How to Use spin dryer motor 2.0: Examples, Pinouts, and Specs

Design with spin dryer motor 2.0 in Cirkit Designer

Design with spin dryer motor 2.0 in Cirkit DesignerIntroduction

The Spin Dryer Motor 2.0 is an essential component designed to power the rotation of the spin dryer drum in laundry machines. This motor is responsible for creating the centrifugal force needed to extract water from clothing by rapidly spinning the drum. It is commonly used in household and commercial laundry appliances due to its reliability and efficiency.

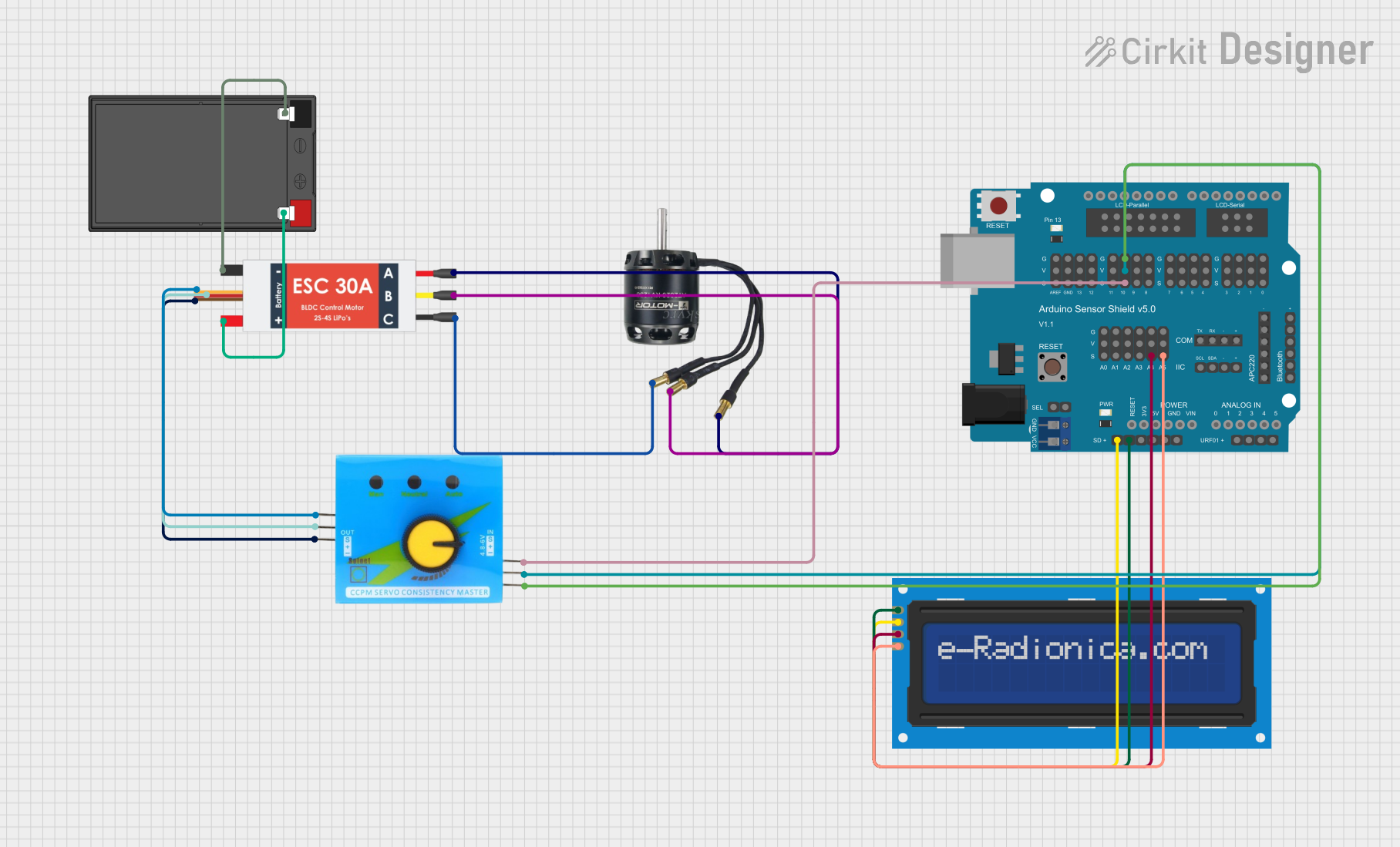

Explore Projects Built with spin dryer motor 2.0

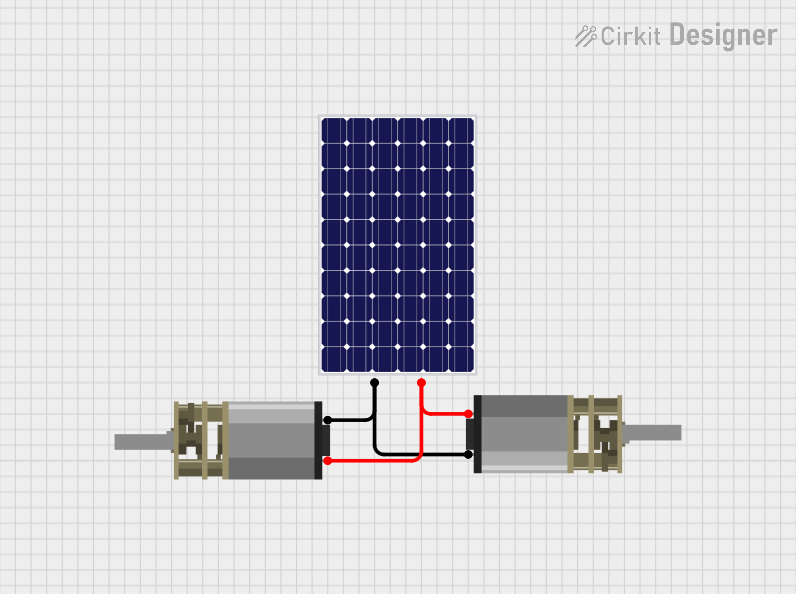

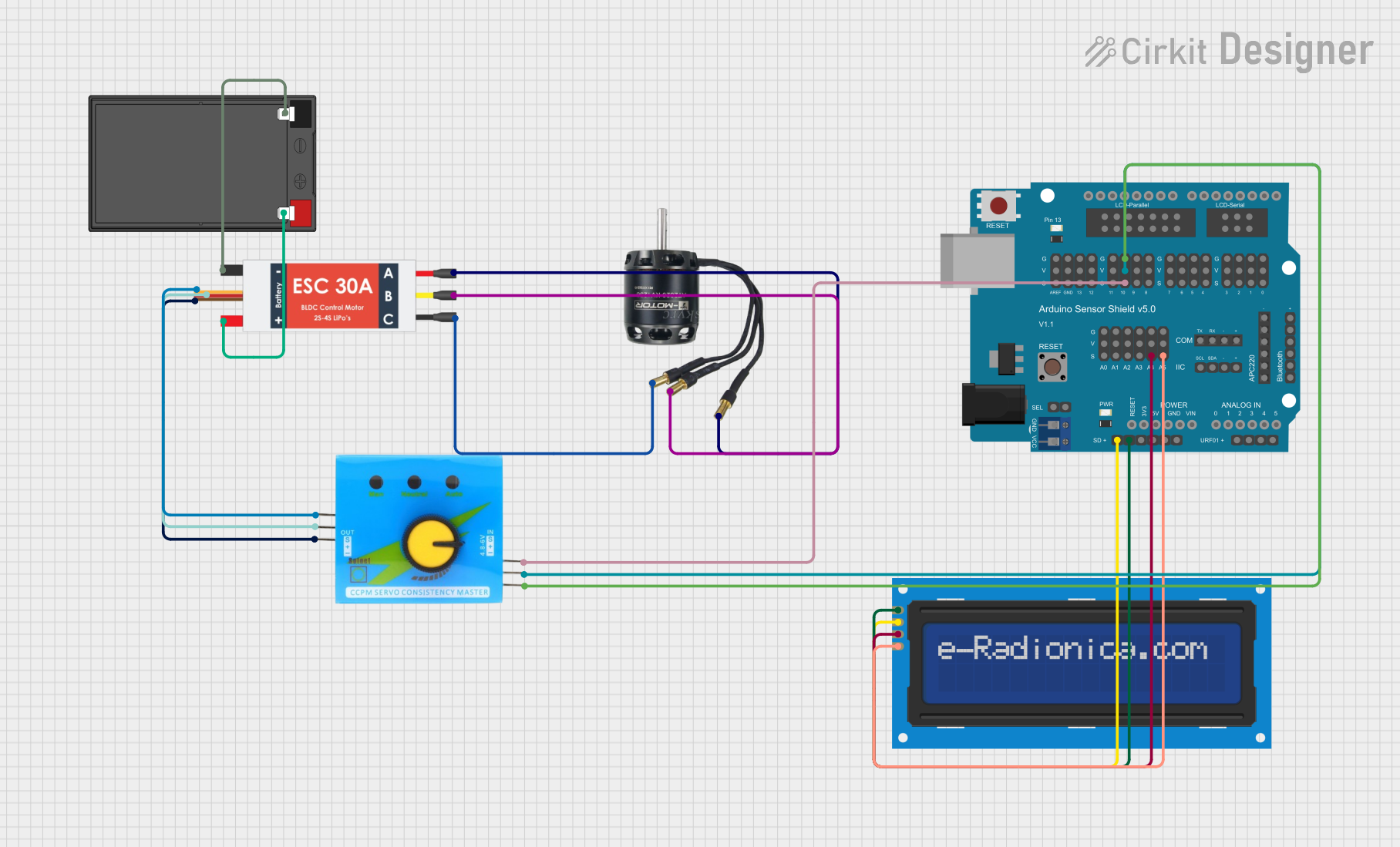

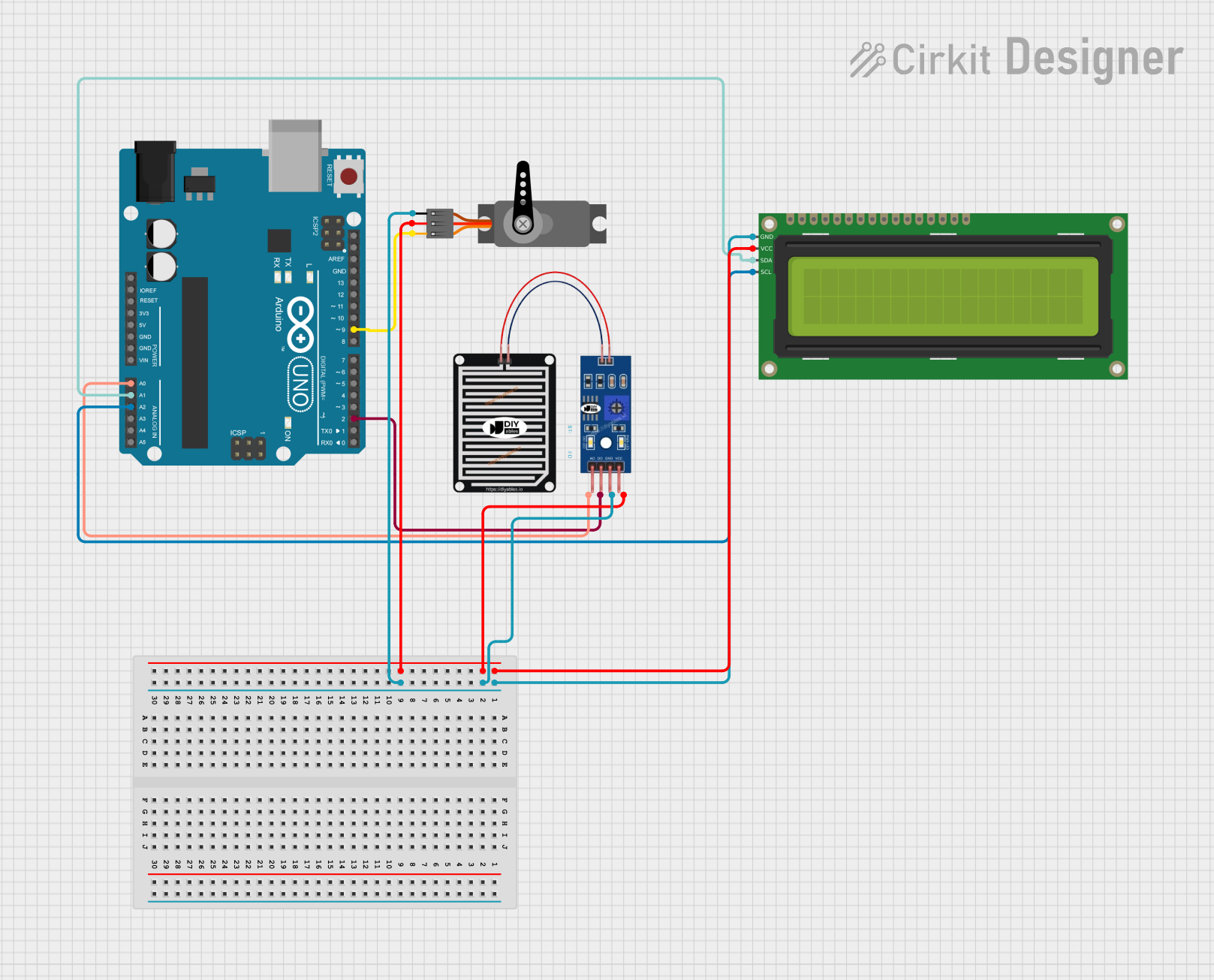

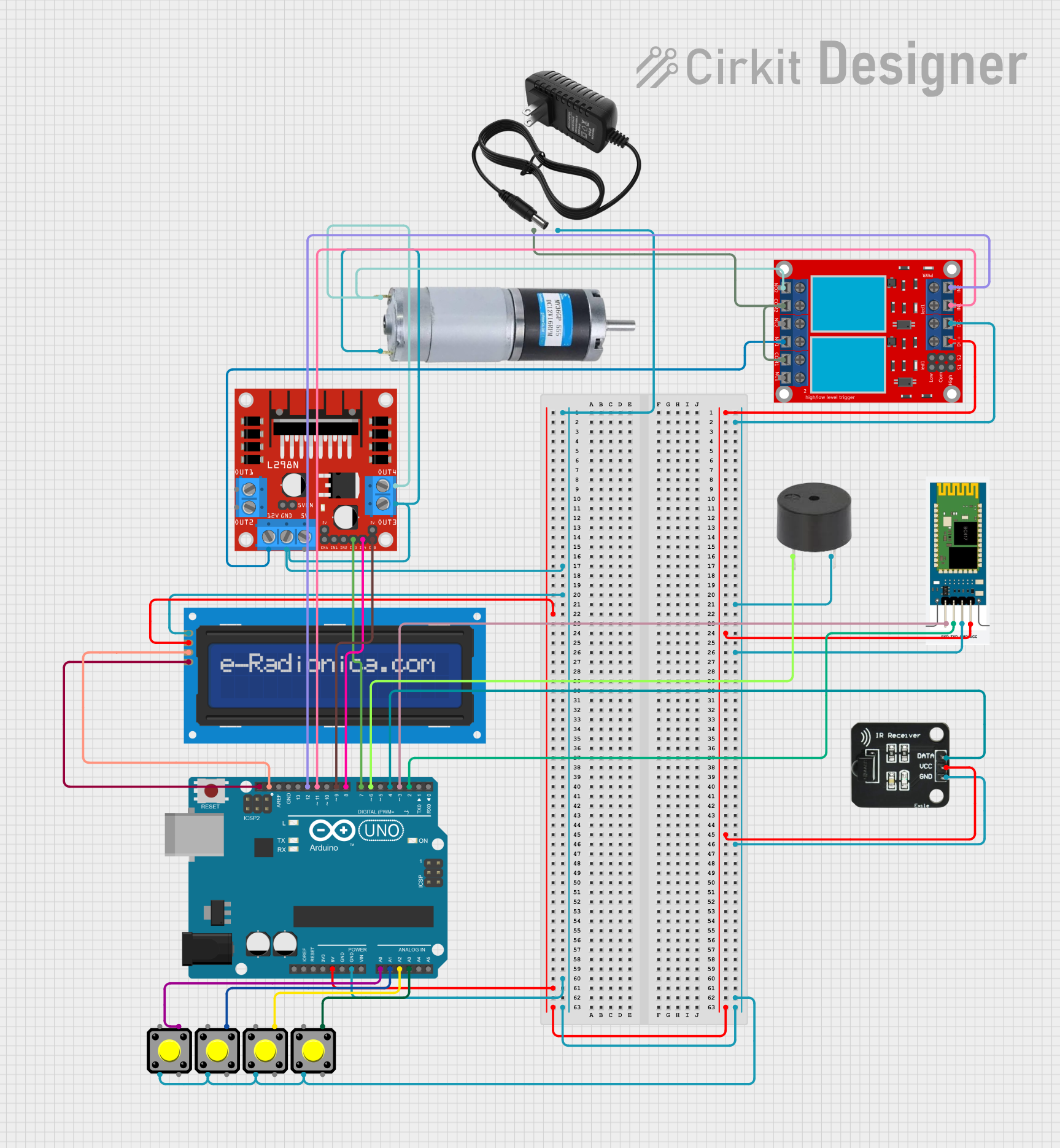

Open Project in Cirkit Designer

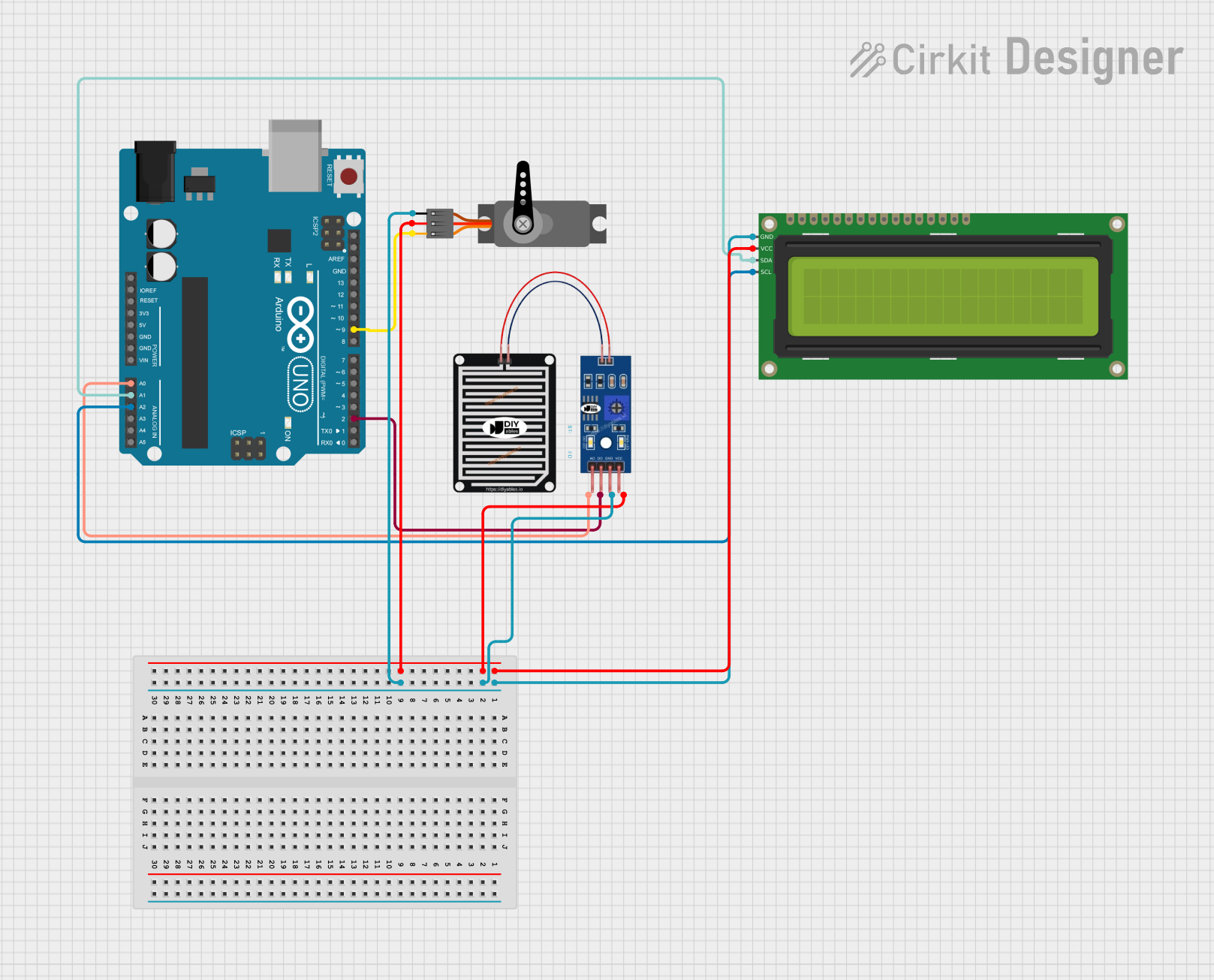

Open Project in Cirkit Designer

Open Project in Cirkit Designer

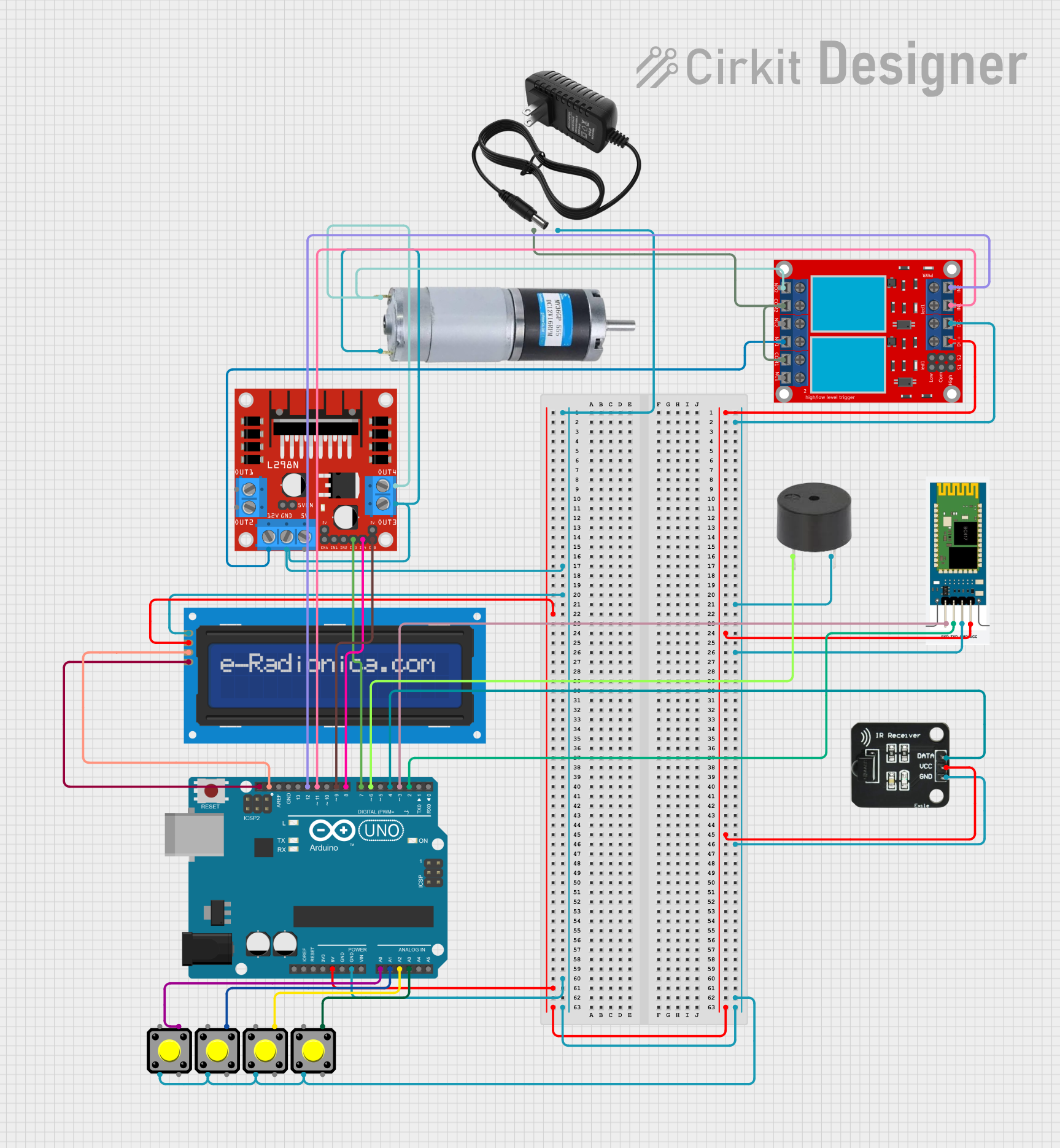

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit DesignerExplore Projects Built with spin dryer motor 2.0

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit DesignerCommon Applications and Use Cases

- Household washing machines

- Commercial laundry dryers

- Industrial centrifuges

Technical Specifications

Key Technical Details

| Specification | Value | Description |

|---|---|---|

| Voltage Rating | 220-240V AC | Operating voltage range |

| Frequency | 50/60 Hz | Compatible power supply frequency |

| Power Rating | 500W | Maximum power output |

| Speed | 2800 RPM | Revolutions per minute at full speed |

| Insulation Class | Class E | Insulation grade for safety |

| Duty Cycle | S2 5 minutes | Intermittent duty with 5 minutes operation |

| Mounting Type | Horizontal/Vertical | Orientation options for installation |

| Protection Class | IPX4 | Protection against water splashes from any direction |

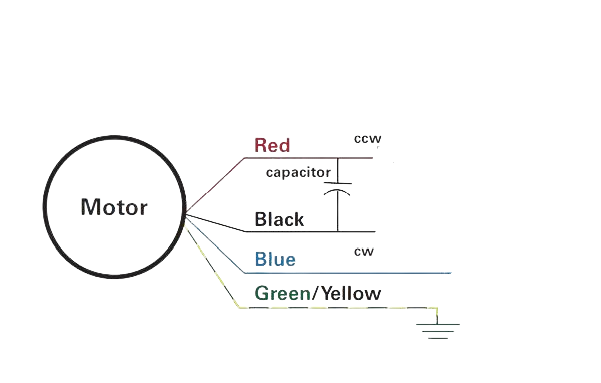

Pin Configuration and Descriptions

| Pin Number | Description | Notes |

|---|---|---|

| 1 | Live (L) | Connect to phase wire of power supply |

| 2 | Neutral (N) | Connect to neutral wire of power supply |

| 3 | Ground (⏚) | Safety ground connection |

Usage Instructions

How to Use the Component in a Circuit

- Mounting the Motor: Secure the motor to the appliance using the provided mounting brackets. Ensure that the motor shaft is aligned with the drum pulley.

- Electrical Connections: Connect the live (L) and neutral (N) wires to the corresponding pins on the motor. The ground (⏚) pin must be connected to the appliance's grounding system.

- Testing: Before full operation, perform a test run to ensure that the motor spins correctly and that there are no unusual noises or vibrations.

Important Considerations and Best Practices

- Electrical Safety: Always disconnect the appliance from the power source before attempting any installation or maintenance.

- Load Balancing: Ensure that the laundry load is evenly distributed to prevent excessive vibration and wear on the motor.

- Ventilation: Adequate cooling is necessary. Ensure the motor has proper ventilation to prevent overheating.

- Compatibility: Verify that the motor's specifications match the appliance's requirements.

Troubleshooting and FAQs

Common Issues and Solutions

Motor Does Not Start:

- Check if the power supply is connected and switched on.

- Verify that the wiring to the motor is correct and secure.

- Inspect the motor's capacitor, if applicable, for signs of damage.

Excessive Vibration:

- Ensure the laundry load is balanced within the drum.

- Check that the motor is securely mounted and that all screws are tightened.

Motor Overheating:

- Confirm that the motor is not running beyond its rated duty cycle.

- Check for adequate ventilation around the motor.

FAQs

Q: Can the motor be used with a variable frequency drive (VFD)? A: Yes, but ensure that the VFD is compatible with the motor's specifications.

Q: What maintenance is required for the Spin Dryer Motor 2.0? A: Regularly check for loose connections and signs of wear. Lubricate bearings if necessary.

Q: Is it possible to reverse the motor's direction? A: The direction is fixed and cannot be reversed due to the design of the motor intended for spin dryers.

Q: What should I do if the motor's thermal protection trips? A: Allow the motor to cool down before resetting the protection device. Check for any conditions that may cause overheating.

Note: This documentation is provided for informational purposes only. Always consult a professional for installation and service of electrical components.