How to Use 3.3V Step-Up Voltage Regulator : Examples, Pinouts, and Specs

Design with 3.3V Step-Up Voltage Regulator in Cirkit Designer

Design with 3.3V Step-Up Voltage Regulator in Cirkit DesignerPololu 3.3V Step-Up Voltage Regulator (u1v11f3) Documentation

1. Introduction

The Pololu 3.3V Step-Up Voltage Regulator (part ID: u1v11f3) is a compact and efficient DC-DC boost converter designed to increase a lower input voltage to a stable 3.3V output. This regulator is ideal for powering low-voltage devices that require a consistent 3.3V supply, even when the input voltage is below 3.3V. It is particularly useful in battery-powered applications, where the input voltage may vary or drop over time.

Common Applications

- Powering 3.3V microcontrollers (e.g., ESP8266, ESP32) from lower voltage sources.

- Extending the usable life of batteries by boosting their voltage.

- Supplying 3.3V to sensors, modules, and other low-power devices.

- Portable electronics and wearables.

- Robotics and IoT devices.

2. Technical Specifications

The following table outlines the key technical details of the Pololu u1v11f3 regulator:

| Parameter | Value |

|---|---|

| Input Voltage Range | 0.5V to 5.5V |

| Output Voltage | 3.3V (fixed) |

| Maximum Output Current | Up to 200 mA (depending on input voltage; see notes below) |

| Efficiency | Up to 90% (varies with input voltage and load) |

| Quiescent Current | 20 µA (typical, with no load) |

| Dimensions | 11.4 mm × 8.9 mm × 3.0 mm |

| Weight | 0.3 g |

| Operating Temperature Range | -40°C to +85°C |

| Protection Features | None (no reverse polarity or overcurrent protection; external protection recommended) |

Pin Configuration and Descriptions

The Pololu u1v11f3 regulator has three pins, as described in the table below:

| Pin Name | Pin Type | Description |

|---|---|---|

| VIN | Input | Connect to the input voltage source (0.5V to 5.5V). |

| GND | Ground | Connect to the ground of the circuit. |

| VOUT | Output | Provides a stable 3.3V output. Connect to the load requiring 3.3V. |

3. Usage Instructions

Connecting the Regulator in a Circuit

- Input Voltage Source: Connect the VIN pin to a power source (e.g., a single AA/AAA battery, a 3.7V LiPo battery, or a low-voltage power supply). Ensure the input voltage is within the range of 0.5V to 5.5V.

- Ground Connection: Connect the GND pin to the ground of your circuit.

- Output Voltage: Connect the VOUT pin to the device or circuit requiring a 3.3V supply.

Important Considerations

- Input Voltage Range: Ensure the input voltage does not exceed 5.5V, as this may damage the regulator.

- Output Current Limitations: The maximum output current depends on the input voltage. For example:

- At 1.2V input, the regulator can supply up to 100 mA.

- At 3.0V input, the regulator can supply up to 200 mA.

- Heat Dissipation: While the regulator is efficient, excessive current draw may cause it to heat up. Ensure proper ventilation or heat dissipation if operating near the maximum current limit.

- External Protection: The regulator does not include built-in reverse polarity or overcurrent protection. Use external diodes or fuses for added safety.

4. Example Application with Arduino UNO

The Pololu 3.3V Step-Up Voltage Regulator can be used to power 3.3V sensors or modules in an Arduino-based project. Below is an example of using the regulator to power a 3.3V temperature sensor (e.g., DHT11) connected to an Arduino UNO.

Wiring Diagram

- Connect the VIN pin of the regulator to a 1.5V AA battery.

- Connect the GND pin of the regulator to the ground of the battery and the Arduino UNO.

- Connect the VOUT pin of the regulator to the VCC pin of the DHT11 sensor.

- Connect the data pin of the DHT11 sensor to a digital pin on the Arduino UNO (e.g., pin 2).

Arduino Code Example

#include <DHT.h>

// Define the DHT sensor type and pin

#define DHTPIN 2 // Data pin connected to DHT11

#define DHTTYPE DHT11 // DHT11 sensor type

DHT dht(DHTPIN, DHTTYPE);

void setup() {

Serial.begin(9600); // Initialize serial communication

dht.begin(); // Initialize the DHT sensor

Serial.println("DHT11 Sensor Test");

}

void loop() {

delay(2000); // Wait 2 seconds between readings

// Read temperature and humidity from the DHT11 sensor

float humidity = dht.readHumidity();

float temperature = dht.readTemperature();

// Check if the readings are valid

if (isnan(humidity) || isnan(temperature)) {

Serial.println("Failed to read from DHT sensor!");

return;

}

// Print the readings to the Serial Monitor

Serial.print("Humidity: ");

Serial.print(humidity);

Serial.print("% Temperature: ");

Serial.print(temperature);

Serial.println("°C");

}

Notes

- The regulator ensures a stable 3.3V supply to the DHT11 sensor, even if the input voltage from the battery drops below 3.3V.

- Ensure the total current draw of the Arduino and connected devices does not exceed the regulator's output current limit.

5. Troubleshooting and FAQs

Common Issues and Solutions

| Issue | Possible Cause | Solution |

|---|---|---|

| No output voltage | Incorrect wiring or input voltage out of range | Verify connections and ensure input voltage is between 0.5V and 5.5V. |

| Output voltage is unstable or noisy | Excessive load current or insufficient input voltage | Reduce the load or increase the input voltage. Add a capacitor across VOUT. |

| Regulator overheating | Output current exceeds the regulator's capacity | Reduce the load current or improve heat dissipation. |

| Device connected to VOUT is not working | Voltage drop due to high current draw or poor connections | Check wiring and ensure the load does not exceed the regulator's capabilities. |

FAQs

Can I use this regulator to power a 3.3V microcontroller?

- Yes, as long as the microcontroller's current requirements are within the regulator's output current limit.

What happens if the input voltage exceeds 5.5V?

- The regulator may be permanently damaged. Use a voltage limiter or zener diode to protect the input.

Can I use this regulator with a rechargeable battery?

- Yes, it works well with rechargeable batteries like NiMH or LiPo, as long as the input voltage is within range.

Does the regulator have reverse polarity protection?

- No, it does not. Use an external diode to protect against reverse polarity.

This documentation provides a comprehensive guide to using the Pololu 3.3V Step-Up Voltage Regulator (u1v11f3). By following the instructions and best practices outlined above, you can ensure reliable and efficient operation in your projects.

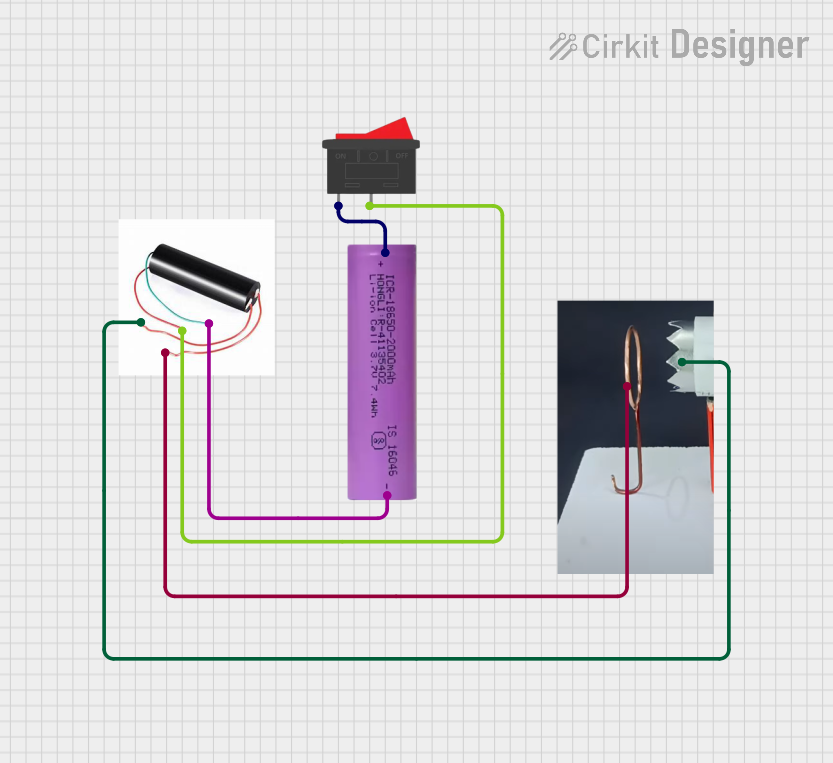

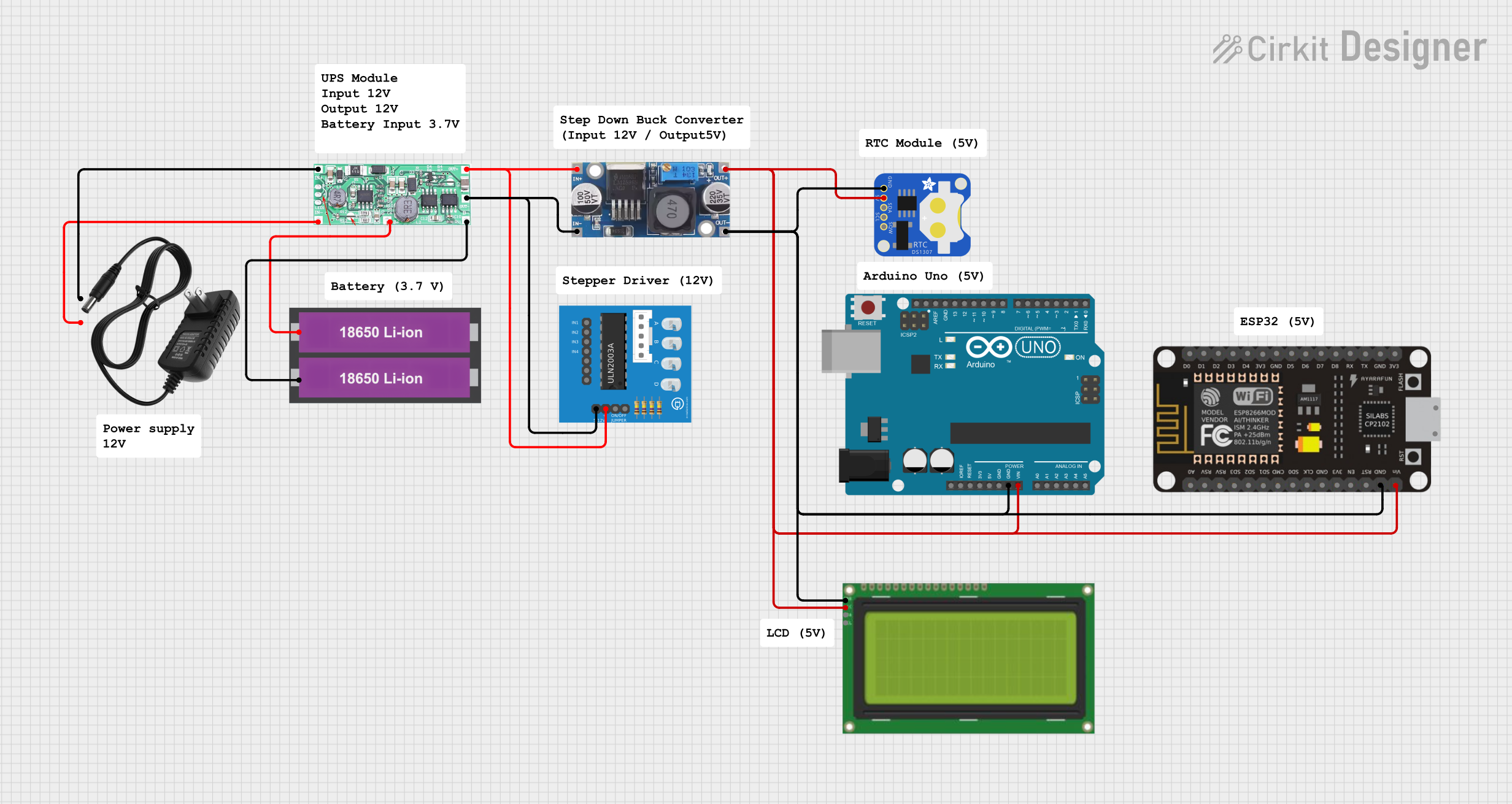

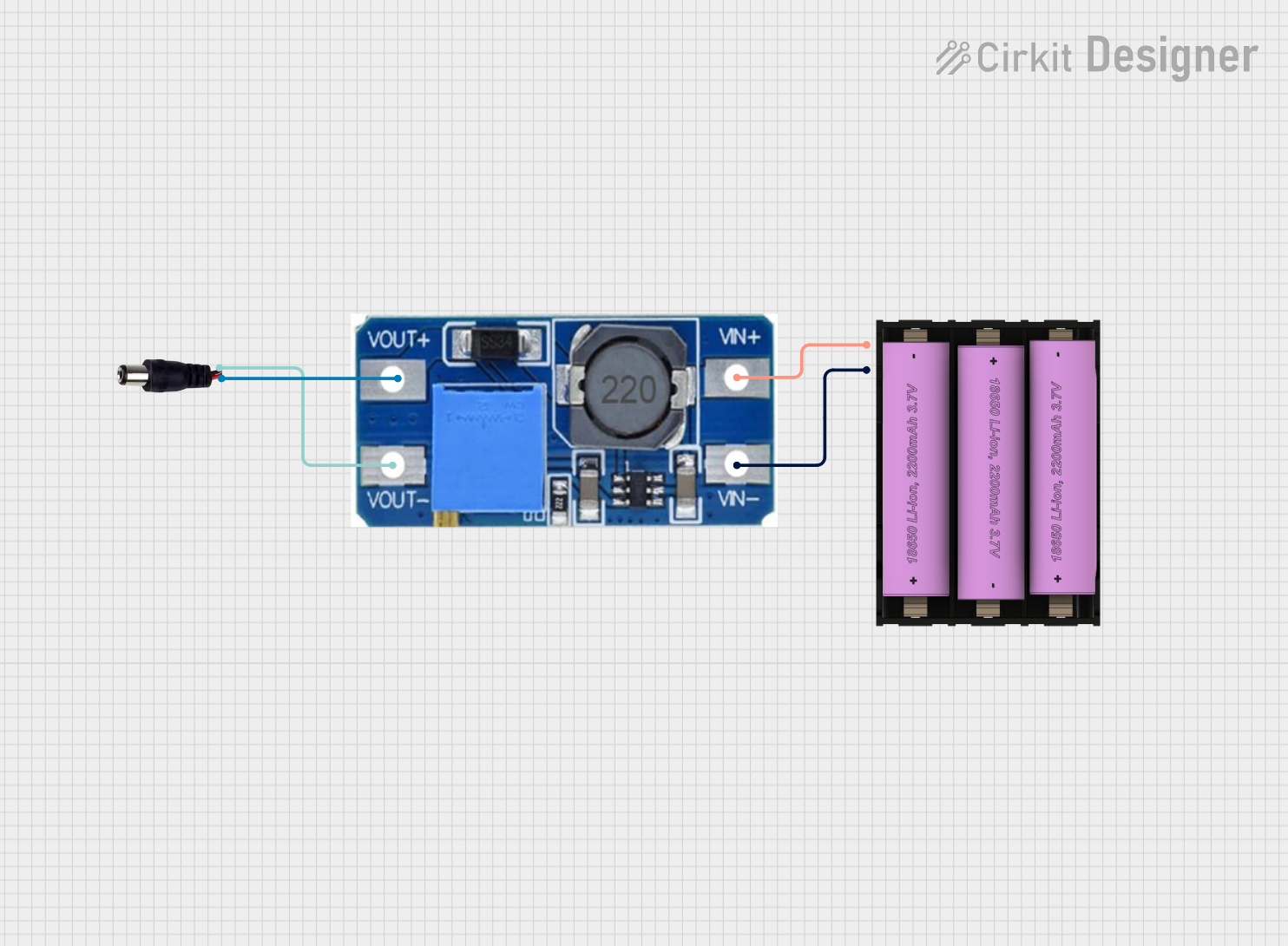

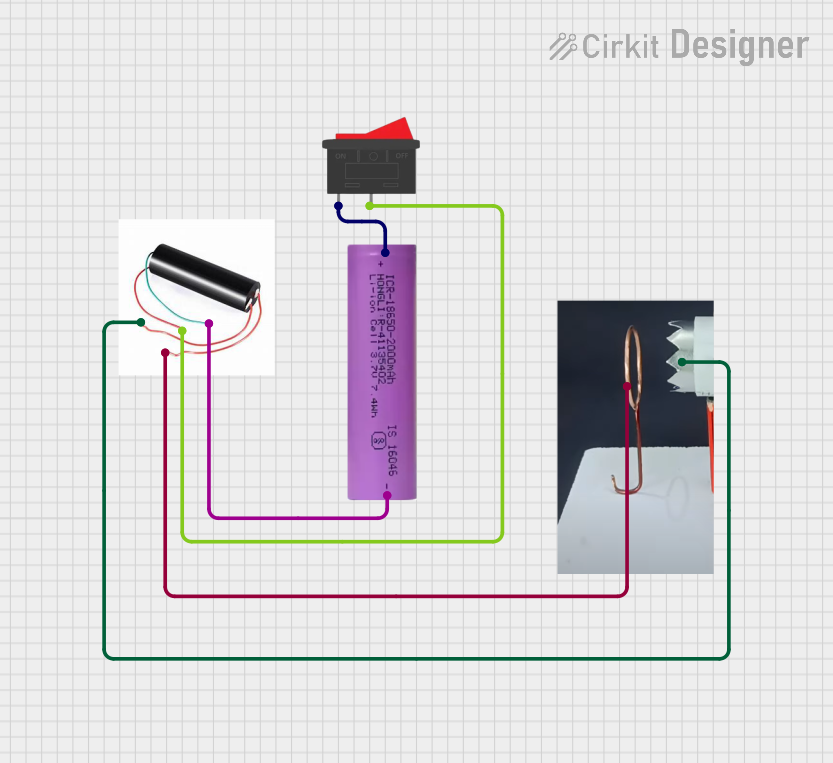

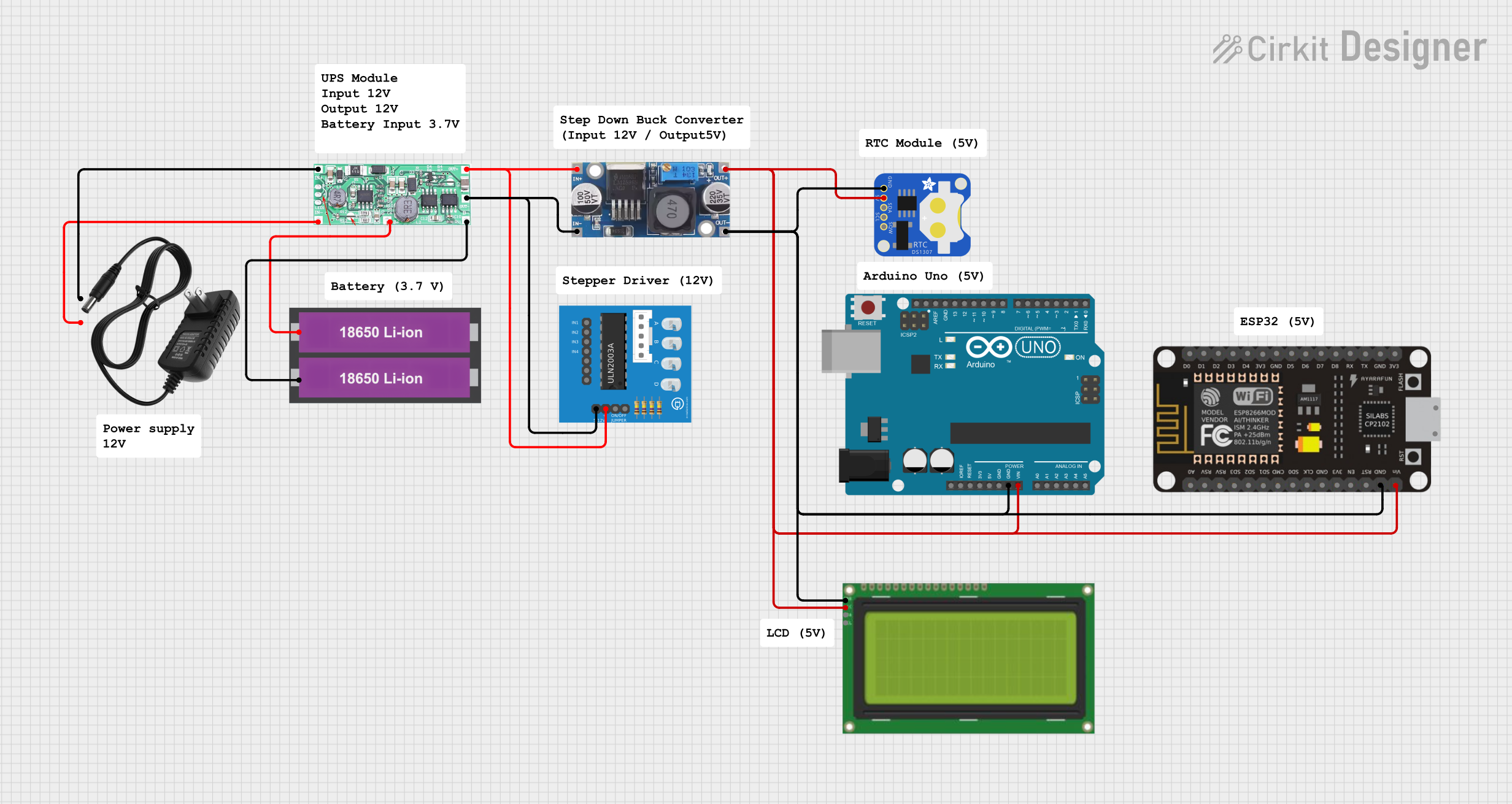

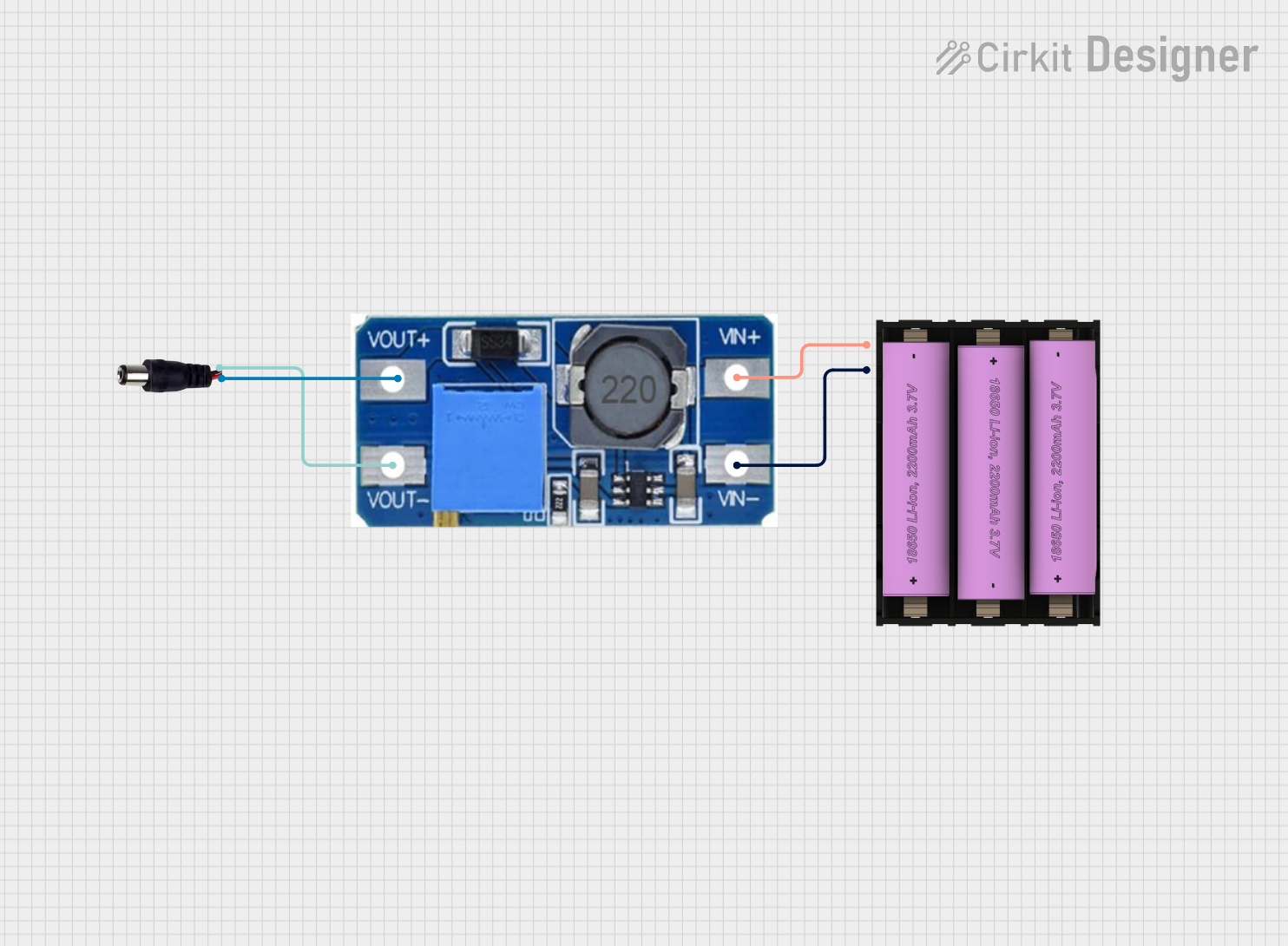

Explore Projects Built with 3.3V Step-Up Voltage Regulator

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit DesignerExplore Projects Built with 3.3V Step-Up Voltage Regulator

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer