How to Use PonteH LN298: Examples, Pinouts, and Specs

Design with PonteH LN298 in Cirkit Designer

Design with PonteH LN298 in Cirkit DesignerIntroduction

The PonteH L298 is a dual H-bridge motor driver IC designed to control the speed and direction of two DC motors or a single stepper motor. It is widely used in robotics and automation projects due to its ability to handle high currents and voltages. The L298 is a robust and versatile component, making it ideal for applications such as motorized vehicles, robotic arms, and conveyor systems.

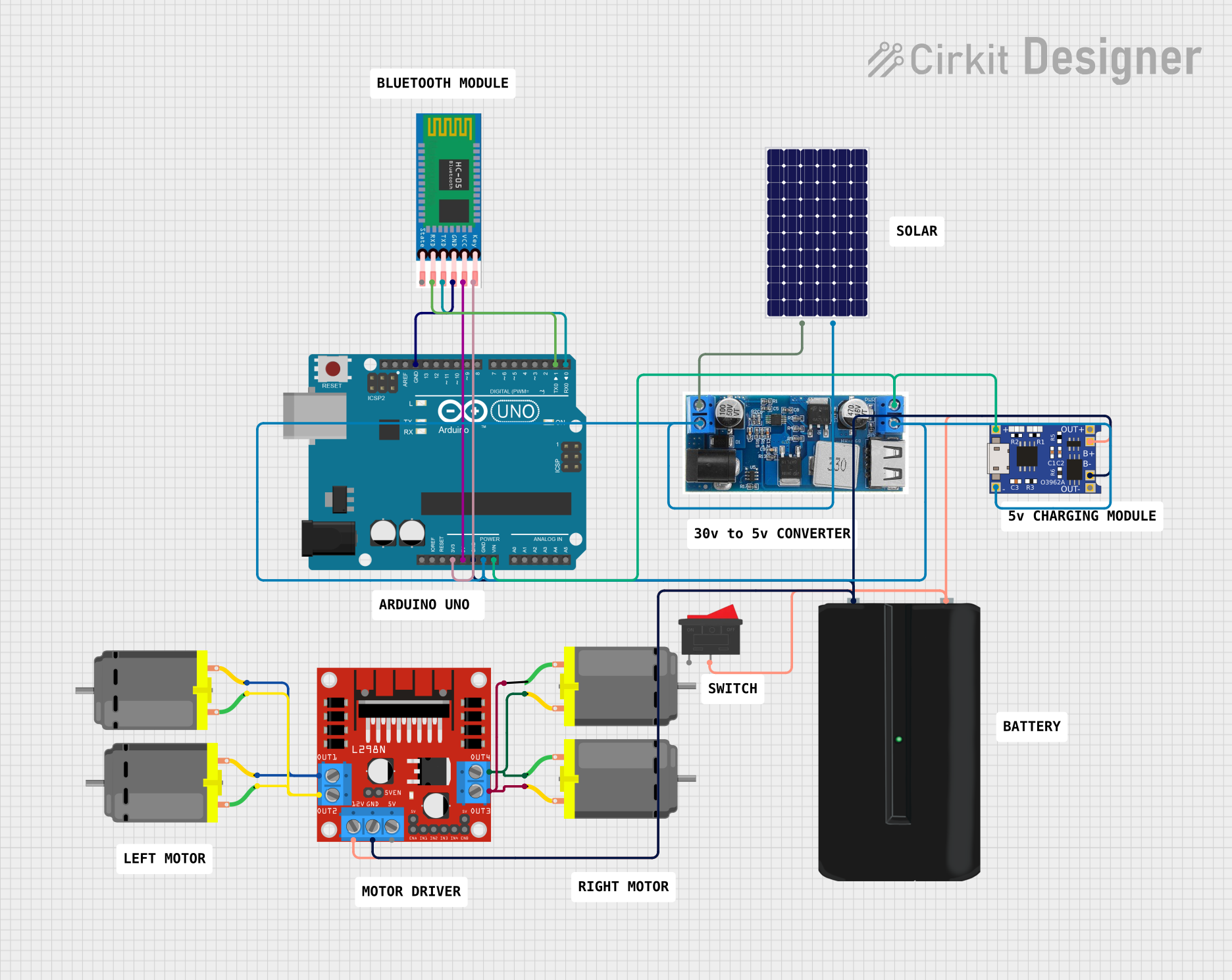

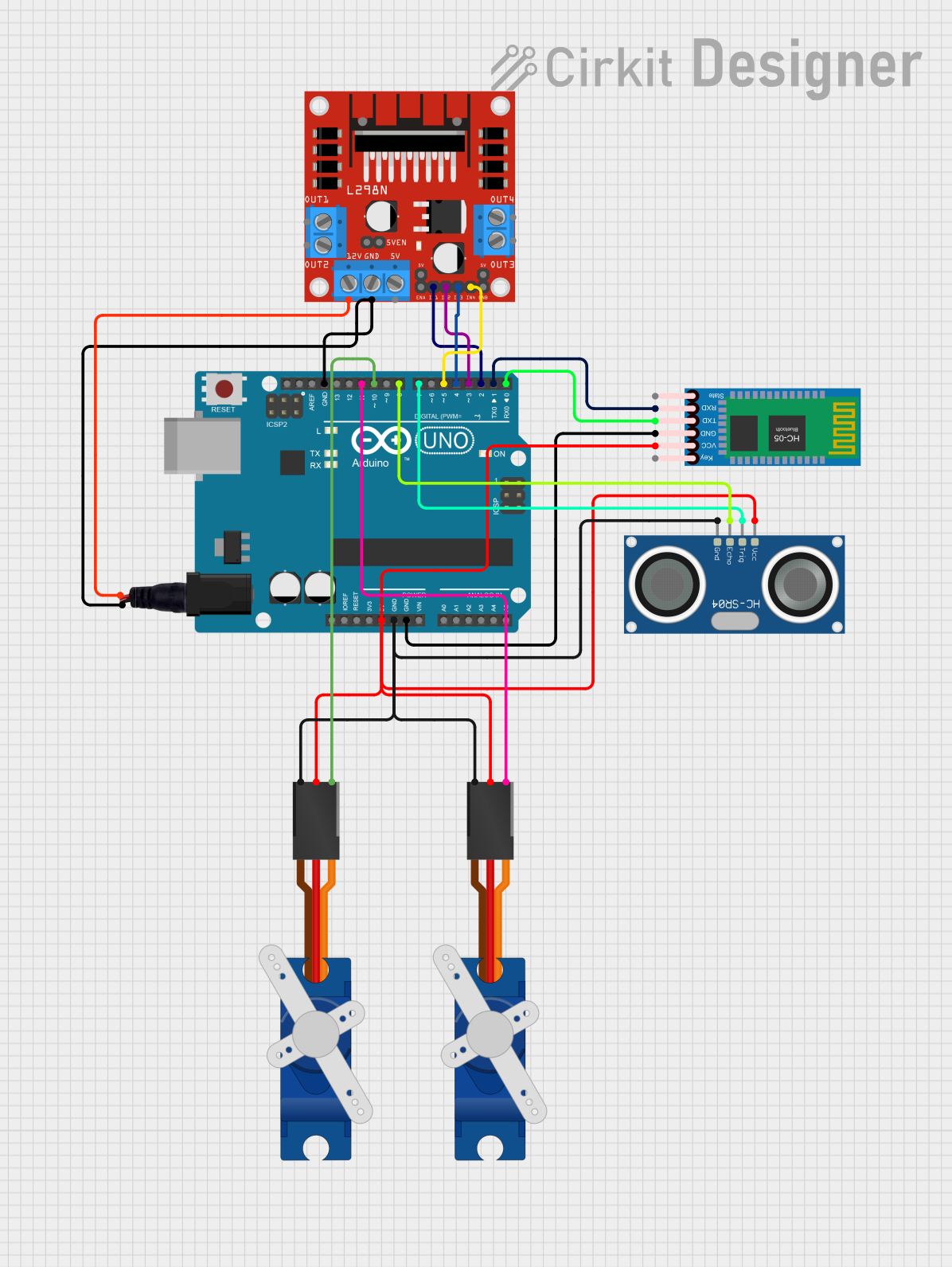

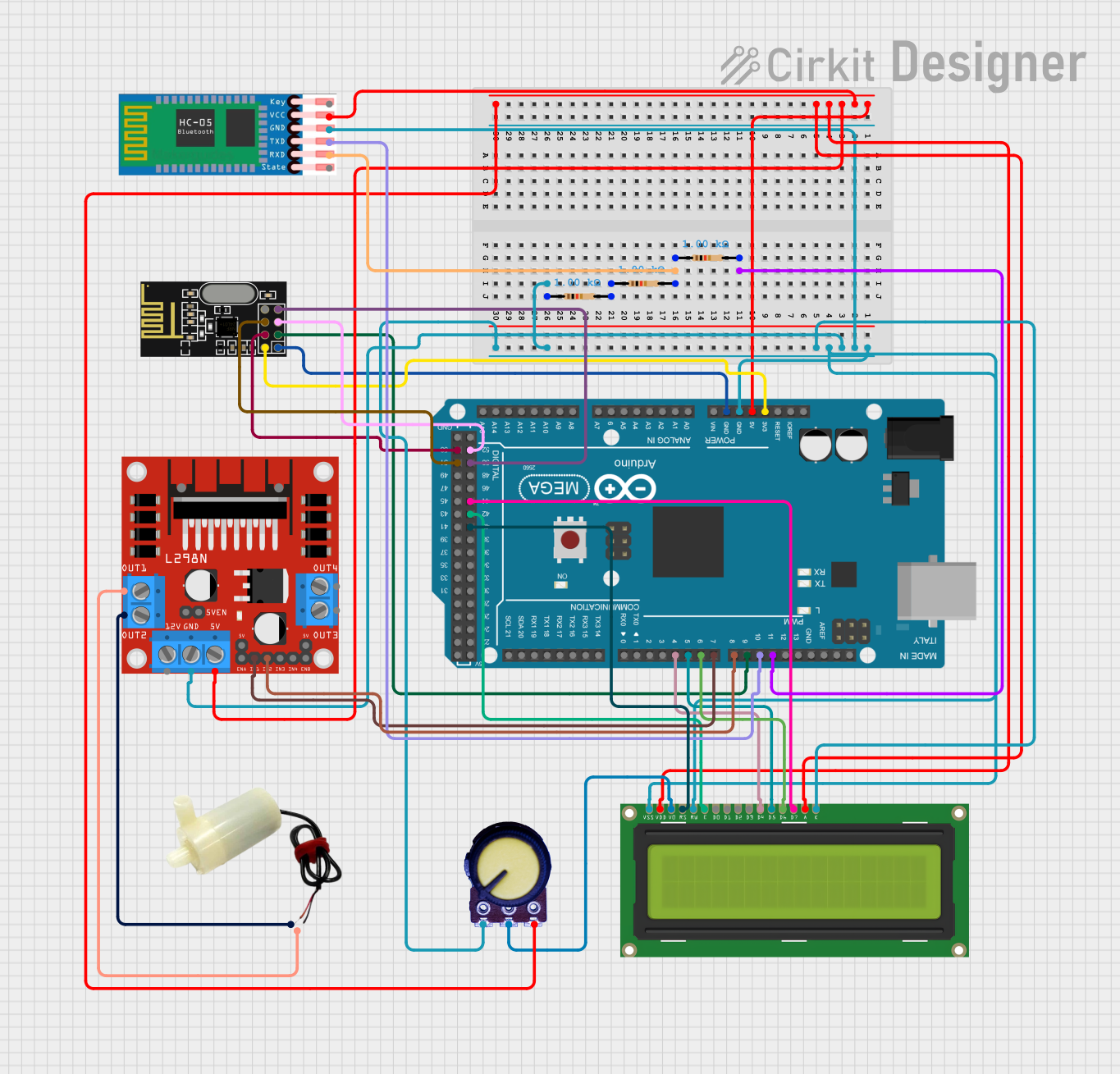

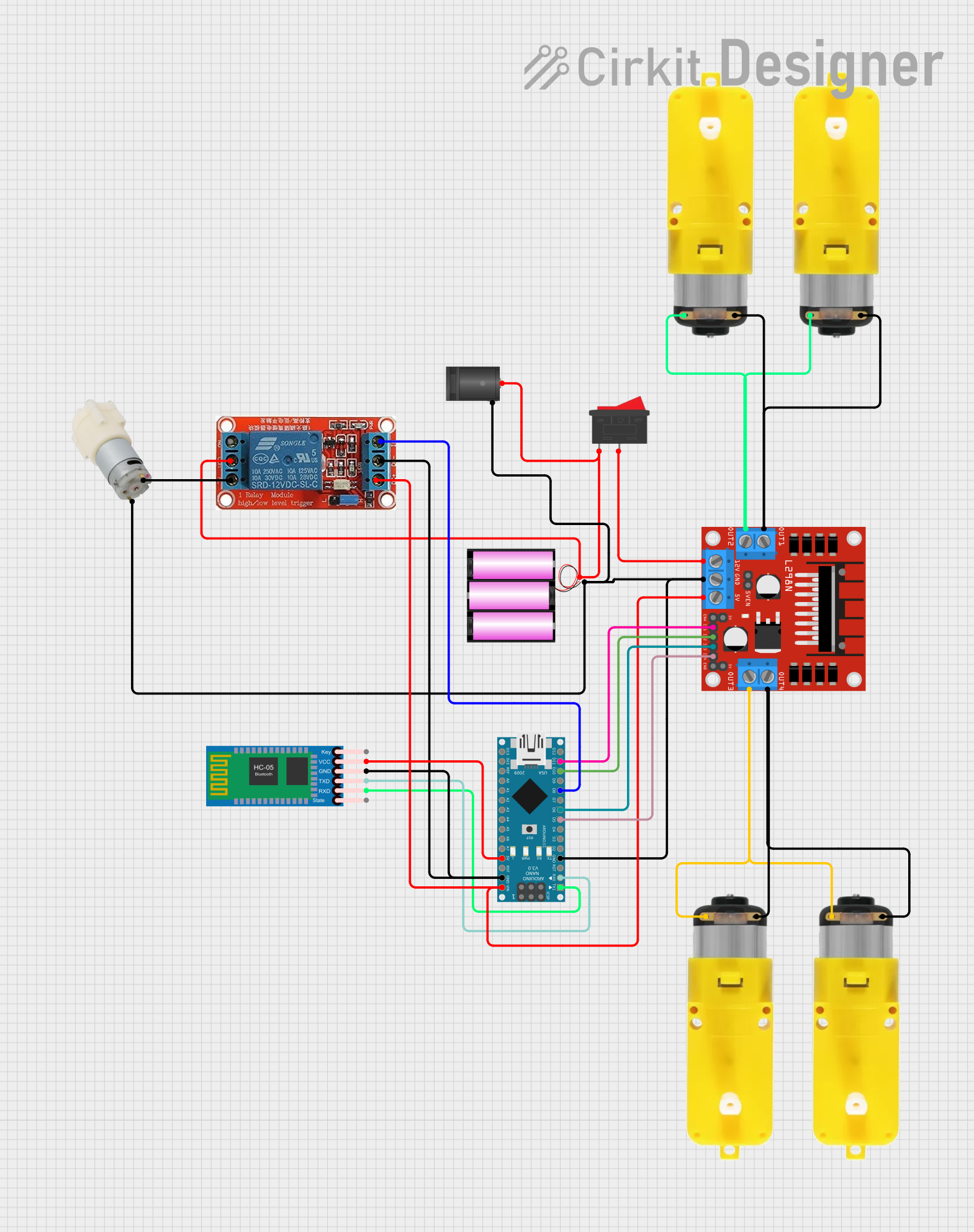

Explore Projects Built with PonteH LN298

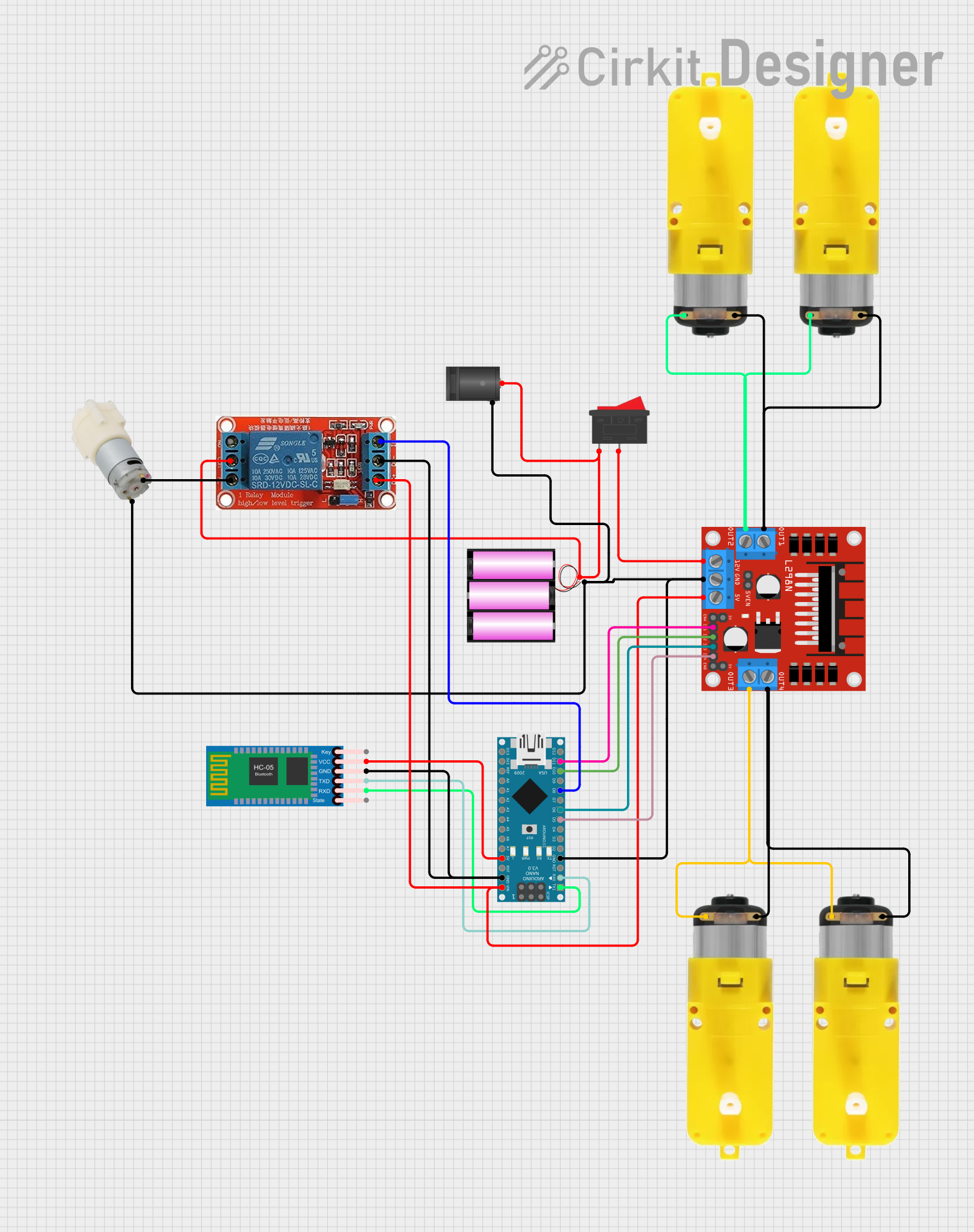

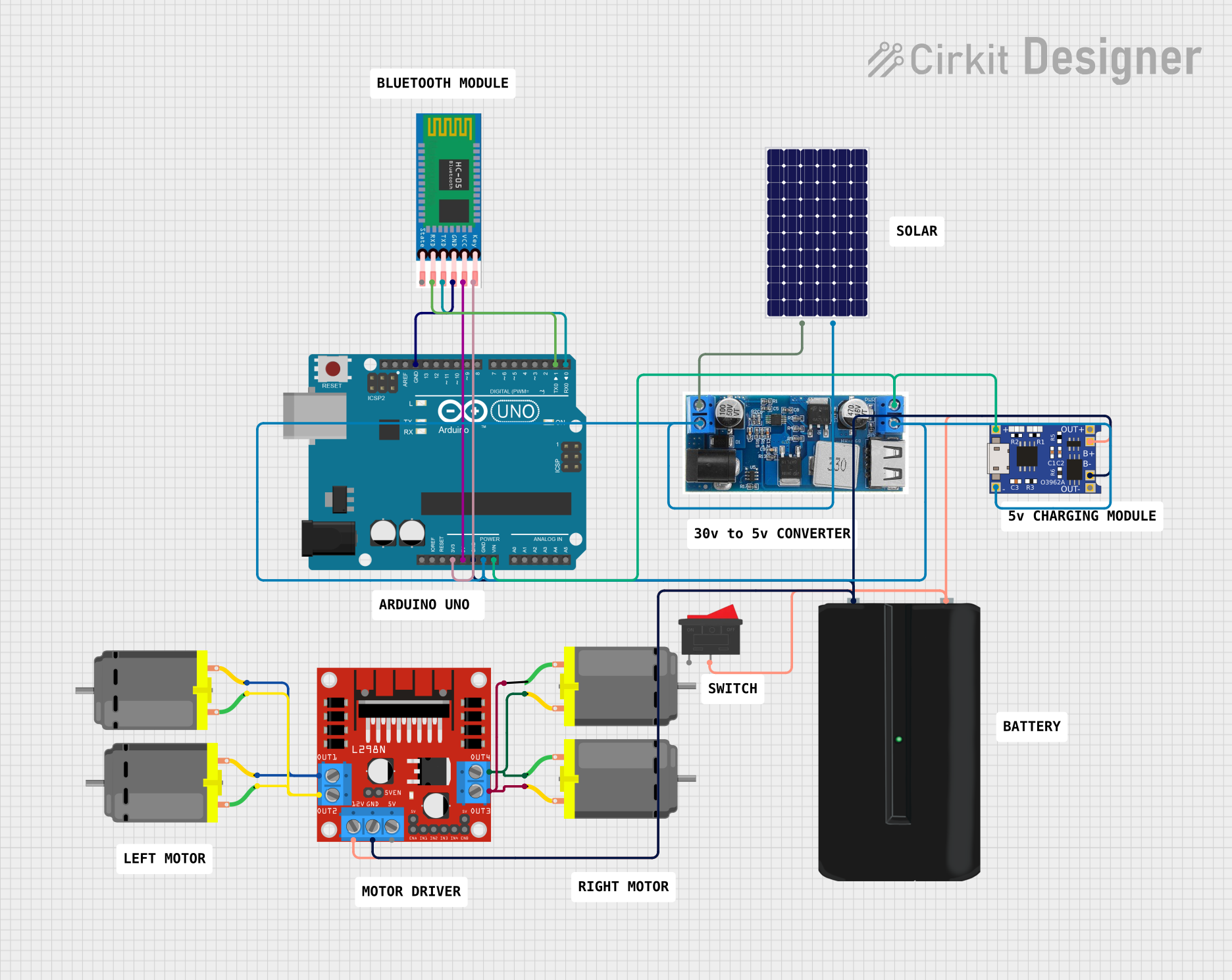

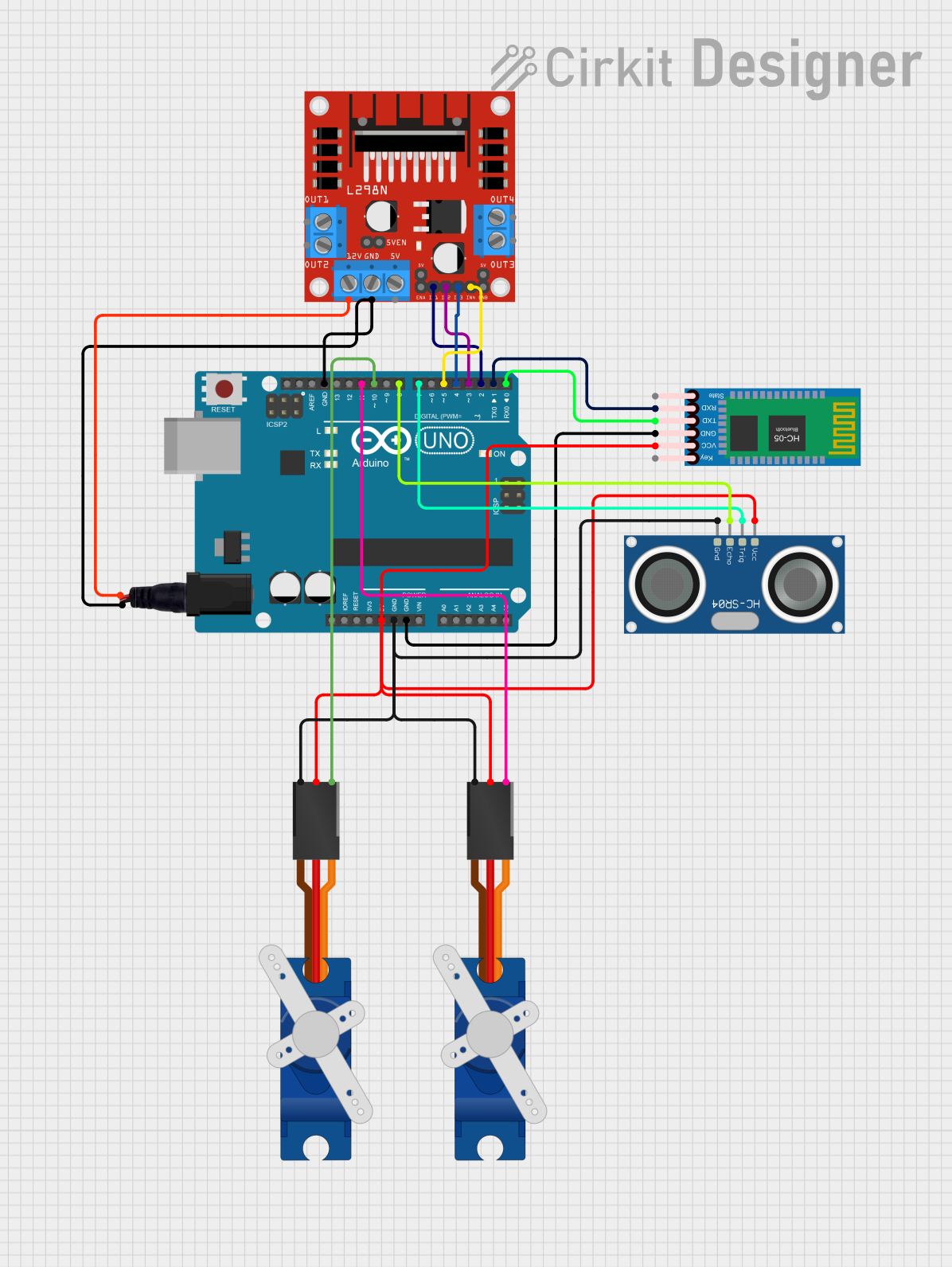

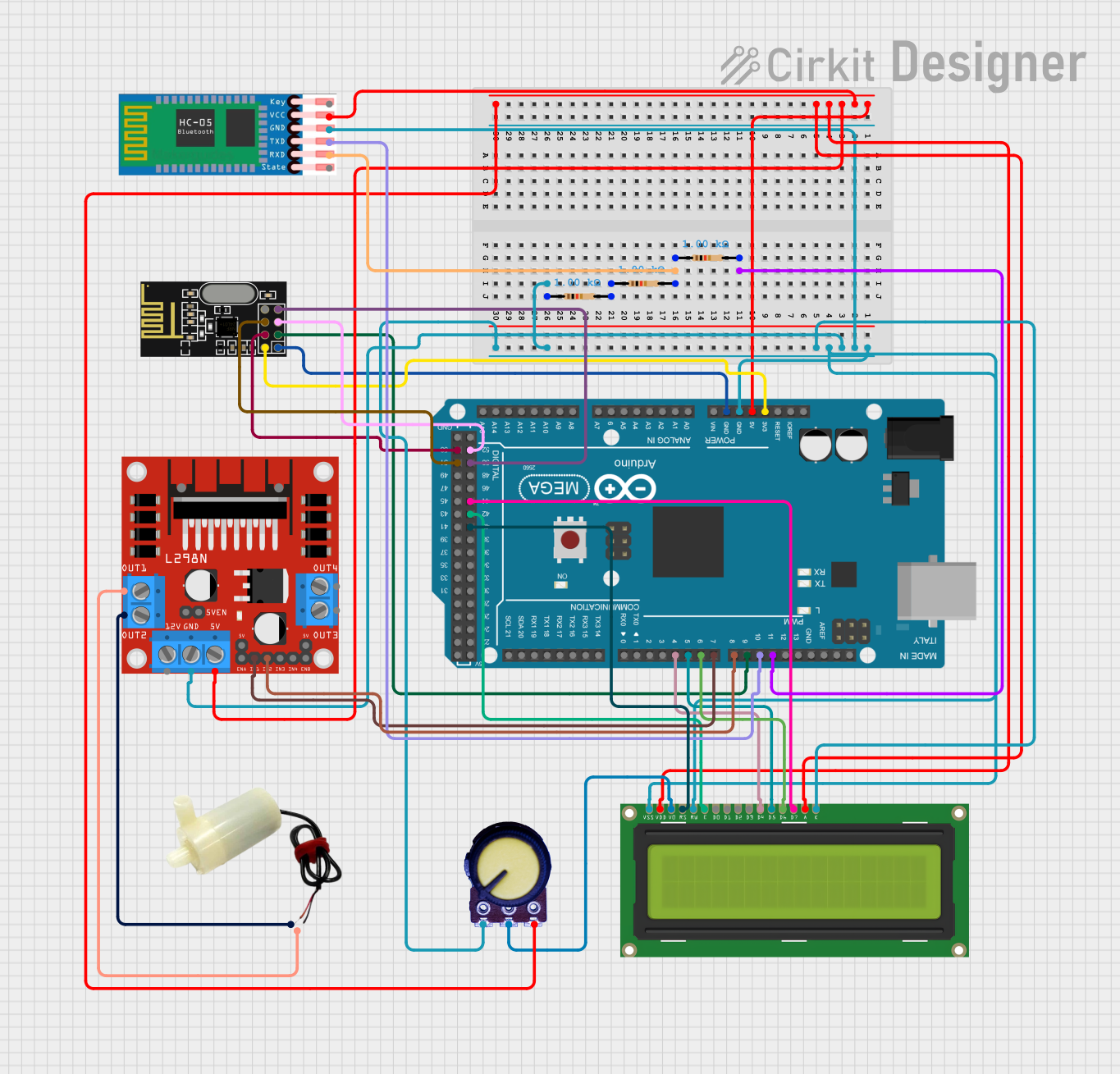

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit DesignerExplore Projects Built with PonteH LN298

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit DesignerTechnical Specifications

- Operating Voltage: 5V logic supply, 4.5V to 46V motor supply

- Output Current: Up to 2A per channel (continuous), 3A peak

- Power Dissipation: 25W (with proper heat sinking)

- Control Logic Voltage: 5V

- Number of Channels: 2 (dual H-bridge)

- Operating Temperature: -25°C to +130°C

- Built-in Protection: Thermal shutdown and overcurrent protection

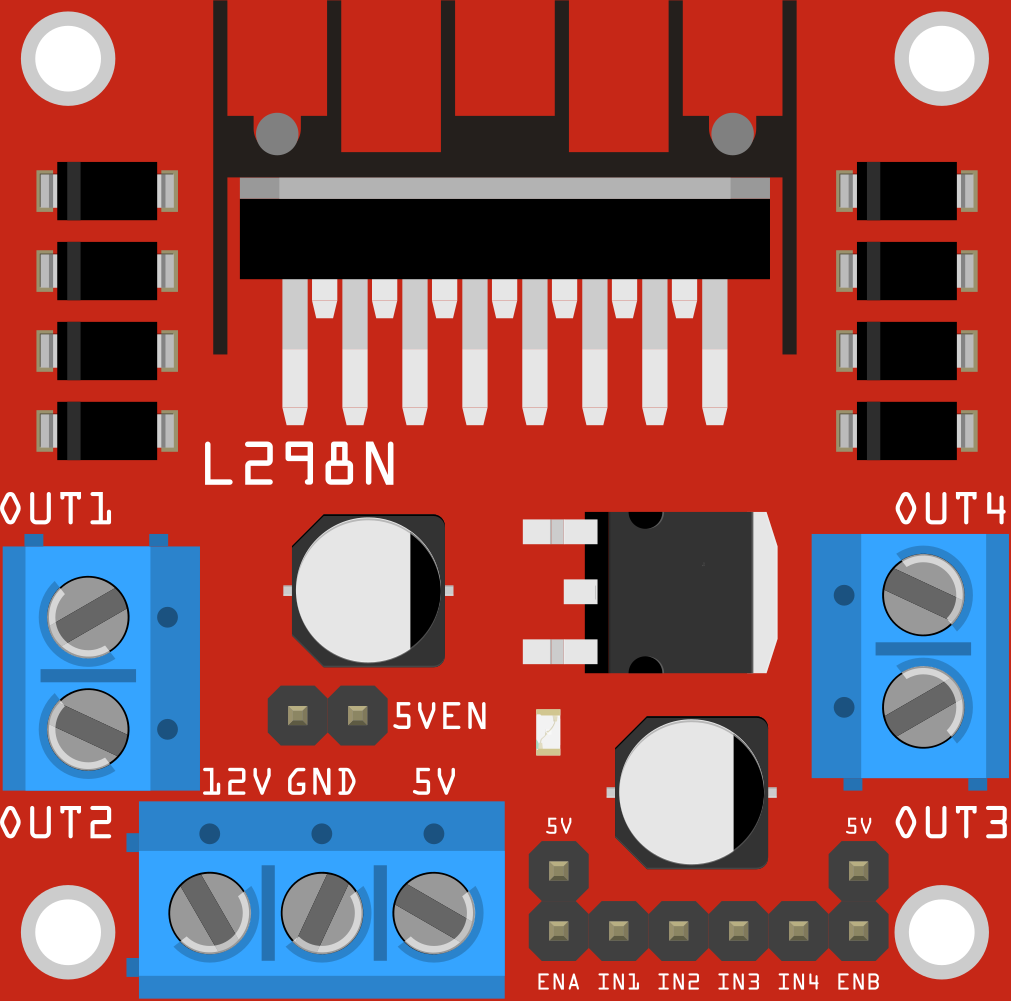

Pin Configuration and Descriptions

The L298 IC has 15 pins, as described in the table below:

| Pin Number | Pin Name | Description |

|---|---|---|

| 1 | Current Sense A | Connect to ground via a resistor to monitor current for Motor A |

| 2 | Enable A | Enables or disables Motor A (High = Enabled, Low = Disabled) |

| 3 | Input 1 | Logic input to control Motor A direction (works with Input 2) |

| 4 | Input 2 | Logic input to control Motor A direction (works with Input 1) |

| 5 | Output 1 | Output terminal for Motor A |

| 6 | Output 2 | Output terminal for Motor A |

| 7 | VSS | Logic voltage supply (typically 5V) |

| 8 | VS | Motor voltage supply (4.5V to 46V) |

| 9 | Output 3 | Output terminal for Motor B |

| 10 | Output 4 | Output terminal for Motor B |

| 11 | Input 3 | Logic input to control Motor B direction (works with Input 4) |

| 12 | Input 4 | Logic input to control Motor B direction (works with Input 3) |

| 13 | Enable B | Enables or disables Motor B (High = Enabled, Low = Disabled) |

| 14 | Current Sense B | Connect to ground via a resistor to monitor current for Motor B |

| 15 | Ground (GND) | Common ground for logic and motor power supplies |

Usage Instructions

How to Use the PonteH L298 in a Circuit

Power Connections:

- Connect the motor power supply to the

VSpin (Pin 8). Ensure the voltage is within the range of 4.5V to 46V. - Connect the logic power supply (5V) to the

VSSpin (Pin 7). - Connect the ground of the power supply to the

GNDpin (Pin 15).

- Connect the motor power supply to the

Motor Connections:

- Connect the terminals of Motor A to

Output 1(Pin 5) andOutput 2(Pin 6). - Connect the terminals of Motor B to

Output 3(Pin 9) andOutput 4(Pin 10).

- Connect the terminals of Motor A to

Control Logic:

- Use the

Inputpins (Pins 3, 4 for Motor A; Pins 11, 12 for Motor B) to control the direction of the motors. - Use the

Enablepins (Pins 2 and 13) to enable or disable the motors.

- Use the

Current Sensing (Optional):

- Connect a resistor between the

Current Sensepins (Pins 1 and 14) and ground to monitor the current flowing through the motors.

- Connect a resistor between the

Important Considerations and Best Practices

- Always use a heat sink with the L298 IC to prevent overheating during operation.

- Ensure the motor power supply voltage matches the motor's rated voltage.

- Use external diodes for additional protection against back EMF, especially when driving inductive loads like motors.

- Avoid exceeding the maximum current rating of 2A per channel to prevent damage to the IC.

Example: Using the L298 with an Arduino UNO

Below is an example code to control two DC motors using the L298 and an Arduino UNO:

// Define motor control pins

const int enA = 9; // Enable pin for Motor A

const int in1 = 8; // Input 1 for Motor A

const int in2 = 7; // Input 2 for Motor A

const int enB = 10; // Enable pin for Motor B

const int in3 = 6; // Input 3 for Motor B

const int in4 = 5; // Input 4 for Motor B

void setup() {

// Set motor control pins as outputs

pinMode(enA, OUTPUT);

pinMode(in1, OUTPUT);

pinMode(in2, OUTPUT);

pinMode(enB, OUTPUT);

pinMode(in3, OUTPUT);

pinMode(in4, OUTPUT);

// Initialize motors to stop

digitalWrite(in1, LOW);

digitalWrite(in2, LOW);

digitalWrite(in3, LOW);

digitalWrite(in4, LOW);

}

void loop() {

// Example: Rotate Motor A forward

digitalWrite(in1, HIGH); // Set direction

digitalWrite(in2, LOW);

analogWrite(enA, 150); // Set speed (0-255)

// Example: Rotate Motor B backward

digitalWrite(in3, LOW); // Set direction

digitalWrite(in4, HIGH);

analogWrite(enB, 200); // Set speed (0-255)

delay(2000); // Run motors for 2 seconds

// Stop both motors

digitalWrite(in1, LOW);

digitalWrite(in2, LOW);

digitalWrite(in3, LOW);

digitalWrite(in4, LOW);

analogWrite(enA, 0);

analogWrite(enB, 0);

delay(2000); // Wait for 2 seconds before repeating

}

Troubleshooting and FAQs

Common Issues and Solutions

Motors Not Running:

- Ensure the

Enablepins are set to HIGH. - Verify that the motor power supply is connected and within the correct voltage range.

- Check the wiring of the motor terminals and control pins.

- Ensure the

Overheating:

- Attach a heat sink to the L298 IC to dissipate heat effectively.

- Reduce the motor load or use motors with lower current requirements.

Erratic Motor Behavior:

- Check for loose or incorrect connections.

- Ensure the logic and motor power supplies share a common ground.

No Current Sensing Output:

- Verify that a resistor is connected between the

Current Sensepin and ground. - Ensure the resistor value is appropriate for the desired current measurement range.

- Verify that a resistor is connected between the

FAQs

Q: Can the L298 drive stepper motors?

A: Yes, the L298 can drive a single stepper motor by using both H-bridge channels. You will need to sequence the control inputs appropriately.

Q: What is the maximum motor voltage the L298 can handle?

A: The L298 can handle motor supply voltages up to 46V.

Q: Do I need external diodes with the L298?

A: While the L298 has internal diodes for back EMF protection, adding external diodes can provide additional safety, especially for high-current motors.

Q: Can I use the L298 with a 3.3V microcontroller?

A: The L298 requires a 5V logic supply, so you will need a level shifter to interface it with a 3.3V microcontroller.