How to Use VNH2SP30: Examples, Pinouts, and Specs

Design with VNH2SP30 in Cirkit Designer

Design with VNH2SP30 in Cirkit DesignerIntroduction

The VNH2SP30 is a full-bridge motor driver integrated circuit (IC) designed for driving high-power DC motors. It is capable of delivering a continuous current of up to 14A and can handle peak currents up to 30A. This IC is well-suited for applications in robotics, automotive, and industrial automation where precise and efficient motor control is required. Its built-in protection features make it a robust and reliable choice for engineers and hobbyists alike.

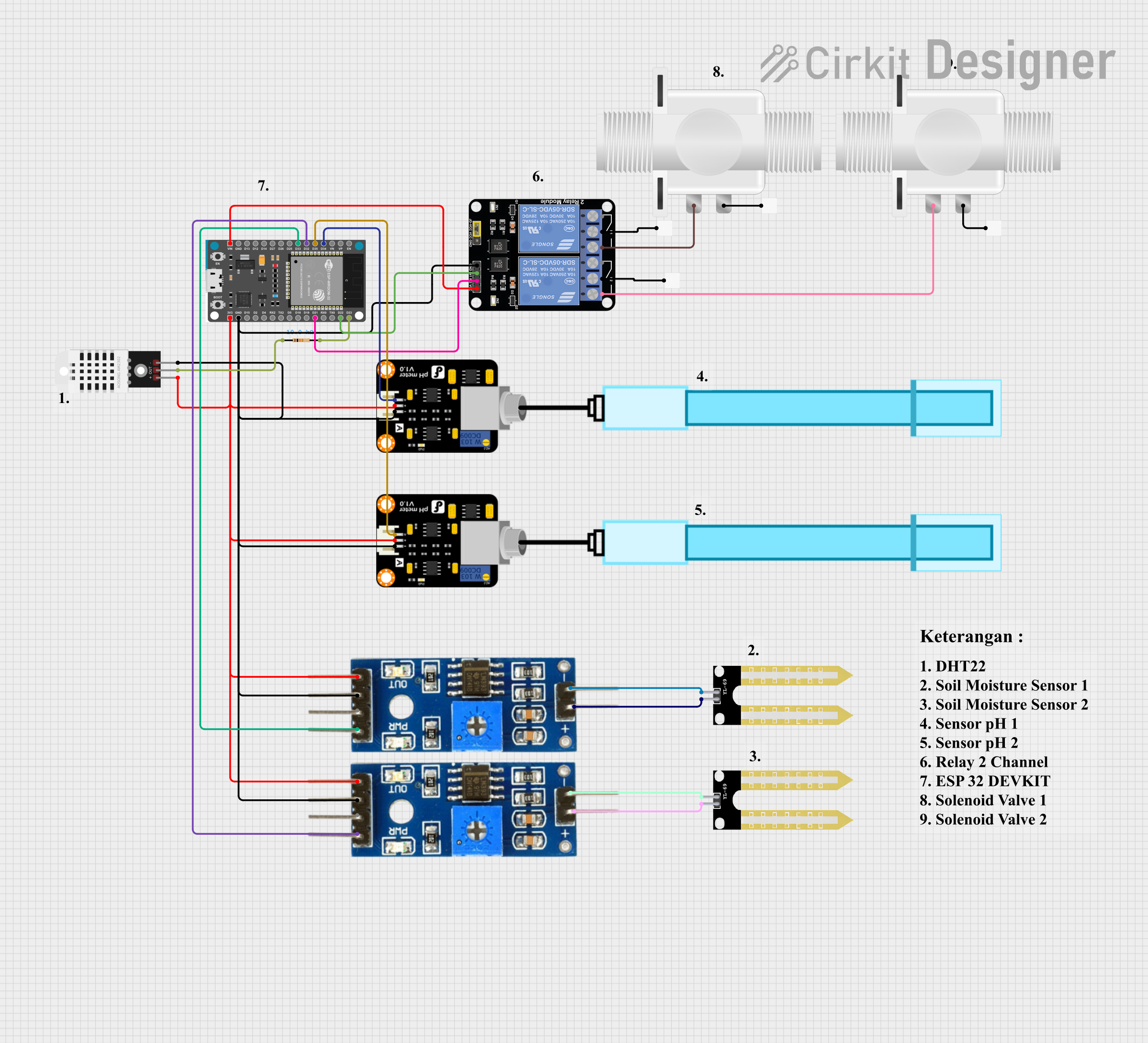

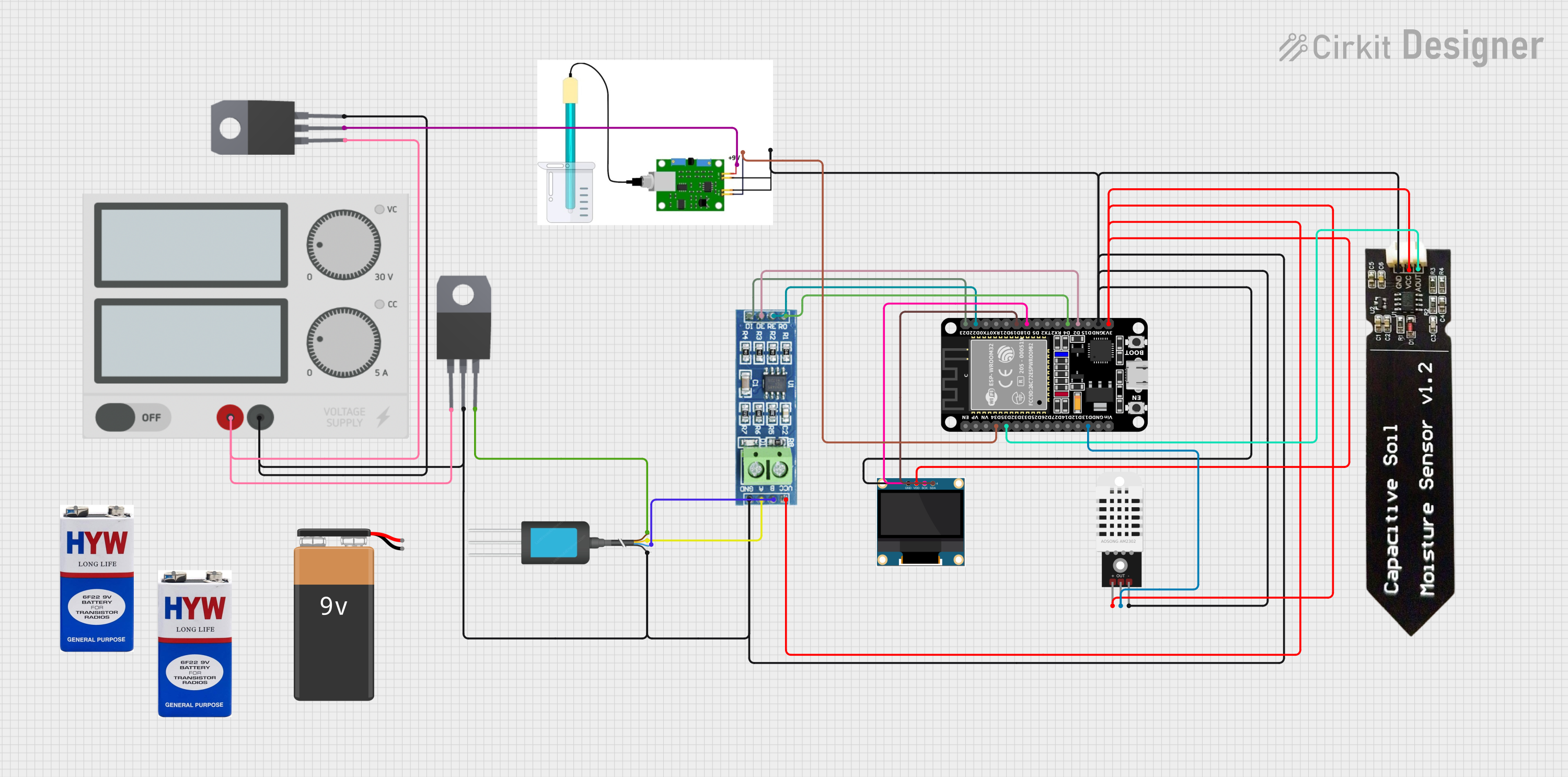

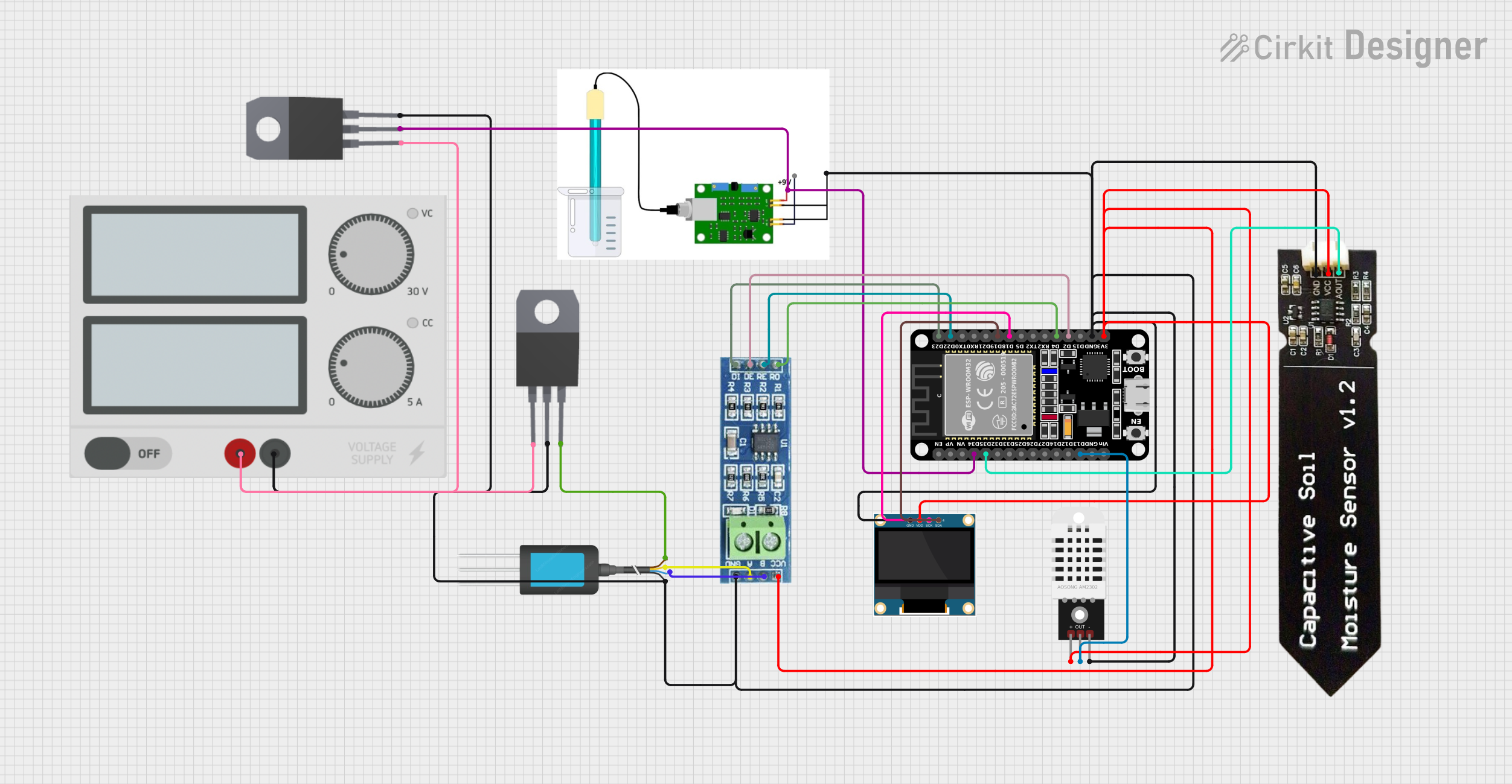

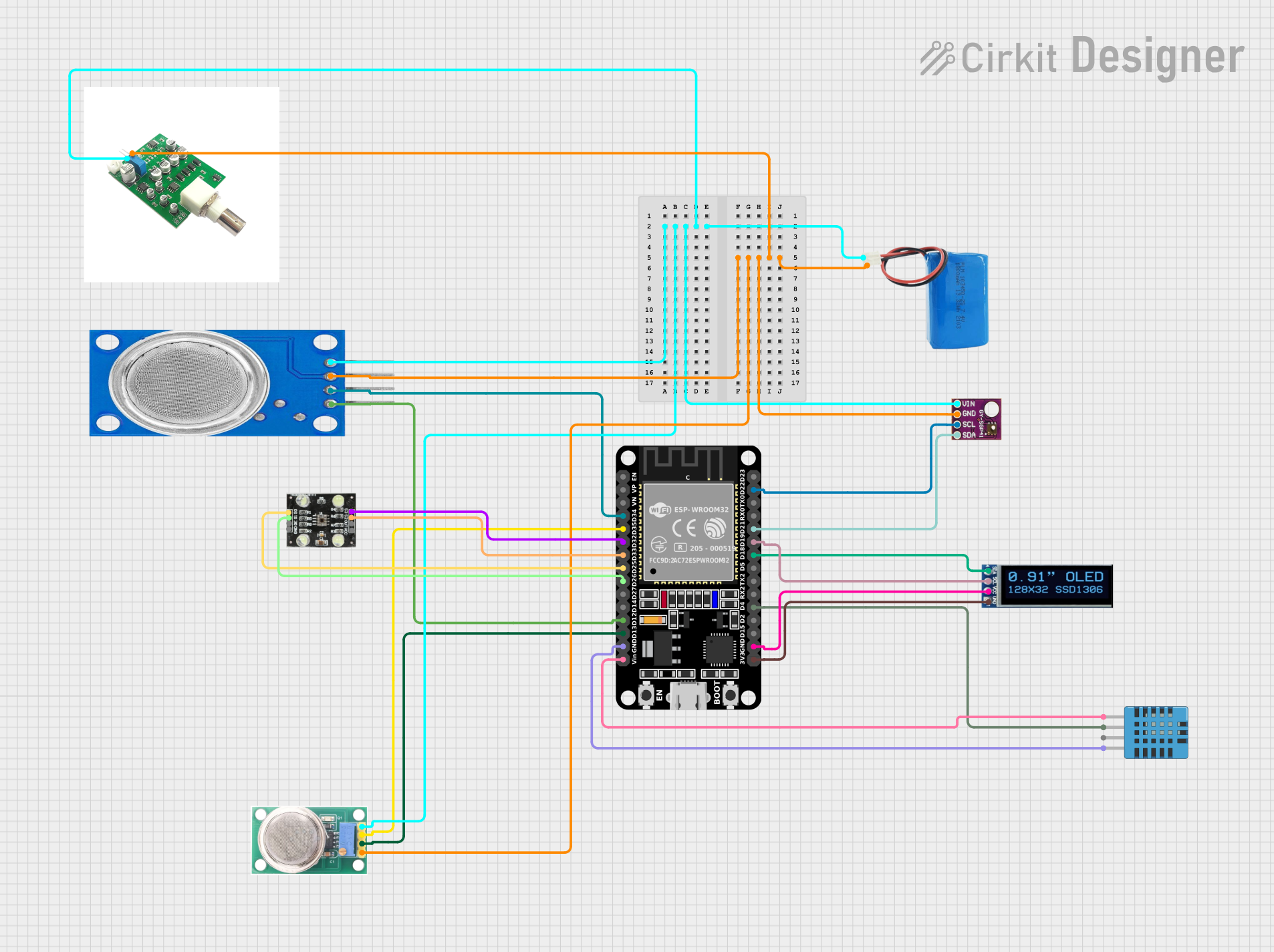

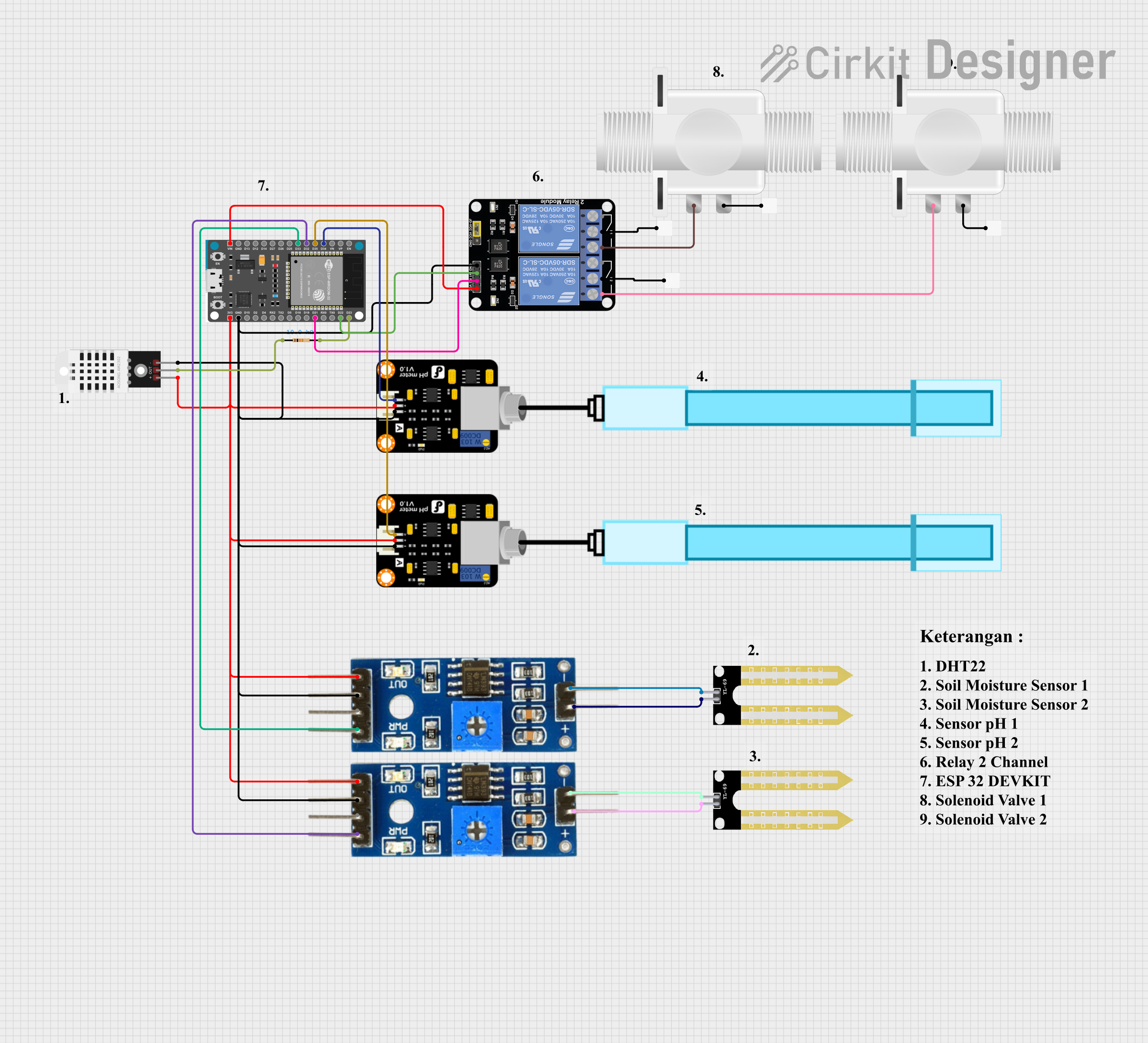

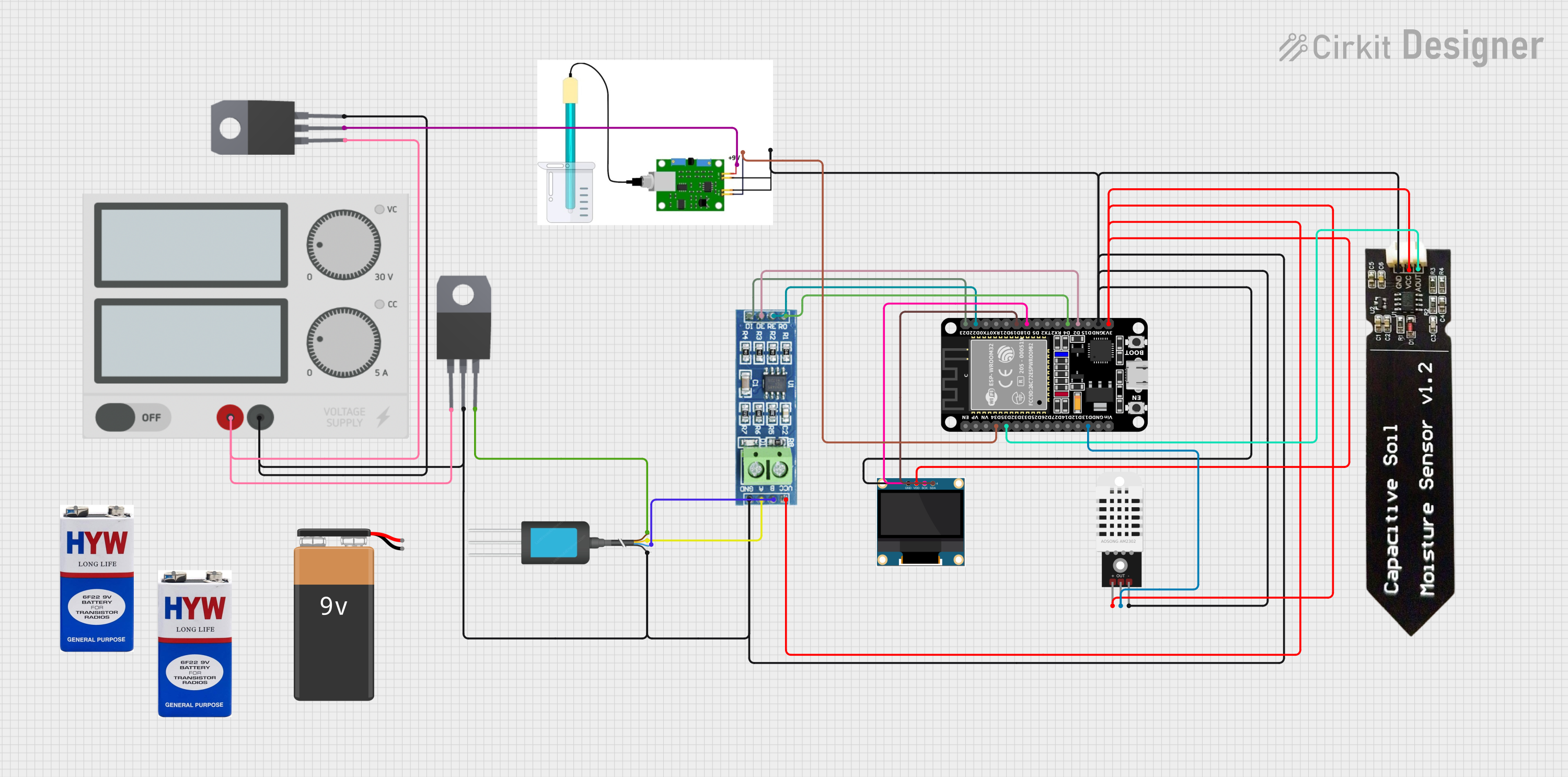

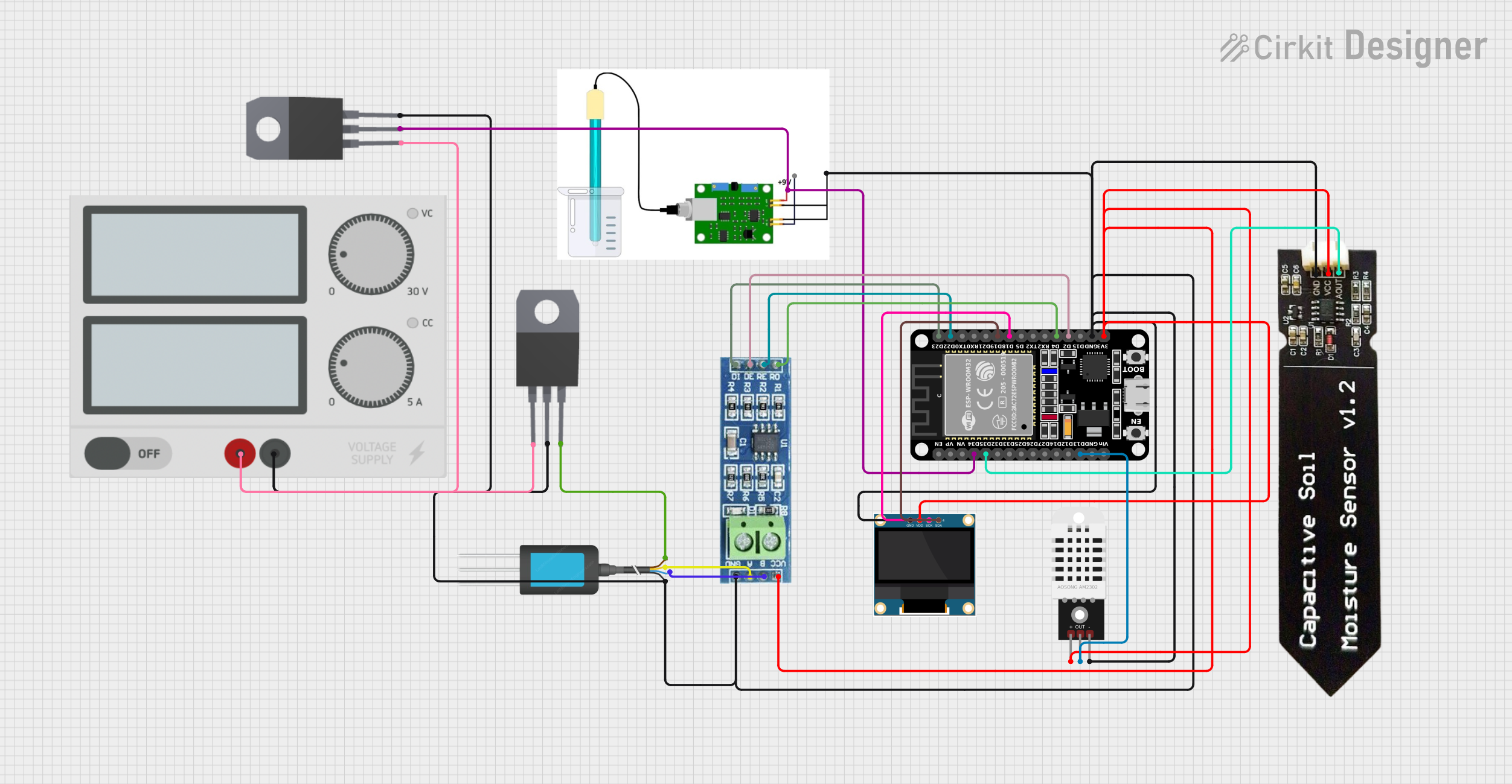

Explore Projects Built with VNH2SP30

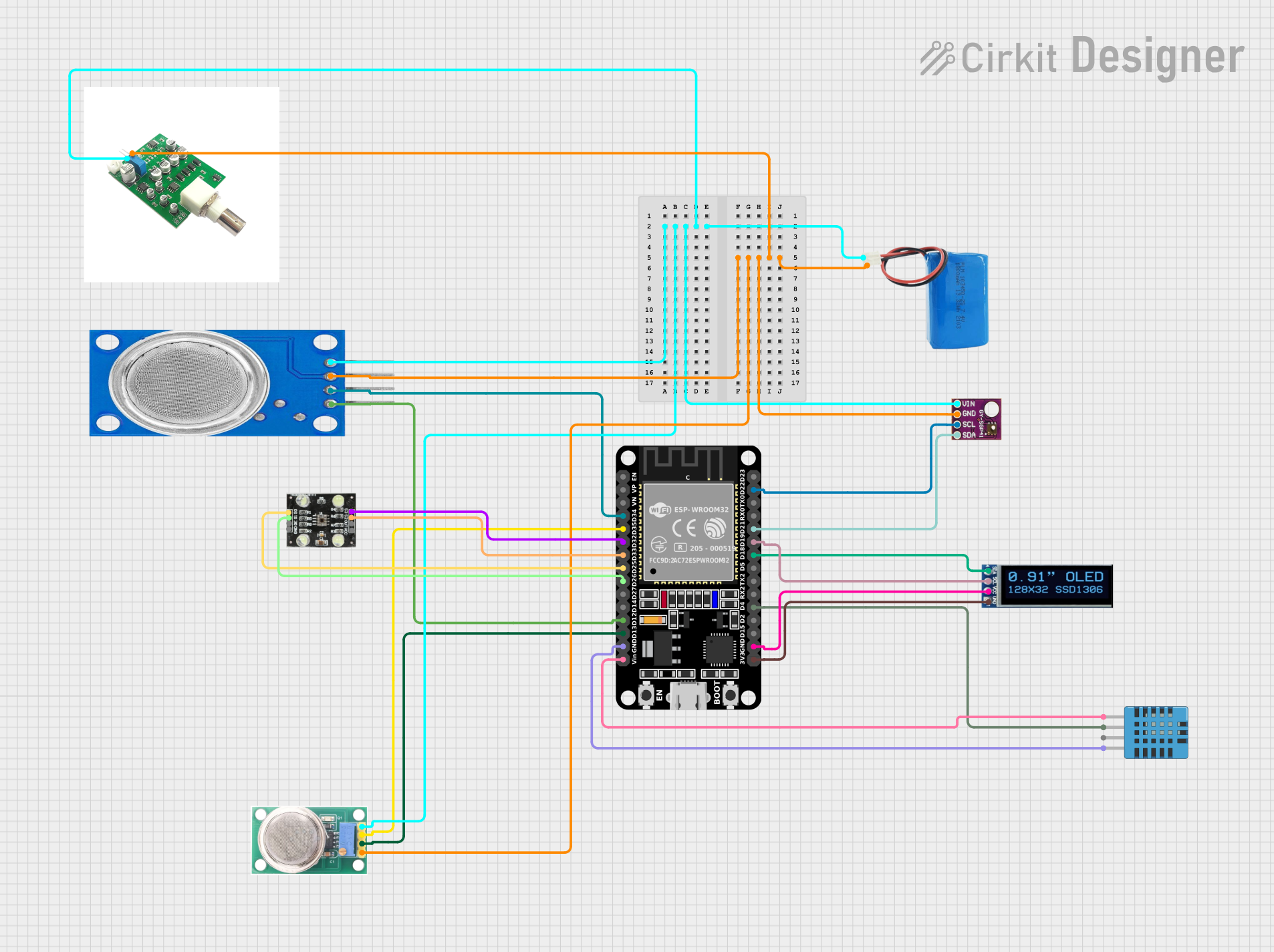

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit DesignerExplore Projects Built with VNH2SP30

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit DesignerCommon Applications and Use Cases

- Robotic vehicles and arms

- Automotive electronic throttle control

- Industrial automation systems

- High-power DC motor control applications

Technical Specifications

Key Technical Details

- Motor Supply Voltage (Vcc): 5.5V to 16V

- Logic Supply Voltage (Vss): 2.5V to 5.5V

- Continuous Output Current (Iout): 14A

- Peak Output Current (Ipeak): 30A (for a few milliseconds)

- PWM Frequency: Up to 20 kHz

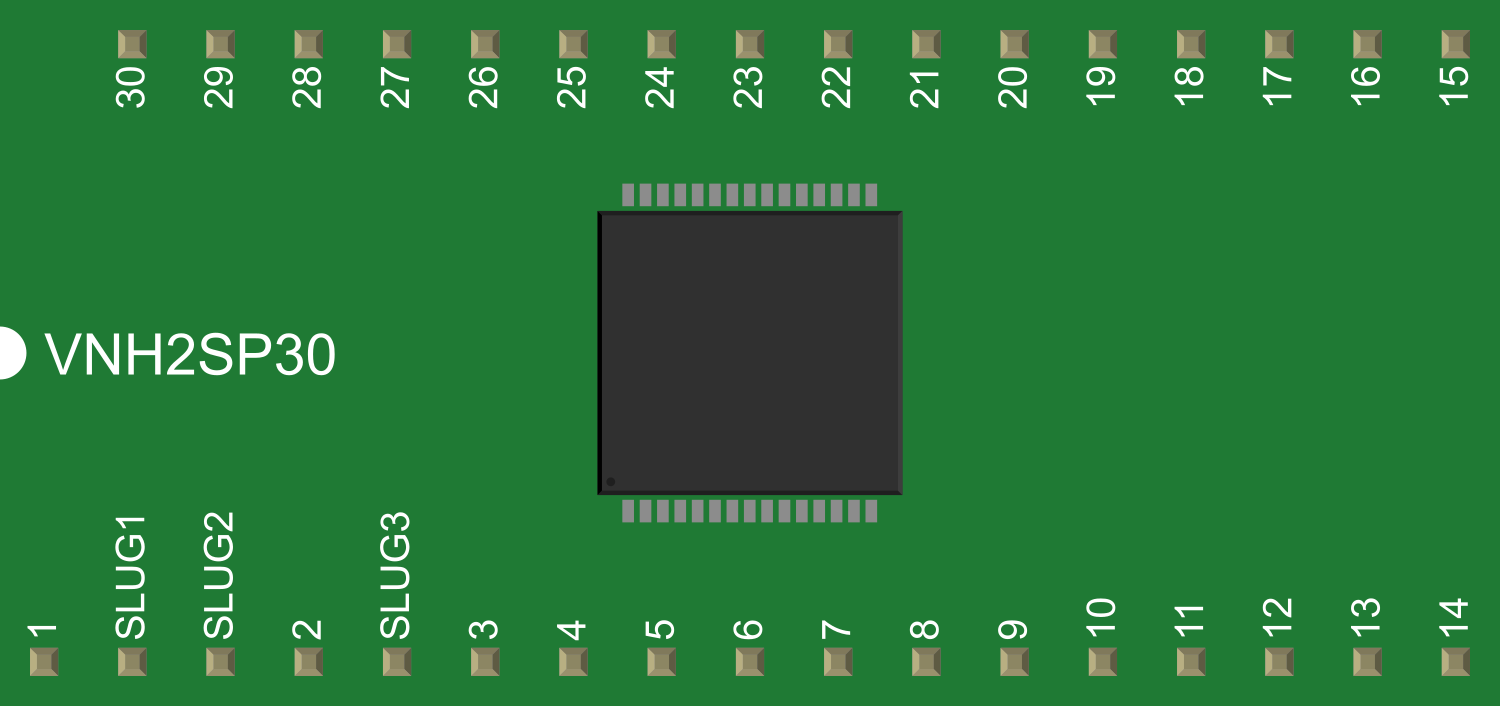

Pin Configuration and Descriptions

| Pin Number | Pin Name | Description |

|---|---|---|

| 1 | Vcc | Motor power supply (5.5V to 16V) |

| 2 | GND | Ground connection |

| 3 | INA | Input A for PWM and direction control |

| 4 | INB | Input B for PWM and direction control |

| 5 | PWM | Pulse Width Modulation input |

| 6 | CS | Current sense analog output |

| 7 | EN | Enable input (active high) |

| 8 | DIAGA | Diagnostic output A |

| 9 | DIAGB | Diagnostic output B |

Usage Instructions

How to Use the Component in a Circuit

- Power Connections: Connect the motor supply voltage (Vcc) to pin 1 and ground (GND) to pin 2.

- Control Inputs: Connect INA and INB (pins 3 and 4) to your microcontroller or control circuit to set the motor direction.

- PWM Input: Apply a PWM signal to the PWM pin (pin 5) to control the speed of the motor.

- Enable Pin: Set the EN pin (pin 7) high to enable the driver.

- Current Sensing: The CS pin (pin 6) provides an analog voltage proportional to the motor current.

- Diagnostics: DIAGA and DIAGB (pins 8 and 9) can be used to monitor the status of the driver and motor.

Important Considerations and Best Practices

- Ensure that the power supply voltage does not exceed the maximum rating of 16V.

- Use a proper heat sink to dissipate heat during high current operation.

- Implement flyback diodes on the motor terminals if inductive loads are used.

- Avoid running the motor driver at its peak current rating for extended periods to prevent thermal shutdown.

- Use short and thick wires for motor connections to minimize voltage drops and power losses.

Troubleshooting and FAQs

Common Issues Users Might Face

- Motor not running: Check power supply connections, ensure the EN pin is set high, and verify that the PWM signal is being applied.

- Overheating: Make sure a heat sink is attached and that the current does not exceed the continuous rating for extended periods.

- Erratic motor behavior: Confirm that the input signals (INA, INB, PWM) are clean and without noise.

Solutions and Tips for Troubleshooting

- Double-check wiring and solder joints for any loose connections or shorts.

- Use an oscilloscope to examine the control signals for integrity.

- Ensure that the power supply is capable of delivering the required current for your motor.

FAQs

Q: Can I drive two motors with one VNH2SP30? A: No, the VNH2SP30 is designed to drive one motor. For two motors, you would need two ICs.

Q: What is the maximum PWM frequency I can use? A: The VNH2SP30 can handle PWM frequencies up to 20 kHz.

Q: How do I use the current sense feature? A: The CS pin outputs an analog voltage proportional to the motor current. You can read this voltage with an ADC to monitor the current draw.

Example Code for Arduino UNO

// Define control pins for VNH2SP30

const int inAPin = 2; // INA pin

const int inBPin = 3; // INB pin

const int pwmPin = 5; // PWM pin

const int enPin = 4; // Enable pin

void setup() {

// Set control pins as outputs

pinMode(inAPin, OUTPUT);

pinMode(inBPin, OUTPUT);

pinMode(pwmPin, OUTPUT);

pinMode(enPin, OUTPUT);

// Enable the motor driver

digitalWrite(enPin, HIGH);

}

void loop() {

// Set motor direction to forward

digitalWrite(inAPin, HIGH);

digitalWrite(inBPin, LOW);

// Set motor speed (PWM value 0 to 255)

analogWrite(pwmPin, 128); // 50% duty cycle

// Add a delay to see the motor in action

delay(2000);

// Change motor direction to reverse

digitalWrite(inAPin, LOW);

digitalWrite(inBPin, HIGH);

// Keep the same motor speed

delay(2000);

}

Remember to adjust the PWM value to control the speed of the motor and ensure that the control signals do not exceed the logic supply voltage (Vss) limits.