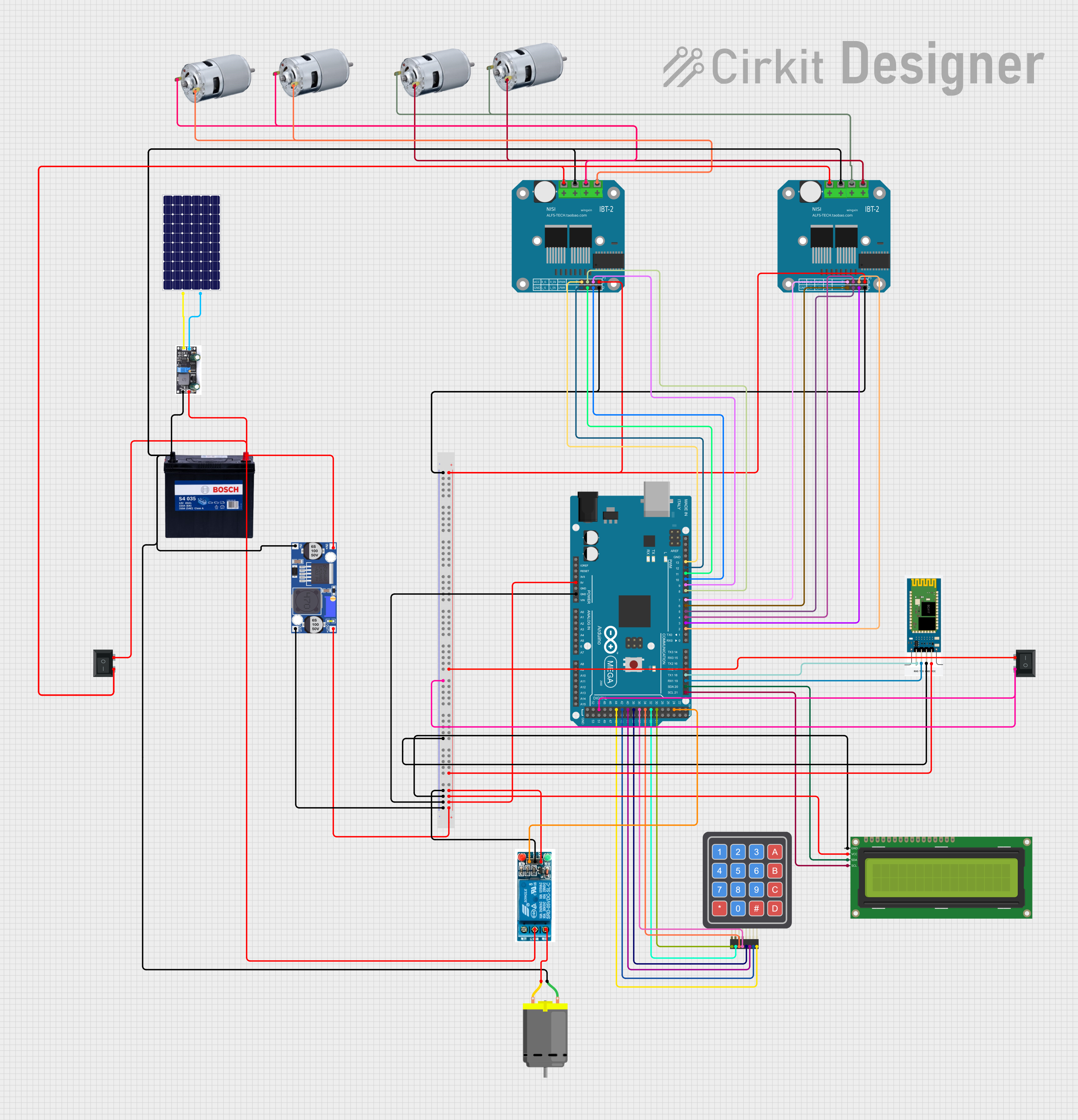

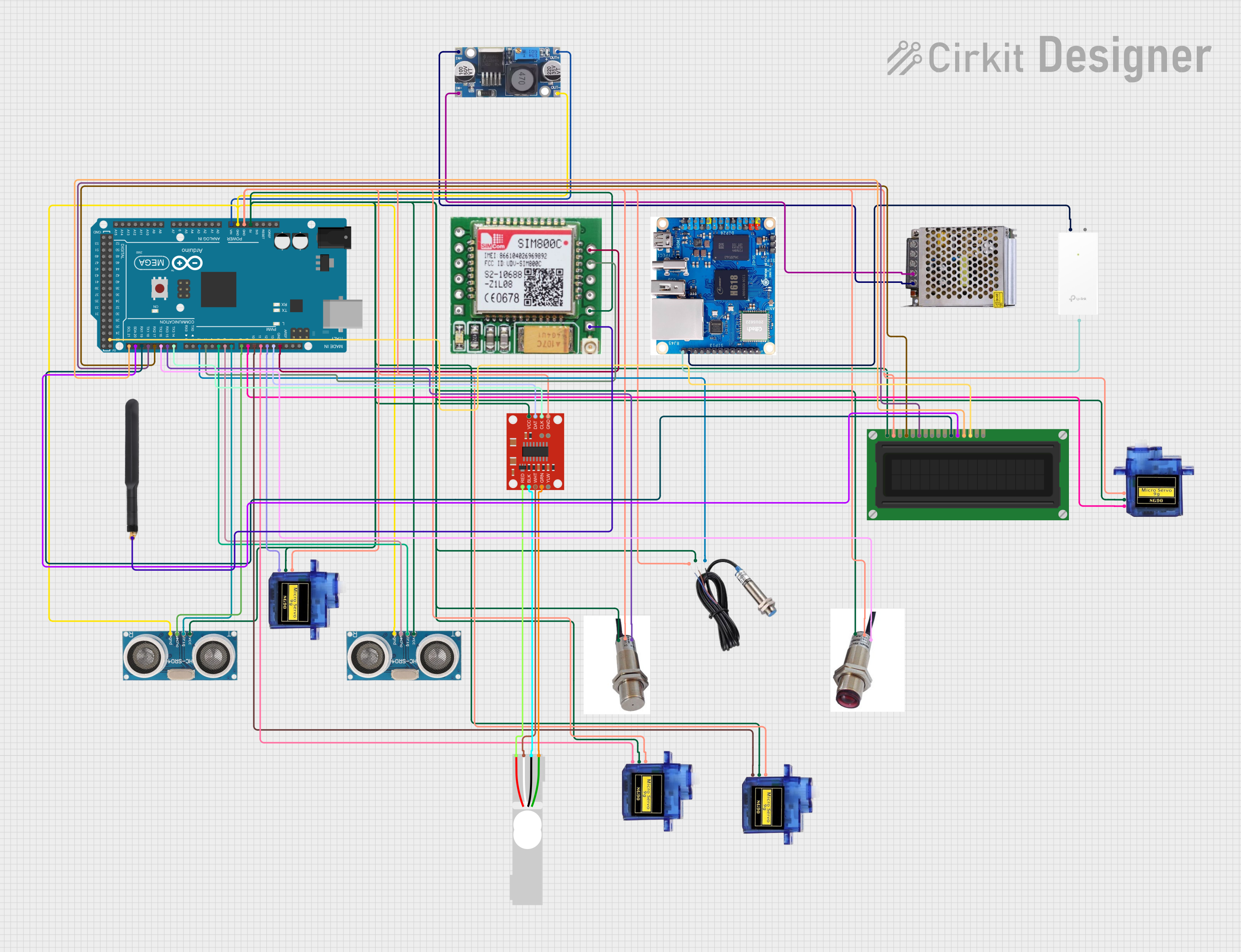

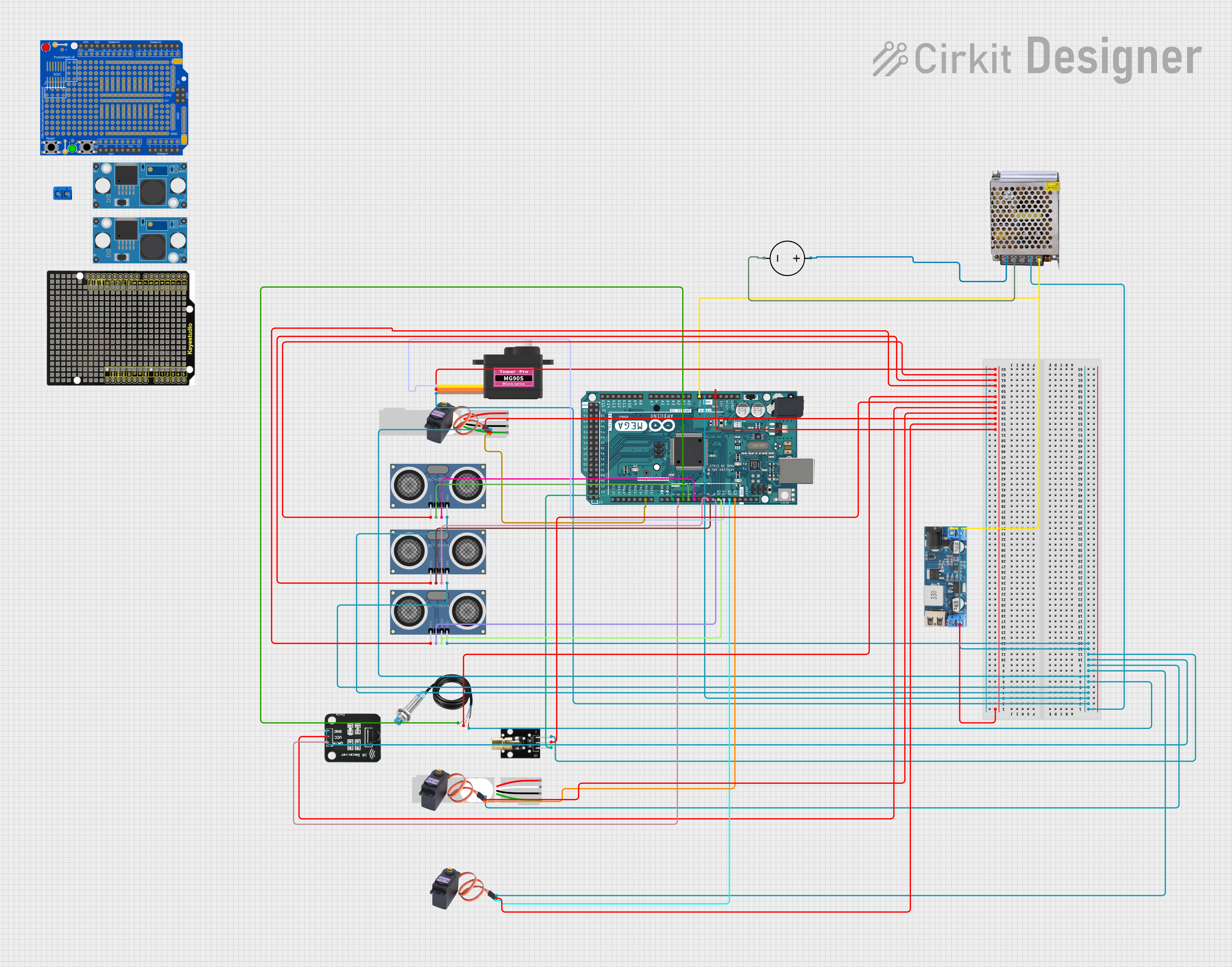

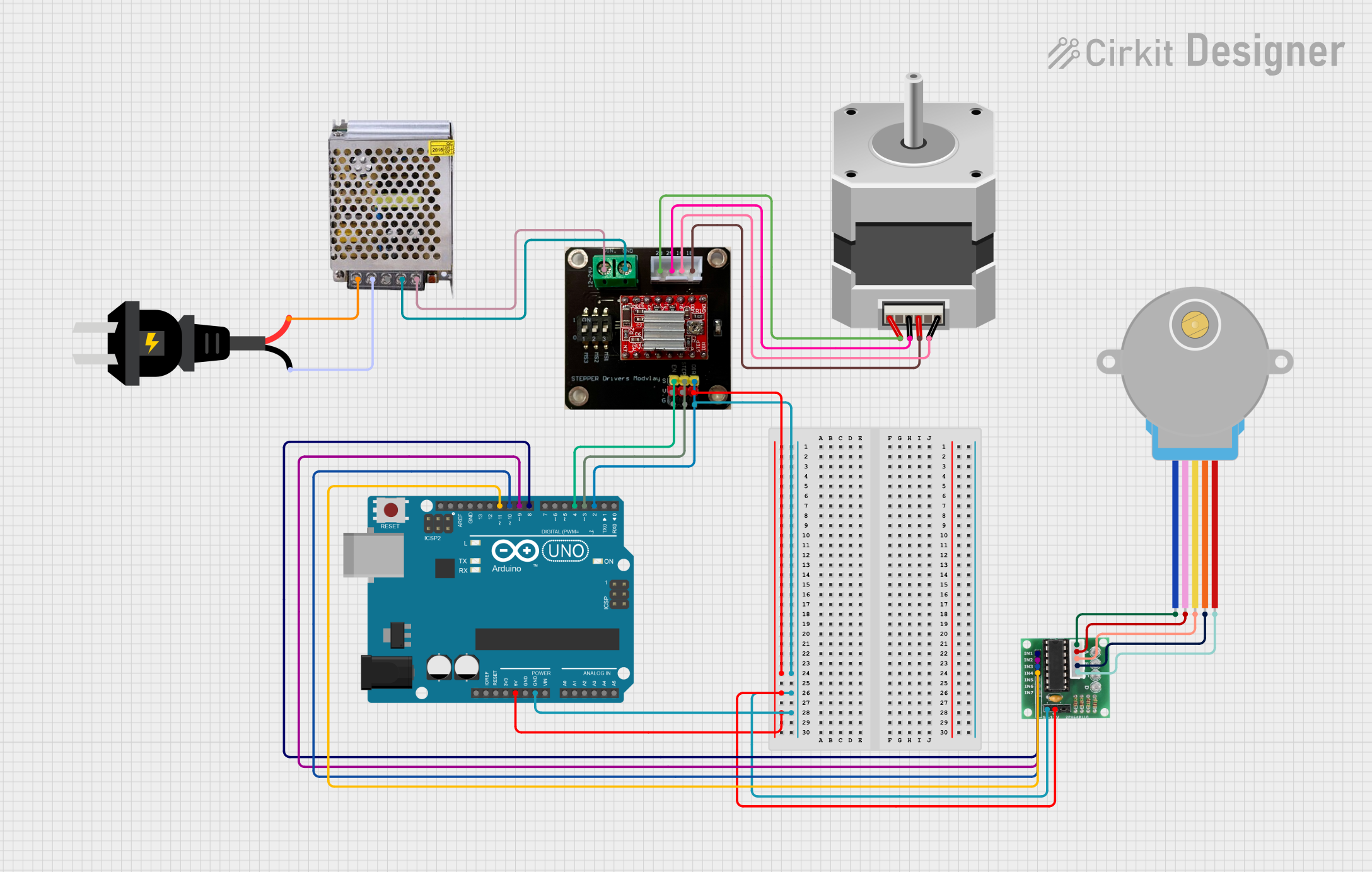

Explore Projects Built with Magnum CUT 55

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit DesignerExplore Projects Built with Magnum CUT 55

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit DesignerCommon Applications and Use Cases

- Metal fabrication and repair

- Automotive and aerospace industries

- Construction and structural work

- Artistic metalworking and DIY projects

- Cutting metal sheets, pipes, and plates with precision

Technical Specifications

The Magnum CUT 55 is engineered to deliver reliable performance with the following key specifications:

| Parameter | Specification |

|---|---|

| Manufacturer | Magnum |

| Model | CUT 55 |

| Input Voltage | 220V ± 10%, Single Phase |

| Input Frequency | 50/60 Hz |

| Output Current Range | 20A - 55A |

| Duty Cycle | 60% at 55A |

| Cutting Thickness (Max) | 16 mm (5/8 inch) |

| Cutting Thickness (Optimal) | 12 mm (1/2 inch) |

| Pilot Arc Technology | Yes |

| Cooling System | Forced Air Cooling |

| Weight | 9 kg (19.8 lbs) |

| Dimensions | 410 mm x 155 mm x 295 mm |

Pin Configuration and Descriptions

The Magnum CUT 55 does not have a traditional pin configuration as it is a standalone plasma cutting machine. However, the following table describes the key input/output connections and controls:

| Connection/Control | Description |

|---|---|

| Power Input Port | Connects to a 220V AC power source |

| Ground Clamp Connector | Connects to the workpiece for grounding |

| Torch Connector | Connects to the plasma cutting torch |

| Air Inlet Port | Connects to an external air compressor |

| Current Adjustment Knob | Adjusts the output current (20A to 55A) |

| Power Switch | Turns the machine on/off |

| Digital Display | Shows the current output settings |

Usage Instructions

How to Use the Magnum CUT 55 in a Circuit

The Magnum CUT 55 is a standalone plasma cutting machine and does not require integration into an electronic circuit. However, it must be properly connected to its power source, air compressor, and workpiece for optimal operation. Follow these steps:

Setup the Machine:

- Place the Magnum CUT 55 on a stable, non-conductive surface.

- Connect the power input port to a 220V AC power source.

- Attach the ground clamp to the workpiece to ensure proper grounding.

- Connect the plasma cutting torch to the torch connector.

- Attach an air compressor to the air inlet port and ensure the air pressure is set to the recommended level (typically 4.5-5.0 bar).

Adjust the Output Current:

- Use the current adjustment knob to set the desired output current based on the thickness and type of metal being cut. For optimal results:

- Thin metals (up to 3 mm): 20A-30A

- Medium thickness (3-8 mm): 30A-45A

- Thick metals (8-12 mm): 45A-55A

- Use the current adjustment knob to set the desired output current based on the thickness and type of metal being cut. For optimal results:

Start Cutting:

- Turn on the power switch and wait for the machine to initialize.

- Position the torch at the starting point of the cut and press the trigger to initiate the pilot arc.

- Move the torch steadily along the cutting path, maintaining a consistent speed and distance from the workpiece.

Important Considerations and Best Practices

- Ensure the work area is well-ventilated to avoid inhaling fumes generated during cutting.

- Always wear appropriate personal protective equipment (PPE), including gloves, safety goggles, and a welding helmet.

- Use a clean and dry air supply to prevent contamination of the plasma arc.

- Avoid cutting painted or coated metals, as this can produce toxic fumes.

- Regularly inspect and replace consumables (e.g., electrodes and nozzles) to maintain cutting performance.

Troubleshooting and FAQs

Common Issues and Solutions

| Issue | Possible Cause | Solution |

|---|---|---|

| Machine does not power on | Power cord not connected or faulty | Check the power cord and outlet |

| Weak or unstable plasma arc | Low air pressure or worn consumables | Check air supply and replace consumables |

| Excessive dross on cut edges | Incorrect current setting or cutting speed | Adjust current and/or cutting speed |

| Torch does not ignite | Faulty ground connection or air supply | Ensure proper grounding and air pressure |

| Overheating during operation | Exceeding duty cycle | Allow the machine to cool before use |

Frequently Asked Questions

What type of air compressor is required?

- The Magnum CUT 55 requires an air compressor capable of delivering clean, dry air at a pressure of 4.5-5.0 bar and a flow rate of at least 120 liters per minute.

Can the Magnum CUT 55 cut non-metal materials?

- No, the Magnum CUT 55 is designed specifically for cutting conductive metals and cannot be used on non-metal materials like wood or plastic.

How often should I replace the consumables?

- The frequency of replacement depends on usage. Inspect the electrode and nozzle regularly and replace them if you notice wear or reduced cutting performance.

Is the Magnum CUT 55 suitable for CNC plasma cutting?

- While the Magnum CUT 55 is primarily designed for manual operation, it can be adapted for CNC plasma cutting with the appropriate torch and control system.

By following this documentation, users can maximize the performance and lifespan of their Magnum CUT 55 plasma cutting machine.