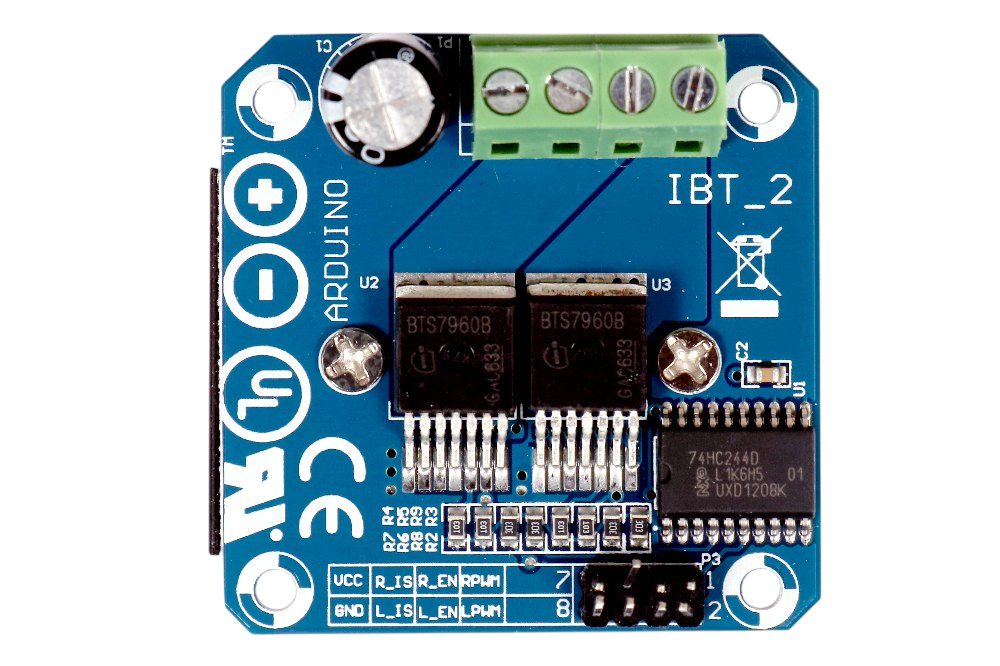

How to Use BTS7960 Motor Driver: Examples, Pinouts, and Specs

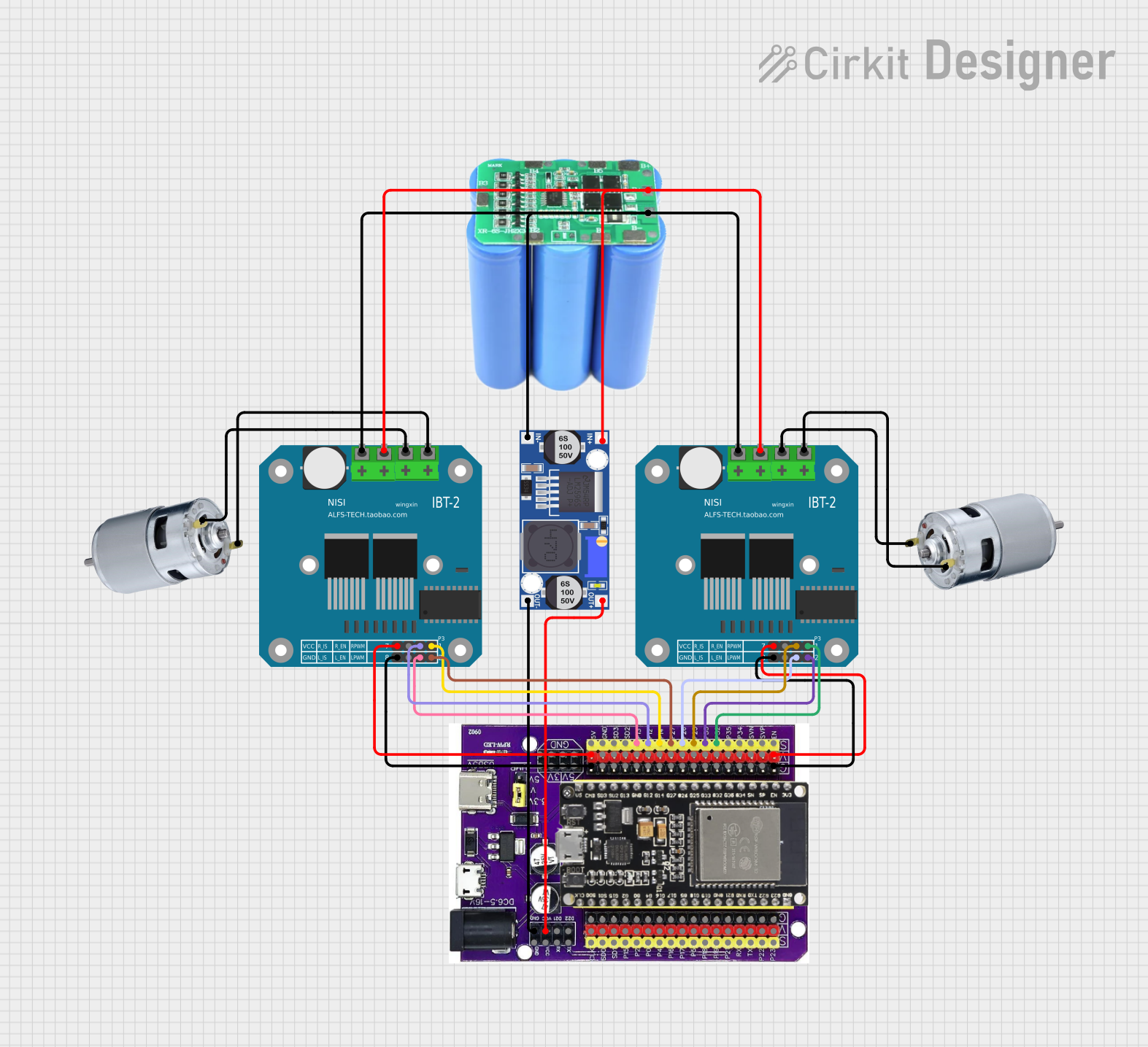

Design with BTS7960 Motor Driver in Cirkit Designer

Design with BTS7960 Motor Driver in Cirkit DesignerIntroduction

The BTS7960 is a high-current H-bridge motor driver designed to control DC motors and stepper motors. It is capable of handling high currents (up to 43A) and features built-in protection mechanisms such as overcurrent protection, thermal shutdown, and undervoltage lockout. These features make the BTS7960 a reliable choice for applications requiring robust motor control.

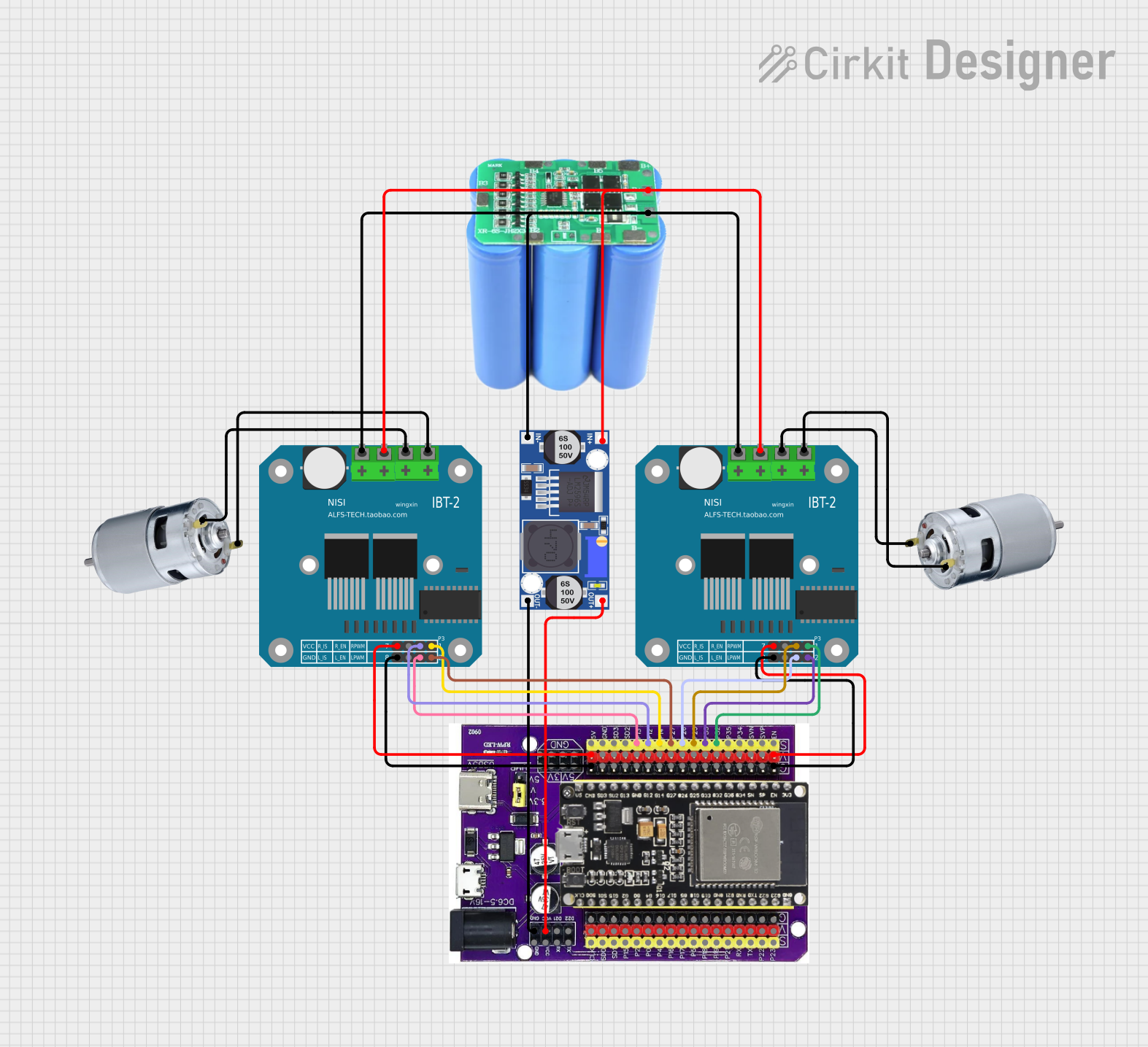

Explore Projects Built with BTS7960 Motor Driver

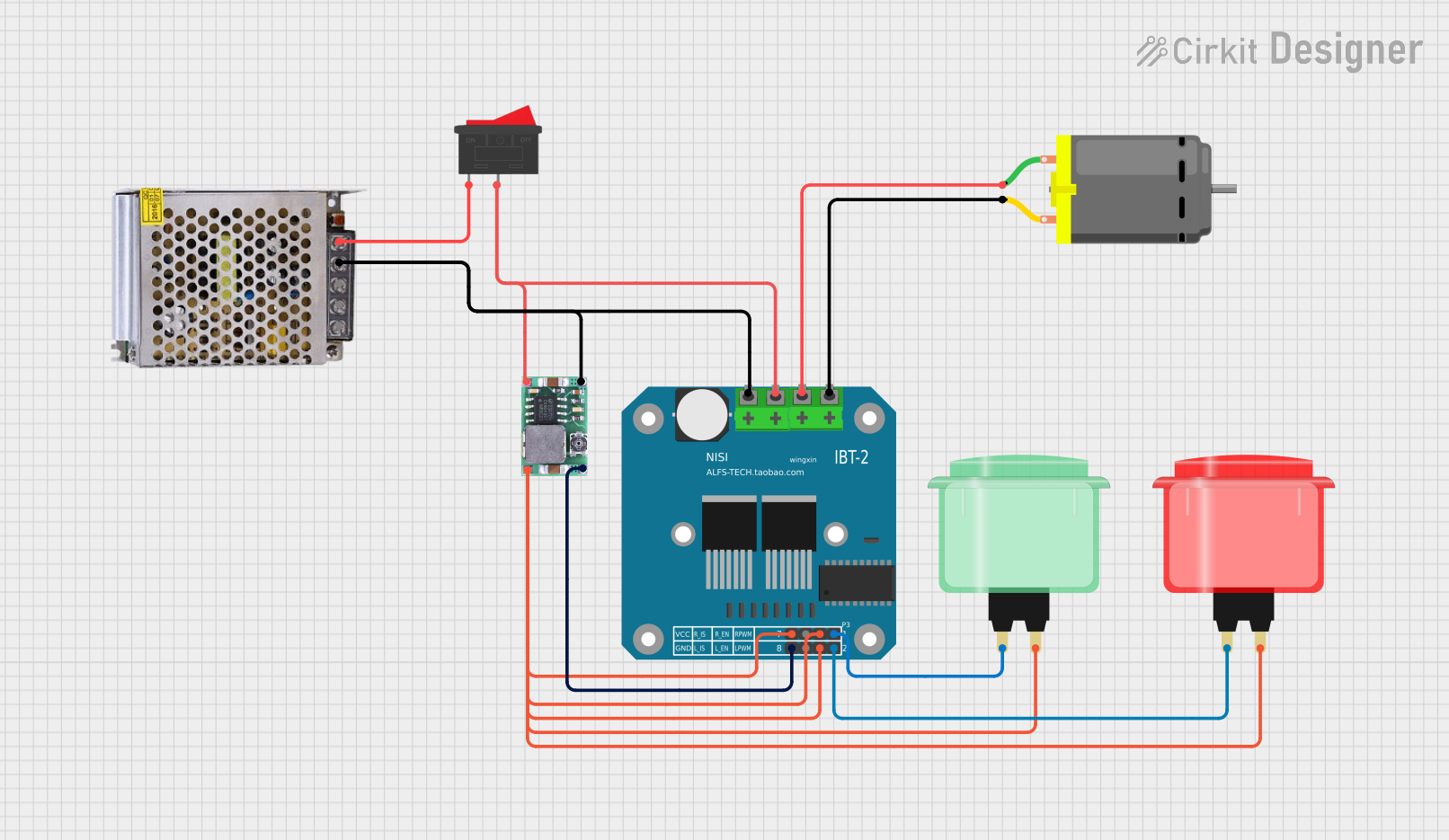

Open Project in Cirkit Designer

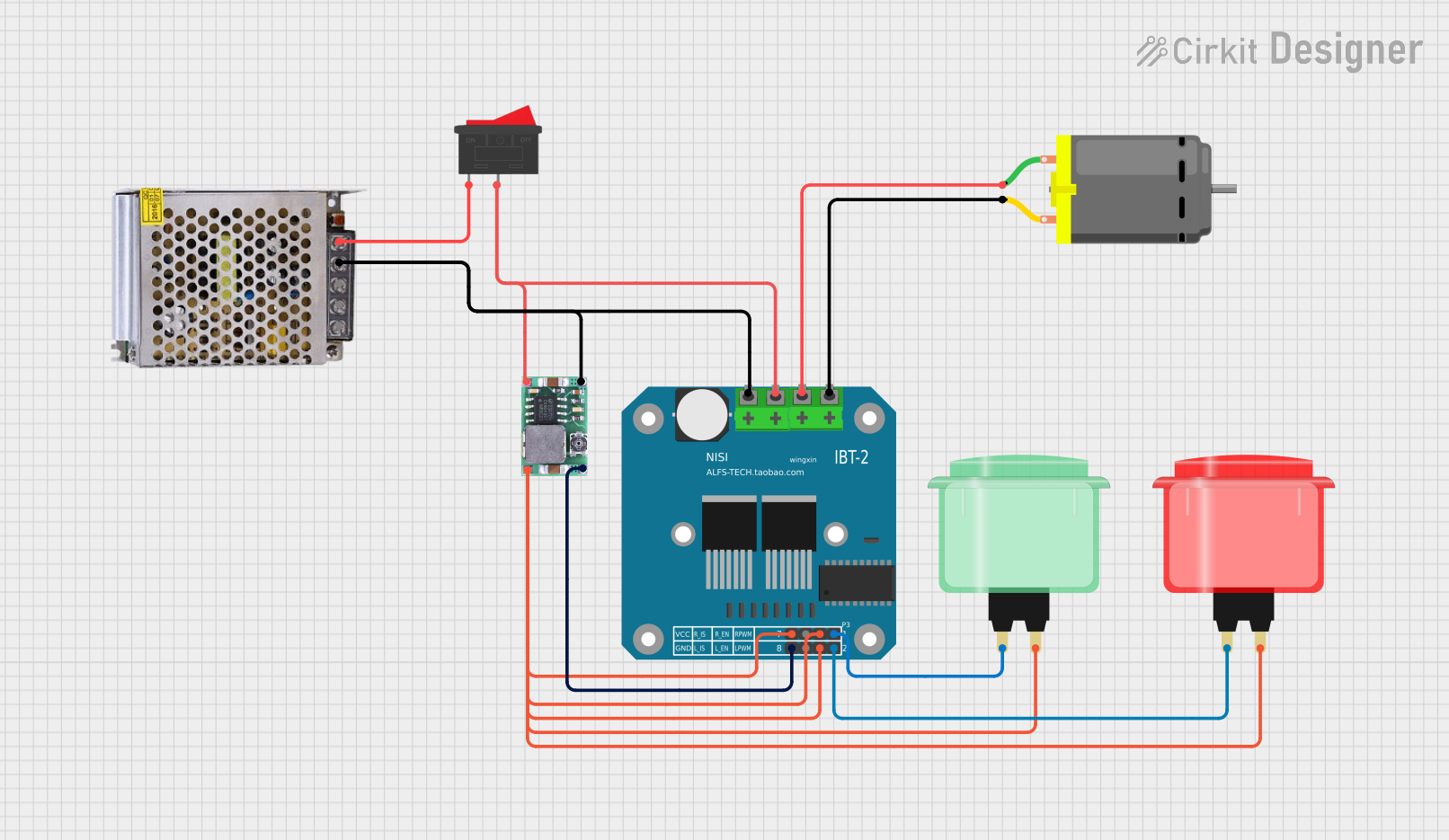

Open Project in Cirkit Designer

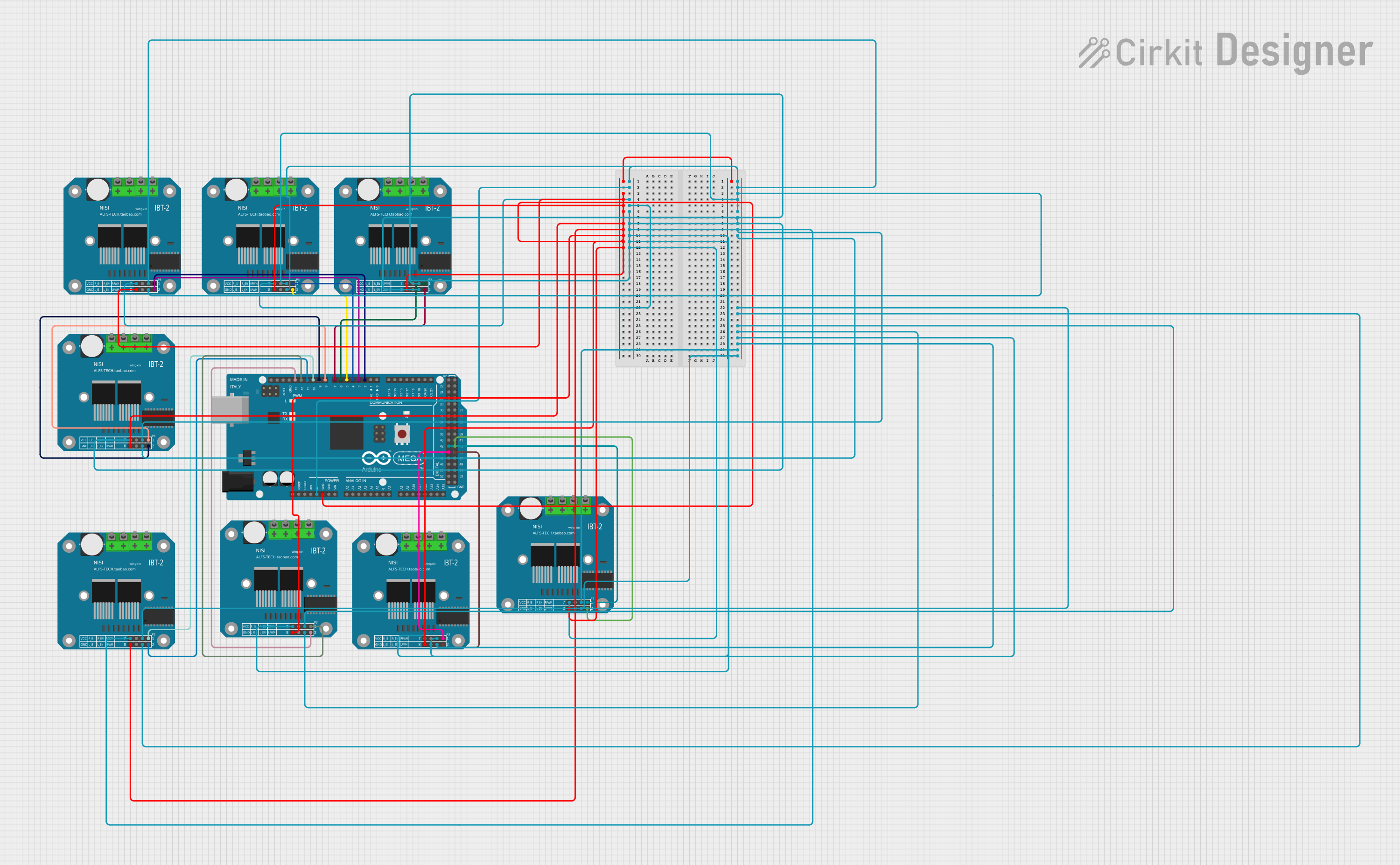

Open Project in Cirkit Designer

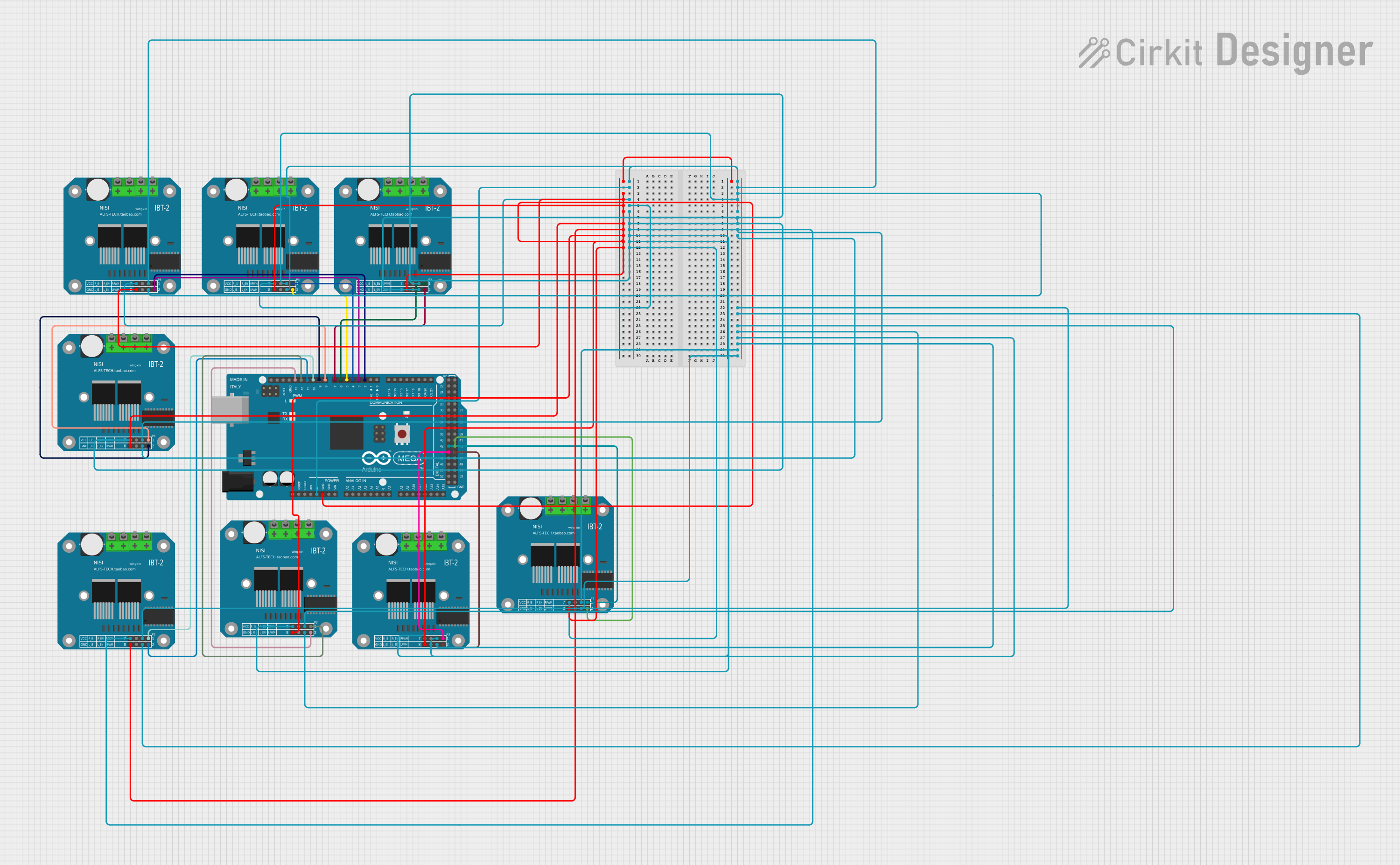

Open Project in Cirkit Designer

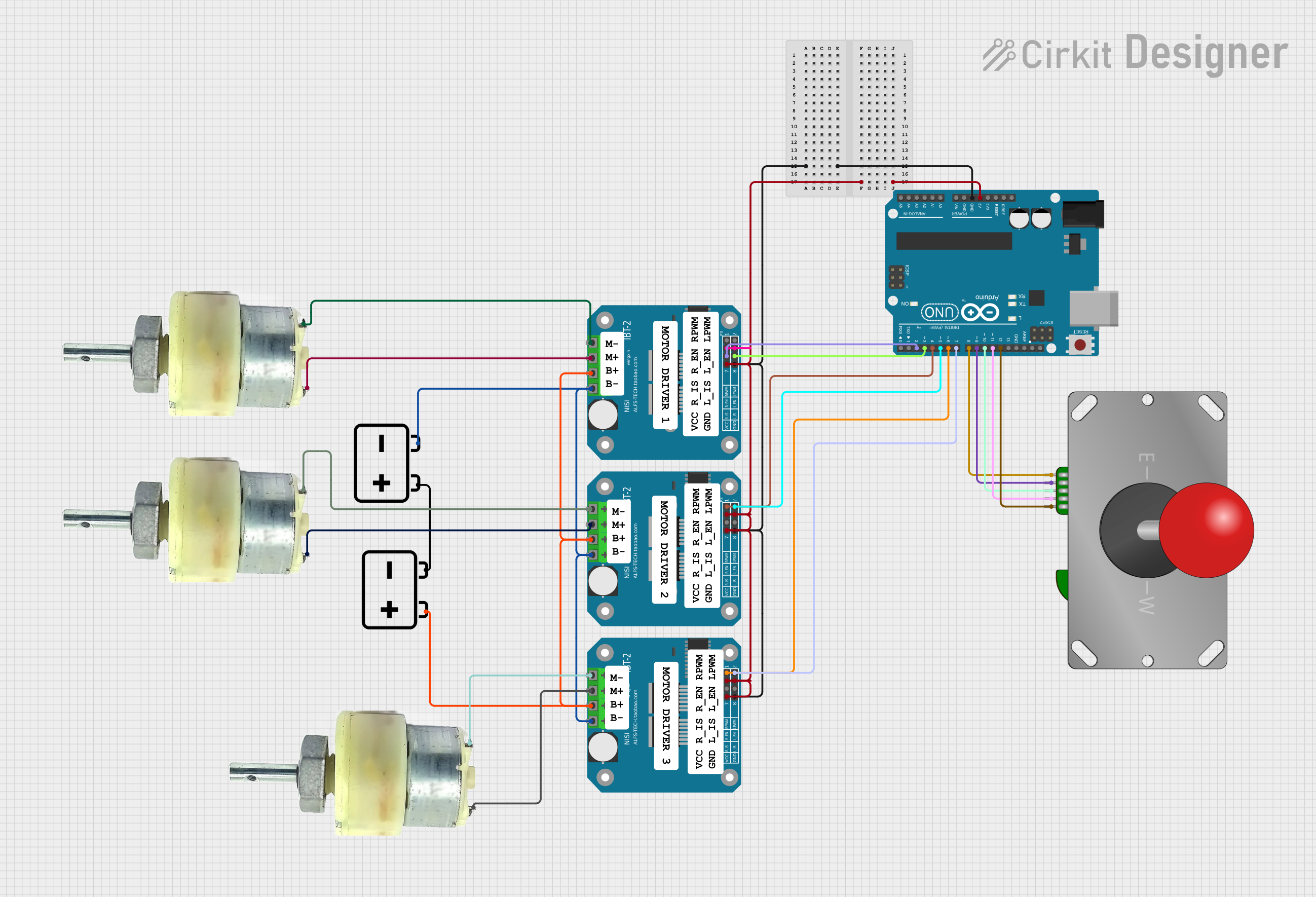

Open Project in Cirkit Designer

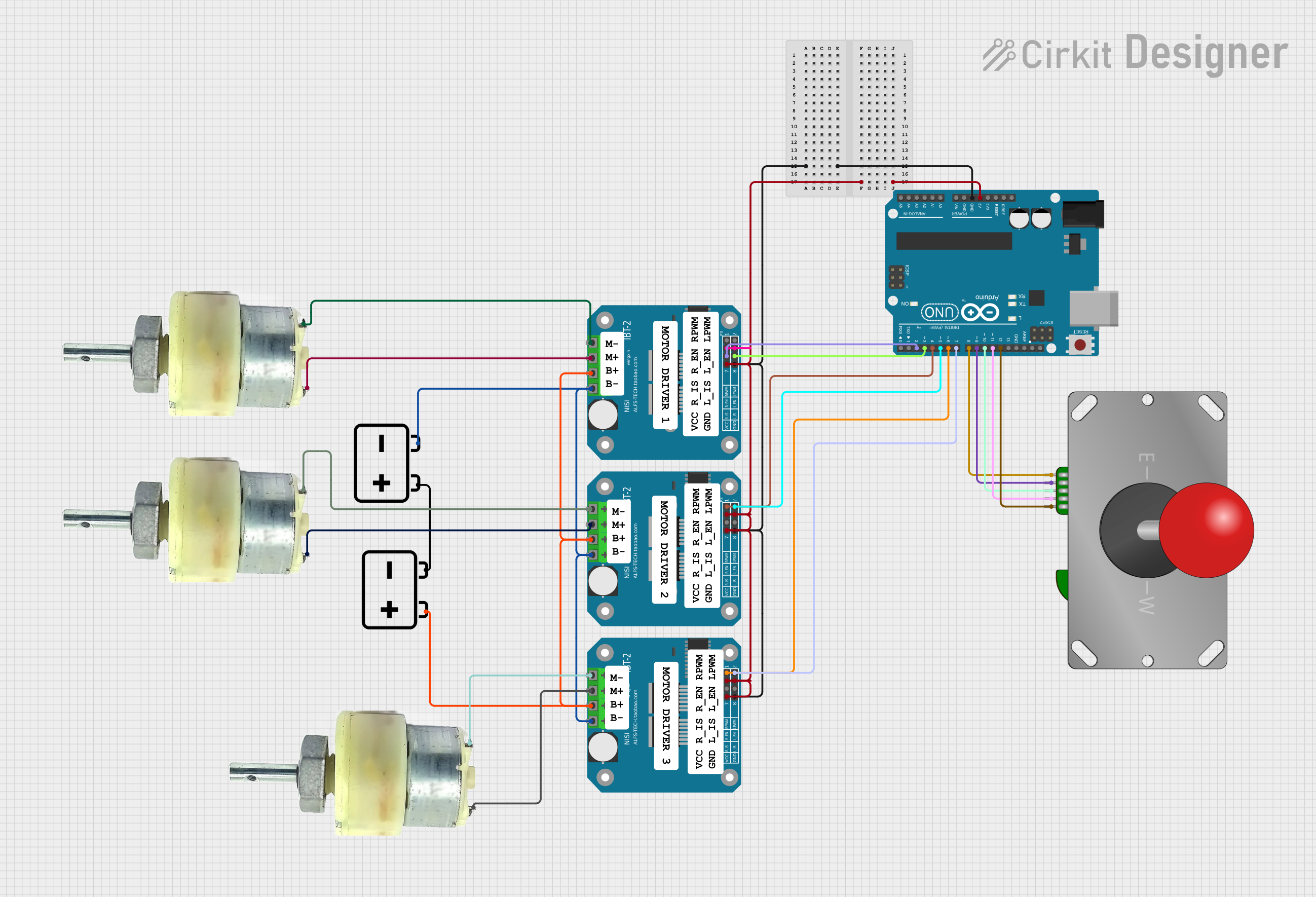

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit DesignerExplore Projects Built with BTS7960 Motor Driver

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit DesignerCommon Applications

- Robotics and automation systems

- Electric vehicles and motorized carts

- Conveyor belts and industrial machinery

- Remote-controlled cars and boats

- CNC machines and 3D printers

Technical Specifications

The BTS7960 motor driver is designed to handle high-power motor control with precision and safety. Below are its key technical specifications:

| Parameter | Value |

|---|---|

| Operating Voltage | 5.5V to 27V |

| Maximum Output Current | 43A |

| PWM Frequency | Up to 25kHz |

| Logic Voltage | 3.3V or 5V (compatible) |

| Overcurrent Protection | Yes |

| Thermal Shutdown | Yes |

| Undervoltage Lockout | Yes |

| Dimensions | 43mm x 43mm x 15mm |

Pin Configuration and Descriptions

The BTS7960 module has several pins for motor control and power input. Below is the pin configuration:

| Pin Name | Type | Description |

|---|---|---|

| VCC | Power Input | Logic voltage input (3.3V or 5V). |

| GND | Ground | Common ground for logic and motor power. |

| RPWM | Input | PWM signal for controlling motor rotation in one direction. |

| LPWM | Input | PWM signal for controlling motor rotation in the opposite direction. |

| R_EN | Input | Enable pin for the right side of the H-bridge. Active HIGH. |

| L_EN | Input | Enable pin for the left side of the H-bridge. Active HIGH. |

| IS | Output | Current sensing output. Provides a voltage proportional to the motor current. |

| VCC (Motor) | Power Input | Motor power supply (5.5V to 27V). |

| OUT1 | Output | Motor terminal 1. |

| OUT2 | Output | Motor terminal 2. |

Usage Instructions

The BTS7960 motor driver is straightforward to use in motor control applications. Below are the steps and considerations for using the module:

Connecting the BTS7960

- Power Supply: Connect the motor power supply (5.5V to 27V) to the

VCC (Motor)pin and the ground to theGNDpin. - Logic Voltage: Connect the logic voltage (3.3V or 5V) to the

VCCpin. - Motor Connections: Connect the motor terminals to the

OUT1andOUT2pins. - Control Pins: Connect the

RPWM,LPWM,R_EN, andL_ENpins to the microcontroller's GPIO pins.

Controlling the Motor

- Use the

RPWMandLPWMpins to send PWM signals for speed and direction control. - Enable the H-bridge by setting

R_ENandL_ENpins HIGH. - Adjust the duty cycle of the PWM signals to control motor speed.

Example: Using BTS7960 with Arduino UNO

Below is an example code snippet to control a DC motor using the BTS7960 and Arduino UNO:

// Define control pins for the BTS7960 motor driver

#define RPWM 9 // PWM pin for forward rotation

#define LPWM 10 // PWM pin for reverse rotation

#define R_EN 8 // Enable pin for right H-bridge

#define L_EN 7 // Enable pin for left H-bridge

void setup() {

// Set control pins as outputs

pinMode(RPWM, OUTPUT);

pinMode(LPWM, OUTPUT);

pinMode(R_EN, OUTPUT);

pinMode(L_EN, OUTPUT);

// Enable both sides of the H-bridge

digitalWrite(R_EN, HIGH);

digitalWrite(L_EN, HIGH);

}

void loop() {

// Rotate motor forward at 50% speed

analogWrite(RPWM, 128); // 50% duty cycle

analogWrite(LPWM, 0); // No reverse rotation

delay(2000); // Run for 2 seconds

// Rotate motor backward at 75% speed

analogWrite(RPWM, 0); // No forward rotation

analogWrite(LPWM, 192); // 75% duty cycle

delay(2000); // Run for 2 seconds

// Stop the motor

analogWrite(RPWM, 0);

analogWrite(LPWM, 0);

delay(2000); // Wait for 2 seconds

}

Best Practices

- Ensure the motor power supply voltage matches the motor's rated voltage.

- Use a heatsink or cooling fan if operating at high currents for extended periods.

- Avoid sudden changes in direction at high speeds to prevent damage to the motor or driver.

- Use appropriate fuses or circuit breakers for additional protection.

Troubleshooting and FAQs

Common Issues and Solutions

Motor Not Running

- Cause: Incorrect wiring or insufficient power supply.

- Solution: Double-check all connections and ensure the power supply meets the voltage and current requirements.

Overheating

- Cause: Prolonged operation at high currents without proper cooling.

- Solution: Add a heatsink or cooling fan to the BTS7960 module.

Erratic Motor Behavior

- Cause: Noise or interference in PWM signals.

- Solution: Use shielded cables for signal lines and ensure a stable power supply.

No Response from the Driver

- Cause: Logic voltage not supplied or enable pins not set HIGH.

- Solution: Verify that the

VCC,R_EN, andL_ENpins are correctly connected and powered.

FAQs

Q1: Can the BTS7960 drive stepper motors?

Yes, the BTS7960 can drive stepper motors, but you will need additional control logic to generate the required step and direction signals.

Q2: What is the maximum PWM frequency supported?

The BTS7960 supports PWM frequencies up to 25kHz.

Q3: Can I use the BTS7960 with a 3.3V microcontroller?

Yes, the BTS7960 is compatible with both 3.3V and 5V logic levels.

Q4: How do I measure motor current using the IS pin?

The IS pin provides a voltage proportional to the motor current. Refer to the datasheet for the exact scaling factor.

By following this documentation, you can effectively use the BTS7960 motor driver in your projects.