How to Use NEMA23: Examples, Pinouts, and Specs

Design with NEMA23 in Cirkit Designer

Design with NEMA23 in Cirkit DesignerIntroduction

The NEMA23 stepper motor is a widely used actuator that converts electrical pulses into discrete mechanical movements. The motor is part of the National Electrical Manufacturers Association (NEMA) standard, with a 2.3-inch faceplate. It is known for its robustness, precision, and relatively high torque capabilities, making it an ideal choice for CNC machines, 3D printers, robotics, and other applications requiring precise control of position and speed.

Explore Projects Built with NEMA23

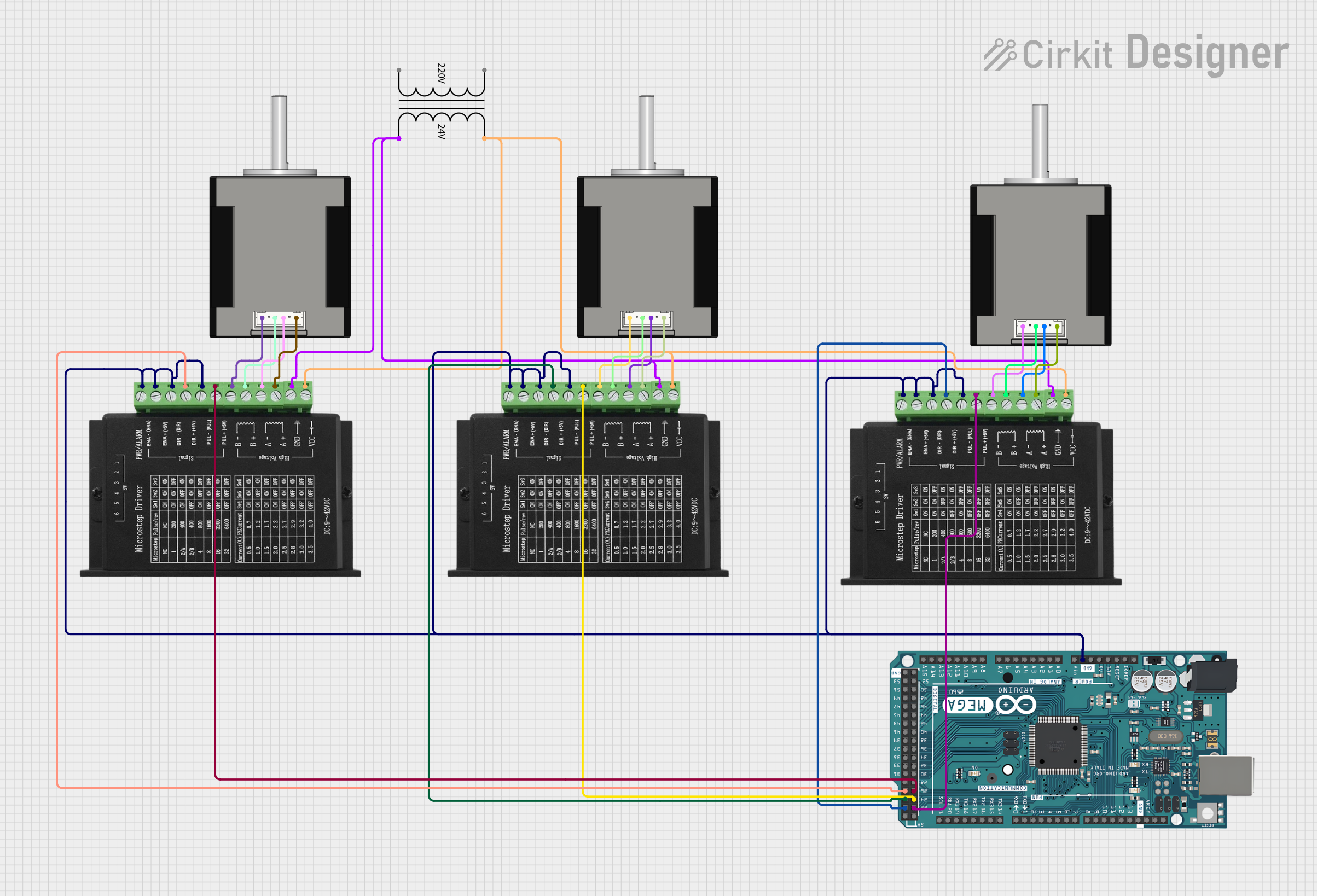

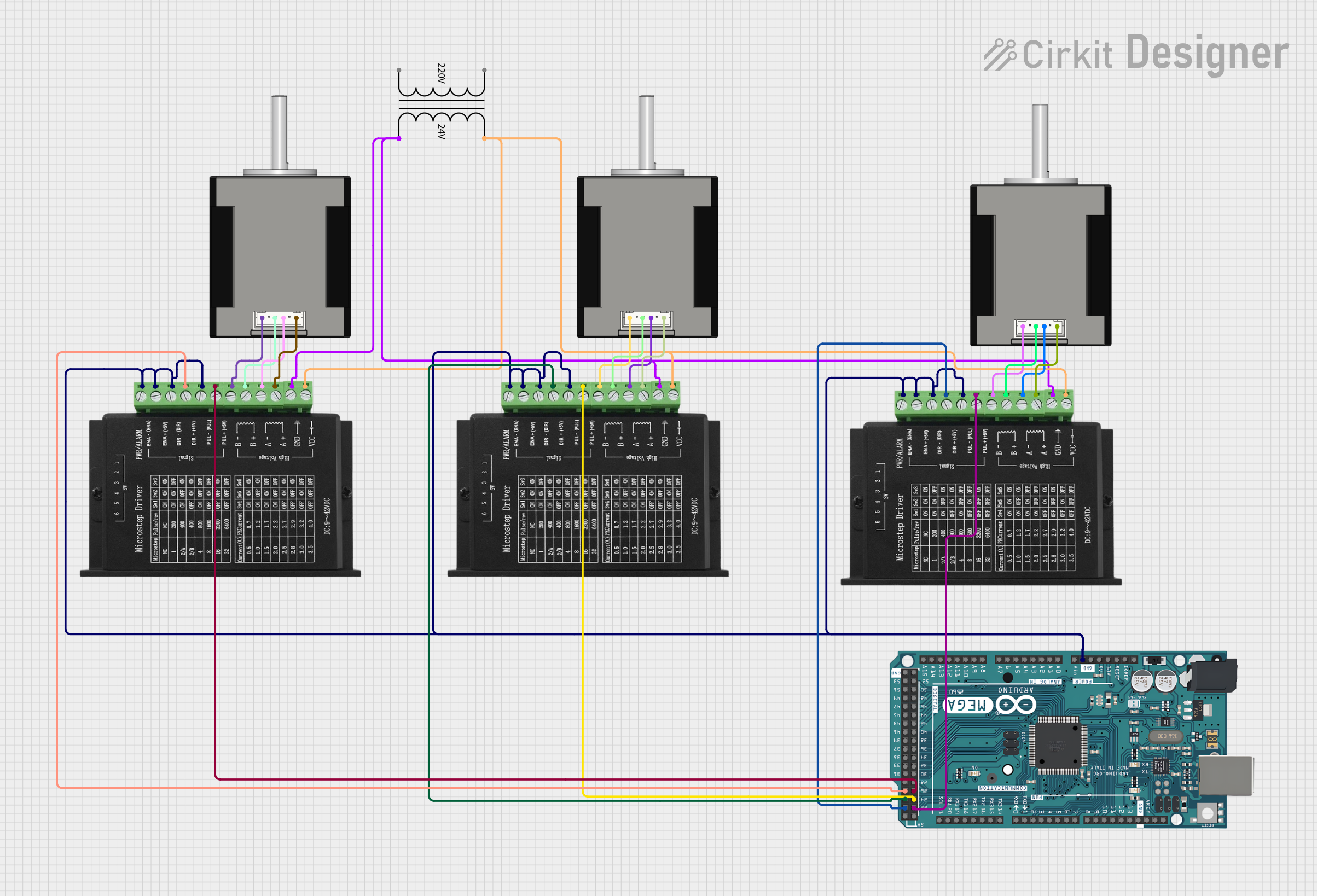

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit DesignerExplore Projects Built with NEMA23

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit DesignerTechnical Specifications

General Characteristics

- Frame Size: 2.3 inch (58.4 mm)

- Step Angle: Typically 1.8 degrees (200 steps per revolution)

- Phase: Usually 2 phases

Electrical Specifications

| Parameter | Value Range | Typical Value |

|---|---|---|

| Rated Voltage | 2.5V to 10V | 3.3V |

| Rated Current | 1A to 5A | 2.8A |

| Resistance per Phase | 0.5Ω to 10Ω | 1.65Ω |

| Inductance per Phase | 1mH to 20mH | 3.8mH |

| Holding Torque | 0.5Nm to 3Nm | 1.26Nm |

Mechanical Specifications

| Parameter | Value |

|---|---|

| Rotor Inertia | 275 g·cm² |

| Weight | Approximately 1.1 kg |

Pin Configuration and Descriptions

| Pin Number | Description |

|---|---|

| 1 | Coil A+ |

| 2 | Coil A- |

| 3 | Coil B+ |

| 4 | Coil B- |

| 5 | (Optional) Center tap for Coil A |

| 6 | (Optional) Center tap for Coil B |

Usage Instructions

Connecting to a Circuit

To use the NEMA23 stepper motor, you will need a stepper motor driver capable of supplying the appropriate current and voltage. The driver will have inputs for step and direction signals, which can be controlled by a microcontroller such as an Arduino UNO.

- Connect the motor coils to the driver. Ensure that Coil A and Coil B are connected to the corresponding outputs on the driver.

- Connect the driver's power supply, ensuring it matches the motor's rated voltage and can supply the necessary current.

- Connect the step and direction inputs from the driver to the microcontroller.

Best Practices

- Use a current limiting driver to prevent damage to the motor.

- Ensure that the motor is mounted securely to prevent vibrations and resonance.

- Use a heatsink or cooling system if the motor is running at high currents for extended periods.

Example Code for Arduino UNO

#include <Stepper.h>

// Change these values based on your motor's specifications

const int stepsPerRevolution = 200; // typically 200 steps for a NEMA23

const int stepPin = 3; // Connect this to the driver's step input

const int dirPin = 4; // Connect this to the driver's direction input

Stepper myStepper(stepsPerRevolution, stepPin, dirPin);

void setup() {

myStepper.setSpeed(60); // Set the speed to 60 RPM

}

void loop() {

myStepper.step(stepsPerRevolution); // Move one revolution in one direction

delay(500);

myStepper.step(-stepsPerRevolution); // Move one revolution in the other direction

delay(500);

}

Troubleshooting and FAQs

Common Issues

- Motor does not turn: Check wiring connections, ensure the power supply is adequate, and verify that the driver is functioning correctly.

- Motor stalls or misses steps: This could be due to insufficient current, mechanical load exceeding the motor's torque, or an incorrect step sequence. Adjust the current limit on the driver and check the mechanical system for binding or excessive friction.

- Motor overheats: Ensure the current settings are within the motor's specifications and improve cooling if necessary.

FAQs

Q: Can I run the NEMA23 motor at a higher voltage than rated? A: Yes, using a higher voltage with proper current control can lead to better performance, but ensure the driver can handle the increased voltage and that the current does not exceed the motor's ratings.

Q: How do I determine the correct current limit for my motor? A: The current limit should be set based on the motor's rated current. Consult the motor's datasheet and the driver's manual for specific instructions.

Q: What is the difference between unipolar and bipolar configurations? A: Unipolar motors have center taps on each coil, allowing for simpler driving circuits but generally lower torque. Bipolar motors do not have center taps and are driven by reversing the current in each coil, resulting in higher torque.

Q: How can I increase the torque of my NEMA23 motor? A: Increasing the current within the motor's rated specifications, using a higher voltage with proper current control, and reducing the speed can increase torque. Additionally, using microstepping can also improve torque at lower speeds.

For further assistance, consult the manufacturer's datasheet and the support forums for the specific driver you are using.