How to Use stepper motor driver: Examples, Pinouts, and Specs

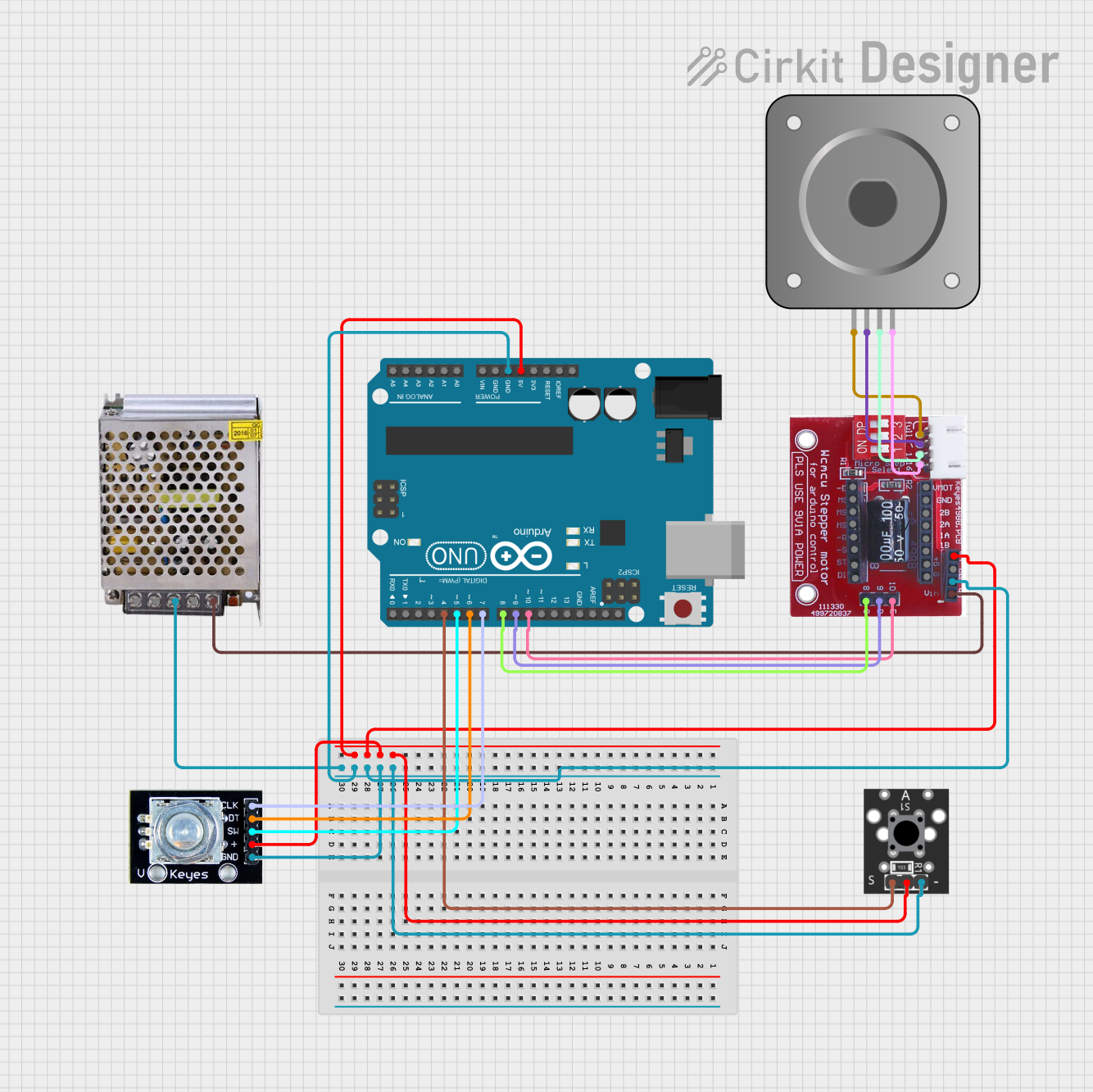

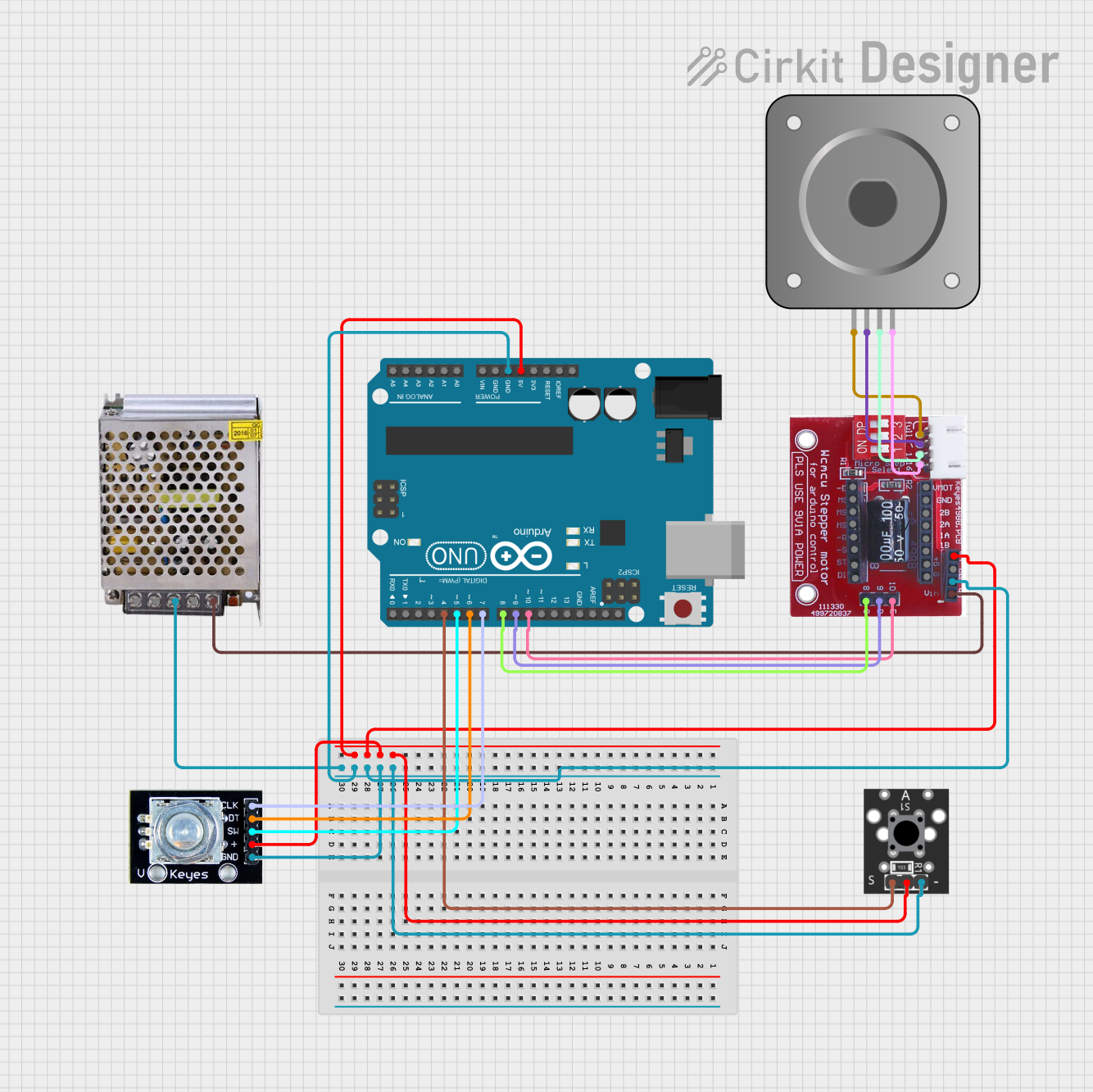

Design with stepper motor driver in Cirkit Designer

Design with stepper motor driver in Cirkit DesignerIntroduction

A stepper motor driver is an electronic device designed to drive a stepper motor, which is a type of electric motor that divides a full rotation into a number of equal steps. The driver controls the current sent to the motor coils, enabling precise control of the motor in both position and speed. Stepper motor drivers are widely used in CNC machines, 3D printers, robotics, and other applications where precise motion control is required.

Explore Projects Built with stepper motor driver

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit DesignerExplore Projects Built with stepper motor driver

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit DesignerTechnical Specifications

Key Technical Details

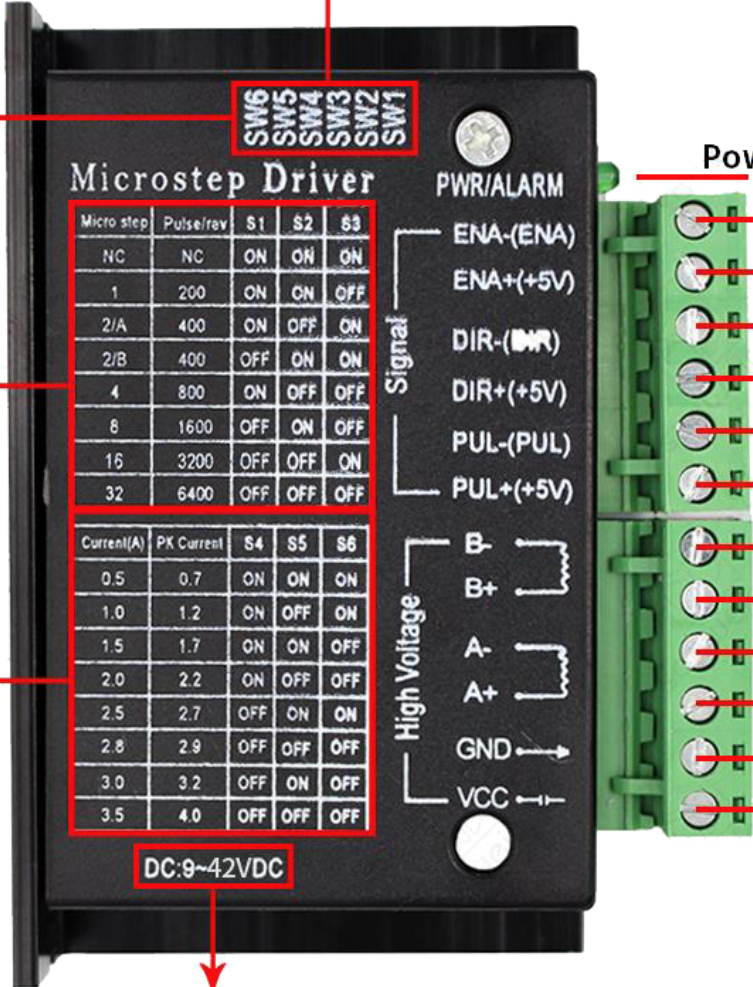

- Input Voltage Range: Typically from 8V to 35V (varies by model)

- Output Current: Up to 2A per coil (varies by model)

- Microstepping Support: Full, 1/2, 1/4, 1/8, etc. (model dependent)

- Logic Input Voltage: 3.3V to 5V (compatible with most microcontrollers)

Pin Configuration and Descriptions

| Pin Name | Description |

|---|---|

| VDD | Logic supply voltage (3.3V to 5V) |

| GND | Ground connection |

| VMOT | Motor supply voltage (8V to 35V) |

| 1A, 1B | Motor coil 1 connections |

| 2A, 2B | Motor coil 2 connections |

| STEP | Step input (pulses to move the motor) |

| DIR | Direction input (high for one direction, low for the opposite) |

| EN | Enable input (active low to enable the driver) |

| MS1, MS2, MS3 | Microstepping configuration pins (logic level sets microstepping mode) |

| FAULT | Fault output (active low indicates a fault condition) |

Usage Instructions

Connecting the Stepper Motor Driver to a Circuit

- Connect the motor coils to the driver's 1A, 1B, 2A, and 2B pins.

- Supply the logic voltage (VDD) and ground (GND) from the microcontroller to the driver.

- Connect the motor power supply to VMOT and ground.

- Set the desired microstepping resolution by configuring the MS1, MS2, and MS3 pins.

- Connect the STEP and DIR pins to the microcontroller's digital output pins.

Important Considerations and Best Practices

- Ensure that the power supply voltage and current capabilities match the requirements of the stepper motor and driver.

- Use appropriate heat sinking or cooling for the driver if operating at high currents.

- Configure microstepping according to the precision and smoothness required for the application.

- Always de-energize the circuit before making or changing connections to prevent damage.

Example Code for Arduino UNO

// Define the connection pins

const int stepPin = 2; // STEP pin connected to digital pin 2

const int dirPin = 3; // DIR pin connected to digital pin 3

void setup() {

// Set the pin modes

pinMode(stepPin, OUTPUT);

pinMode(dirPin, OUTPUT);

}

void loop() {

// Set the direction

digitalWrite(dirPin, HIGH); // Set to HIGH for one direction

// Move the motor with a simple stepping pattern

for (int i = 0; i < 200; i++) {

// Trigger one step forward

digitalWrite(stepPin, HIGH);

delayMicroseconds(1000); // Wait for 1000 microseconds

digitalWrite(stepPin, LOW);

delayMicroseconds(1000); // Wait for 1000 microseconds

}

delay(1000); // Wait for a second

// Change direction

digitalWrite(dirPin, LOW); // Set to LOW for the opposite direction

// Move the motor in the opposite direction

for (int i = 0; i < 200; i++) {

// Trigger one step backward

digitalWrite(stepPin, HIGH);

delayMicroseconds(1000); // Wait for 1000 microseconds

digitalWrite(stepPin, LOW);

delayMicroseconds(1000); // Wait for 1000 microseconds

}

delay(1000); // Wait for a second

}

Troubleshooting and FAQs

Common Issues

- Motor not moving: Check power supply, connections, and ensure the enable pin is set correctly.

- Motor stalling or skipping steps: This may be due to insufficient current, overloading, or incorrect microstepping settings.

- Overheating: Ensure proper heat dissipation and check if the current settings are too high.

Solutions and Tips for Troubleshooting

- Verify all connections are secure and correct.

- Use a multimeter to check the power supply voltage and current.

- Adjust the current limit according to the motor's specifications.

- Ensure the microcontroller's code matches the desired motor behavior.

FAQs

Q: Can I use a stepper motor driver with any stepper motor? A: While many drivers are quite versatile, always check that the driver's voltage and current ratings are compatible with the motor.

Q: What is microstepping and why is it important? A: Microstepping divides a full step into smaller steps for smoother motion and increased resolution. It's important for applications requiring precise positioning.

Q: How do I adjust the current limit on the driver? A: This depends on the specific driver model. Some have a potentiometer that can be adjusted with a screwdriver, while others may require setting via software or digital inputs.

Remember to always consult the specific datasheet for your stepper motor driver model for the most accurate and detailed information.