How to Use Non-contact Digital Liquid Level Sensor: Examples, Pinouts, and Specs

Design with Non-contact Digital Liquid Level Sensor in Cirkit Designer

Design with Non-contact Digital Liquid Level Sensor in Cirkit DesignerIntroduction

The Non-contact Digital Liquid Level Sensor is an advanced electronic component designed to detect the level of liquid in a container without making physical contact with the liquid. Utilizing digital technology, this sensor provides accurate and reliable measurements, making it ideal for a variety of applications where hygiene, safety, and precision are paramount.

Explore Projects Built with Non-contact Digital Liquid Level Sensor

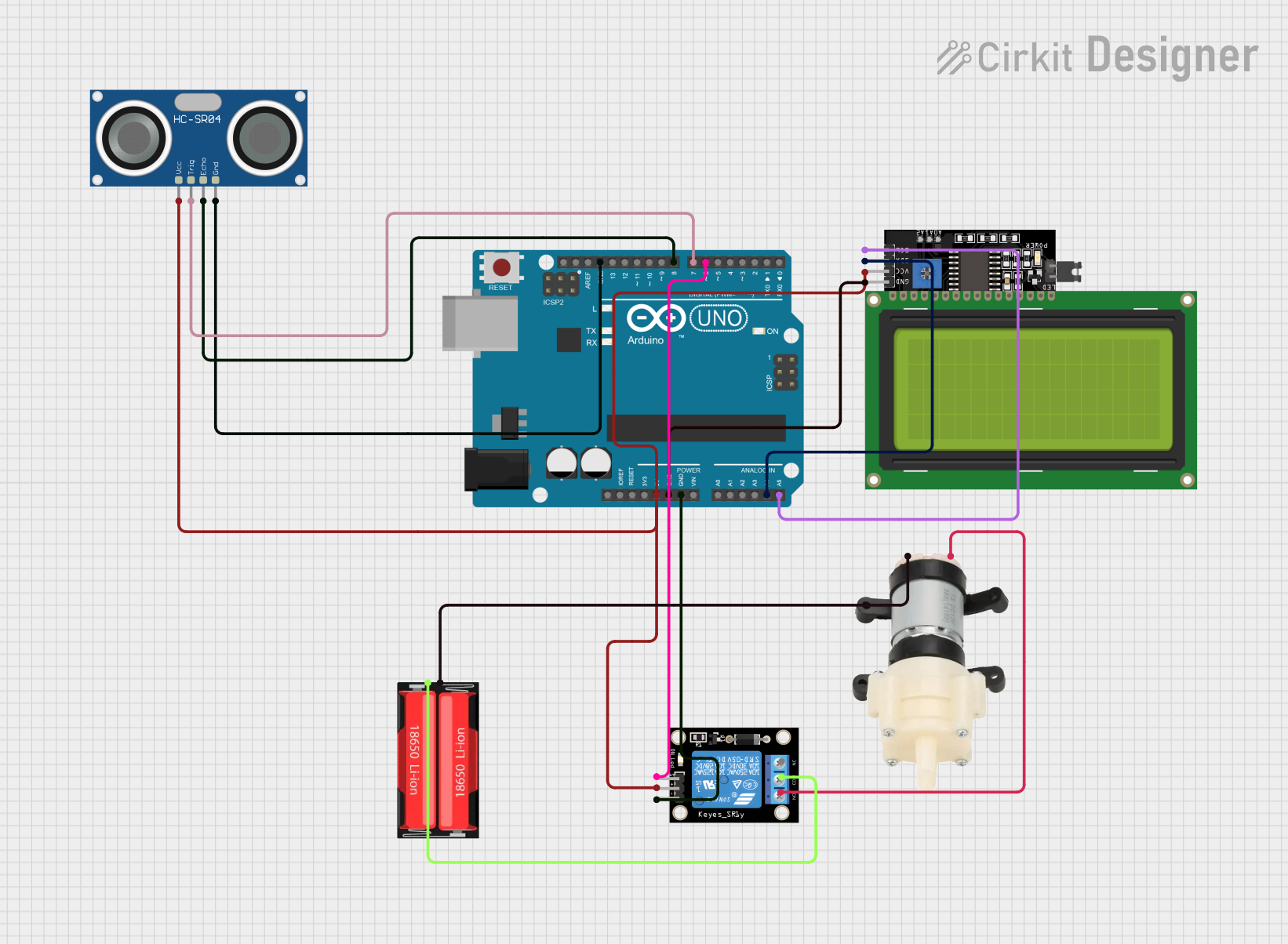

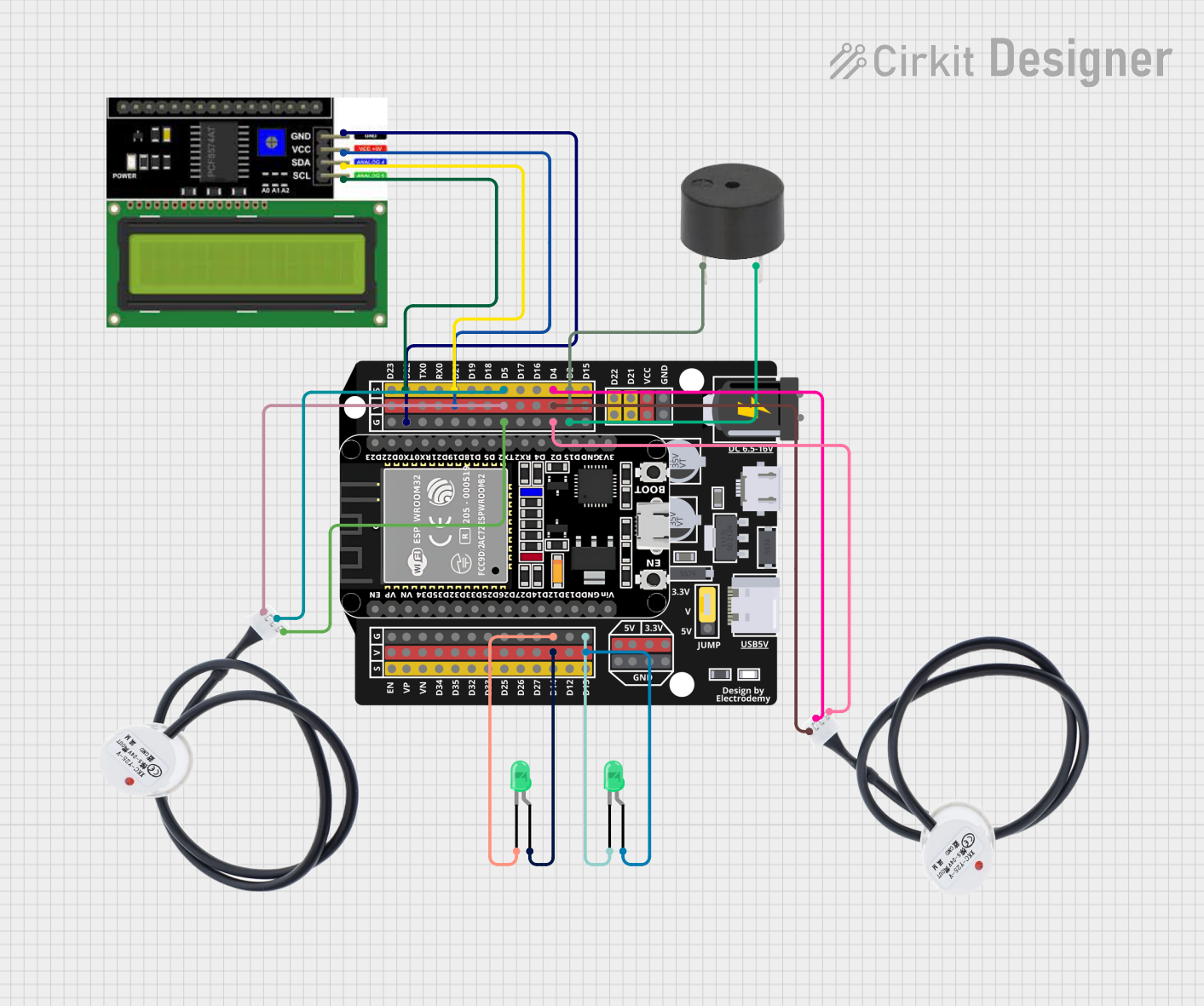

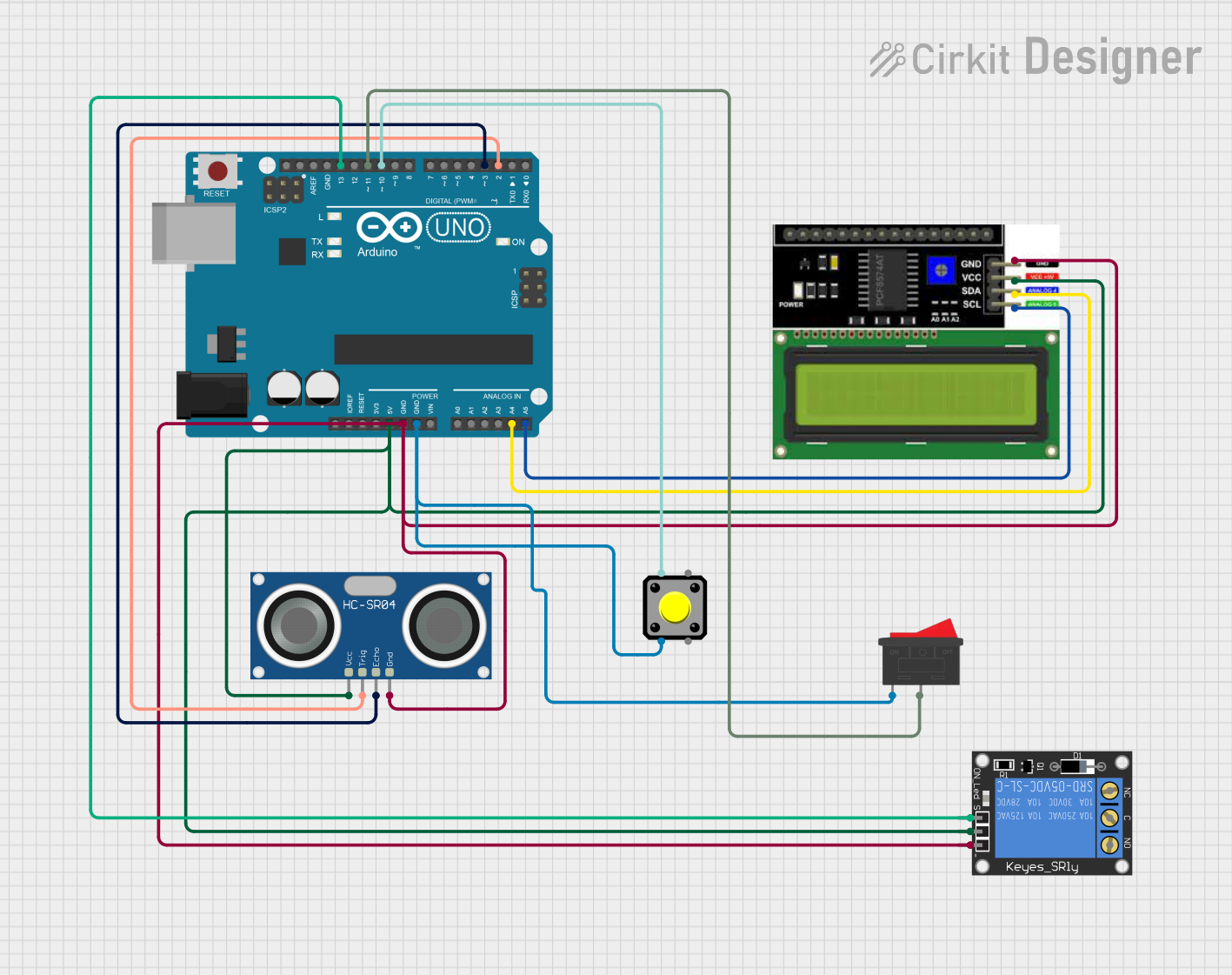

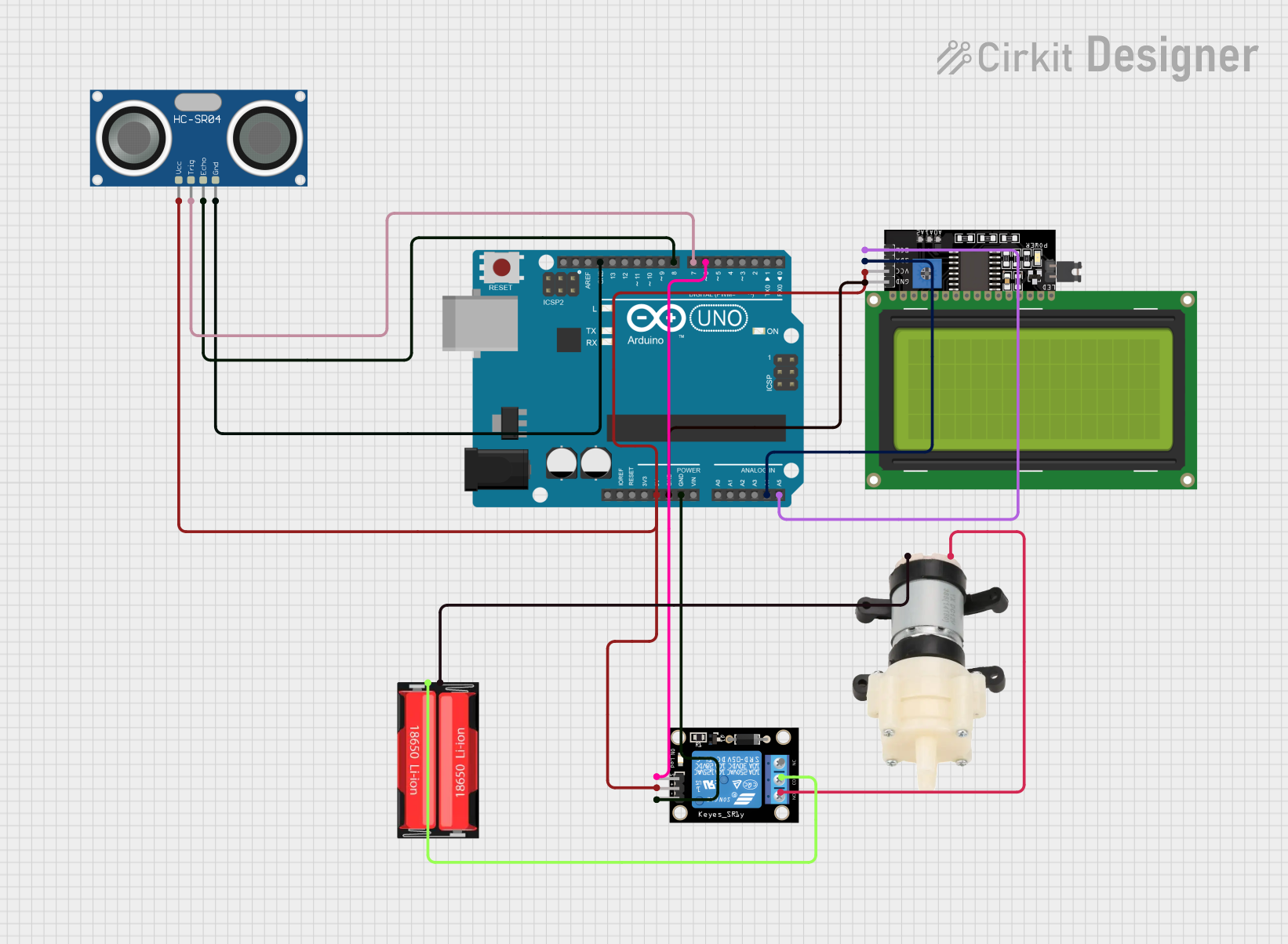

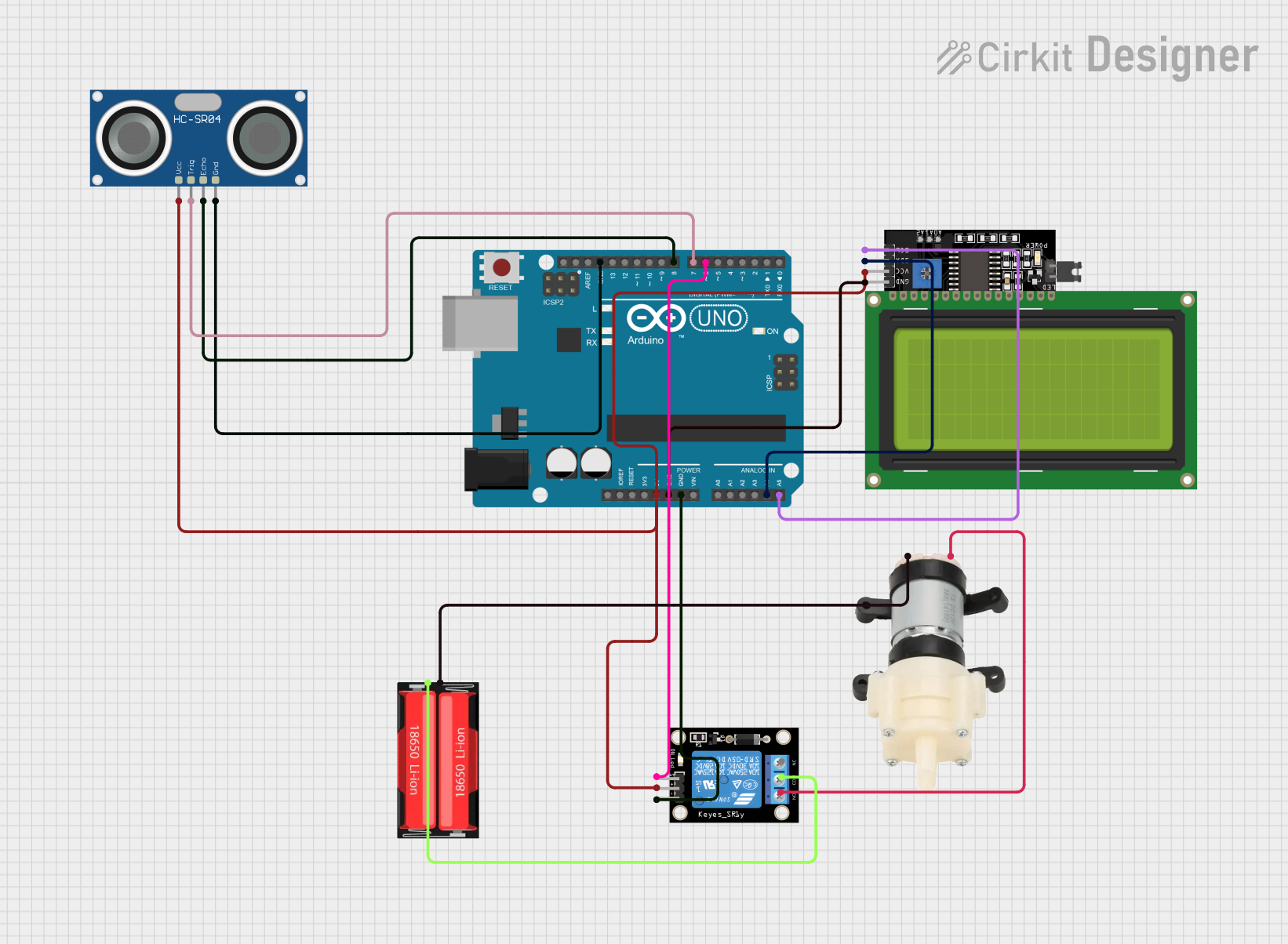

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

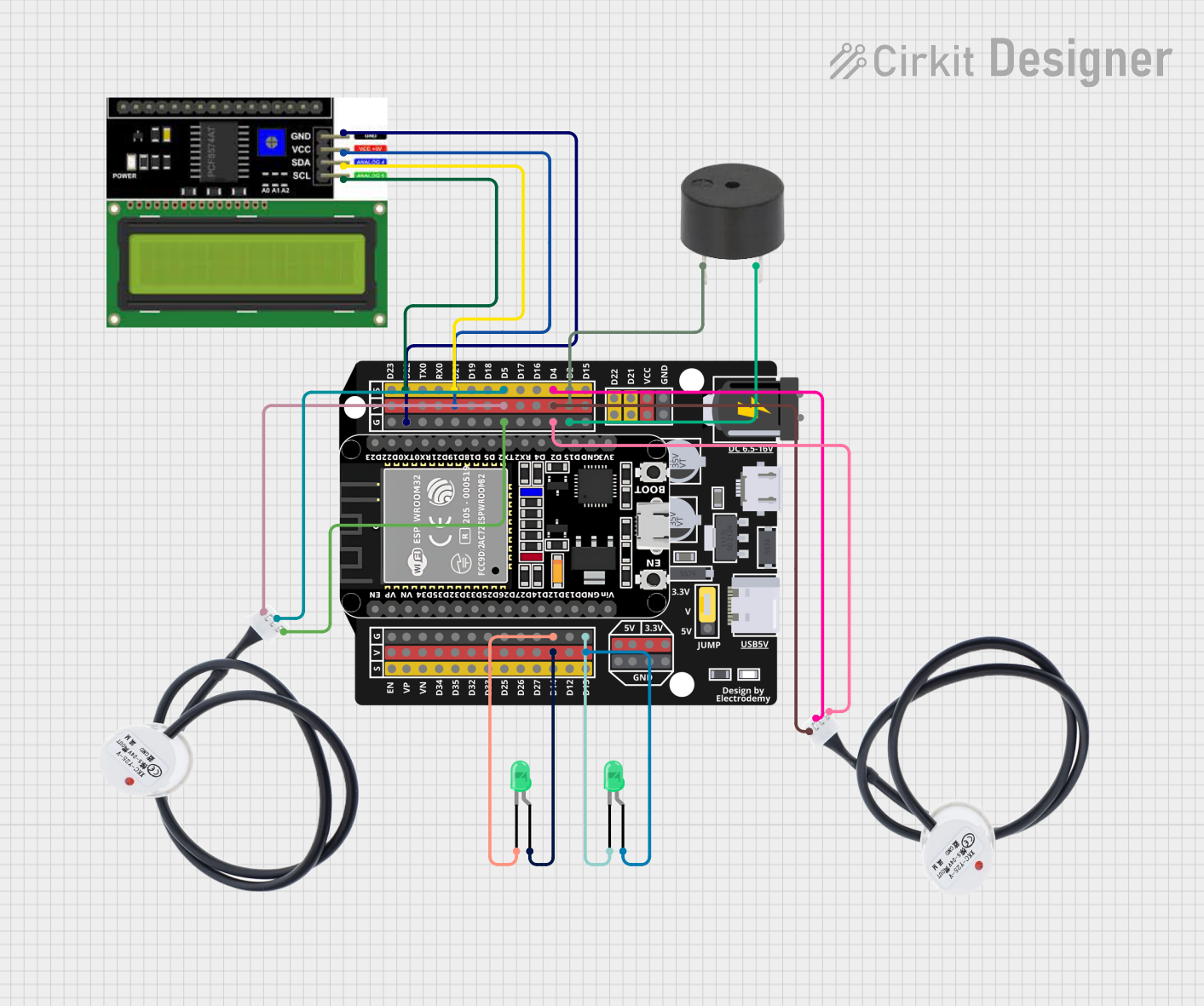

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit DesignerExplore Projects Built with Non-contact Digital Liquid Level Sensor

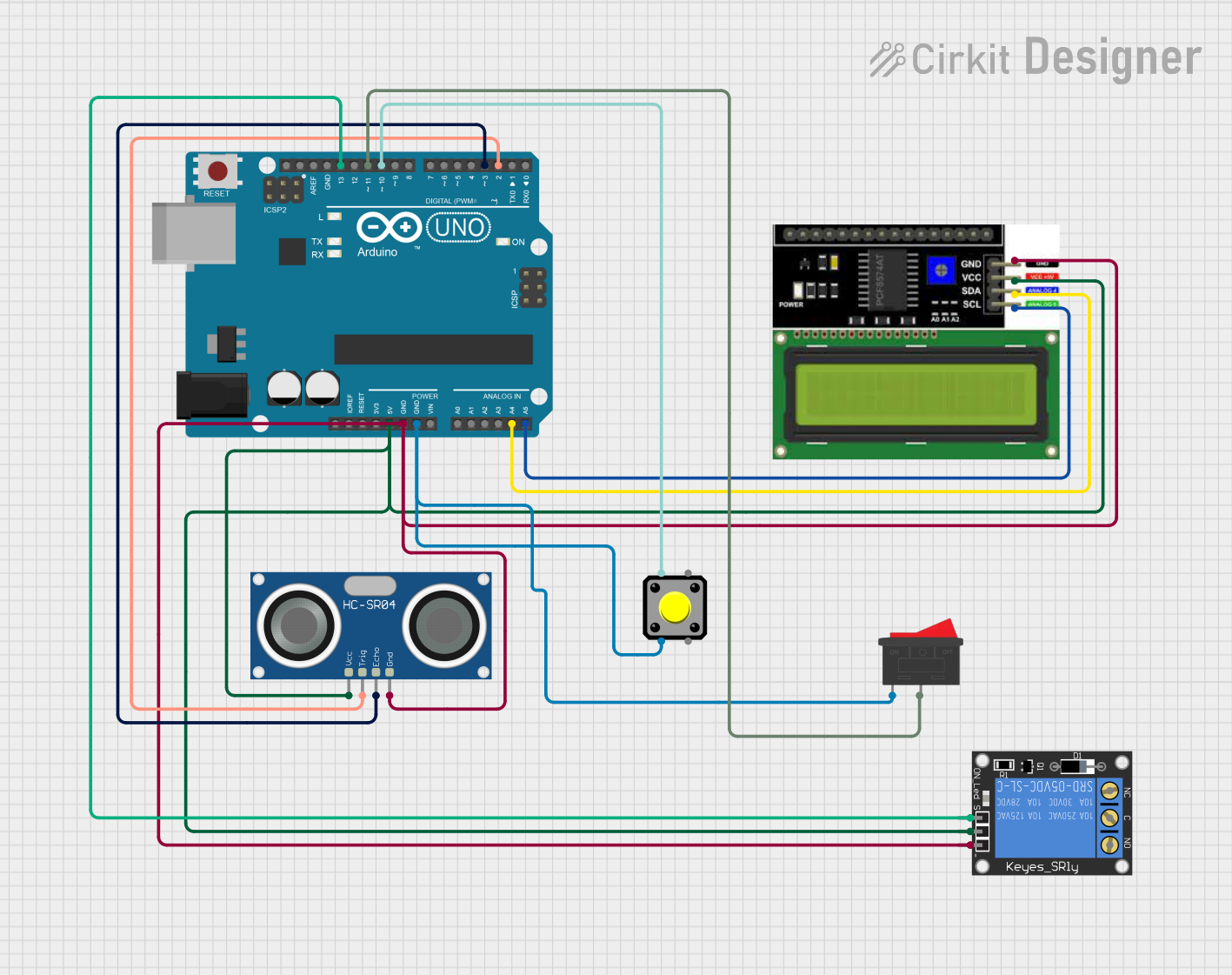

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

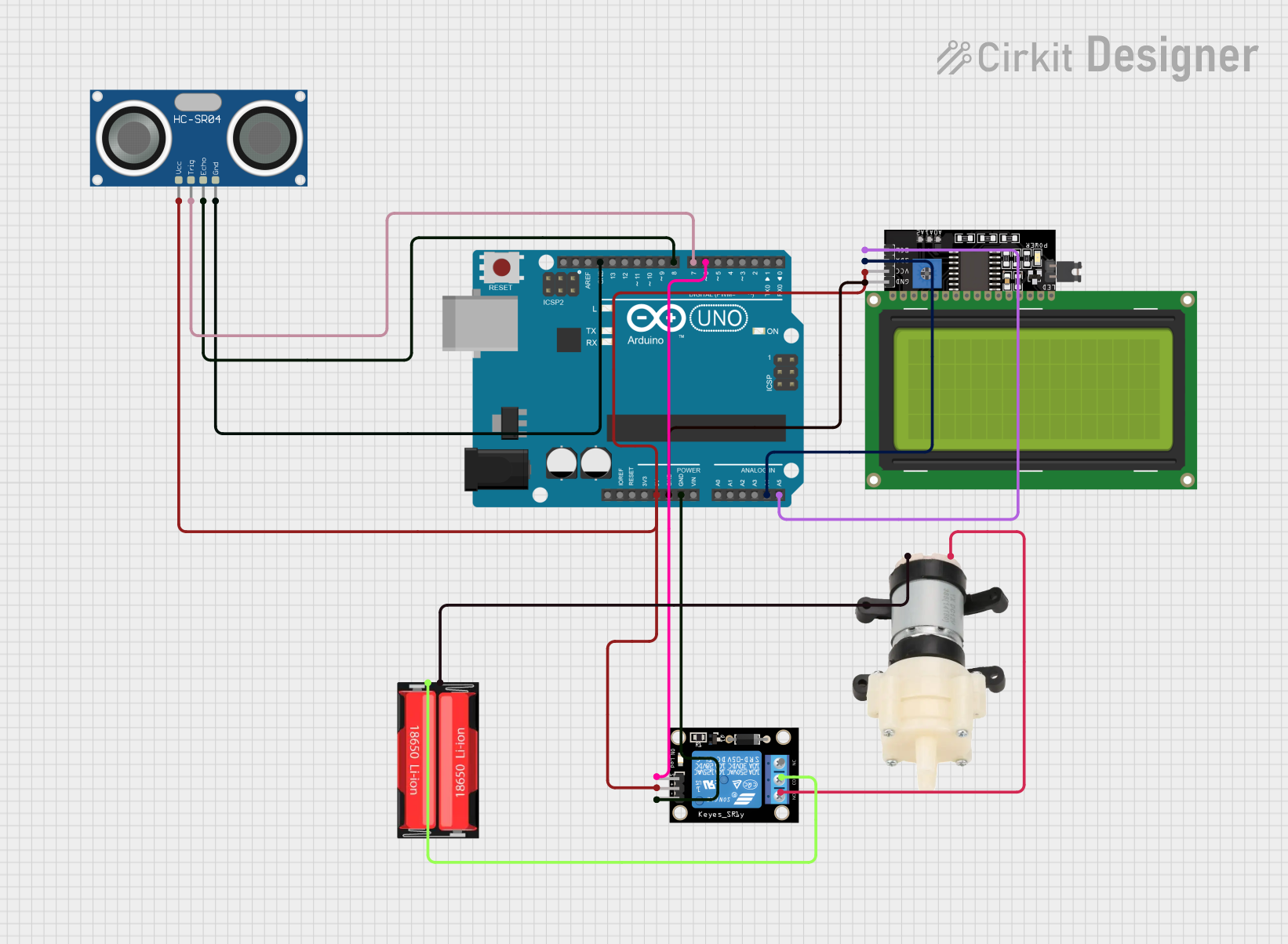

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit DesignerCommon Applications and Use Cases

- Medical Devices: Monitoring liquid levels in IV bags, dialysis machines, and other medical equipment.

- Industrial Automation: Managing liquid levels in tanks, reservoirs, and pipelines.

- Consumer Electronics: Used in smart appliances like coffee makers and water dispensers.

- Environmental Monitoring: Measuring water levels in natural and artificial reservoirs.

- Automotive: Monitoring coolant and fuel levels in vehicles.

Technical Specifications

Key Technical Details

| Parameter | Value |

|---|---|

| Operating Voltage | 5V DC |

| Operating Current | ≤ 5mA |

| Output Type | Digital (High/Low) |

| Response Time | ≤ 500ms |

| Detection Range | 0-20mm (distance from sensor) |

| Operating Temperature | -10°C to 70°C |

| Humidity Range | 5% to 100% RH |

| Waterproof Rating | IP67 |

Pin Configuration and Descriptions

| Pin Number | Pin Name | Description |

|---|---|---|

| 1 | VCC | Power supply (5V DC) |

| 2 | GND | Ground |

| 3 | OUT | Digital output (High when liquid is detected) |

Usage Instructions

How to Use the Component in a Circuit

- Power Connection: Connect the VCC pin to a 5V DC power supply and the GND pin to the ground of your circuit.

- Output Connection: Connect the OUT pin to a digital input pin on your microcontroller (e.g., Arduino UNO).

Example Circuit Diagram

+5V --------------------+

|

[VCC]

|

[OUT] ----> Digital Input Pin (e.g., D2 on Arduino)

|

[GND]

|

GND --------------------+

Important Considerations and Best Practices

- Mounting: Ensure the sensor is securely mounted at the desired height on the container.

- Calibration: Some sensors may require calibration for optimal performance. Refer to the manufacturer's guidelines.

- Interference: Avoid placing the sensor near strong electromagnetic fields or metal objects that could interfere with its operation.

- Environment: Ensure the sensor is used within its specified temperature and humidity ranges.

Sample Arduino Code

// Define the pin connected to the sensor's OUT pin

const int sensorPin = 2;

// Variable to store the sensor state

int sensorState = 0;

void setup() {

// Initialize the serial communication

Serial.begin(9600);

// Set the sensor pin as an input

pinMode(sensorPin, INPUT);

}

void loop() {

// Read the state of the sensor

sensorState = digitalRead(sensorPin);

// Check if the sensor detects liquid

if (sensorState == HIGH) {

Serial.println("Liquid detected!");

} else {

Serial.println("No liquid detected.");

}

// Wait for a short period before reading again

delay(500);

}

Troubleshooting and FAQs

Common Issues Users Might Face

False Positives/Negatives:

- Solution: Ensure the sensor is properly mounted and calibrated. Check for any sources of interference.

No Output Signal:

- Solution: Verify the power connections and ensure the sensor is receiving 5V DC. Check the wiring to the microcontroller.

Intermittent Readings:

- Solution: Ensure stable power supply and secure connections. Check for environmental factors affecting the sensor.

FAQs

Q1: Can this sensor detect any type of liquid?

- A1: Yes, the sensor is designed to detect a wide range of liquids, including water, oil, and chemicals.

Q2: How do I clean the sensor?

- A2: The sensor is waterproof (IP67 rated), so you can clean it with a damp cloth. Avoid using harsh chemicals.

Q3: Can I use this sensor with a 3.3V microcontroller?

- A3: The sensor is designed for 5V operation. Using it with a 3.3V microcontroller may require a level shifter.

Q4: What is the maximum distance the sensor can detect liquid?

- A4: The sensor can detect liquid up to 20mm away from its surface.

By following this documentation, users can effectively integrate and utilize the Non-contact Digital Liquid Level Sensor in their projects, ensuring accurate and reliable liquid level measurements.