How to Use Generic Domestic Boiler: Examples, Pinouts, and Specs

Design with Generic Domestic Boiler in Cirkit Designer

Design with Generic Domestic Boiler in Cirkit DesignerIntroduction

A Generic Domestic Boiler is a heating device commonly used in residential settings to provide hot water for space heating and domestic hot water supply. These boilers are essential for maintaining comfortable indoor temperatures, especially in colder climates. They typically operate using gas, oil, or electricity as their energy source. Domestic boilers are integral to central heating systems and are often paired with radiators or underfloor heating systems.

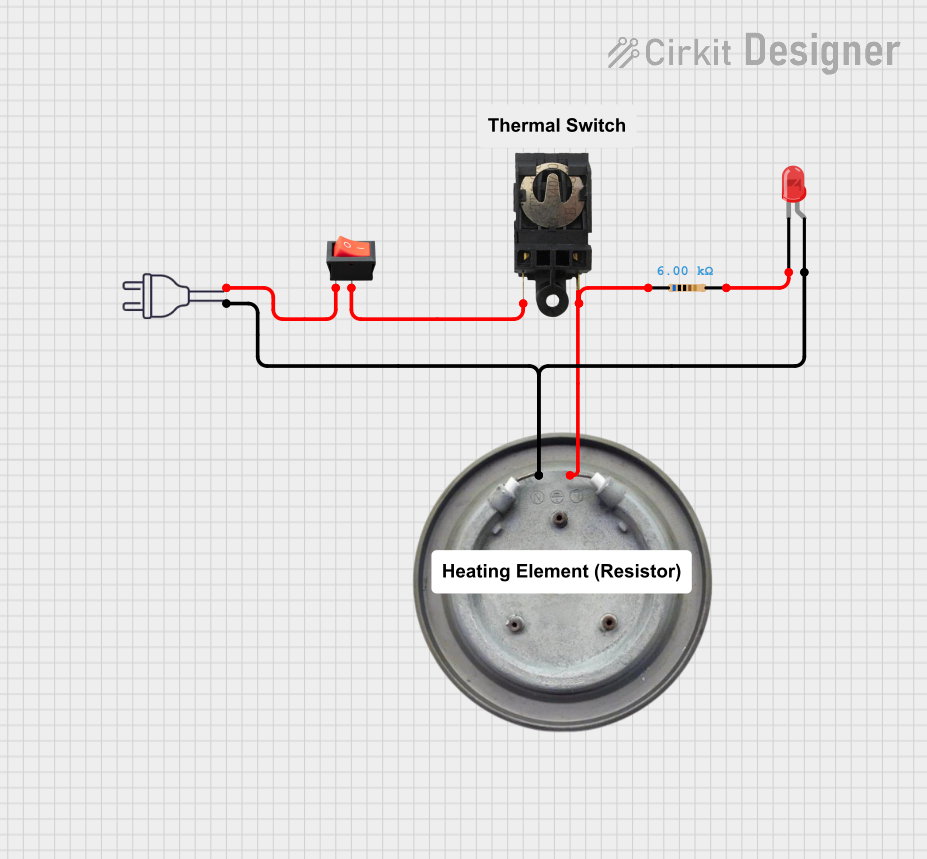

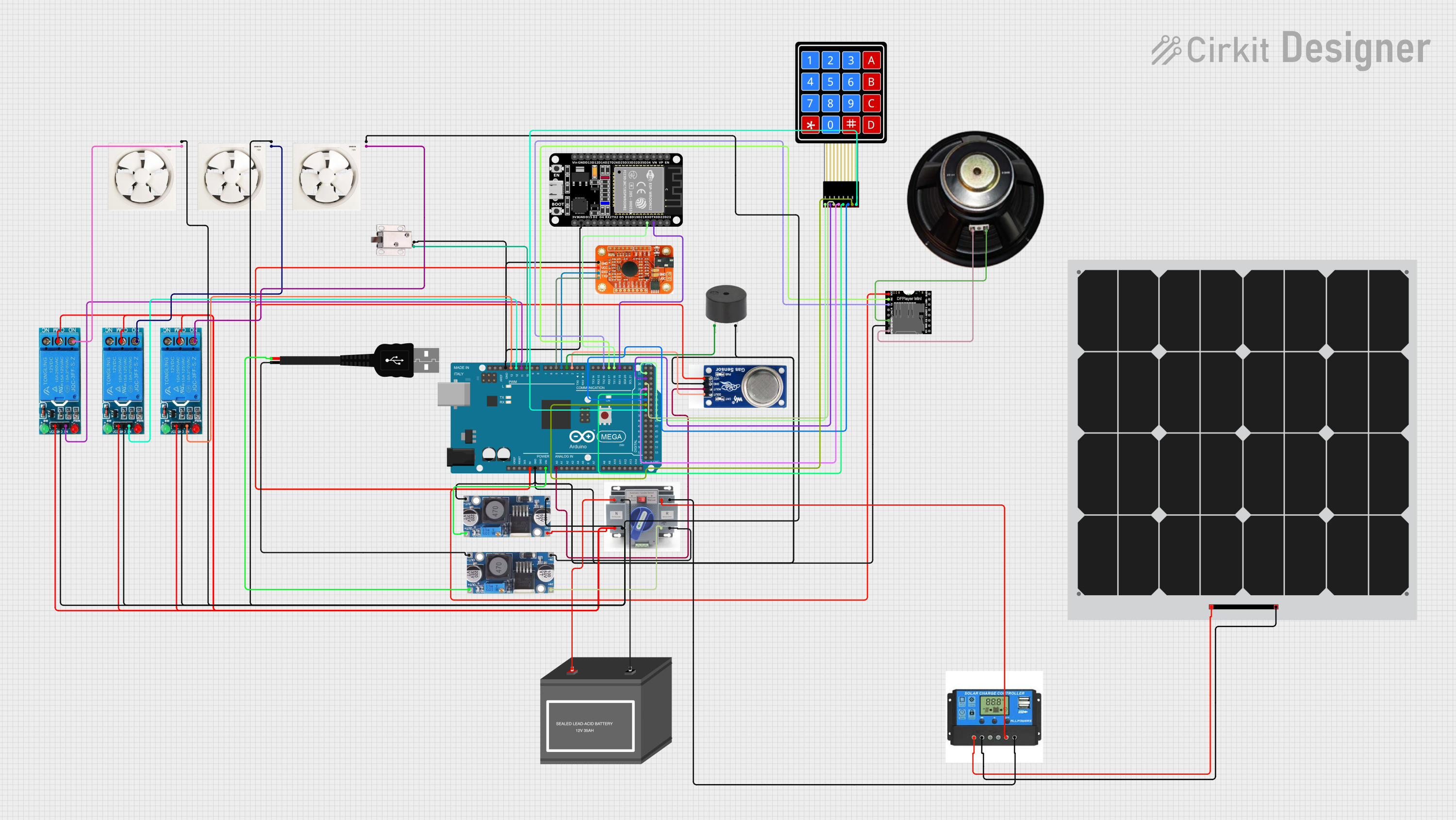

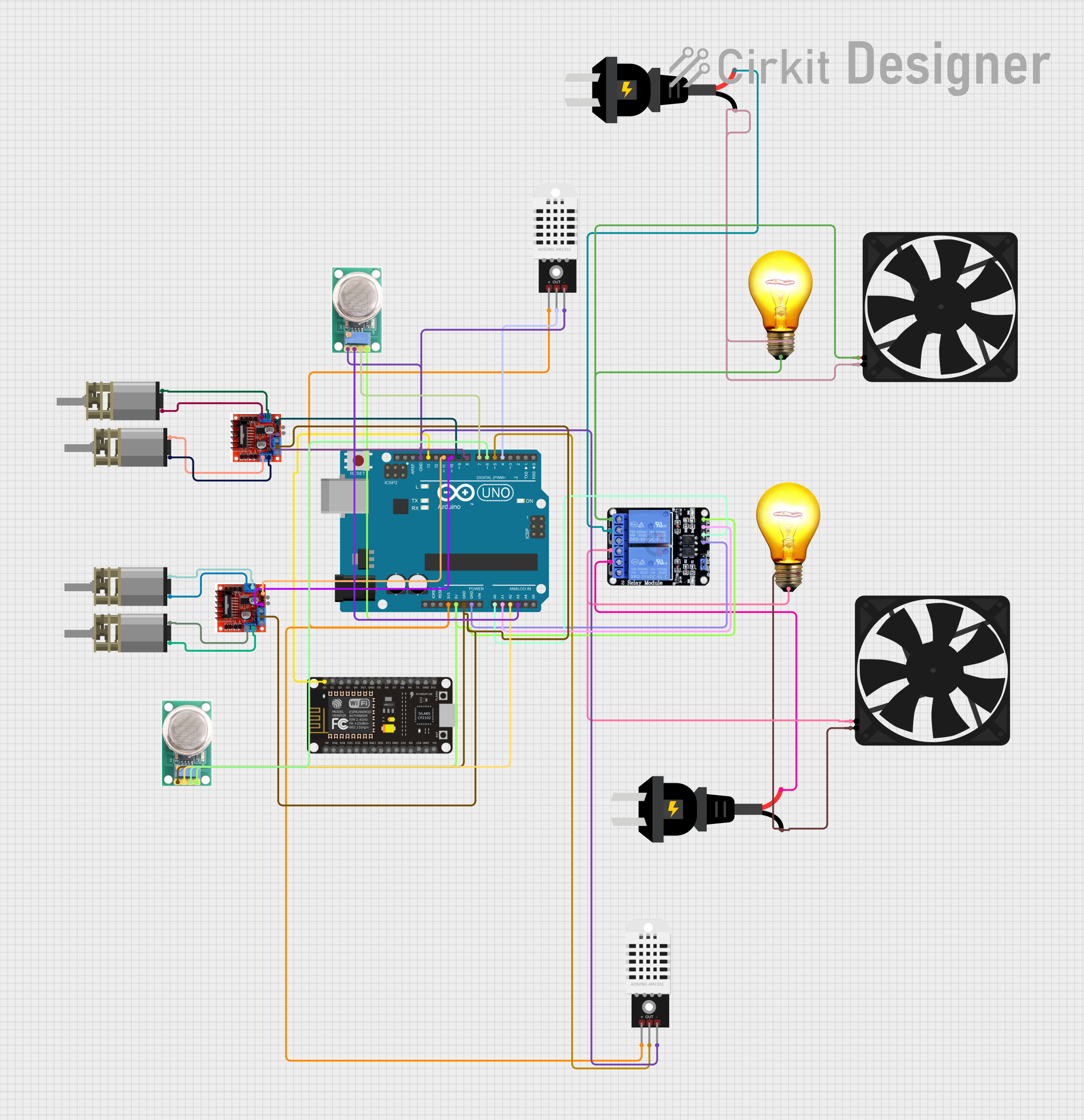

Explore Projects Built with Generic Domestic Boiler

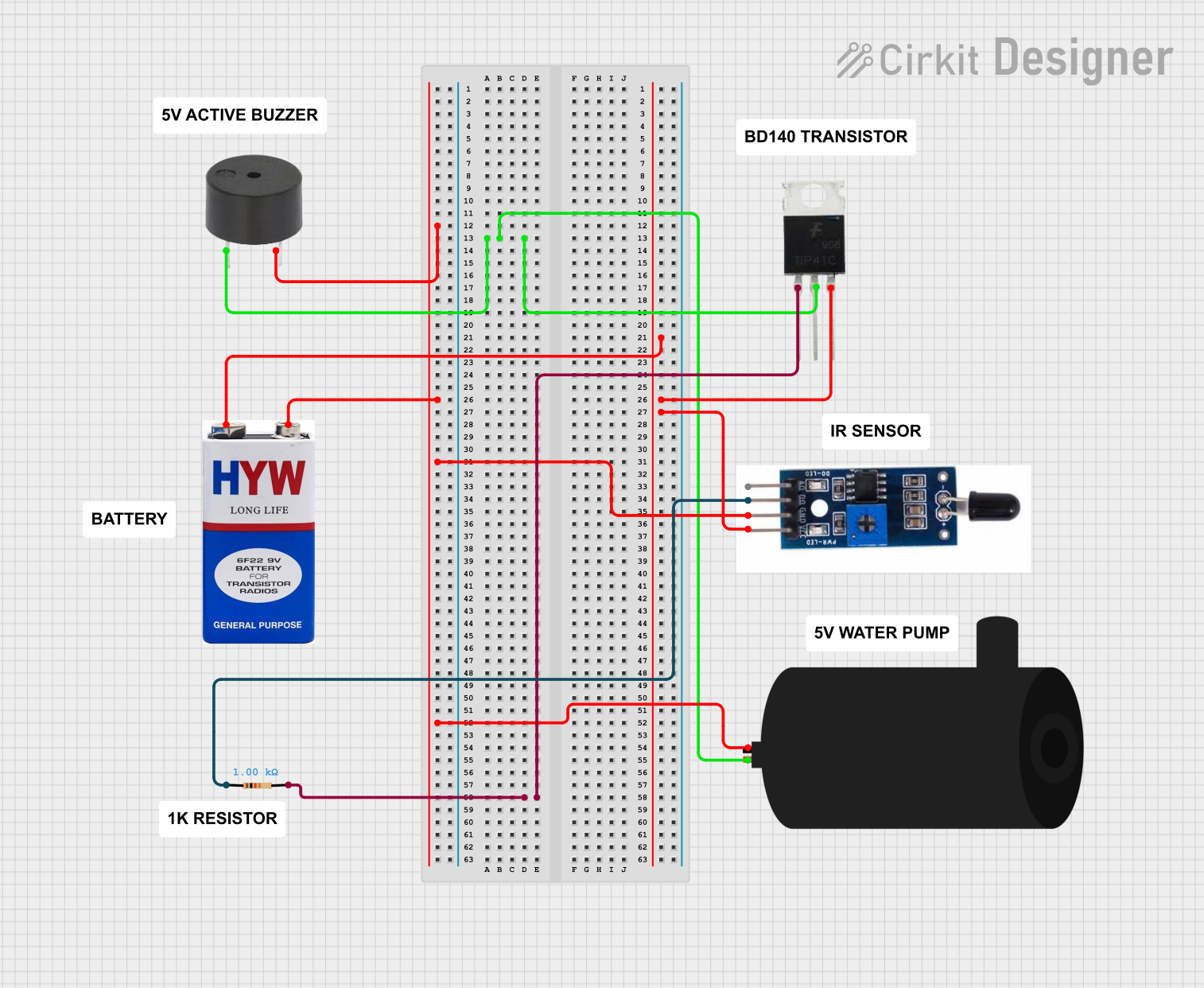

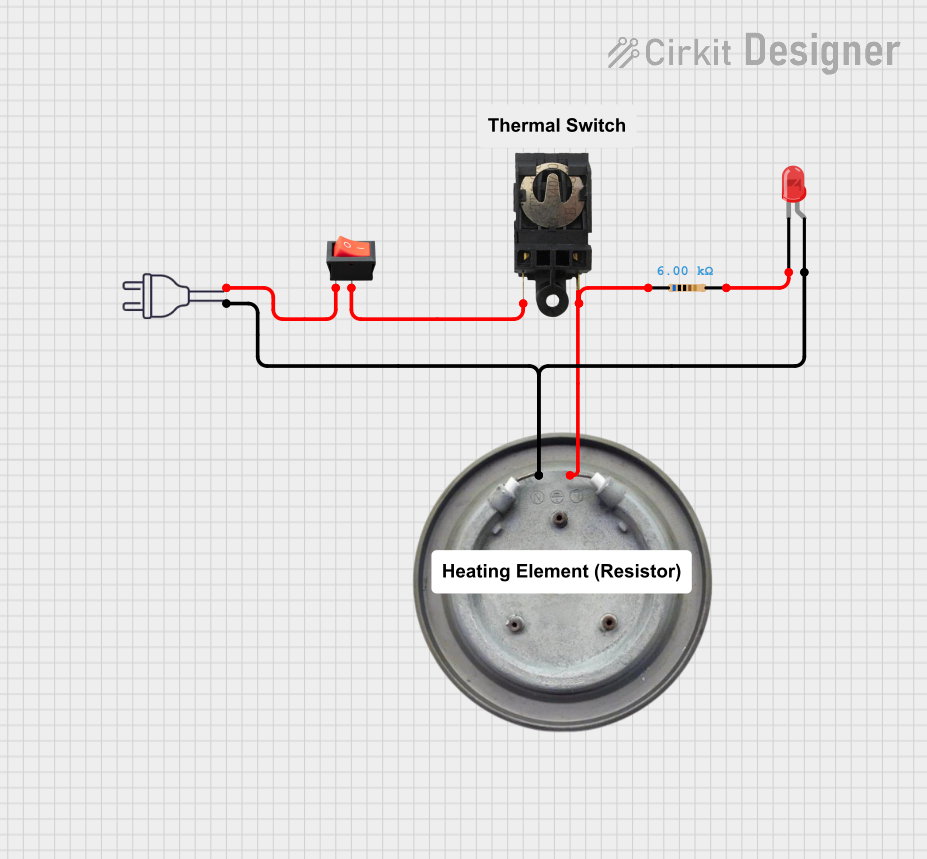

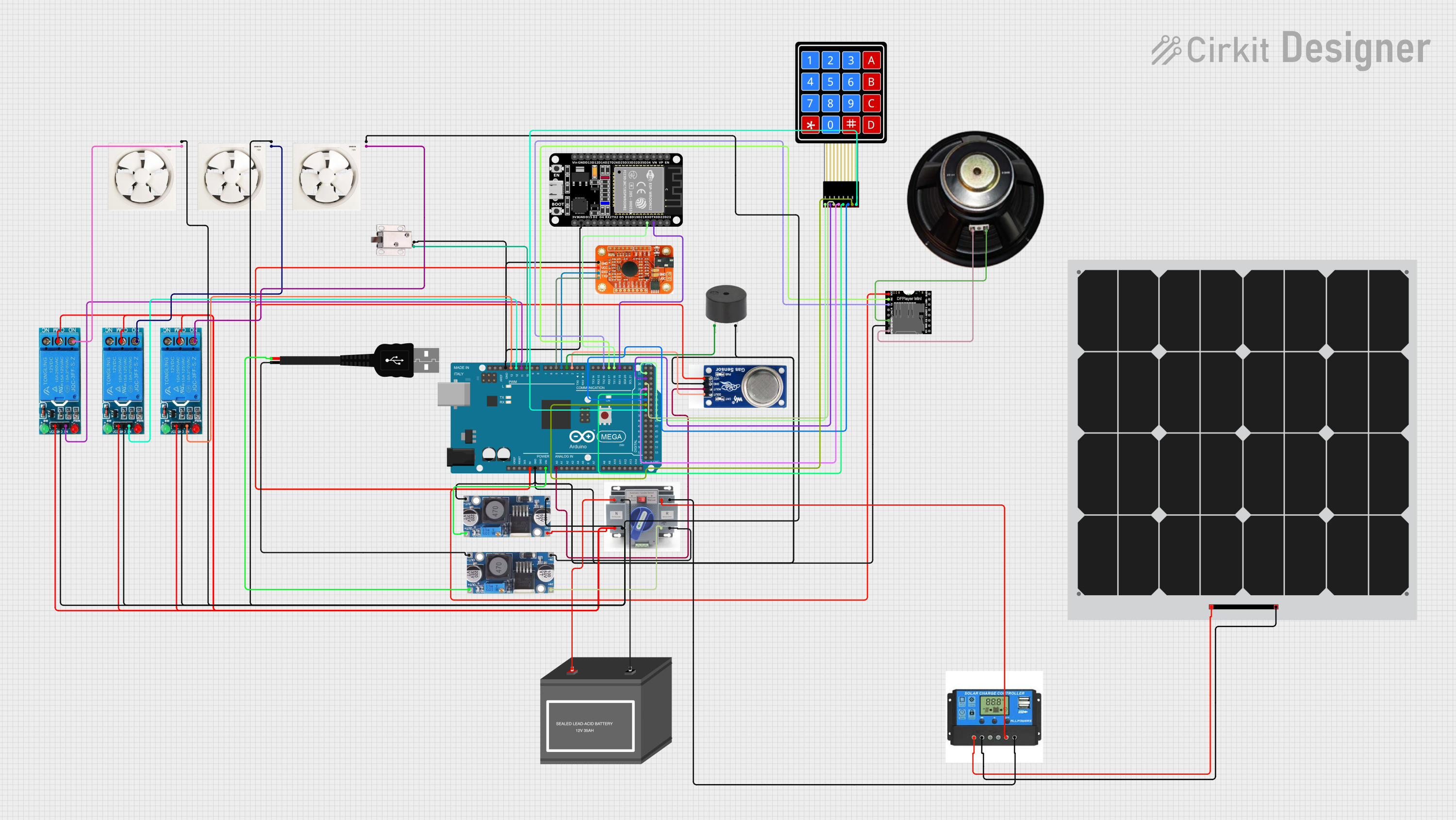

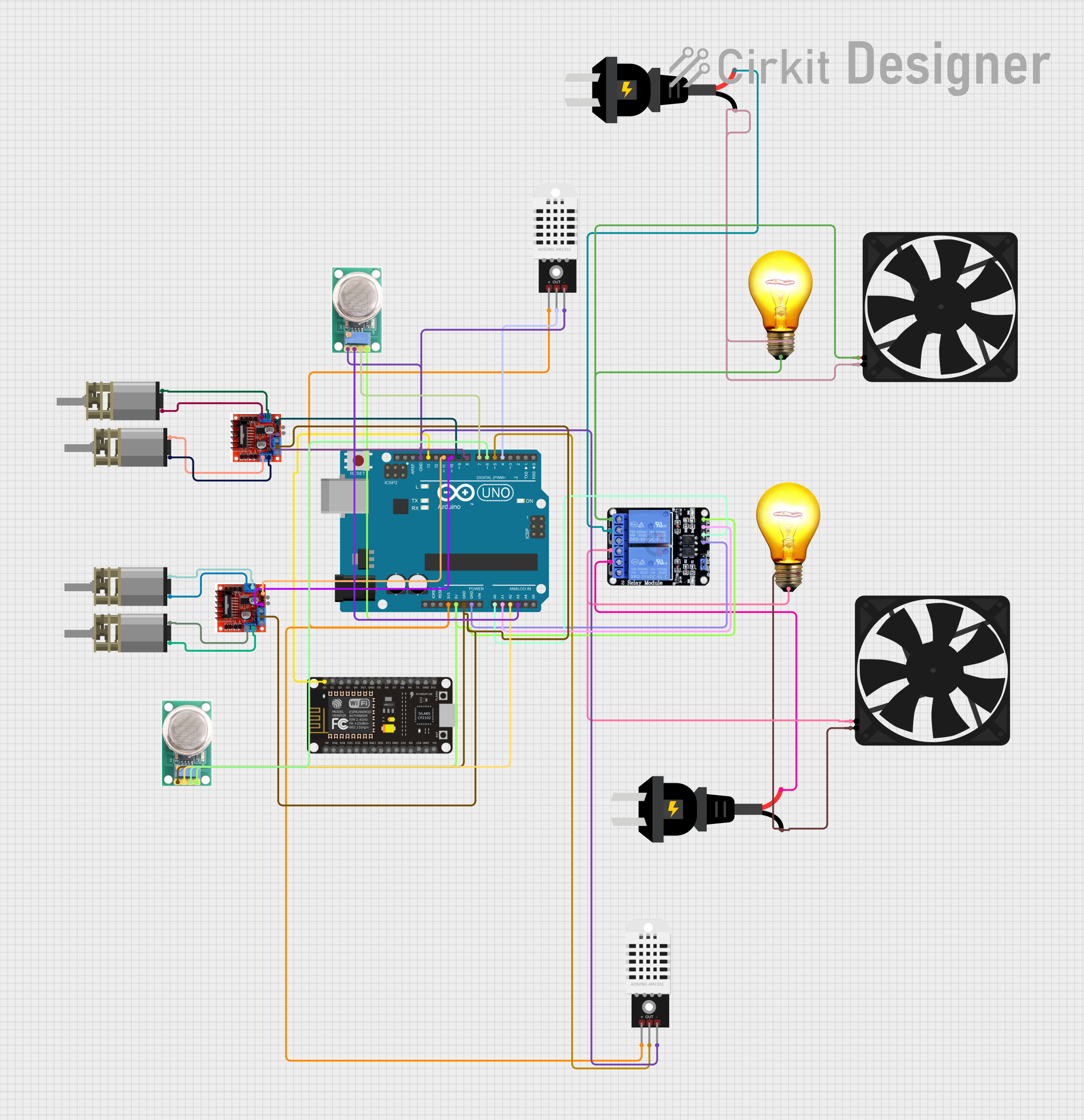

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit DesignerExplore Projects Built with Generic Domestic Boiler

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit DesignerCommon Applications and Use Cases

- Central heating systems for residential homes

- Domestic hot water supply for showers, sinks, and appliances

- Integration with smart home systems for temperature control

- Use in underfloor heating systems for even heat distribution

Technical Specifications

Key Technical Details

| Parameter | Value/Range |

|---|---|

| Energy Source | Gas, Oil, or Electricity |

| Heating Capacity | 20 kW to 50 kW (typical range) |

| Efficiency Rating | 85% to 98% (depending on model) |

| Operating Voltage | 230V AC (for electric models) |

| Water Pressure Range | 1.0 to 2.5 bar |

| Maximum Water Temperature | 80°C to 90°C |

| Ignition System | Electronic or Pilot Light |

| Safety Features | Overheat protection, pressure relief |

Pin Configuration and Descriptions

For electric boilers or boilers with electronic control systems, the following table outlines the typical terminal connections:

| Pin/Terminal Label | Description |

|---|---|

| L (Live) | Connects to the live wire of the power supply. |

| N (Neutral) | Connects to the neutral wire of the power supply. |

| E (Earth) | Ground connection for safety. |

| T1/T2 | Thermostat connections for temperature control. |

| Pump | Output to control the circulation pump. |

| CH (Central Heating) | Input for central heating control signal. |

| DHW (Domestic Hot Water) | Input for domestic hot water control signal. |

Usage Instructions

How to Use the Component in a System

Installation:

- Ensure the boiler is installed by a certified professional.

- Verify that the energy source (gas, oil, or electricity) matches the boiler's specifications.

- Connect the boiler to the central heating system and domestic hot water supply.

Wiring:

- For electric models, connect the live (L), neutral (N), and earth (E) terminals to the power supply.

- Connect the thermostat to the T1 and T2 terminals for temperature control.

- If applicable, connect the circulation pump to the designated pump terminal.

Operation:

- Set the desired temperature on the thermostat or boiler control panel.

- Turn on the boiler and monitor the pressure gauge to ensure it is within the recommended range (1.0 to 2.5 bar).

- Regularly check for any error codes or warning lights on the control panel.

Important Considerations and Best Practices

- Safety First: Always follow local regulations and safety standards during installation and operation.

- Regular Maintenance: Schedule annual servicing by a qualified technician to ensure optimal performance and safety.

- Water Pressure: Monitor the water pressure regularly. Repressurize the system if the pressure drops below 1.0 bar.

- Ventilation: Ensure proper ventilation for gas or oil boilers to prevent the buildup of harmful gases.

- Smart Integration: For advanced control, consider integrating the boiler with a smart thermostat or home automation system.

Arduino UNO Integration (for Smart Control)

If you wish to control the boiler using an Arduino UNO, you can use a relay module to switch the boiler on and off based on temperature readings. Below is an example code snippet:

// Example Arduino code to control a boiler using a relay module

// and a temperature sensor (e.g., DHT11 or DS18B20).

#include <DHT.h> // Include library for DHT sensor

#define RELAY_PIN 7 // Pin connected to the relay module

#define DHT_PIN 2 // Pin connected to the DHT sensor

#define DHT_TYPE DHT11 // Define the type of DHT sensor

DHT dht(DHT_PIN, DHT_TYPE);

void setup() {

pinMode(RELAY_PIN, OUTPUT); // Set relay pin as output

digitalWrite(RELAY_PIN, LOW); // Ensure relay is off initially

dht.begin(); // Initialize the DHT sensor

Serial.begin(9600); // Start serial communication

}

void loop() {

float temperature = dht.readTemperature(); // Read temperature in Celsius

if (isnan(temperature)) {

// Check if the temperature reading failed

Serial.println("Failed to read from DHT sensor!");

return;

}

Serial.print("Temperature: ");

Serial.println(temperature);

if (temperature < 20.0) {

// If temperature is below 20°C, turn on the boiler

digitalWrite(RELAY_PIN, HIGH);

Serial.println("Boiler ON");

} else {

// If temperature is 20°C or above, turn off the boiler

digitalWrite(RELAY_PIN, LOW);

Serial.println("Boiler OFF");

}

delay(2000); // Wait for 2 seconds before the next reading

}

Note: Ensure the relay module is rated for the boiler's voltage and current requirements. Use proper isolation techniques to prevent electrical hazards.

Troubleshooting and FAQs

Common Issues and Solutions

| Issue | Possible Cause | Solution |

|---|---|---|

| Boiler not turning on | Power supply issue or blown fuse | Check the power supply and replace the fuse if necessary. |

| Low water pressure | Leak in the system or insufficient water | Repressurize the system and check for leaks. |

| Boiler overheating | Faulty thermostat or blocked heat exchanger | Replace the thermostat or clean the heat exchanger. |

| Error code displayed | Manufacturer-specific fault | Refer to the boiler's user manual for error code details. |

| No hot water | Faulty diverter valve or thermostat | Replace the diverter valve or thermostat. |

FAQs

Can I install the boiler myself?

- No, boilers must be installed by a certified professional to ensure safety and compliance with local regulations.

How often should I service my boiler?

- It is recommended to service your boiler annually to maintain efficiency and safety.

What should I do if the boiler pressure is too high?

- Bleed the radiators to release excess pressure. If the issue persists, contact a technician.

Can I use the boiler with a smart thermostat?

- Yes, most modern boilers are compatible with smart thermostats. Check the boiler's specifications for compatibility.

What is the lifespan of a domestic boiler?

- A well-maintained boiler typically lasts 10 to 15 years. Regular servicing can extend its lifespan.