How to Use DC Motor_small: Examples, Pinouts, and Specs

Design with DC Motor_small in Cirkit Designer

Design with DC Motor_small in Cirkit DesignerIntroduction

The DC Motor_small is a compact direct current motor designed to convert electrical energy into mechanical energy. It is widely used in low-power applications due to its simplicity, efficiency, and ease of control. This motor is ideal for projects involving toys, small appliances, robotics, and other applications requiring rotational motion.

Common applications include:

- Driving wheels in small robots

- Operating fans or propellers

- Powering conveyor belts in miniature systems

- Actuating mechanisms in toys and small devices

Explore Projects Built with DC Motor_small

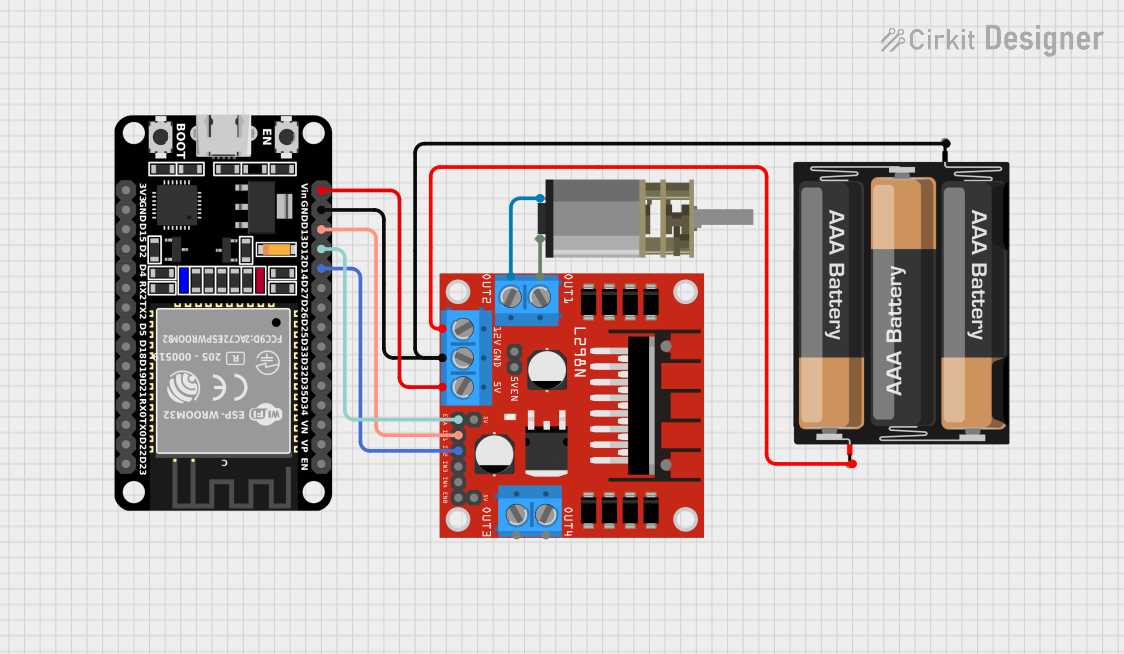

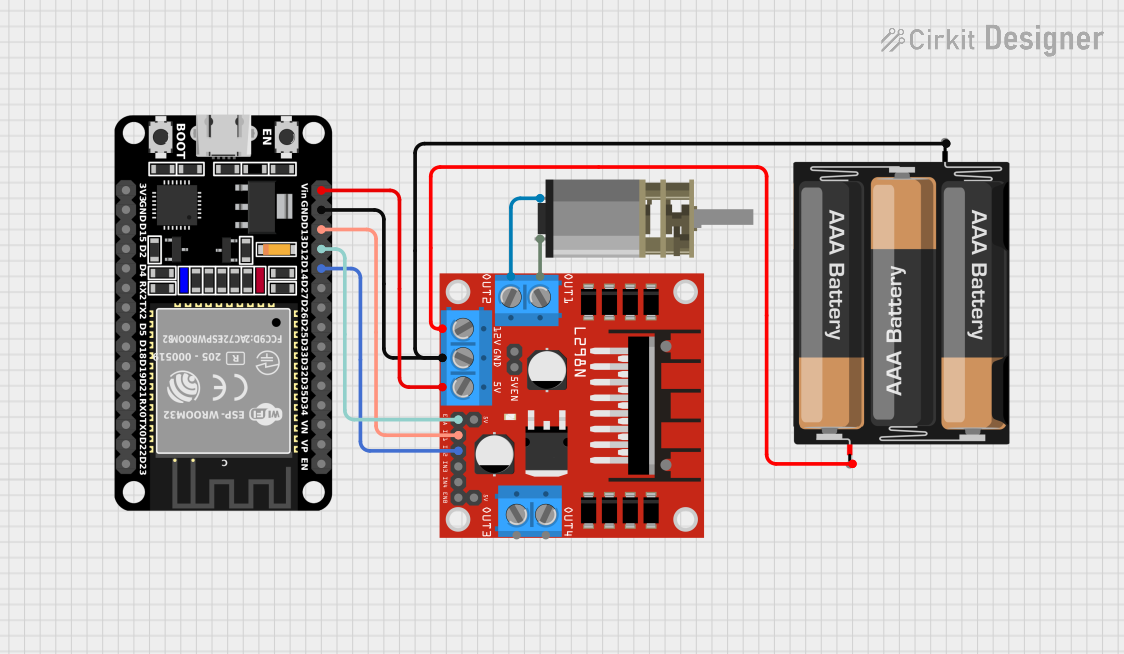

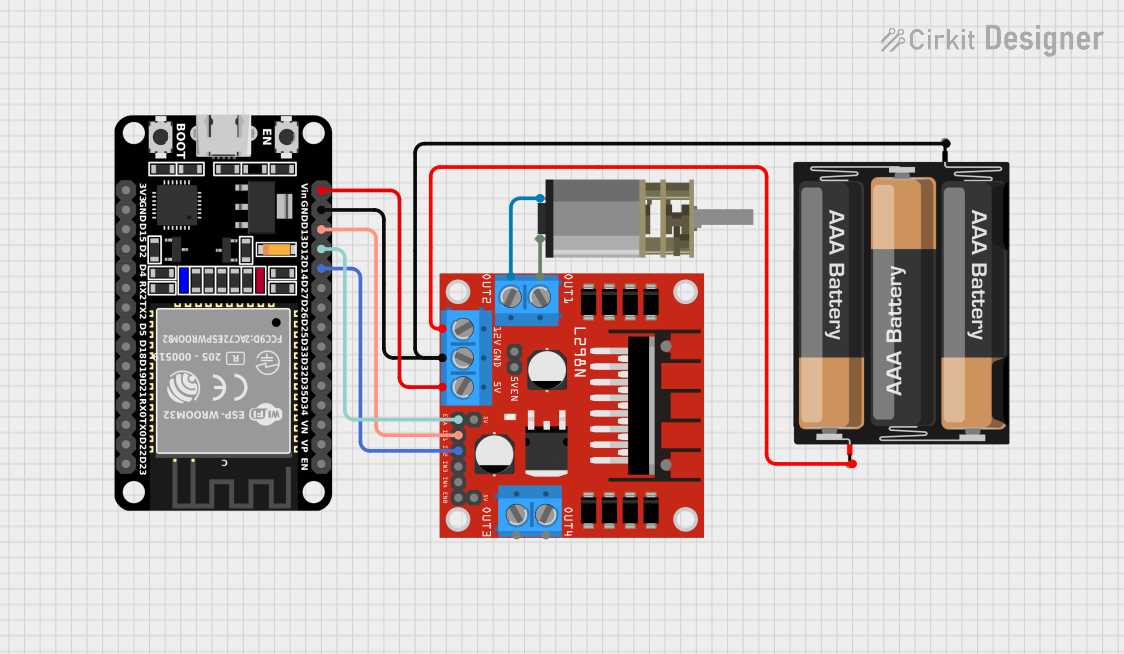

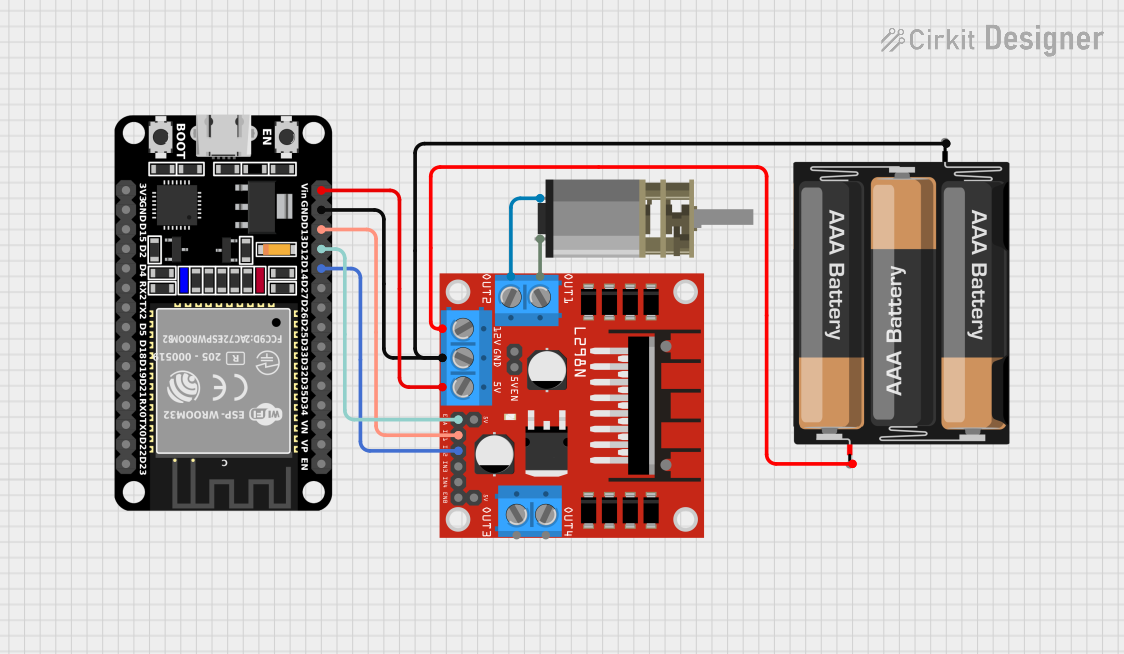

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit DesignerExplore Projects Built with DC Motor_small

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit DesignerTechnical Specifications

The following table outlines the key technical details of the DC Motor_small:

| Parameter | Value |

|---|---|

| Operating Voltage | 3V to 12V |

| Rated Current | 100mA to 300mA (no load) |

| Stall Current | ~1A (varies by model) |

| Rated Speed | 3000 to 12000 RPM (no load) |

| Torque | Low (suitable for light loads) |

| Shaft Diameter | 2mm to 3mm |

| Dimensions | ~25mm x 20mm x 15mm |

| Weight | ~20g |

Pin Configuration and Descriptions

The DC Motor_small typically has two terminals for electrical connections:

| Pin/Terminal | Description |

|---|---|

| Positive (+) | Connect to the positive terminal of the power supply. |

| Negative (-) | Connect to the negative terminal of the power supply. |

Note: The motor's direction of rotation can be reversed by swapping the polarity of the connections.

Usage Instructions

How to Use the DC Motor_small in a Circuit

- Power Supply: Connect the motor to a DC power source within the operating voltage range (3V to 12V). Exceeding the voltage range may damage the motor.

- Polarity: Ensure correct polarity for the desired direction of rotation. Reversing the polarity will reverse the motor's direction.

- Motor Driver: For precise control (e.g., speed or direction), use a motor driver IC (e.g., L298N or L293D) or an H-bridge circuit.

- Load Considerations: Avoid overloading the motor, as excessive torque demands can cause stalling or overheating.

Important Considerations and Best Practices

- Current Limiting: Use a current-limiting resistor or a motor driver to prevent excessive current draw, especially during startup or stalling.

- Heat Dissipation: Ensure proper ventilation to prevent overheating during prolonged operation.

- Noise Suppression: Add a capacitor (e.g., 0.1µF) across the motor terminals to reduce electrical noise and protect other components in the circuit.

- Mounting: Secure the motor using appropriate brackets or mounts to minimize vibration and ensure stable operation.

Example: Controlling the DC Motor_small with an Arduino UNO

Below is an example of how to control the DC Motor_small using an Arduino UNO and an L298N motor driver:

// Example: Controlling a DC Motor_small with Arduino UNO and L298N driver

// Define motor control pins

const int motorPin1 = 9; // IN1 on L298N

const int motorPin2 = 10; // IN2 on L298N

const int enablePin = 11; // ENA on L298N (PWM pin)

void setup() {

// Set motor control pins as outputs

pinMode(motorPin1, OUTPUT);

pinMode(motorPin2, OUTPUT);

pinMode(enablePin, OUTPUT);

}

void loop() {

// Rotate motor in one direction

digitalWrite(motorPin1, HIGH); // Set IN1 high

digitalWrite(motorPin2, LOW); // Set IN2 low

analogWrite(enablePin, 128); // Set speed (0-255, 128 = ~50% speed)

delay(2000); // Run for 2 seconds

// Stop the motor

digitalWrite(motorPin1, LOW);

digitalWrite(motorPin2, LOW);

delay(1000); // Wait for 1 second

// Rotate motor in the opposite direction

digitalWrite(motorPin1, LOW); // Set IN1 low

digitalWrite(motorPin2, HIGH); // Set IN2 high

analogWrite(enablePin, 200); // Set speed (0-255, 200 = ~80% speed)

delay(2000); // Run for 2 seconds

// Stop the motor

digitalWrite(motorPin1, LOW);

digitalWrite(motorPin2, LOW);

delay(1000); // Wait for 1 second

}

Note: Ensure the L298N motor driver is powered with a voltage matching the motor's requirements. The Arduino UNO cannot directly power the motor.

Troubleshooting and FAQs

Common Issues and Solutions

Motor Does Not Spin:

- Cause: Insufficient voltage or loose connections.

- Solution: Verify the power supply voltage and ensure all connections are secure.

Motor Spins Erratically:

- Cause: Electrical noise or unstable power supply.

- Solution: Add a capacitor (e.g., 0.1µF) across the motor terminals and use a regulated power supply.

Motor Overheats:

- Cause: Excessive current draw or prolonged operation under heavy load.

- Solution: Reduce the load on the motor and ensure proper ventilation.

Motor Stalls:

- Cause: Load exceeds the motor's torque capacity.

- Solution: Use a motor with higher torque or reduce the load.

FAQs

Q: Can I control the speed of the DC Motor_small?

A: Yes, you can control the speed using pulse-width modulation (PWM) via a motor driver or an H-bridge circuit.

Q: Can the motor run on a 5V power supply?

A: Yes, the motor can operate at 5V, but its speed and torque will be lower compared to higher voltages within the operating range.

Q: How do I reverse the motor's direction?

A: Swap the polarity of the motor's connections or use a motor driver to control the direction programmatically.

Q: Is the DC Motor_small suitable for heavy loads?

A: No, this motor is designed for light loads. For heavier loads, consider using a motor with higher torque ratings.